Fuelling dispenser pumps are the modern-day essential parts of the gas stations to function properly, as they are the main distributors of gasoline, diesel, and other petroleum products. They are not just machines for quick and efficient transfer of fuel but also for accurate and safe, plus user-friendly refueling process. In addition to technological advancements, the variety of fuels used globally has increased; hence, the diversity of fuel dispensers has also grown to meet different needs and applications. This article intends to highlight the different types of fuel dispenser pumps along with their distinct attributes, working processes, and main fields of application. Furthermore, whether you are the owner of a fuel station, a maintenance worker, or just a general reader with an interest in the subject, this all-inclusive resource will try to explain the main features of these machines that are not only necessary but also the energy sector’s support pillars.

Introduction to Fuel Dispenser Pumps

Fuel dispenser pumps are indispensable tools that facilitate the movement of fuel from the storage tanks to the vehicles or machines with high accuracy and efficiency. These devices have internal mechanisms that manage the flow of fuel, determine its volume, and thus maintain the precision of delivery for the various types of fuels like gasoline, diesel, or substitutes. Moreover, the contemporary fuel dispensers contain sophisticated metering systems, security measures, and easy-to-use interfaces that not only increase but also make precision enjoyable for the users. Such pumps are found everywhere in fueling operations, and their presence is mainly due to the high-demand capabilities in commercial and consumer markets, which are powered by sectors such as transport, farming, and building.

What is a Fuel Dispenser?

A fuel dispenser is an instrument that can be defined as such: it is a compromised apparatus that not only pumps the liquid fuels, which are either gasoline or diesel or even alternative fuels, but also delivers these fuels straight to vehicles or into storage containers. It does this by pulling the liquid out of the underground or above-ground storage tank, and after measuring the exact volume of the liquid that has been dispensed, finally, it sends the liquid through a nozzle. State-of-the-art fuel dispensers come with sophisticated metering systems for accuracy, payment systems for transactions at points of sale, and safety devices like vapor recovery and leak detection. These machines are most important in the fuelling and distribution sectors, their current applications being mainly in automotive, agriculture, and construction industries, and they are being operated in accordance with the very demanding regulatory and environmental standards.

Importance of Fuel Pumps in Fuel Dispensing

Fuel pumps are indispensable parts in the supply of fuel, assuring the complete and precise movement of fuel from the fuel tanks to the vehicles or machines. They also provide the necessary constant pressure and flow, which is required for drip-free operation, and at the same time, the amount of fuel lost through evaporation is minimized. The pumps are fitted with high-accuracy meters that allow them to dispense the exact required amount of fuel; this way, the pumps are not only complying with the industry standards and regulations but are also winning the trust of the consumers. Furthermore, new-age fuel pumps come outfitted with sophisticated safety features like automatic shut-offs and vapor recovery systems that significantly reduce the environmental risks by controlling leaks and cutting down the output of pollutants. They are dependable and powerful, and their use is widespread in transportation, agriculture, and construction, all of which have their dependability on fuel supply. Fuel pumps are, therefore, the most critical factor in combining the technology of safety measures with the environmental acknowledgement of the operational performance.

Overview of Types of Fuel Pumps

Fuel pumps are the utmost necessary devices in diverse systems and are mainly classified into mechanical, electric, and high-pressure fuel pumps.

Mechanical Fuel Pumps

These are mostly used in vintage or carbureted engines, and the mechanical fuel pumps are activated through a diaphragm, which pumps the fuel from the tank to the engine by creating suction. They are relatively easy to manufacture, inexpensive, and efficient for low-pressure fuel delivery systems. However, due to their limited pressure output, they are not recommended to be used with high-performance or modern fuel injection engines.

Electric Fuel Pumps

The electric fuel pump is a standard component in today’s cars that are equipped with fuel injection systems. These pumps are usually either located inside or close to the fuel tank. They work by utilizing an electric motor that constantly pumps the fuel into the engine at high pressure, thus supporting the engine’s performance. Electric fuel pumps have the latest safety features, including pressure relief valves, and their efficiency and reliability are much higher than those of the mechanical variant.

