Until just recently, fuel management for commercial fleets had been truly a quandary — something only possible with innovative solutions to increase efficiencies and minimize idle time. To address this problem has been introduced a mobile fuel-dispensing truck has been introduced, a revolution that brings forth a dynamic, scalable, and operational alternative to the very-long-lived model. The present article discusses the many ways in which the invention is changing the refueling practices within the military, automotive fleets as a whole. Its implications for the fuel industry include flexibility, less operational downtime, and cost-efficient methods over the establishment of a more accurate control system. Understand our young concept, based wholly upon the perfect strand of this ground and the happenings that now, more than ever, make roadside refueling indispensable to contemporary fleet operations.

Introduction to Mobile Fuel Dispensers

The mobile fuel dissipates are highly sophisticated systems that are the next step up in filling technology due to their ability to fuel an array of vehicles or equipment onsite, minimizing the need to visit gas stations. These effects are not just great for operational effectiveness due to little or no downtime, but also an effective, convenient, and reliable refueling solution for the fleet, construction machines, including all fuel-consuming operations. Designed to provide accuracy and lawful continuity with state tracking rules, the mobile fuel dissipaters are tied to invent, or use-the-length automated fuel management systems. They revolutionize the industry’s activity in the management of fuel logistics. Mobility provides a modern-day solution to a primitive refueling setup.

What is a Mobile Fuel Dispenser?

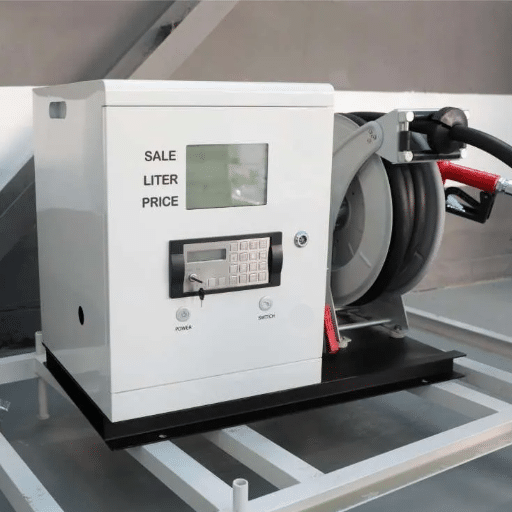

Mobile fuel dispensers boast being small and portable and are designed for high-yield and efficient refueling of vehicles, machinery, and equipment at various locations. These units come as assemblies of parts, such as a fuel storage compartment, pump, meter, and nozzle for distributing fuel, all of them mounted onto a mobile platform such as a truck or a trailer. The wheel-out aspect of the mobile fuel dispensing unit would mean the van would bring its dispensing services to the doorstep. It will save vehicles and machines the trip to the fuel station. Found mostly in the realms of construction, agriculture, logistics, and mining, mobile fuel dispensers help enhance operational efficiency by reducing downtime and providing accurate fuel measurement through advanced metering systems, and doing so within safety and environmental limits. Besides such notable attributes, their quality, accuracy, and reliability are also central to managing fuel needs in highly fuel-consuming industry sectors.

Importance of Fuel Dispensers in the Industry

Fuel dispensers are very instrumental in allowing the smooth operation and progress of those industries that require large fuel volumes. They foster efficiency by being able to give precise and quick fuel delivery to equipment and vehicles, thereby keeping repair and process delays at bay. The modern fuel dispensers are fantastic with metering devices and control systems that not only add the accuracy of fueling but also the accountability, thereby helping avoid wastage on fuel cost-effective manner. Safety of the environment has been taken very seriously by embracing the concept of technology to intervene for safety design reasons and thus giving heavier on consideration for reducing threats.

This then enhances safety in the strict adherence to prevalent safety regulations that there is no opportunity for spillages or vapors to escape. Fuel dispensers are the crux of these industries, such as aviation, agriculture, mining, and construction; without them, resource allocation cannot be worked out. Indispensable while ensuring transcending productive moods are transcended, which results from the necessary fuel to sustain industries without interruptions.

