The act of transferring gasoline between two cars is a skill that might not be of daily use, but can come in handy in emergencies or certain situations, like helping a stranded driver or managing fuel in out-of-the-way places. Nonetheless, the procedure has to be done in a manner that is safe and effective so that spills, contamination, or accidents do not occur, and thus, this guide is going to lead you stepwise through siphoning gas, while at the same time making sure that you are aware of the necessary tools, precautions, and techniques involved. You are an automotive enthusiast, survivalist, or anyone else preparing for unforeseen situations, and this article will equip you with the know-how and confidence to deal with the fuel transfer in a responsible manner. Keep reading to find a detailed breakdown of this crucial skill.

Understanding the Need to Siphon Gas

There are a few circumstances where siphoning gas is imperative. One of the uses is transferring gas among vehicles, especially in emergencies when gas stations are far away. The ability to siphon gas is also useful in the scenario of taking out tainted fuel from the tank and thus avoiding damage to the engine. Moreover, siphoning is sometimes a necessity during the maintenance or repair of a car’s fuel system. When following the correct safety precautions, the whole process will be carried out in an effective manner, thus reducing the chances of accidents or spillage.

Reasons for Transferring Gas Between Cars

In various situations, the transfer of gasoline between cars is needed frequently. The primary reason for this is to help a vehicle that is out of fuel and is stuck in a remote area without a gas station. Another reason is when there is a need to pump out dirty gas from the tank, which would otherwise lead to serious mechanical problems or engine damage. In some cases, fuel transfer may also be required during certain maintenance tasks, like replacing a faulty fuel tank or pump. Proper fuel levels in different cars for activities like caravanning or emergency preparedness also require gas transfers. During this operation, safety measures must be strictly followed, like performing it in a well-ventilated area and using suitable equipment to reduce the risks associated with fuel handling.

When You Might Need to Siphon Gas

Gas siphoning, a skill that can be used in several circumstances, is a necessary limitation in situations of transferring fuel between cars, reclaiming gas from a broken engine, or managing the case of limitations in fuel availability. The task is extremely beneficial during mechanical repairs, where an empty fuel tank is required, or in the case of redistributing fuel to balance the loads of caravans or fleets.

To carry out the siphoning process safely and properly, follow these steps:

- Select the Right Equipment – Choose a manual or electric siphon pump specifically made for fuel transfer to avoid contamination or spills.

- Work in a Well-Ventilated Area – Always work outside or in a well-ventilated place to protect yourself from breathing in dangerous fumes.

- Make Ready the Container and Source – Check that the container receiving the fuel and the tank from which it is being taken are both secure, clean, and gasoline compatible.

- Start the Transfer Slowly – Insert and secure the siphon pump’s hose before you turn on the flow so that you can effectively control the transfer rates and prevent splashing.

These practices, combined with the use of tools that meet OSHA safety requirements, make gas siphoning a low-risk process that can therefore remedy a variety of maintenance and operational needs.

Safety Considerations When Siphoning

Critical Safety Warning

Siphoning gasoline is a procedure where safety takes the topmost position every time because it is the only way to avoid injuries, the environment would not be harmed, and the regulations would not be violated. Let’s take a look at some major factors:

Essential Safety Measures

- Avoid Direct Oral Siphoning – It is a very risky method to start siphoning with the mouth since the person is at risk of swallowing gasoline or inhaling poisonous fumes, and finally, respiratory injury or death.

- Utilize Properly Designed Tools – A high-quality siphon pump that complies with the required safety standards should always be used to transfer the liquid in a controlled manner and prevent spills or vapor release.

- Work in Well-Ventilated Areas – The operation of siphoning should be done in the open air or in places with good ventilation so that the harmful gas does not build up, thus reducing the chance of inhalation or fire hazards.

- Use Appropriate Personal Protective Equipment (PPE) – Basic protection against leaks or spills consists of gloves, safety spectacles, and flame-proof clothing.

- Inspect Equipment Before Use – A preventive maintenance program for hoses, pumps, and containers receiving the material should be done regularly. The presence of leaks or damaged equipment can cause accidents such as spills or fire.

