Nothing can be emphasized enough about the explosion-proof light fixtures when it comes to safety and efficiency in hazardous environments. These particular products are designed to withstand hazardous conditions and, in doing so, prevent accidents and promote safety standards. Industrial sites, chemical plants, or other areas of volatile substances: the right lighting fixtures for these areas must be selected to ensure safety for both people and property. This article addresses what makes an explosion-proof light fixture an absolute need, its major features, and how to select an option that is right for you. Read on to uncover the crucial points that will illuminate a safer work zone.

Understanding Explosion-Proof Lighting

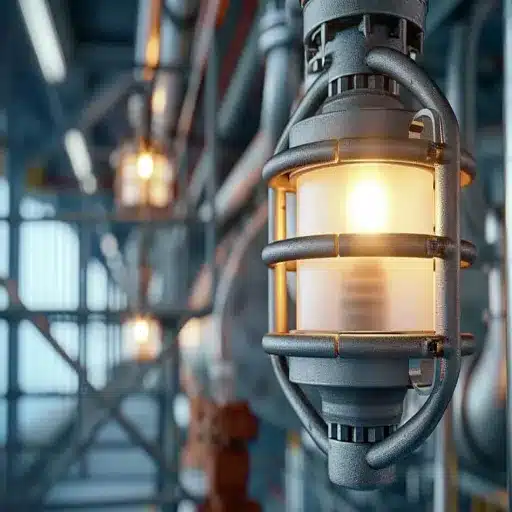

Explosion-proof lighting refers to specially designed fixtures meant to function safely in hazardous environments involving flammable gases, vapors, or combustible dust. The fixtures have been designed to prevent any internal spark from igniting the surrounding atmosphere. This they do by means of strong enclosures which contain any explosion so that sparks or heat do not escape and endanger the atmosphere. The importance of explosion-proof lighting is evident for applications related to oil and gas, chemicals, and mining sectors, where life, safety, and stringent regulations matter.

What is Explosion-Proof Lighting?

Explosion-proof lighting is a term used to describe lighting that is meant for hazardous environments. Here, the presence of flammable gases or vapors, or combustible dust, could lead to a potential risk of explosion. Such lighting design includes features to ensure that any sparks or excessive heat generated internally never come into contact with the volatile substances in the immediate vicinity. A typical feature of the design is a robust enclosure that is dust-and water-proof and built from materials like cast aluminum or stainless steel and tempered glass to provide safety and durability even under very harsh conditions.

Key Fact: Explosive location lighting is rated from industry standards, wherein Class I Division 1 or Zone 1 applications are covered in these standards prepared by the NFPA or IEC on safety guidelines. LED explosion-proof lighting fixtures are getting in demand for energy conservation and low heat generation, showing energy savings of at least 60% compared to conventional incandescent or fluorescent lights.

How Explosion-Proof Lighting Works

Explosion-proof lighting is designed to prevent the ignition of the surrounding flammable gas or dust in hazardous environments. Such fixtures usually attain their explosion-proof nature by virtue of strong housing materials resisting sparks or high heat. Their enclosures are made of very sturdy bodies, such as aluminum, stainless steel, or reinforced glass, so that any internal explosion arising from electrical sparks or malfunctioning cannot escape from the fixture.

The other very important feature of explosion-proof lighting is that the internal part of the fixture isolates any possible source of ignition and contains it. The internal components, including wires and connections, are enclosed in flame-proof chambers. This stops a propagating fire, if any, from spreading in an environment where flammable substances exist. Some designs would actually use flame paths to cool escaping gases and put out any flames before they show in the external atmosphere.

Importance of Explosion-Proof Fixtures in Hazardous Locations

Explosion-proof fixtures play a very important role in hazardous environments, as they prevent the ignition of volatile substances, ensuring the safety of the workplace and the smooth running of the operations. They are designed and tested to prevent any spark or arc, or excessive heat from escaping from the enclosure and thereby igniting a flammable gas, vapor, or dust, which may exist in oil refineries, chemical plants, grain elevators, etc.