Overview of Truck Fueling Solutions

One of the primary purposes of truck fueling solutions in this modern era is to address the multifaceted requirements of industries relying on fleet operations. The high point of such fueling systems is the ability to cater to the highest-demanding fuel-dispensing systems with high capacity, the most sophisticated maintenance technology for remote monitoring, and expansion unit design, facilitating a maintainable-designed scaling. Fast-flow fuel and metered pumps cut back on non-productive times by boosting pumping time, and integrated fuel management ensures extra fuel-management support like accurate fuel use data, tracking, and unauthorized leaks to always hold operations under close watch and accountability. High-level filtration is also essential to maintaining fuel quality, preventing contaminants from entering the engines of these vehicles, and also prolonging the service life of equipment tires.

In a giant leap forward of environmental compliance, the newest answers for truck fueling also include integrating vapor-recovery units and SpillSafe containing systems integrated together to alleviate impacts on the environment. Mobile fuel tanks will provide an excellent degree of versatility regarding specific requirements of the site, from fueling isolated islands to municipal split-depot fueling locations. Many of these systems have embedded IoT capabilities for remote diagnostics, asset tracking, and automated refill schedules – a move intended to boost power operations while reducing human-related errors to the minimum. Integrated technologies make the truck fueling solutions a crucial toolkit for fleet management, aiming at cost-efficiency with sustainability at heart.

Components of a Mobile Fuel Dispenser

Storage TankA container of fuel that holds any fuel stored securely; its capacity varies according to requirements.

PumpUsed to move fuel from the storage tank to the nozzle by maintaining flow and pressure.

Fuel Dispensing NozzleHandheld device used to dispense fuel directly into the vehicle or machine, equipped with an automatic shutoff mechanism for precision and safety.

FlowmeterIt precisely measures the fuel dispensed to ensure accurate records of transactions.

Hoses and FittingsConnect different components that enable a safe, spill-free transfer of fuel.

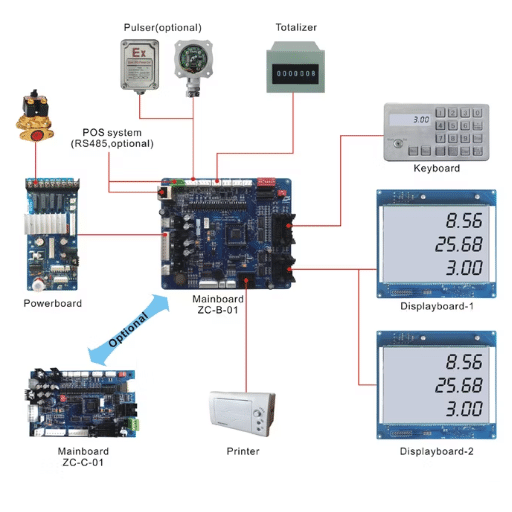

Control PanelProvides the user interface for controlling the operation of the dispenser systems, very frequently including digital displays that stream real-time information about quantity and price.

Filtration SystemRemoves any impurities from the fuel to keep up the level of fuel quality and protect engines or equipment from any damage.

These systems together can make sure all mobile fuel-dispensing operations are smooth, dependable, and fully functional.

The Dispenser Pump and Its Functionality

The dispenser pump is an essential equipment that plays a great role in mobile fuel dispensing operations to effectively and accurately transfer fuel. The efficient and crucial role played by motor power to draw fuel from the fuel storage tank, as it is subsequently delivered from the nozzle to the receiving procedure or machinery, is the prime function of the pump. Modern dispenser pumps have been designed with sophisticated flow meters to calculate the exact amount of fuel passed out, ensuring 1) accuracy and compliance with laid-down measurability in compliance with industry standards. Plus, the pump, through the use of a pressure regulator and nozzle with an auto shut-off facility, assures no overflow for the sake of safety. The same pump uses efficient filtration systems so as to remove any other contaminant that could compromise the integrity of the fuel’s existence in it. The blend of precision, safety, and efficiency describes the basic insignificance of dispenser pumps in fuel management systems.