- Store and Handle Gasoline Safely – Strictly follow DOT (Department of Transportation) standards for the containers used to hold the gasoline, and make sure they are labeled, and the level is not above the brim, so there is room for expansion of the fuel.

If all the critical safety measures discussed above are followed, then the risks linked with siphoning gasoline can be drastically reduced, leading to safety in operations and meeting regulatory requirements.

Methods to Siphon Gas from a Car

Manual Siphoning with a Hose

- Get hold of a transparent, clean hose and push one end into the gas tank to the point where it touches the fuel.

- Put the other end in a proper and allowed fuel container that is lower than the tank.

- Suction at the container end of the hose till liquid starts flowing, letting gravity assist the siphoning process further.

Using a Hand Pump

- Get a hand pump for automobiles or a siphon pump designed for fuel transfer.

- Place the intake hose in the gas tank and the output hose in the fuel container.

- Pump manually to refill the container with gasoline safely and fast.

In all cases, make sure to contain the gas properly and follow all safety measures, such as no inhalation of fumes and opening flames or sparks away from the process.

Using a Siphon Pump

A siphon pump is a useful device that can transfer liquids, gasoline included, in a controlled and safe manner. The siphon pump can be used effectively by observing the following:

Get Ready for the Equipment

Make sure that the siphon pump is clean and suitable for the transfer of gasoline. Verify that the intake hose is long enough to reach the liquid and that the output hose is securely placed in the receiving container.

Set the Pump Right

Insert the pump’s intake hose into the tank of gas, making sure it is submerged in fuel. Put the output hose in the container that you are going to receive gasoline in, and make sure it is fixed so that there is no spillage.

Start the Siphon

Employ the pump’s mechanism—like a squeeze bulb, hand-operated pump, or any other manual feature—to create suction. This will cause gasoline to flow from the tank into the container through the hoses.

Keep an Eye on the Transfer

As soon as the liquid begins to flow, it should keep on transferring because of the force of gravity and the siphon effect. Watch the process carefully and stop the flow immediately when the desired amount of fuel has been transferred.

Safety Precautions

It is important to always work in a spot that has good ventilation, not to inhale any fumes, and to make sure that there are no sources of ignition nearby. Once the transfer is done, properly seal the gas container and adhere to all safety guidelines for flammable liquid handling that apply to your situation.

If these steps are followed, the siphon pump technique will be applied effectively, with safety risks being minimized and proper containment of the fuel.

Manual Siphoning Techniques

Manual siphoning is an old technique for the liquid transfer from one container to another using gravity and a siphon system. Below are two of the most commonly practiced manual siphoning methods:

Using a Tube and Oral Suction:

This particular method calls for a hose or tube that is made of a flexible and durable material. Dip one end of the tube into the liquid that is to be siphoned, making sure it goes right to the bottom. Now suck slowly and gently on the other end of the tube until the liquid starts flowing, but take very good care not to accidentally swallow any poisonous or harmful substances. Then quickly put the outlet of the tube into the container that is going to receive the liquid. The liquid flow will be continued by gravity once initiated.

Using a Priming Motion with a Tube:

This method, however, is much safer; hence, you have to completely dip the hose in the liquid and make sure it is full of liquid with no air pockets. While the hose is submerged, put your thumb on one end, then take it out of the source container. Next, put it under the level of the liquid in the receiving container, and finally take your thumb off to start the siphoning. This method prevents any direct oral contact.

Both methods need great attention and caution in order not to spill or come in contact with dangerous liquids. Do not forget to clean all the equipment and check if they are suitable for the liquid that is going to be transferred, and keep on following the safety rules to avoid any accidents or contamination.

Common Mistakes to Avoid When Siphoning

Using the Wrong Equipment

One of the most serious errors is using a siphon hose that is incompatible with the liquid to be moved. Always verify that the tube materials are compatible with the fluid, at least from the aspect of chemical stability, thus preventing any degradation or mingling.

Improper Assembly of the Siphoning Setup

Improper positioning of the source container with respect to the receiving container can cause the flow to be interrupted by the insufficiency of gravitational force. Moreover, make sure that the hose is completely inside the liquid during the process so that air pockets are not created, which will lead to breaking the siphon.