High-Pressure (Direct Injection) Fuel Pumps

The main prerequisite for direct fuel injection systems is the high-pressure fuel pumps, which are the ones that directly inject the fuel into the combustion chamber at extremely high pressures. These pumps are coordinated with the engine’s control system to optimize the fuel delivery, thus leading to the achievement of higher power output, lower emissions, and improved efficiency. They are vital in modern gasoline and diesel engines, especially in cases where vehicles are set to comply with stringent environmental regulations.

Note: All the different kinds of fuel pumps carry out various tasks according to the design and functional needs of the system, which also illustrates the progression of fuel pump technology in keeping with the demand of present industries.

Main Types of Fuel Dispenser Pumps

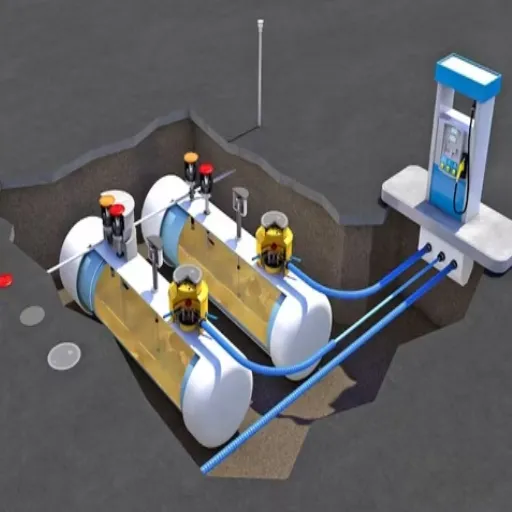

Submersible Pumps

These pumps are submerged in the storage tank and are the ones pushing the fuel to the dispenser system. They function very well in a situation where high-volume fueling is done because they are capable of maintaining the same pressure even over a long distance.

Suction Pumps

Suction pumps make a vacuum, and thus they are able to pull the fuel from the tank to the dispenser. They are more likely to be used in small fueling operations and are characterized by their simple design, which requires less maintenance than submersible pumps.

Hybrid Pumps

Hybrid systems bring together the advantages of both submersible and suction pumps, and thus, they are flexible depending on the site-specific fueling requirements. They are perfect for installations that need system integration to be versatile.

Mechanical Fuel Dispenser Pumps

Mechanical fuel dispenser pumps run entirely on mechanical components that accurately gauge and distribute the fuel. Engines, pistons, and mechanical meters are the primary elements in these pumps, and thus, the delivery of fuel is perfect without requiring any electronics. These pumps are perfect for situations where simplicity and longevity of the product are the main factors, and they are often found in less developed or remote locations where the electrical supply is not very reliable.

The working of the system is simple, as it employs a manual or motor-driven technique that pulls the fuel and passes it through a meter that has been calibrated for measuring the flow. Even though these pumps are not up to the complexity standard of electronics, they are indeed highly reliable and demand next to nothing when it comes to maintenance. It is a very notable feature that these systems will hardly be affected by power fluctuations, which makes them the best choice when it comes to off-grid operations or as backup. Moreover, these pumps have been around for a long time, and they have proven their toughness by enduring heavy use in many different industrial and commercial applications.

Electric Fuel Dispenser Pumps

Electric fuel dispenser pumps are now very technical instruments using electronics to distribute fuel with perfect accuracy, effectively, and quickly. The pumps have their digital meters, which help in making very accurate measurements and monitoring of fuel dispensed at the same time. The electronic control units that are built in make calibration, diagnostics, and interfacing with the point-of-sale systems to be done without any interruption, which in turn makes the operations in the commercial settings, such as gas stations to be smoother.

Usually, modern electric fuel pumps come with an advanced variety of components, including flow sensors, solenoid valves, and programmable software that provide wide-ranging adaptability to different fuel types and regulations. They can also be IoT-integrated, which helps in remote monitoring, inventory management, and predictive maintenance. Though always needing a power supply and a stricter maintenance schedule, the new technology brings about considerable operational efficiency and flexibility for the locations with high demands.

Centrifugal Fuel Dispenser Pumps

Centrifugal fuel dispenser pumps are based on the centrifugal force principle, wherein the impeller’s rotation provides the suitable flow and pressure for dispensing fuel. They are the most efficient system that delivers the non-pulsating, continuous flow, which is the main factor for making fuel measurement and delivery precise. Being designed for high-capacity operations, these pumps are ideal for scenarios that need instant fuel transfer, which is the case in aviation or ship fueling.