Understanding Hoses and Reels

Flexible systems in the handling of fluids come from hoses and reels, too. Hoses are soft lines for fluid transfer and processes, and their design focuses on selecting the perfect material with fluids, pressure, and environmental conditions in focus. The range of materials utilized includes rubber, polyurethane, and thermocomposites that grant anything from durability to flexibility and resistance to abrasion or chemical exposure.

Reel and hose management serve to store hoses so that they remain in good condition. Different designs of reels, including a manual design, spring-driven, or motor-driven designs, serve different purposes regarding the correct handling of hoses. Reel needs differ depending on the specific operational part in question in terms of hose length, hose diameter in relation to possible position, and operating environment. Quality reels prevent hose damage from wear and kinking, and thereby increase prolonging the useful lives of hosing and enhancing overall system performance.

Integrated hoses and reels enhance workplace safety by preventing trip hazards and offering efficient fluid delivery and retrieval. Selection, installation, and maintenance become crucial in making systems more reliable, minimizing downtime, and assuring optimal performance in industries of varying types.

Features of Mini Fuel Dispensers

Mini fuel dispensers are the most sought-after compact, portable fueling solutions intended for frugality and user-friendliness in multiple sectors, ranging from fleet management to agriculture. The following are some features of mini fuel dispensers:

Compact and Portable Design

Strategic spacing and mobility characterize mini-fuel dispensing, allowing them to occupy small spaces or be carted off from one job to the next as necessary.

Metering Accuracy

An integrated flow meter and accurate calibration ensure accurate discharge of diesel and minimize discrepancies that could otherwise result in unanticipated expenses for the fuel.

Inbuilt Pumping Unit

Specified dispensers come with pumps designed to deliver a uniform flow, favoring efficient dieseling under heavy-duty or severe-conditions circumstances.

Hard-Wearing Banquets

Incised from stainless steel or high-grade plastics, mini fuel dispensers are built to last in a corrosion-endured environment.

Multi-Fuel Supportive

A variety of types of mini fuel dispensers support various kinds of fuels, including regular diesel, unleaded gasoline, and biodiesel, to cater to diverse operational needs with all necessary features.

Display objectives in a digital way

A display object in the form of either an EEPROM+-101.de-gne.It is an LCD or LED can make available just the stats of fuel, thereby changing the way fuel is consumed with the help of more critical information and tools.

Security System

The not-so-modern development is the insertion of anti-theft measures such as locked nozzles, access control, and housing to ensure safety and prevent fuel abuse.

Back Office Integration

Few machines have been designed in such a way that they can connect to any fleet or any kind of fuel management software, which would prove the easiest mode of providing real-time monitoring, overview, and data analysis for effective and responsible fuel accounting.

Therefore, this entitles mini fuel dispensers to be an absolute provider when the issue is effective, reliable, and secure at a fuel management system in a satisfactory little, hands-off design for small to medium-sized users.

Types of Mobile Fuel Dispensers

Manual mobile fuel dispenser

The easy-to-use dispensing machines, ideal for the simplest of bulk fueling needs, are used to service users where electric power is not an option.

Electric mobile fuel dispenser

When mains power will suffice, these systems make the perfect solution for medium to large operations, offering faster throughput and a high degree of efficiency.

Battery-operated mobile fuel dispenser

Being able to operate on batteries that are chargeable, these two pumpers are easy to carry for filling in fleet in remote areas. It also furnishes situations where electricity does not reach.

Integrated system type mobile fuel dispenser

This type of dispenser generally includes various forward-looking technologies with digital meters and connections to other fleet data. This kind of solution provides the benefit of better control over the fuel usage and tracking performance in real-time.