Absence of Safety Measures

The neglect of protective gear, including gloves and goggles, might lead to inhalation or skin absorption of harmful or even toxic substances during siphoning. Never sacrifice safety, especially when working with harmful liquids.

The Siphon Hose Not Being Primed Properly

Not filling the siphon tube with liquid before flow initiation can let air in to block the process. Right priming facilitates smooth and even liquid transfer.

Not Fixing the Tube

If the siphon hose is not tightly fixed in both the source and receiving containers, then movement or displacement will cause either spill or halt the transfer. Take advantage of clamps or other securing tools to keep the hose immovable.

A lot of errors in a common manner and compliance with best practices make the siphoning process not only smooth and fast but also safe by cutting down on the risks of accidents or contamination.

Preparing for the Gas Transfer Process

For gas transfer that is both safe and effective, the following key steps must be taken:

- Inspect Equipment: Make sure that all transfer equipment, such as hoses, clamps, and containers, is functioning properly and is free of defects or damage.

- Ensure Adequate Ventilation: Carry out the transfer in a place that is well-ventilated in order to avoid the accumulation of noxious vapors.

- Use the Right Containers: Check that both the source and receiving containers are capable of adequately handling the particular gas that is being transferred.

- Ground and Bond Equipment: If the gas is flammable, connect the source and receiving containers to ground to eliminate the possibility of static electricity that could cause the fumes to ignite.

- Wear Protective Gear: Utilize personal protective equipment (PPE) that is appropriate, such as gloves and safety goggles, to protect against possible splashes or leaks.

These rules, when strictly adhered to, will make the gas transfer process safer and more effective with a significant decrease in the chances of accidents and contamination.

Tools and Equipment You Might Need

Essential Equipment for Safe Gas Transfer

- Grounding and Bonding Cables: To prevent static discharge by ensuring proper grounding between containers.

- Gas Transfer Pumps: Specialized pumps designed for handling flammable or non-flammable gases safely and efficiently.

- Pressure Regulators: Devices to control and maintain the correct pressure during the transfer process, avoiding potential hazards.

- Personal Protective Equipment (PPE): Gloves, safety goggles, flame-resistant clothing, and face shields to protect against leaks, splashes, or accidental exposure.

- Spill Containment Kits: To swiftly manage and contain accidental spills, reducing potential contamination.

- Hoses and Fittings: Certified hoses and connectors compatible with the specific gas types to ensure a secure transfer process.

- Gas Detectors: Instruments to monitor and detect any gas leaks in the surrounding environment, ensuring safety compliance.

- Monitoring Systems: Pressure gauges or flow meters for real-time tracking of gas transfer rates and conditions.

These tools should always align with the specifications of the gas involved and adhere to regulatory safety standards for handling hazardous materials.

Checking the Cars’ Fuel Tanks

The initial step of confirming the fuel level in the tank of a car is to verify that the vehicle is in a horizontal and stable position so as to get an accurate reading. Look for any noticeable damage, rust, or leaks on the surface of the fuel tank. Inspect tank seams as well as all fuel lines going in and out of the system. Then, check the fuel level either by the fuel gauge or, if you suspect the gauge is not working, measure the fuel level manually with a proper dipstick or sensor-based device. Also, consider checking the fuel cap for proper sealing, as a loose or damaged cap could result in vapor leaks and, therefore a drop in efficiency. Apart from that, the compatibility of tank materials with the type of fuel used is crucial because it influences both the lifespan and safety of the tank. Always make sure to follow the manufacturer’s instructions and the safety standards of the industry in the same way that you would when inspecting and servicing the fuel tank.

Safety Precautions Before Starting

Critical Pre-Start Safety Checklist

Before any fuel tank inspections or maintenance, it is essential to guarantee that the vehicle or equipment is stationed on a flat surface, the engine is turned off to remove any possible ignition risks, and all safety measures have been followed. To eliminate accidental electrical sparks, the battery must be disconnected during the operation. Adequate ventilation has to be provided to prevent the accumulation of hazardous fuel vapors in the work area. Personal protective equipment (PPE), such as gloves and safety goggles, should be used to guard against fuel and chemical contact. Moreover, fire extinguishers suitable for flammable liquids should always be in the vicinity, and there should be no smoke, sparks, or heat sources in the area where the work is going on. Always check the manufacturer’s service manual for detailed instructions and comply with the local regulations and environmental rules.