- Global standards bodies, such as UL and ATEX, have strict criteria that must be met by explosion-proof lighting

- Modern LED-based explosion-proof lights consume drastically diminished energy

- These LED systems last for a life well beyond 100,000 hours, limiting maintenance needs

- Additional explosion-proof luminaires might be set via motion sensors and networks for efficient operations

Types of Explosion-Proof Light Fixtures

| Type | Description | Best Applications |

|---|---|---|

| LED Explosion-Proof Lights | Energy-efficient, offer a long life span, and render great illumination while requiring minimal maintenance | All hazardous areas require long-term reliability |

| Fluorescent Explosion-Proof Lights | Common in industrial sectors, providing a balance between energy efficiency and affordability | Budget-conscious industrial applications |

| High-Intensity Discharge (HID) Explosion-Proof Lights | Used in areas with high lumen requirements, good for large, open spaces | Large warehouses, outdoor industrial areas |

| Portable Explosion-Proof Lights | For flexibility, meant for use in temporary working conditions or tasks requiring movement | Maintenance work, temporary installations |

| Emergency Explosion-Proof Lights | Provide illumination during power outages and give safety and visibility in emergencies | Emergency exits, safety systems |

LED Explosion-Proof Light Fixtures

The modern solution for explosion-proof lighting in hazardous environments equates to extreme durability, energy efficiency, and safety. Explosion-proof light fixtures are designed to work in an area filled with flammable gases, vapors, or dust, even ensuring illumination without the risk of ignition.

Key Benefits of LED Explosion-Proof Fixtures:

- Energy Efficiency: LED technology uses up to 70% less power compared to traditional lighting systems like HID or incandescent bulbs, with minimal heat output contributing to a safe working environment.

- Longevity and Durability: LEDs can last over 50,000 hours of operation. Explosion-proof light fixtures are made strong enough to resist shocks, vibrations, and ever-changing weather conditions.

- Advanced Illumination Performance: Explosion-proof LED lighting supplies better illumination with a high CRI because of enhanced ability for vision and workplace safety. Most models have adjustable beam angles for customized application.

- Compliance and Certification: LED explosion-proof lights go through strict testing and are certified to international bodies such as UL, ATEX, and IECEx to meet safety requirements.

- Lower Maintenance Cost: Longer life with durability minimizes the frequency of replacements and maintenance with explosion-proof LED fixtures.

- Environmental Benefits: LEDs contain no harmful substances like mercury and are recyclable. Their energy efficiency helps lower carbon emissions in line with sustainable goals.

Explosion-Proof Flood Lights

Explosion-proof flood lights are created to provide bright illumination to high-hazard zones while ensuring enormous protection. Such lights are needed where they could be exposed to explosive gases or combustible dust, while on the other hand, they are subjected to harsh environmental conditions. Such places would now include oil and gas, chemical processing, mining, and manufacturing.

Performance Specifications: Modern explosion-proof flood lights using LED technology often have high lumen output, often above 140 lumens per watt, and consume significantly less energy than typical lighting systems. These lights also have a long life—50,000 hours or more—which reduces maintenance and replacements in hostile environments.

Comparing Different Explosion-Proof Options

Property and Design Features

| Feature | Specification Range | Considerations |

|---|---|---|

| Materials and Finish | Aluminum alloy or stainless steel | Aluminum: lightweight, corrosion-resistant Stainless steel: superior corrosion protection for marine/chemical use |

| Lumen Rating | 10,000 – 50,000+ lumens | LEDs preferable for efficiency, many designs exhibiting above 130 lm/W |

| Beam Angles | 30° (narrow) to 120°+ (wide flood) | Choose based on application: task lighting vs. area lighting |

| Temperature Rating | -40°F to 140°F | Must withstand extreme climates |

| IP Rating | IP65 – IP67 | IP67: dust-tight, waterproof to 1 meter depth for 30 minutes |

Choosing the Right Explosion-Proof Light

Factors to Consider for Hazardous Areas

When it comes to lighting or equipment for hazardous areas, several critical factors have to be established and assessed for safety and efficiency:

- Area Classification: Understanding the classification of the hazardous area according to substances present is the starting point. Locations are classified by zones or divisions: IEC standards use Zone 0, Zone 1, and Zone 2, while NEC standards use Class I, II, and III divisions.

- Temperature Ratings: Equipment should have an appropriate temperature rating to ensure it does not ignite flammable substances. Many hazardous location devices are tested for maximum surface temperature T1 (450°C) through T6 (85°C).

- Material Durability: Equipment materials must resist corrosion, impact, and degradation. Stainless steel and aluminum are preferred materials for enclosures.

- Ingress Protection (IP) Rating: Devices must maintain high ingress protection ratings of IP65 and above to supplement protection against water or dust particles.

- Energy Efficiency and Long Life: LED lights are increasingly favored for energy efficiency with good life expectancy. LED fixtures can last 50,000 hours compared to 10,000 hours from traditional lighting systems.