No matter how they operate, each kind functions the same to fix a specific kind of fueling job while also granting diversity and adaptability.

Mobile Mini Fuel Dispenser Options

Mobile mini fuel dispensers are designed in various product lines to fit the user’s requirements. Some of the various options emerging in the industry include:

Standard mini fuel dispensers

This concludes a compact pump arrangement for minor fuel transfer modes. It contains a flow and control computer along with the hose assembly. The very well-demanded mini dispensers are the most user-friendly fueling equipment that is ideal for starters.

High-throughput mini fuel dispensers

For fuel transfers made through heavy construction machinery and areas where the flow rate is enhanced, high-throughput lines come with a better pump arrangement and measuring system that will reduce downtime and put fuel into all types of mechanized engines faster.

Mini flow meter dispensers are readily customizable

Mini tankers can be customized as per the user’s requirements to match their unique workflow requirements. The key features might include, but not be confined to, an incorporated filtration mechanism, digital calibration for accurate readings, and connectivity to enhance control and supervision of tanks and fuel transfer operations.

This is the option to guarantee operational flexibility and customization to fulfill any industry demand to the point of possessing a multitude of dispensing features that transport fuel to construction, agriculture, or fleet management purposes.

Comparison Between Tanker Trucks and Mini Fuel Dispensers

| Feature | Tanker Trucks | Mini Fuel Dispensers |

|---|---|---|

| Capacity | 1,000 to tens of thousands of gallons | 200 to 5,000 liters |

| Primary Use | Bulk fuel transport over long distances | On-site fuel management |

| Portability | Limited – requires infrastructure | High – plug-and-play utility |

| Setup Requirements | Loading terminals and staff needed | Minimal setup required |

| Best For | Large-scale distribution | Localized operations with flexibility needs |

| Control Systems | Sophisticated discharge mechanisms | Advanced control with real-time monitoring |

| Applications | Supplying stations and industries | Construction sites, farms, fleet refueling |

Comparing moving tankers with mini fuel dispensers deals with gross disparities of capacity, portability, and the applications they serve. These vehicles are tailored for transporting bulk fuel over long distances, with minimum capacities starting at 1,000 or 2,000 gallons and going as high as tens of thousands of gallons. In terms of reliability, this is equivalent to a guarantee of supplying stations or industries coupled with spacious storage and a sophisticated discharge mechanism.

On the contrary, it is known that mini fuel dispensers are small systems designed to manage small fuel recipes on the spot. You will find, thus, that such dispensers are characterized by volumes between 200 and 5,000 liters, whereas they are equipped with state-of-the-art control systems allowing amazing accuracy in dose measurement and dispensing. They further rock in situations where flexibility-and thus agility and access-is the name of the game, like at construction sites, farms, or refueling campers.

From an operational standpoint, a tanker truck requires infrastructure. The preconditions are loading terminals and staff, while the mini fuel dispensers can simply be seen as plug-and-play utilities that require no significant setup at all. This notwithstanding, the tanker trucks are advantageous in terms of economy and scale due to the vast logistics they can afford. Mini fuel dispensers provide end-users semi-autonomy and could be integrated with some features, for example, real-time monitoring, electronic displays, and filtration systems to further their market.

The simple choice between the two remains, however, every potential buyer must choose the tanker truck for large-distribution oriented support, while mini fuel dispensers are ideally suited to the smaller solar fuel operations.

Advantages of Using a Mini Fuel Dispenser

Mini refueling dispensers have made it an easy, practical answer to the localized management of fuel. Majorly, it is their compact design that allows them to operate everywhere by instantly permitting their placement in small spaces and the need to move about. They are created for accurately fitting the fuel in the tank and, thus, reducing wastage and ensuring cost control. New-generation features such as digital meters assure the right quantity, inbuilt filters guarantee the purity of fuel, and very user-friendly displays are nothing short of ease of handling.

