Are gas stations a vital daily matter, essentially providing refueling avenues for fuel vehicles? How much do we really know about the intricate setup underneath the ground? One important part of this hidden system is. Here, the underground storage tank safely stores thousands of gallons of fuel out of sight. This article goes down under to these storage tanks to see how far they are buried and why. Exploring their placement in terms of safety regulations and environmental considerations weighs in on a very unpredictable and usually overlooked aspect of present-day fueling systems. Get ready to take a sneak peek at the fascinating world under the asphalt and learn more about ensuring gas stations keep your fuel safe yet accessible.

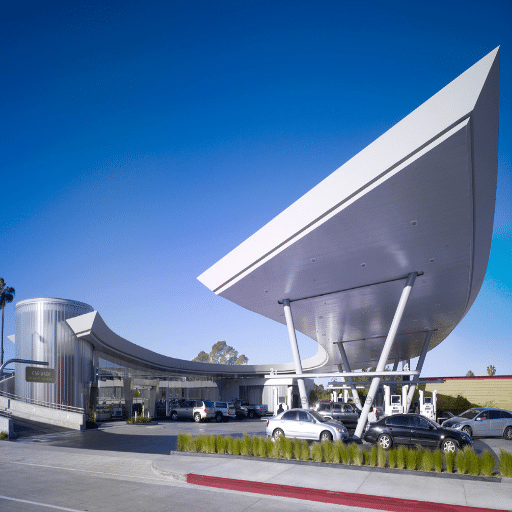

Gas Station Basics

Gas station fuel tanks are ordinarily buried anywhere between four and ten feet underground. This range in depth affords protection against possible external risks such as vehicular traffic and environmental hazards while also allowing some ease for maintenance. The exact burial depth might thus vary depending on local regulations, soil type, and safety requirements. Carefully installed and inspected periodically, the underground tanks will work well without posing any danger to the public.

What is an Underground Storage Tank (UST)?

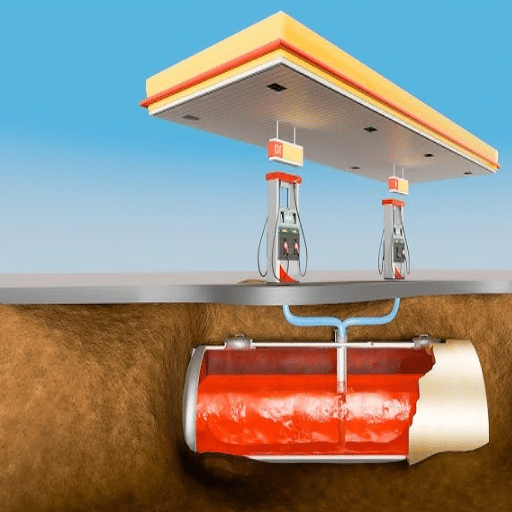

An underground storage tank (UST) consists of a container, mainly made from metals such as steel or fiberglass, meant for storing liquids or gases below the surface. USTs are commonly used to store petroleum products, diesel, or hazardous chemicals; in other words, USTs find use in many industries that include transportation, energy, or manufacturing.

Under the stringent regulations to ensure safety and environmental protection, USTs are governed by agencies such as the Environmental Protection Agency. These regulations specify tanks so that they would resist corrosion; they should not leak, and they must have spill prevention controls measures. Modern UST systems also come with state-of-the-art monitoring measures that use automated sensors to detect and signal leaks early, thereby reducing any environmental impact caused.

Modern UST Components

Generally speaking, a UST could consist of underground tanks, associated piping, leak detection systems, and overfill prevention devices. The proper installation and maintenance of such equipment are crucial owing to the potential risks these systems may pose through leaks, contamination, or simply malfunctioning if installed incorrectly. Regular compliance inspections, coupled with best practices followed during installation and maintenance, go a long way toward mitigating such risks while ensuring that upstream operational efficiencies are preserved.

Purpose of Gas Station Tanks

The USTs or gas station tanks supply gasoline, diesel, and other fuels for transportation and logistics industries. These tanks are designed to safely store large quantities of fuel underneath the surface, simultaneously maximizing space utilization and minimizing fire hazards on the surface. Modern UST systems have integrated advanced technologies with safety and environmental considerations in mind. For example, double walls and corrosion-resistant materials are used to prevent leaks and give the tanks a longer life, while accurate leak detection helps in early identification of faults.

| UST Statistics | Current Numbers | Annual Impact |

|---|---|---|

| Total USTs in Operation | 540,000 systems | Fuel distribution nationwide |

| Total Storage Capacity | Over 6 billion gallons | Petroleum and hazardous substances |

| Annual Fuel Distribution | 120 billion gallons | Vehicles across the United States |

| Regulatory Impact | Significant reduction | Spills and leaks over the years |

UTS Systems has recently reported holding over six billion gallons of petroleum and hazardous substances all over the U. S. There stand 540,000 USTs at work, over the years, hence the regulatory steps have significantly reduced spills and leaks. Given the huge consumer demand, gas stations provide 120 billion gallons of fuel annually to vehicles all over the United States. Thus, combining environmental regulations with technology, gas station tanks promote economic activity and environmental safety to deliver the fuels safely and efficiently to consumers.