Centrifugal pumps, when talking about their merits, are durable and efficient in dealing with large amounts of liquid at low to moderate pressure. Still, they are not that efficient in the case of handling high-viscosity fuels when compared to positive displacement pumps. Maintenance is to be done regularly through inspections of seals, bearings, and impellers to keep the wear-induced inefficiencies from occurring. The combination of advanced metering systems and IoT technology leads to better control, diagnostics, and automation, which is in line with the current regulatory and operational requirements.

Centrifugal pumps, notwithstanding their pros, still need accurate adjustments to keep their precision and thus avoid fuel loss or spillage. They also need a constant pressure source and are prone to performance-affecting conditions such as air entrainment or vapor locking. Consequently, a deep knowledge of system dynamics and ongoing compliance checks is necessary to ensure optimal functionality.

Types of Fuel Used in Dispenser Pumps

Dispenser pumps are specifically designed to take in and manage different kinds of fuels according to the needed application and system setup. Below are the main fuels commonly found in the market:

| Fuel Type | Description | Primary Applications |

|---|---|---|

| Gasoline | Causing the largest carbon footprint among the automotive fuels, but still widely used and chosen mostly due to its high availability and low price | Automotive vehicles, motorcycles |

| Diesel | Its high energy density makes it the choice for trucks and other heavy-duty machines | Heavy-duty vehicles, trucks, construction equipment |

| Ethanol Blends | Two of the most popular ethanol blends are E10 and E15, which are eco-friendly combinations of hydrocarbons and ethanol with greatly reduced emissions | Flex-fuel vehicles, environmental applications |

| Kerosene | Used mainly as a fuel source in small amounts for heating systems or certain aviation applications | Heating systems, aviation |

| Biodiesel | This eco-friendly fuel made from vegetable or animal fats can be used in many diesel engines without any modifications | Diesel engines, eco-friendly transportation |

Important: For each of the fuel types, it is required that there are proper precautions and the dispenser’s materials are compatible with the respective fuel type to maintain safety and performance standards.

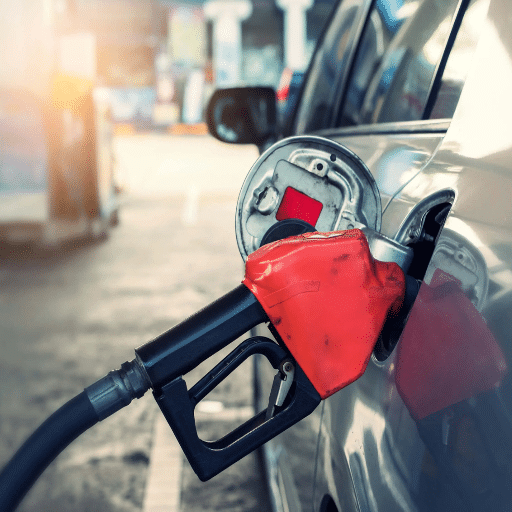

Petrol Pump: Features and Functionality

A gas station, referred to as a fuel dispenser, is an essential infrastructure component in the fuel distribution of motor vehicles. Its operation is carried out through an integrated system that is characterized by precision dispensing, heavier-than-usual durability, and compliance with safety standards. The main aspects of the pump are these:

Metering and Flow Control Systems

The latest metering system ensures that the quantity of fuel dispensed is measured with utmost accuracy, essentially relying on either positive displacement or turbine meters. Control valves of the flow manage the rate of delivery in such a way that the eventual overflow is avoided and the upholding of the vehicle’s tank capacity is ensured.

User Interface for Transactions

The current petrol pumps have at their disposal the use of digital displays and touch-sensitive screens for interaction with the customer. These interfaces not only furnish the user with information about fuel like price and quantity but also provide the means to complete the transaction. Payment options frequently consist of cash, cards, mobile wallets, and contactless methods.

Safety Mechanisms

The most significant safety features are the automatic shut-off nozzles, pressure relief valves, and anti-siphon devices. Their goal is to avert fuel overflow, vapor leakage, and possible hazards during dispensing.

Compatibility with Multiple Fuel Types

The dispensers are constructed to bear the various fuel grades, which include gasoline, diesel, ethanol blends, or even compressed natural gas (CNG). The choice of material for construction guarantees that there will be no rusting and no chemical degradation.