Furthermore, these mini dispensers fit almost any application as they come in an assortment of small outflow rates for agricultural, industrial, and construction jobs. Additionally, greater control is set over fuel management as many of these implementations are based on real-time monitoring and fuel-usage-tracking functions. Beyond reduced fuel spoilage, therefore, comes improvement in keeping track of the fuel inventory.

Anyone who’s looking for an optimized solution for businesses and individuals in the market demand area for fuel-dispensing times can basically rely upon mini fuel dispensers for precision, portability, and operational efficiency.

How Mobile Fuel Dispensers Work

The fuel dispenser needed to comply with the primary motor vehicle fuel pump was established within a system, making it possible to deliver the product thoroughly and accurately. The fuel pump churns the products from the storage tank to the further branch from which the nozzle is working. Starting the process, the dispenser comes into play as the operator triggers fuel flow or petrol at grab off, and then the dispenser, powered by a motor or an external power supply, kicks into action, dispensing it in measured volumes. More advanced versions are now highly accurate in respect of the extent to which they can measure the quantity being dispensed.

Ιntegrated control systems on mobile fuel dispensers go a long way in assisting an operator in real-time fuel flow monitoring and adjustment of outlet delivery. Various safety mechanisms, such as pressure regulators and automatic shut-off valves, are included to prevent any kind of overflow or spill during operation. Moreover, pretty much all mobile fuel dispensers now come with digital displays that give definite readings of fuel dispensed and prices calculated, as well as other pertinent data, thereby making data collection efficiency a priority while promoting transparency and accountability. All these aspects combined serve to make mobile fuel dispensers the instrument par excellence in the controlled and equitable distribution of fuel across a variety of sectors.

Operational Mechanics of Dispenser Pumps

The combination of accurate mechanical and electronic functionalities in a fuel or fluid-conveying process ensures the elaboration of an accurate and valid double approach, like this dispense, occupying all requirements and criteria of (in the process of waste and balancing affected) trade. It is a mutual relationship between the dispensing nozzle and the liquid storage tank connected by a motor-controlled pump. Liquid is captured from the intake arm and dispatched on passing through a set of filters that filter out any debris or contaminants from the flowing liquid. Work still to be set up to measure accurately the amount of fluid pouring out, so when this gets read, developed for the control panel from an overflow of data-hauling techs for enforcement everywhere, for much centrality to throw (lots of ess-1 in step two of segregation) to one code-printing application.

The best pumps use solenoid valves controlling the flow of liquid at a very fast rate that switch off instantly, hardly allowing any wastage or spillage. The electronic control unit interfaces with the hardware components to realize pricing calculation and transaction recording in an automated manner. Moreover, some models feature software for remote monitoring, diagnostics, and integration with inventories for assured operation and real-time supervision. All are favorable scenarios for challenging industries with applications of the most operational dispensation regarding accuracy and efficiency under all scenarios.

Preset Functions and Efficiency

The preset functions that are built into dispensing systems help increase operational efficiency by automating routine procedures that eliminate low-level human participation. This permits system users to preset dispensing volumes, flow rates, or time-deliverying patterns for the mixing; this ensures accuracy and repeatability. Through reducing human error and standardizing dispensed quantities, the preset functions promise gains in reliability and lower operation costs.

Additional efficiencies come with functions like real-time monitoring and adjustable settings that allow quick reactions to changes in requirements. More advanced equipment integrates with digital screens and Internet of Things (IoT) platforms for more efficient inventory management, predictive maintenance, and operational analytics. This set of advancements, therefore, intimately links performance enhancements on the one hand with downtime potential reduction while at the same time offering scalable solutions together for industrial and commercial, or beyond, applications.