Components of Underground Fuel Systems

The underground fuel system encompasses numerous components required for proper fuel storage and dispensing. These are:

Designed to securely hold fuel and prevent leakage.

To carry the fuel from the storage tanks to the dispensing pumps.

Dispense fuel for filling vehicles at gas stations.

Checks the system for leaks that might cause environmental hazards.

Safe filling and venting of storage tanks.

Allow data gathering of fuel level in the tank and ensure the functioning of the system.

Each one of these is a facet working in harmony to ensure safe and efficient fuel management.

The Role of Pipes in Gas Station Tanks

The piping system plays a vital role in the gas station tank infrastructure to ensure its unobstructed movement at any stage of the fuel. Usually, the pipes are categorized into suction pipes, pressure pipes, and vent pipes. Suction pipes channel fuel from underground tanks to dispensers, while pressure pipes generally work in systems with submersible pumps to feed fuel into the dispensers efficiently. Vent pipes provide the appropriate venting to avoid the build-up of undue pressures that could lead to explosions or tank damage.

Modern Piping Improvements

With newer applications and correct use of materials, pipe usage has been vastly improved in terms of durability and corrosion resistance. In some instances, fiberglass-reinforced plastic and polyethylene pipes are being glorified over conventional steel piping for longer life and minimum maintenance. Among other things, regulations, such as those enforced by the Environmental Protection Agency (EPA), impose the use of double-walled piping systems to contain leaks and preserve the environment.

These piping systems will usually be provided with sensors that can detect a leak occurring within the piping structure, so that prompt actions can be taken against the hazard. Research shows that with proper design and maintenance, the fuel piping system has less spill into the environment, while reported incidents place advanced leak detection technology as detecting up to 99 percent of anomalies. Through the use of these modern amenities, the gas station ensures the safer delivery of fuel and environmental sustainability compliance. Thus, piping systems continue to constitute an integral part of a dependable and efficient fuel management system.

Fuel Dispenser Connections

Fuel connections play an essential role in facilitating the safe and efficient transfer of fuel from commercial storage tanks to vehicles. Modern connections, designed with advanced sealing technologies to prevent leaks and minimize fumes, support environmental protection and operational safety.

Critical Connection Statistics

Studies show that nearly 70% of the fuel dispenser leaks occur due to failures in connections, which highlights the importance of proper maintenance and installation.

Swivels and breakaway couplings, among other new technologies, are commonplace in many systems today to reduce stress and prevent accidents while vehicles are fueling. Stainless steel and UL-approved polymers are just some of the premium materials being chosen for durability in harsh working conditions. Moreover, conformity to such standards as PEI/RP300 maintains a level of uniformity and safety in installations across the globe. By choosing to equip their sites with these modern systems, the operators can effectively work towards safety first, reduce downtime, and ensure smooth refueling for their customers.

Maintenance of Underground Fuel Infrastructure

The right maintenance of underground fuel supply systems becomes a matter of operational efficiency, environmental compliance, and safety. Inspections are carried out either on a scheduled basis or due to a complaint. Examples include tank integrity testing, corrosion monitoring, leak detection, and periodic maintenance to keep operational costs low and avoid serious environmental hazards. In their view, the application of advanced technologies, such as cathodic corrosion protection and ATG (automatic tank gauging), would be best recommended to retain longevity and provide more accurate monitoring.

Essential Maintenance Requirements

- Comply with UST (Underground Storage Tank) specifications as issued by the EPA

- Keep proper documentation of inspections, repairs, and upgrades

- Demonstrate adherence and track system health over its lifespan

- Perform regular cleaning of piping systems

- Replace worn-out components to ensure smooth running

- Consult with trained technicians and certified service providers

To comply with regulations either by local environmental agencies or to avoid punitive sanctions against themselves, individuals should abide by the UST (Underground Storage Tank) specifications as issued by the EPA. Keeping proper documentation of inspections, repairs, and upgrades to demonstrate adherence and to track the health of the system over its lifespan is imperative. Maintenance operations such as cleaning the piping systems and replacing worn-out components should be carried out regularly to ensure smooth running and to avoid downtime.