Automation and Monitoring Systems

A great number of pumps have IoT-enabled systems installed to allow for remote monitoring, inventory management, and prediction of maintenance needs. Automation assures that there is reliability and efficiency in places where there is high demand for fuel.

Assistive Features for Accessibility

The ADA (Americans with Disabilities Act) regulations have been complied with so as to allow disabled persons to access fuel stations, incorporating design features like nozzles that are at lower heights and assistive signaling.

Key Insight: Petrol pumps that have combined strong engineering with user-friendly technologies continue to provide a distribution of fuel that is efficient, safe, and reliable while changing along with customer needs and environmental standards.

Diesel Fuel Dispensers

Diesel fuel dispensers are made with the intent of dispensing diesel fuel in an effective and safe way, plus they also ensure the durability of the product and compliance with the very strictest of environmental and safety regulations. The nozzles used in these dispensers are high-flow, accompanied by the robust filtration systems and precise metering mechanisms, all working together to provide accurate fuel delivery, and at the same time, preventing contamination of the fuel no more. The modern diesel dispensers are all equipped with advanced vapor recovery systems, which are already being integrated into the new models, thus helping to reduce emissions during the selling process, which means that these machines are highly environmentally friendly and meet the standards set by the environmental regulators.

Moreover, these systems are digital technologies that are being used more and more often, for instance, automated payment systems, remote monitoring, and IoT connectivity, which improve the user experience and operational efficiency. The materials used for construction are diesel fuel compatible, thus making the dispensers last longer and minimizing wear and tear. By focusing on reliability and sustainability, the diesel dispensers become the indispensable infrastructure that supports the needs of industrial, agricultural, and commercial transportation.

Alternative Fuels and Their Dispensers

The use of alternative fuels, among which are compressed natural gas (CNG), liquefied natural gas (LNG), hydrogen, biofuels (like ethanol and biodiesel), and electricity, is a common trend to cut down on the dependence on fossil fuels and also to minimize the release of greenhouse gases. Every type of fuel has its specific set of dispensers that are specially designed for its properties.

CNG and LNG dispensers are capable of dealing with either high-pressure or cryogenic situations, and at the same time, they include temperature compensation and safety features that are very strong. Dispensers for hydrogen need highly accurate systems because of the fuel’s low molecular weight and high reactivity, usually using technologies like mass flow meters and communication protocols for vehicle compatibility. Conversely, dispensers for biofuels must be made from materials that can withstand the corrosive nature of biodiesel or blended ethanol fuels. Electric vehicle (EV) chargers have a different concept from liquid fuel dispensers, but they are still a vital part of the alternative energy infrastructure since they provide charging speeds from Level 1 to DC fast charging.

These specialized dispensing systems play a major role in the transition to cleaner energy sources, assuring safety, endurance, and efficiency while also being able to handle diverse fuel properties.

Fuel Dispensing Pumps Techniques

Fuel dispensing pumps use precision measuring systems and delivery methods to transfer the fuel accurately and efficiently. The flow meters measure the dispensed volume in modern pumps, which are accompanied by electronic controls for monitoring in real-time and easy operation. Safety measures incorporated, such as the automatic shutoff valves, avert overflowing and spilling during refueling. Moreover, the modern systems are capable of dealing with not only traditional fuels such as gasoline and diesel but also alternative fuels, thus guaranteeing compatibility in different applications. These methods underscore reliability, safety, and flexibility, making them indispensable for meeting different fueling needs.

Gravity Dispensing Method

The gravity dispensing method is one of the most basic and oldest techniques for transferring fuel, and it makes it happen along with the gravitational force only. That is why no pumps are required, making it a very inexpensive and simple way of transferring fuel. The main parts normally consist of a tank that is higher than the other containers; a hose for dispensing, and a valve to control the flow. Although gravity-based systems are operating with a very high reliability rate, their flow rates still depend on the liquid’s viscosity, the height difference (head), and the hose diameter. Gravity dispensing is still prevalent in small operations or regions without a power supply, but it is typically not as efficient as pumps for high-volume or long-distance fueling applications due to the limitations of the flow rate. Among the steps taken to ensure safety are the installation of shutoff valves and proper venting to avoid spills and maintain pressure equilibrium in the system.