Step-by-Step Guide to Transfer Gas

Prepare the Work Area

The area where the work will be done should be highly ventilated and should not have any sources of ignition, such as open flames or electrical sparks, at the same time. A fire extinguisher should be placed in the vicinity as a safety measure.

Gather Necessary Equipment

Select a suitable gas transfer pump or siphon specifically made for fuel transfer. Make sure that all the equipment is spotless and devoid of any contaminants.

Inspect Containers

Make sure that both the source and receiving containers are gas storage-approved and non-leaking. The receiving container should be placed on a flat and stable surface that is below the source container.

Establish a Secure Connection

Securely connect the transfer pump or siphon hose to both containers. During the transfer, make sure there are no spills or leaks by ensuring the hose fits tightly.

Begin Transfer Carefully

Follow the manufacturer’s directions to switch on the pump or siphon. Be vigilant and keep a close eye on the gas flow so that the receiving container does not get overfilled.

End the Process Safely

After the transfer, do not delay; disconnect the pump or hose immediately. Make the containers airtight to eliminate any chance of vapor escape.

Clean Up and Store

Spilled fuel should be absorbed by the use of absorbent material immediately. Containers should be in a safe place free from heat or flame, i.e., in an approved location.

By observing these measures, you will be able to carry out gas transfer safely and efficiently, allowing the risks related to flammable materials to be minimized.

Preparing the Cars for Gas Transfer

To do gas transfer to vehicles, you must perform the following steps:

Park well and stabilize

Place the two automobiles on the level ground and activate the parking brakes. This will greatly reduce the risk of the accidental movement of the vehicles during the gas transfer process.

Cut Off Engines and Electronics

Make sure both cars’ engines are off and all electronic devices are also off in order to prevent any possible sources of ignition. Also, make sure that the area around the gas transfer is clear of any flammable materials.

Fuel Caps Open and Check

Open up the fuel caps of both cars so that gas can flow easily. Check the fuel openings and the areas next to them for any damage or dirt that might block the gas transfer.

Right Tools Use

A proper siphon pump or transfer hose made specifically for gas transfer should be employed. Make sure the equipment is good and has no cracks or leaks. Do not use any makeshift methods that might put you in danger.

Following these preparatory steps guarantees that you have created the foundation for a safe and smooth gas transfer between vehicles.

Executing the Siphon Process

Position the Vehicles

Сoordinate that the vehicles to be transferred are parked on a flat area, close enough that the siphon pipe can be connected without tension between them. Switch off both vehicles’ engines and set the parking brakes for safe and stable operation.

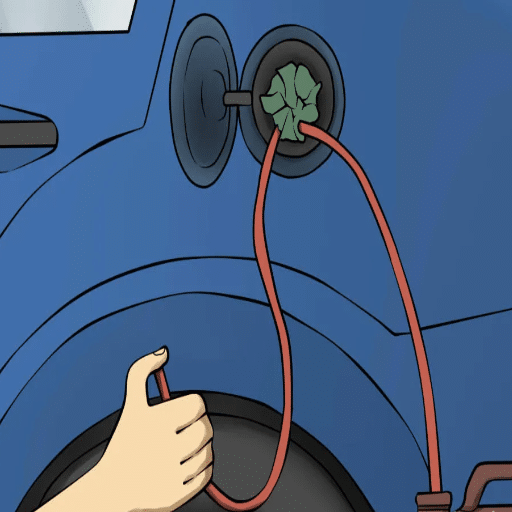

Insert the Siphon Hose

To get the best possible flow, the end of one siphon hose is put into the fuel tank of the car from which fuel is being taken, and then the other end is inserted into the tank of the car that is receiving the fuel. Both ends are held firmly so that no spills occur.