Consulting with trained technicians and certified service providers can further assure that repairs are professionally conducted and that all maintenance activities are performed in accordance with the guidelines relevant to their field, thus cultivating a safer and more robust fuel infrastructure.

How Deep Are Gas Station Tanks Buried?

Gas station tanks are typically buried at a depth of 4 to 6 feet from the surface to the top of the tank. Also, this depth ensures the tanks are adequately protected from external forces, as vehicles traveling above them, as well as ensuring that the installations comply with legal regulations concerning safety and the environment. The burial depth may vary depending on local code requirements and soil conditions, but improper installation may inhibit maintenance through accessibility and the prevention of contamination.

Typical Depths for Underground Fuel Tanks

The depth below ground for underground fuel tanks varies depending on several elements, such as regulations, soil conditions, and tank details. Generally, these tanks are buried four to six feet below the surface, from the surface to the top of the tanks. Such depth avoids damage from external forces like heavy vehicles, considering environmental standards on their safety. In some areas, local regulations might call for more depth, especially if freezing temperatures prevail or peculiar soil conditions exist. Access is an important consideration for inspection and maintenance. This, therefore, should not exceed what can be handled by standard equipment. Always refer to local building codes and environmental guidelines for the installation that meets the standards.

Factors Influencing Burial Depth

Key factors influence the burial depth for underground utilities or pipelines:

1

Soil Type

Soil type is an important consideration in deciding the depth; loose or disturbed soil can necessitate deeper placement so that the buried structure does not shift.

2

Utility Type

The type of utility being buried generally determines the flooring depth-gas lines, electrical cables, and water lines all have different standards and requirements to avoid damage either from external interference or other infrastructure.

3

Environmental Conditions

Environmental conditions may cause injuries to the installation, where digging in areas with freezing temperatures demands a deeper burial so as to avoid damage through frost heave.

4

Surface Loads

Anticipated surface loads-from vehicle traffic to loads imposed by heavy machinery-may also question the ability of the associated level of burial to ensure safety.

5

Building Codes

All installations must strictly follow building codes and relevant regulations set forth by state and local agencies, which vary by geographic location and application, and remain safe.

Regulatory Guidelines for Tank Installation

When installing a tank, safety and proper performance were of paramount importance; thus, regulatory compliance would be deemed critical. Initially, one must ascertain the exact prescribing regulations depending on the tank type (for example, above-ground and underground tanks) and its application (such as for the storage of fuel or water). Depending on jurisdiction, local regulations usually dictate the minimum distance a tank must be kept away from a building, property line, or water source. In the case of underground tanks, local regulations often specify the minimum depth of burial and require protective measures such as corrosion-resistant coatings or a secondary containment system to prevent leakage.

More rules state that the proper permits must be obtained before installation, and inspections shall have to be made by certified professionals during and after installation. Following these regulations would include, for example, the EPA in the United States and comparable bodies abroad, which also cover environmental and safety expectations. And finally, maintenance requirements are generally laid out, such as regular inspections of wear and leak testing, to keep the system compliant with the regulations and operationally sound. An attempt must be made to consult the local authorities or professionals one trusts about regional requirements.

Inspection and Maintenance of USTs

Regular inspections and maintenance on underground storage tanks (USTs) prevent leaks and ensure safe operations. An inspection could involve checking for corrosion, structural damage, or faulty components. The leak detection systems should also be tested regularly to make sure they are working properly. Maintenance of tanks involves cleaning, checking for fluid levels, and ensuring that spill prevention or overfill prevention equipment is working as intended. Effecting compliance and environmental protection requires strict adherence to the manufacturer’s specified directions, with adherence to local and federal regulations such as those from the EPA.

Importance of Regular Inspections

Regular inspection ensures that storage tanks and associated systems stay safe and efficient. It helps to spot potential problems, for instance, leaks, corrosion, or wear, before they become serious problems. Having the job done regularly will also help uplift the environmental standards, for instance, the EPA. The inspection does provide for some safer working conditions by identifying any hazards and ensuring that all legal protective systems, such as hardware for spill and overfill prevention, are in working condition. The inspection should be maintained on a regular schedule to minimize long-term repair costs, preserve the environment, and maintain regulatory compliance.

Common Inspection Techniques

Visual Inspection

This inspection technique involves a thorough examination of equipment, facilities, or systems for any observable signs of damage, wear, or malfunctions. It is very simple and can quickly pick up a few basic problems, such as corrosion, leaks, and misalignments. Usually, it is the first inspection done.