Positive Displacement Dispensing

The positive displacement dispensing technique uses mechanical parts like pistons or gears to regulate the flow of liquids with extreme precision. The system works by trapping a specific volume of liquid and pushing it out through a discharge point, which measures the flow rates and delivery very accurately and constantly. In contrast to gravity dispensing, positive displacement works better for thick liquids and applications requiring accurate measurements, such as chemical processing or fuel metering.

Moreover, these systems continue to operate with the same accuracy and reliability even under varying pressure conditions or with different fluid characteristics, thus they are very dependable for both small and large-scale production. The main types of pumps are gear pumps, piston pumps, and diaphragm pumps, each designed for particular kinds of liquids and certain operational conditions. In addition, safety measures may consist of pressure relief valves and monitoring systems to avoid overpressure situations. To sum up, positive displacement dispensing is the best choice in terms of accuracy and adaptability in harsh environments or when dealing with liquids that require special treatment.

Flow Meter Technology in Fuel Pumps

Flow meter technology should be considered one of the main components of modern-day fuel pumps, which guarantees exact measurements and efficient fuel dispensing over time. Generally, these systems are based on either volumetric or mass flow meters. Each type of meter is specifically tailored for a particular application. For example, volumetric flow meters, which consist of turbine and positive displacement meters, determine the volume of fuel transferred; hence, they are commonly used in commercial and retail fuel dispensers. In contrast, mass flow meters, specifically Coriolis meters, are extremely accurate and capable of measuring fuel density and temperature; therefore, they are recommended for applications where the least measurement uncertainty is needed.

To an even greater extent, flow meter technologies have been developed into digital monitoring systems that are able to allow for the real-time acquisition of data and the communication with fuel management software. It is a win-win situation since it not only guarantees adherence to the regulations but also improves the effectiveness of operations. The current focus is on accuracy, with modern designs reducing the cases of fuel loss or meter creep. Besides, compliance with regulatory power standards usually determines the calibration and certification techniques to be used for flow meters, and thus inaccuracies are avoided even when the conditions are different in terms of fuel types and delivery.

Key Considerations When Choosing a Fuel Dispenser Pump

Choosing a fuel dispenser pump entails considering the following primary aspects:

- Accuracy and Reliability – The pump should be able to assure exact measurement, thus preventing fuel loss, and at the same time be in line with the industry standards for calibration.

- Compatibility – Check the pump’s appropriateness for the particular fuel types you are going to dispense, such as diesel, gasoline, or environmentally friendly fuels.

- Durability – Go for a pump that is made of premium materials, which are intended for heavy applications and different environmental conditions.

- Safety Features – Choose pumps with built-in safety features like an automatic shut-off for overflowing or leaking.

- Ease of Maintenance – Choose a model that makes servicing and routine maintenance easy to reduce downtime.

- Integration with Software – Opt for a pump that allows connection with fuel management systems for enhanced tracking and supervision of operations.

Note: Considering these factors, you will be able to obtain a fuel dispenser pump that will very efficiently and effectively meet your operational needs.

Efficiency and Performance Factors

It is important to have a grasp ofIt is important to have a grasp of the efficiency and performance factors when one is picking a fuel dispenser pump, as this will guarantee the effectiveness of the operation. The dams that are dubbed as top-performance should undoubtedly carry the best flow rate capabilities, which would mean that there is no difference in the accuracy and precision of the pump while it is performing or not. Also, the energy consumption would be low, and at the same time, the output would be high thanks to the hydraulic technology that has been optimized. Moreover, an accurate metering system would not only take care of the losses that are due to inaccuracies but would also add to the overall efficiency of the operations.

The ability of the dispenser pump to handle heavy loads is another major point to think about. Among other things, producing pumps from corrosion-proof materials and using strong parts will give the longevity of performance and less need for repairs. Also, the technology used alongside the pump, e.g., temperature compensation and vapor recovery systems, must be up to par, as those are the ones that will keep it efficient despite the variations in environmental and operational conditions.

Modern fuel dispenser pumps must have the capability to connect digitally with monitoring systems so as to improve the analytics in real-time, as well as to avoid any downtime. Automation technologies, such as self-diagnostics, are not only going to be a part of the future, but their contribution to performance will be in terms of identifying and mitigating inefficiencies, thus making the operation continuous and reliable.