Integration with Electronic Gas Management (EGM) Systems

The integration of modern dispensing systems with Electronic Gas Management (EGM) provides precise control and improved process efficiency in a variety of applications. The EGM systems, thanks to their continuous monitoring capabilities and on-the-fly regulation of gas flow, pressure, and consumption, ensure compliance with safety regulations and reduce the risk associated with human manual errors. Taking advantage of advanced Internet of Things (IoT) technology, the EGM systems further provide real-time monitoring and remote management, effectively standardizing workflows and allowing for predictive maintenance. The compatibility of dispensing systems with EGM frameworks greatly elevates the scalability factor for any industrial installations by providing flexibility in controlling the flow of gases, optimizing use, and reducing wastage. This is especially critical when you make mention of end use or use of precision, such as manufacturing, medical fields, and research laboratories as a whole.

Applications of Mobile Fuel Dispensers

In numerous industries, portable fuel dispensers are truly useful for remote refueling where continued running of heavy equipment and vehicles is essential. Common applications consist of construction sites, mining operations, and agricultural sites. Beyond this, mobile dispensers are helpful for fleet operators looking to centralize fueling activities. And they appeal to their portable nature and utmost dependability, first responders know where to best deploy them to the scene of emergencies in distant or disaster-stricken settings. Working under extreme conditions or rendering fuel services on off-grid sites, its portability has a tangible value in specific industries.

Mobile Fueling Solutions for Industries

Benefits of mobile fueling solutions

Mobile fueling has a variety of advantages perfectly tailored to the needs of industries that rely on uninterrupted fuel access. Mobilize fuel directly to job sites or vehicles to eliminate downtime associated with traditional refueling methods, which will increase operational efficiency and productivity. This also reduces the need for on-site fuel storage, eliminating risks and costs in regard to the upkeep of huge storage tanks. Commonly managed safety and security standards during mobile fueling, thus conforming to regulatory requirements, illustrate that environmental liabilities are also significantly reduced due to leaks. In other words, there will be total transparency and control over fuel consumption and usage through real-time monitoring and reporting, thus saving the industry in terms of cost.

Field Applications Across Major Sectors

The significant benefits of the mobile fueling service are often found in industries such as construction, where heavy equipment requires constant fueling to avoid operational delays. Similarly, in mining operations, it is not uncommon to relocate all refueling sites to remote sites, giving these locations an arduous degree of provision for fueling purposes. Agriculture also takes advantage of keeping its machines fuelled during crucial planting or harvesting periods when limiting downtime is a priority. On the other hand, logistics’ mobile fueling is suitable for making the fueling process easy and efficient, thanks to the approach of bringing the fuel straight to the truck while it’s stationed, as it saves time and maximizes the vehicles’ time on the road. Meanwhile, some first-response teams base their entire emergency response capabilities on mobile fueling, usually in disaster zones or areas without refueling infrastructure in place.

Environmental and Logistics

Latest mobile refueling services would hardly forgo environment-friendly technology, including sophisticated spill prevention systems and strictly enforced regulatory standards. Very efficient logistics further sorts out inadequacies with delivery routes and fuel loads looked over by GPS and other tracking systems, enhancing the technology. Besides environmental compliance enhancement to the maximum extent, these technologies are proposed to reduce fuel wastage and carbon footprints.

Industries integrate mobile fueling for many economic and environmental benefits. It has proved to be a viable and beneficial solution, especially where urgent demands and applications are concerned.

Benefits for Truck Fleets

I honestly believe that mobile refueling stands with unparalleled efficiency and cost management in favor of truck fleets. No longer do drivers need to drive off course to refuel their trucks. This helps reduce downtime while adding actual working operational productivity gains as fuel consumption is closely managed, meaning correct reporting and hence minimization of wasteful consumption. Money is saved by this efficiency, and sustainability objectives are achieved while decreasing emissions absolutely through optimized practices for fuel delivery.

Utilization in Remote Locations

The use of high-performance fuel transportation solutions in remote locations addresses the most important challenges of insufficient infrastructure, transport logjams, and difficult access. High-performance transport solutions guarantee an uninterrupted fuel supply through upgraded planned routes with on-site refuelling options that, in turn, lower dependency on the conventional local filling stations. Technologies such as telematics and monitoring their real-time satellite positioning enable very precise tracking of where fuel was delivered or its consumption. This makes a critical contribution to responding to inefficiencies even in the most isolated regions. Moreover, the operating risks associated with supply chain interruptions are significantly reduced, thereby ensuring the operability of companies by way of an enhancement of their dependability and cost efficiency in far-flung places.