Activate the Siphon Mechanism

The manual siphon pump, if in use, will be the beginning of the suction process. By the pumping of the procedure, the fuel transfer will be started. For the gravity-driven siphons, the flow would be initiated by either taking a little bit of fuel manually or using a primer bulb. Direct fuel contact is to be avoided at all times.

Monitor the Transfer

Fuel flow should be checked all the time for its uniformity, and at the same time, no leaks should be detected at the connection points. Stop the process immediately as soon as the tank of the receiving vehicle approaches full, to prevent over-filling.

Remove and Store Equipment Safely

When the transfer is finished, the siphon hose is to be taken out from both tanks very carefully, while any fuel left in the hose can be drained back into the right tank so that it does not cause spillages. The equipment should be cleaned and then placed in a safe, ventilated storage area that is far from the sources of ignition.

The above-listed actions will manage to make the fuel transfer process effective and under control while safety and the integrity of the equipment are prioritized. Make sure to check your vehicle’s manual and adhere to local regulations regarding fuel handling.

Finishing Up and Ensuring Safety

At the end of the fuel transfer operation, make a complete and thorough examination of the area for any possible spills or leaks, taking quick and efficient action to absorb them with the help of only approved absorbents. The fuel caps on both tanks should be inverted and tightly secured to preclude any loss or contamination through evaporation. Properly aerate the place of work to eliminate the fume buildup, as the presence of gases may ignite and cause serious health issues. The remaining fuel plus the equipment must always be in labeled containers for flammable liquids, and the location of their storage must conform to local fire codes – far away from heat and sunlight.

To ensure maximum safety, check the condition of all tools and hoses that were involved in the transfer and only then proceed to store them where possible malfunctions can be prevented in future operations. Last but not least, if record-keeping is required, document the transfer according to the regulations and make reviewing procedures a routine practice to ensure that they are in line with the latest safety standards and environmental guidelines.

Common Mistakes and How to Avoid Them

| Common Mistake | Consequences | How to Avoid |

|---|---|---|

| Improper Storage Practices | Safety issues and violations of industry rules | Ensure storage locations comply with fire safety regulations and are well-ventilated |

| Neglecting Equipment Inspections | Breakdowns at wrong time, safety hazards | Carry out regular inspections and repairs to keep tools working and safe |

| Incomplete Documentation | Compliance problems, regulatory issues | Keep detailed records according to regulatory requirements and check periodically |

| Overlooking Procedure Updates | Exposure to risks, noncompliance with current standards | Regularly revisit and modernize procedures to align with latest safety rules |

| Misusing the Siphon Pump | Chemical reactions, material degradation, leaks | Follow manufacturer’s instructions, check compatibility, do routine maintenance |

| Ignoring Safety Precautions | Equipment failure, injuries, contamination | Always put safety first and follow established rules and guidelines |

| Not Checking the Fuel Type | Mechanical failure, performance decline, expensive repairs | Check equipment manual, match fuel type to manufacturer’s recommendations |

Misusing the Siphon Pump

When a siphon pump is properly used, it always brings safety, efficiency, and no damage to equipment. Wrongly siphoning and downright using the pump are ways of misuse. The most common misuse is applying the pump without first checking whether the substance to be transferred is compatible with the pump, which may cause chemical reactions, degradation of material, and leaks, among others. Moreover, not keeping the suction height sufficiently high or not properly priming the pump may cause the flow to be disrupted, leading to an uneven or incomplete transfer. Those users who do not conduct regular inspections and cleaning of the pump are in danger of clogging, wear, and contamination, all of which can adversely affect performance and safety. The manufacturer’s instructions should be followed exactly, compatibility with materials checked, and routine maintenance done in order to avoid misuse and guarantee efficient operation.

Ignoring Safety Precautions

In ignoring safety measures, I have both the machinery and myself in danger. Not obeying the standards of safe practice might result in equipment failure, an injured person, or contamination problems. By disregarding the maker’s guidelines or skipping the scheduled maintenance, I put the operations’ efficiency and safety at risk. Therefore, I always try to put safety first and follow the rules laid down.