Safety Standards and Regulations

I think that the adherence to safety standards and regulations is non-negotiable in maintaining compliance and operational integrity. I acknowledge that compliance with the specific guidelines, like those of the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA), is of great significance. Through the application of these standards, I can reduce risks, guarantee the safety of workers, and also protect the environment. Besides that, I am supported by the regular audits and the continuous training of the staff, as well as the application of the latest technology in my efforts to keep a strong safety framework and also be up to date with the changes in regulations.

Cost Factors and Maintenance Needs

The maintenance of equipment and systems brings in a lot of cost factors that depend on some main factors, such as the initial procurement cost, utilization, operational environment, maintenance requirements over the lifespan of the equipment, etc. Quality usually is the reason behind higher costs, but that goes to the degree of lower frequency of repairs and longer lifetimes. By contrast, the usage of the equipment in a bad environment or under continuous operation brings about high wear and tear, and thus, more frequent servicing is required, leading to an increase in total cost of ownership (TCO).

The long-term requirements for maintenance have usually been classified into three categories: preventive, predictive, and corrective maintenance. Preventive maintenance consists of regular inspections and servicing schedules aimed at preempting potential failures and ensuring compliance with industry regulations. Predictive maintenance utilizes condition-monitoring technologies that allow anticipating failures, thus reducing downtime and optimizing the system’s efficiency. Corrective maintenance, although unavoidable in some cases, is the most expensive as it usually consists of unplanned repairs or replacements of the equipment.

The strategic planning is very important as it allows us to keep a good look at the different cost factors and to set the best maintenance schedule, which will guarantee that the systems are reliable and up to operating standards without spending extra money.

Reference Sources

Automatic Vehicle Fueling System Using PLC-Controlled Robotic Arm

Consumer Protection Related to Dispensing Pump Manipulation in Gas Stations

Frequently Asked Questions (FAQs)

What are the different types of fuel pumps that are used in fuel dispensers?

Fuel dispensers pump out fuel through different pumps, such as centrifugal, diaphragm, and gear pumps. Every kind of pump not only has its distinct role but also contributes to the smooth flow and good quality of the fuel through different applications, ranging from huge commercial fuel pumps down to those in private homes.

How do fuel dispenser pumps work in drawing fuel from underground storage tanks?

The fuel dispenser pumps fully draw and mix the ice-cold fuel from the underground tanks using one of the most sophisticated pumping systems. This hydraulic system allows the pump to lift a steady flow of fuel in liters per minute from the tank to the nozzle, which is used for dispensing.

What are the major safety risks that come with fuel dispensing?

Dispensing of fuel does come with certain safety risks, which include the possibility of fire and spills. One cannot overstate how important it is to keep the pump system regularly maintained in order to reduce the risks associated with it. Maintenance should include checking the fuel filter and electronic components, among others.

In what manner do fuel pumps affect fuel efficiency in cars?

Fuel pumps are very important with respect to fuel efficiency because they make sure that only the exact amount of fuel that is needed gets to the engine. A functioning pump system indeed does the motoring of fuel to internal combustion engines, thereby improving their performance and decreasing the amount of fuel consumed.

What is the lubrication’s part in fuel dispenser pumps?

Lubrication is something very crucial for the mechanical section of the fuel dispenser pumps. If lubricated properly, the friction at the various moving parts is minimized, thus smooth operation is achieved and the pump’s lifespan is prolonged. This is highly important for both industrial use and commercial applications.

How do gasoline pumps compare with other fuel dispensers?

Gasoline pumps are dedicated solely to the dispensing of gasoline, whereas other kinds of fuel dispensers might be able to process diesel or other alternative fuels. The construction and features of gasoline pumps have been tailored to meet the specifications set by the chemistry of gasoline, thus offering safe and effective dispensing of fuels.

Is it possible for a single fuel dispenser pump to be used with several dispensers but still work perfectly?

A single fuel dispenser pump could indeed be organized to cater to more than one dispenser. Such a configuration is usually found at commercial fuel stations, wherein a single pumping unit can now deliver the fuel efficiently to several dispensing points, thus optimizing the operational efficiency.

What is the nature of ATEX requirements for pumps used in fuel dispensers?

The ATEX requirements stipulate safety regulations that apply to the equipment used in areas where there is a risk of explosions. As far as pumps used in dispensers are concerned, they need to be ATEX-certified so as to ensure their safe use in places where the presence of flammable vapor is likely, such as underground storage tank areas.