- Certification and Compliance: Ensure equipment is certified by ATEX (Europe), IECEx (Global), or UL (United States).

Understanding Division Classifications

Division classifications are used to describe and categorize environments where hazardous materials may be present. The National Electrical Code (NEC) establishes Division 1 and Division 2 classifications:

- Division 1: Areas where hazardous material is present under normal operating conditions or frequently due to repairs or maintenance

- Division 2: Locations where hazardous substances are normally absent but could appear in unusual cases due to equipment failure or leakage

Safety Impact: Recent data shows that in Division 1 areas, safety measures reduce the risk of ignition by about 60%, whereas in Division 2, the focus is more on avoiding emergencies and providing adequate containment measures.

Evaluating Light Output and Efficiency

For the question of light output and efficiency, both luminous efficacy and environmental application go hand-in-hand. Luminous efficacy, or lm/W, is a measure of how efficient an electric source is at turning energy into visible light:

| Light Source | Efficacy (lm/W) | Typical Wattage |

|---|---|---|

| LED | 150-200 | 10-15W |

| Incandescent | 10-15 | 60W |

| Fluorescent | 50-100 | 15-20W |

Installation and Maintenance of Explosion-Proof Lights

Proper Installation Guidelines

The ideal method of installation of explosion-proof lighting is exactly as per safety standards, so that it offers maximum protection in the hazardous location:

- Determine the exact classification applicable to the hazardous zone and select lights certified for that particular atmosphere

- Mount fixtures firmly using brackets or supports to avoid vibrations or loosening with time

- Make power supply connections using sealed and approved junction boxes

- Ensure all connections and seals conform to applicable industry regulations

- Verify proper bonding and grounding to eliminate static buildup

- Check the ambient temperature rating compatibility

Installation Guidelines for Hazardous Locations

- Equipment must be certified for use in the particular hazardous area classification (Class I, II, or III Divisions, or Zones 0, 1, or 2)

- Ensure enclosures have the required IP or NEMA rating (an IP66-rated enclosure is highly resistant to water jets and particulate matter)

- Wiring should comply with NEC or IEC requirements

- Use explosion-proof fittings and seal-offs for conduits

- Consider ambient temperature rating (equipment must operate safely within temperature class T1 through T6)

Regular Maintenance Practices

Regular maintenance is vital to ensure that explosion-proof lighting systems perform reliably and are safe to use:

Routine Maintenance Checklist:

- Regular Inspections: Monitor any damage to the fixture, including cracks, loose parts, or broken seals

- Periodic Cleaning: Remove dust and grime that might have accumulated to maintain maximum light output and operational life

- Component Replacement: Replace faulty components or bulbs with certified ones to observe safety regulations

- Safety Testing: Use thermal imaging cameras to detect overheating components and insulation resistance testers for cables and connections

- Calibration: Ensure gas detectors and pressure relief devices are properly calibrated according to the manufacturer’s instructions

- Professional Audits: Conduct periodic audits by qualified professionals to achieve compliance with standards such as NFPA 70E or IEC 60079

Safety Reminder: Always ensure that the system is de-energized before carrying out any maintenance work to avoid electrical hazards.

Common Issues and Troubleshooting

Understanding common problems helps in quick resolution:

- Electrical Overloading: Causes about 25% of downtimes. Ensure proper load balancing and correct circuit protection devices

- Equipment Degradation: Accounts for roughly 70% of machinery issues. Adopt predictive maintenance using IoT sensors

- Human Error: Responsible for nearly 23% of workplace accidents. Provide extensive training and regular refresher courses

Benefits of LED Explosion-Proof Lighting

Key Advantages Summary

| Benefit | Description | Impact |

|---|---|---|

| Increased Safety | Engineered to handle extreme conditions | Mitigates accident possibilities in hazardous regions |

| Energy Efficiency | 50-75% energy savings vs. traditional lighting | Lower operational costs and reduced electricity bills |

| Durability | Resistant to impact, corrosion, and adverse temperatures | Long-term performance guarantee |

| Low Maintenance | Longer LED lifespan (25,000-50,000 hours) | Reduced replacement costs and downtime |

| Enhanced Visibility | Brighter, clearer illumination | Improved workplace safety and productivity |

Energy Efficiency and Longevity

LED lighting technology is highly energy-efficient and long-lasting, making it a viable solution for sustainability in various applications:

- Energy savings between 50% and 75% compared with old lighting systems

- LED bulb uses about 10-15 watts compared to 60 watts for incandescent bulbs

- LEDs last 25,000 to 50,000 hours vs. 1,000 hours for incandescent bulbs

- Compact fluorescents last 8,000 to 10,000 hours

- Longer life means less changeover and maintenance, decreasing expenses and material waste

Environmental Impact of LED Options

LEDs represent a green lighting solution with a much lighter environmental footprint:

- Reduced Energy Consumption: Lower electricity use reduces greenhouse gas emissions from power plants

- Extended Lifespan: At least 25 times longer than incandescent bulbs, reducing waste and manufacturing needs

- Mercury-Free: Unlike fluorescent lamps, LEDs can be disposed of more safely

- Directional Lighting: Reduces light pollution outdoors, aiding ecological preservation

- Recyclable Materials: Components can be recycled at end of life

Conclusion

Selecting the proper explosion-proof light is governed by the environment in which it is used. Assign the hazardous area an appropriate classification, depending upon whether flammable gases, vapors, or combustible dusts are present. Ensure that the light conforms to the safety regulations required, such as UL, ATEX, or IECEx standards. Look for energy-efficient sources that offer a long lifespan and build materials that support maintenance reduction and downtime. Consider special features such as smart control or adjustable brightness with regard to operational needs, which shall enhance both safety and usability.

Final Recommendation: When energy-saving properties are combined with durability and minimal environmental impact, LED explosion-proof lighting truly represents an eco-friendly and cost-effective lighting choice for hazardous environments. These fixtures not only enhance safety but also contribute to operational efficiency and regulatory compliance across various industrial applications.

Reference Sources

Electrical equipment in hazardous areas

“Evaluation of Systems and Technologies Of Underground Pipeline Gallery, Haikou”

“Dust Explosion Fundamentals: Recognizing the Dust Hazard”

Frequently Asked Questions (FAQs)

What is an explosion-proof light fixture?

An explosion-proof lighting fixture is a kind of light meant to be set in place safely in hazardous locations, wherein flammable gases, vapors, or dust may be present. The fixtures are built so as to sustain any explosion originating within the fixture itself, thereby preventing the ignition of the atmosphere outside.

Why is explosion-proof lighting so imperative in hazardous set-ups?

Explosion-proof lighting is so very much needed for hazardous areas in order to ensure safety with respect to the rules and regulations governing these places. The lights are made in such a fashion as to bear the conditions that could lead to explosions and yet provide light without risking the lives of workers and equipment.

What are the different types of explosion-proof lighting fixtures?

There are classes and divisions given to explosion-proof light fixtures, which can vary according to the type of hazardous environment for which they are designed. Class I is with flammable gases, Class II with combustible dust, and Class III deals with ignitable fibers within an area. These classifications ultimately determine the design characteristics and safety features of the fixtures.

What types of lighting are suitable for hazardous locations?

There are many hazardous location lighting options, including LED explosion-proof lights, high bay lights, and vapor-proof fixtures. These lights are produced and guaranteed to meet safety standards for installs in warehouses, for instance, manufacturing plants, or chemical processing facilities.

How is the performance of LED explosion-proof lights compared to that of traditional lights?

Several advantages of LED explosion-proof lights over conventional lighting: energy saving, longer life, and less heat emission. Available in wattages such as 60W and 100W to satisfy applications in hazardous locations, they reduce the risk of ignition.

What are some explosion-proof lighting solution examples?

Such explosion-proof lighting solutions would include LED flood lights, shop lights, and premium industrial light fixtures designed exclusively for hazardous areas. These fixtures provide safe lighting and ensure that safety rules are met, having the illumination needed for the job.

What are explosion-proof light fixtures?

The price of explosion-proof light fixtures varies depending on several variables, such as wattage, design, and manufacturer. Generally speaking, one must invest in top-quality explosion-proof lighting for the sake of safety in hazardous places, which is certainly a valuable point to consider for any business functioning in such an area.

What are the advantages of LED lighting in hazardous locations?

There are many advantages to using LED lighting in hazardous locations, such as energy efficiency, low maintenance costs, and improved safety. LED lights of 150W and 200W offer bright illumination and are generally less susceptible to explosions by design and low heat generation.

How do I choose the correct explosion-proof light fixture for my needs?

Some factors include the specific hazardous location classification, the nature of the work being done, and the type of illumination desired while choosing the correct explosion-proof light fixture. It is best to consult experts or manufacturers in order to have light fixtures that provide safe lighting and meet safety standards.