Not Checking the Fuel Type

If one forgets to check the fuel type before using the machine, it can lead to very costly and severe consequences like mechanical failure, a decline in performance and efficiency, and exorbitant repair bills. Incorrect fuel can cause filters to clog, heavy knocking in the engine, or even total system failure, thereby shortening the life of the equipment. Moreover, the latest engines generally demand certain fuel grades or blends that match their design, and the use of wrong fuel types might result in the cancellation of guarantees or a decrease in compliance with environmental regulations. Therefore, to avoid such problems, it is vital to check the equipment manual, match the fuel type to the manufacturer’s recommendations, and practice proper labeling and storage techniques. Making this step a priority reduces the risk of disruption and, at the same time, guarantees that the equipment is working in optimal conditions that are safe.

Safety Comparison: Siphoning Methods

| Method | Safety Level | Equipment Required | Best Use Case |

|---|---|---|---|

| Manual Siphon Pump | High | Hand-operated siphon pump, hoses, containers | Most situations, recommended for safety |

| Electric Siphon Pump | Very High | Electric pump, power source, hoses | Large volume transfers, frequent use |

| Gravity Siphon with Primer | Medium-High | Clear hose, primer bulb, containers | Emergency situations, no power available |

| Oral Suction Method | Very Low (Dangerous) | Hose only | NOT RECOMMENDED – Risk of ingestion/inhalation |

Key Takeaways

Essential Points for Safe Gas Siphoning

- Never Use Oral Siphoning: This dangerous method risks gasoline ingestion, toxic fume inhalation, and serious respiratory injury or death.

- Always Use Proper Equipment: Invest in quality siphon pumps designed specifically for fuel transfer that meet OSHA safety requirements.

- Ventilation is Critical: Always work outdoors or in well-ventilated areas to prevent dangerous fume accumulation and reduce fire hazards.

- Wear Protective Gear: Use gloves, safety goggles, and flame-resistant clothing to protect against spills, splashes, and vapor exposure.

- Inspect Equipment Before Use: Check all hoses, pumps, and containers for damage, leaks, or wear that could cause accidents.

- Follow DOT Standards: Use approved containers for gasoline storage that are properly labeled with room for fuel expansion.

- Eliminate Ignition Sources: Keep all flames, sparks, cigarettes, and electrical equipment away from the transfer area.

- Position Vehicles Properly: Park on level ground, engage parking brakes, turn off engines, and disconnect batteries before starting.

- Monitor the Transfer: Watch the process constantly to prevent overfilling, detect leaks, and stop immediately if problems occur.

- Clean Up Thoroughly: Use approved absorbents for spills, seal containers tightly, and store equipment safely away from heat sources.

- Know Local Regulations: Comply with local laws regarding fuel handling, storage, and transfer to avoid legal issues.

- Check Fuel Compatibility: Verify that you’re transferring the correct fuel type to prevent engine damage and maintain warranties.

Conclusion

Siphoning gas from one car to another is a valuable skill that can prove essential in emergency situations, during vehicle maintenance, or when managing fuel distribution in remote locations. However, as this comprehensive guide has demonstrated, the process demands strict adherence to safety protocols, proper equipment selection, and careful execution to prevent accidents, injuries, and environmental contamination.

The most critical takeaway is that safety must always be the top priority. Never attempt oral siphoning—a dangerous practice that can lead to gasoline ingestion, toxic fume inhalation, and serious health consequences. Instead, invest in quality siphon pumps or manual transfer equipment specifically designed for fuel handling. Always work in well-ventilated areas, wear appropriate personal protective equipment, and keep all potential ignition sources far from the transfer zone.

Understanding the various methods available—from manual siphon pumps to gravity-based systems—allows you to choose the most appropriate technique for your specific situation. Each method has its advantages, but all share common safety requirements: proper equipment inspection, secure connections, careful monitoring, and thorough cleanup procedures.

The common mistakes outlined in this guide—using incompatible equipment, neglecting safety measures, improper setup, and inadequate priming—are all entirely avoidable through careful preparation and attention to detail. By following the step-by-step procedures provided, checking fuel compatibility, and maintaining your equipment properly, you can perform gas transfers safely and efficiently.