Key Takeaways

- Mobile fuel dispensers represent a revolutionary approach to fleet fuel management, bringing refueling services directly to vehicles and equipment

- These systems combine portability, accuracy, and advanced technology to minimize downtime and enhance operational efficiency

- Various types of mobile fuel dispensers cater to different operational needs, from manual systems for basic applications to integrated systems with IoT capabilities

- Mini fuel dispensers offer compact, cost-effective solutions ideal for small to medium-sized operations

- Modern mobile fueling solutions incorporate environmental safeguards, real-time monitoring, and advanced safety features

- Applications span multiple industries including construction, agriculture, mining, logistics, and emergency response

- The technology delivers significant benefits in terms of cost savings, productivity improvements, and environmental compliance

Conclusion

Mobile fuel dispensers have transformed the landscape of fuel management across multiple industries, offering innovative solutions that address the critical challenges of efficiency, cost control, and operational flexibility. From compact mini dispensers to sophisticated integrated systems, these technologies provide businesses with the tools needed to optimize their fuel logistics while maintaining strict safety and environmental standards. As industries continue to evolve and demand more agile refueling solutions, mobile fuel dispensers stand at the forefront of this transformation, delivering measurable benefits in productivity, cost savings, and sustainability. Whether serving remote mining operations, busy construction sites, or sprawling agricultural operations, mobile fuel dispensing technology has proven itself as an indispensable component of modern fleet management and industrial operations.

Reference Sources

Automatic Vehicle Fueling System using PLC Controlled Robotic Arm-A Simulation Design

Design and operation of the hydrogen supply chain for fuel-cell vehicles in Expo Shanghai 2010

Frequently Asked Questions (FAQs)

Can a mobile fuel dispenser dispense fuel to various vehicles at the same time?

Yes, a portable fuel dispenser is designed especially to transfer fuel to different vehicle types such as trucks, vans, and machinery. In addition, its capacity to support a variety of fuel types and nozzle configurations makes it capable of catering to different kinds of fleet sizes, thus making it a redundant logic for most industries needing flexible fueling.

What is the average life span of a portable fuel dispenser?

The mobile fuel dispenser’s lifespan could well be dictated by its quality and maintenance. Hence, a good quality one should last long if well-maintained. Inspection and servicing of the mobile fuel dispenser can easily be done to ensure its flawless operation, since minor defaults of wear and tear could be detected from time to time for an immediate response.

Are there mini dispensers for smaller operations?

Yes, a few different options would deliver pleasant service. Those working in the same way, in the sector in which they are applicable, are mini fuel dispensers. Small-profile mobile fuel dispensers have been configured to fuel competently yet occupy a very small amount of space. Very typically, they come with a smaller fuel tank and have one nozzle, making them useful for businesses with little need for fuel.

What are the security features to consider in a mobile fuel dispenser?

Most importantly, make sure to consider certain safety features, such as an automatic shutoff valve, overfill protection, and a spill containment system. Besides, it is certainly a good idea to have emergency shutoff switches along with visible warning labels, which guarantee a reasonable degree of safety and awareness, especially in the environment of construction sites or under fuel deliveries to emergency services.

How can I integrate fuel management seamlessly into my daily situation using a mobile fuel dispenser?

Streamlining fuel management with the help of mobile fuel dispensers may require dispensers equipped with advanced features, such as fuel tracking, automatic reporting, and interfacing with inventory management systems. Some fuel dispensers (such as VFD-equipped) may come with built-in hardcopy printers for record-keeping, while others may be integrated with electronic solutions for real-time monitoring or reporting of fuel levels in burn-[notification_numeric] mode.