Ultrasound Testing

Ultrasonic testing uses high-frequency sound waves employed to detect internal flaws or variations in thickness through a material. This non-destructive testing is very useful for identifying cracks and corrosion while evaluating structural integrity without causing damage to the equipment.

Pressure Testing

Pressure testing evaluates pipes, vessels, and other pressurized systems for strength and leak resistance. It tests if the system, under working conditions, can safely withstand events of unexpectedly high pressure whilst looking for weak points which would fail in actual use.

Infrared Thermography

With infrared thermography, thermal imaging is used to detect heat irregularities that would suggest problems in electric circuits, faulty insulation, or overheating of equipment. This non-invasive method would keep operational inefficiencies from settling and also prevent hazards.

Hydrostatic Testing

Hydrostatic testing checks out the strength and performance of pressure systems by filling such with a liquid and pressurizing them. This is mostly used in the case of pipelines, tanks, and pressure vessels for locating leaks and assessing structural weaknesses.

By pulling these techniques together in a group, an organization will ensure a comprehensive inspection that guarantees optimum safety, functionality, and compliance across its operations.

Addressing Issues Found During Inspections

If inspection issues arise, it is important to address them systematically to preserve operating efficiency and safety. The following steps provide a condensed procedure to effectively manage inspection findings:

- Find the Root Cause – Analyze the matter thoroughly to discover whatever gives rise to it. This may involve reviewing the inspection data, operational records, and maintenance schedules to identify certain contributing factors.

- Prioritize Issues – Classify the problems based on severity and safety risks and their potential effect on operations. Immediate remediation to give precedence to any high-priority issues will help avert hazards and downtime.

- Create a Corrective Action Plan – Corrective action plans should contain detailed corrective measures for the issues identified. A corrective action plan should clearly define the steps needed to carry out the corrective action, assign responsibilities, and identify deadlines to ensure corrective actions are completed in a timely fashion.

- Implement Corrective Actions – Follow through on corrective actions to repair, replace faulty parts, improve structural integrity, or upgrade to meet compliance standards.

- Verify Corrective Actions – Upon completion of the remedial process, another inspection or test may be required, such as a hydrostatic test, to confirm that the matter has been resolved and that the systems are safe and functional.

- Document and Report – Keep records of all activities conducted for managing inspection findings; these might include the inspection findings themselves and details about repair work done and the results of verification. Documenting such information will contribute to continuous improvement, compliance audits, and knowledge sharing.

These steps enable organizations to resolve inspection issues efficiently, thus enhancing the safety, reliability, and long-term performance of their systems and processes.

Safety and Environmental Considerations

Ensure safety and environmental compliance by identifying hazards, applying controls, and complying with all applicable laws. Thus, hazard assessment, use of personal protective equipment, and compliance with safe operating practices become important. Environmentally, the organization should reduce waste, emissions, and the disposal of hazardous materials. Regular training and awareness can aid in strengthening safety and supporting sustainability initiatives for a safer workplace and healthier environment.

Potential Risks Associated with Underground Tanks

Considered as threats in the world of leaking and contamination, underground storage tanks (USTs) can create a host of problems. The structural integrity of a UST can be compromised as a result of corrosion, improper installation, or failures at source, giving rise to soil and groundwater pollution. This degradation risks ecologically and physically damaging, especially when drinking water sources are compromised. If the leak continues its illicit acts undetected, cleanup efforts would be extraordinarily expensive, and environmental fines would be realized for non-conformity. Another risk USTs pose is an ignition with explosion hazards when flammable substances are stored incorrectly or when improper ventilation occurs. Prevention of such hazards and ensuring safety and regulatory compliance can only now be achieved by regular inspections, maintenance, and leak detection monitoring systems.

Environmental Impact of Fuel Leaks

Fuel leaks can prove very damaging environmentally, and in my opinion, these must be addressed. Fuel leaks contaminate soil and groundwater, thus threatening ecological balances as well as sources of drinking water. A harmful release of petroleum materials would be detrimental to wildlife and encourage air pollution. I think that prevention techniques, such as regular inspection of tanks and use of state-of-the-art leak detection equipment, must be used as preventative measures to minimize these effects and thus ensure sufficient protection for the environment.

Best Practices for Safe Operations

Here are some of the basic building blocks of best practices to ensure operational safety while minimizing risks to the environment:

Routine Maintenance and Inspections

Regular inspection of tanks, pipelines, and storage facilities is required to address any leakage issues at an early stage or structural weaknesses. Advanced tools and technologies shall be used–ultrasonic testing, automated sensors, and systems for real-time monitoring.