Remember that gasoline is a highly flammable and toxic substance that requires respect and careful handling. Compliance with DOT standards for container storage, adherence to local regulations, and proper documentation when required are not just bureaucratic requirements—they’re essential safeguards that protect you, others, and the environment.

Whether you’re helping a stranded motorist, removing contaminated fuel, performing vehicle maintenance, or managing fuel distribution for a caravan or fleet, the knowledge and techniques presented in this guide will enable you to handle fuel transfer responsibly and confidently. The key is preparation: having the right tools, understanding the proper procedures, recognizing potential hazards, and never compromising on safety measures.

By mastering these skills and maintaining a safety-first mindset, you’ll be equipped to handle fuel transfer situations effectively while minimizing risks to yourself, your vehicles, and your surroundings. Always remember that taking a few extra minutes to prepare properly and follow safety protocols is infinitely preferable to dealing with the consequences of shortcuts or oversights.

Final Safety Reminder

Always prioritize safety over convenience. If you’re unsure about any aspect of the siphoning process, don’t hesitate to consult with automotive professionals or emergency services. The risks associated with improper fuel handling far outweigh any time saved by taking shortcuts. Stay safe, follow proper procedures, and be prepared for emergencies with the right knowledge and equipment.

Reference Sources

“How Total is a Total Cost of Ownership?”

“The Analysis of the Emission Influence on the Human’s General Condition”

“Electric Vehicle Policy: The Main Pillar of Indonesia’s Future Energy Security”

Frequently Asked Questions (FAQs)

What materials will I need to get gas out of one car and put it in another?

To get gas out from one car and put it in another, you are going to need a clear tube or hose of sufficient length to reach from the gas car’s filler neck to the gas tank of the other car. Although a siphon pump can ease the operation, it is not a strict requirement.

What is the siphon pump process for gas transferring?

The siphon pump method is the simplest way to do a gas transfer. First, the hose’s one end should be inserted into the gas tank of the car from which you want the gas, and then it must be pushed through the flap. After that, the hose’s opposite end should be put into the filler neck of the car receiving the gas. If using a siphon pump, the manufacturer’s instructions should be followed for starting the flow, making sure the end of the hose is lower than the gas tank so that gravity can help.

Is it possible to siphon gas without a pump?

Indeed, you can effortlessly siphon gas without a pump. For that, you need to insert the hose into the gas tank of the donor car and place the other end inside the receiving car’s tank. Creating a vacuum by sucking on the end of the hose is necessary to get the flow started, which is why it is crucial not to let gasoline get into your mouth. When the flow is established, lower the end of the hose to allow gravity to assist in the gas transfer.

What are the important facts about anti-siphon devices that I should be aware of?

The majority of contemporary cars have an anti-siphon feature that makes it difficult to siphon gas. These anti-siphon devices are found at the gas filler neck and prevent the siphoning hose from going deep into the gas tank. If you face this issue, you might need to either look for another method to transfer gas or opt for using a siphon pump that is capable of bypassing the anti-siphon flap.

Is it possible to transfer gas safely in my garage?

Yes, gas transfer in your garage is safe if you follow the proper precautions. The area should be adequately ventilated, and no open flames or sparks should be present. You should use a clear hose so that you can see the gas flow, and also have a container ready for catching spills. It is always a good practice to wear gloves when dealing with gasoline to avoid skin contact.

What is the simplest method of gas transfer?

The simplest method of gas transfer is the use of a siphon pump. This equipment causes the emergence of the gases from the donor’s tank to the receiver’s tank through the process of vacuum created. Ensure that the donor car is situated lower than the receiving car and follow the instructions given by the siphon pump for excellent results.

Will I have the ability to see the gas while siphoning?

Definitely, if you use a transparent hose, you will see the gas passing from one car to the other. Such visibility can aid you in the monitoring of the transfer process and confirming that you are not spilling any gas. Always make sure that your hose is correctly positioned to avoid any backflow or mess.

What should I do if I have to transfer gas in a short time?

If gas transfer in a short time is your need, then the use of a siphon pump is your top choice. This method requires less energy to start the siphon action and guarantees a faster flow. To prevent any obstructions, be sure to insert the hose correctly and keep the receiving tank’s filler neck clear for effective gas transfer.