Install State-of-the-Art Leak Detection Systems

Investments must be made to use state-of-the-art leak-detection systems, such as pressure sensors or remote-monitoring equipment, for prompt detection of anomalies. Such systems would ensure early detection of small issues, preventing them from emerging as major incidents.

Train Employees Properly

Provide the staff with complete training on equipment handling, emergency procedures, and maintenance operations. Only such well-trained personnel will be able to work safely and adequately react in emergency circumstances.

Stay Compliant with Regulatory Standards

Respect the local, state, and federal rules and regulations concerning storage, transport, and disposal to remain in good legal and environmental standing. Conduct audits and certification regularly to keep up to industry standards.

Environmental Contingency Planning

Maintain an active contingency plan for spill response and environmental hazards. The local authority and experienced parties must be involved to ensure a prompt response that mitigates any damage to the ecosystem and communities.

Following these guidelines allows an organization to drastically reduce the risks associated with operations, thereby helping to nurture a better environment.

Key Takeaways

Underground storage tanks are critical infrastructure that requires careful planning, installation, and maintenance. Understanding their proper burial depth, regulatory requirements, and safety considerations is essential for protecting both public health and the environment. Regular inspections, proper maintenance, and adherence to best practices ensure these systems continue to safely serve our fuel distribution needs while minimizing environmental risks.

Reference Sources

Evaluation of the Internal Control System for Inventory at U.D Nina Usman SPBU

Frequently Asked Questions (FAQs)

Gas Station Tanks: How Deep Are They?

The depth of burial for gas station tanks varies. In most cases, USTs are buried anywhere between about 3 and 15 feet. Factors influencing the depth of burial include local regulations, groundwater levels, and the terrain of the soil. Often, regulatory requirements dictate how deep gas station tanks should be installed to ensure that they are safe and minimize the environmental hazard.

What Does the Law Say About Underground Storage Tanks?

Owners and operators of gas station tanks must adhere to the underground storage tank regulations, which include the 40 CFR guidelines. The rules require that USTs must be able to contain the substance they store at all times and be equipped with facilities for release detection and interstitial monitoring. A compliance program for these regulations is an integral part of protecting the environment and the health of the people.

Why Tightness of Tanks and Pipes Important?

Penetrating the surrounding soil by leaks and contaminants can occur because of loosening between the tank and piping. Basically, to ensure their safety, a condemnation is done on the occasion of the tightness test, i.e., a leakage test, to ensure that the underground storage tank system is free from leakage. They are also responsible for carrying out regular inspections and maintenance to prevent expensive cleanup from crashing down on the station in case of leakage.

Do Groundwater Levels Affect an Installation’s Burial Depth?

Groundwater levels can significantly influence the burial depths of gas station tanks. In cases where groundwater levels are high, the tanks should be placed deeper to ensure their stability and security. Furthermore, soil testing would be conducted to establish the compatibility of the tank system with the soil and groundwater conditions of the locality.

What Are The Mechanics of Tank Removal?

Once the gas station tank has reached the end of its lifecycle or is required to be replaced, tank removal has to be performed. This usually includes the removal of the existing underground storage tank and any of the associated piping. In cases of removing tanks, station owners must ensure that the removal procedure complies with the regulations of underground storage tanks so as not to cause environmental pollution.

What Are the Environmental Impacts of Gas Station Tanks?

While a gas station tank not adequately maintained poses significant environmental risks, spills of hazardous substances may enter the soil and groundwater. Contaminated leaky sites reiterate the need for an assured release detection system in place in compliance with all regulations that govern the activities of fuel delivery vehicles and operators of fuel tanks.

What Is the Role of Installers in UST Compliance?

The installer of the underground storage tank system is very important in ensuring compliance with the regulations of the UST program. A competent installer is responsible for installing tanks and pipes in such a way as to comply with regulations that prevent leaks and thereby protect human health and the environment.

How Does a Line Leak Detector Work?

A line leak detector is one of the most important components of an underground storage tank system and monitors the piping connected to the tank. It will detect leaks from the system and warn the station owners of a potential problem before it becomes a serious environmental incident. Regular testing and maintenance will be required to fulfill compliance and safety.

What Is Financial Responsibility Related to Underground Storage Tanks?

Financial responsibility is a requirement imposed on gas station owners concerning their underground storage tanks’ management and operation. It includes provision of funds for the cleanup of leaks or spills of contaminated sites, should they arise, and further for satisfying the requirements of the authorities on remediation measures. Compliance with regulations for financial responsibility alleviates some of the dangers that come from hazardous waste and contaminated sites.