The important decision that stands in the way of the successful operation of a service station is the selection of gas dispensers or fuel pumps. These items are mainly the backbone of the daily process of fueling, yet they also play an important role in ensuring accuracy, security, and customer satisfaction. This blog will deliver a detailed discussion on gas dispensers and pumps for sale, discussing the more working aspects of these products while telling the ancillary technological structures that separately boost utility for service stations. Being it is an overhaul for your current equipment or installation in a fresh station, composing the crucial considerations detailed in this guide will surely make you confident in your choice for purchase in order to optimize performance along with profit.

Overview of Gas Dispensers

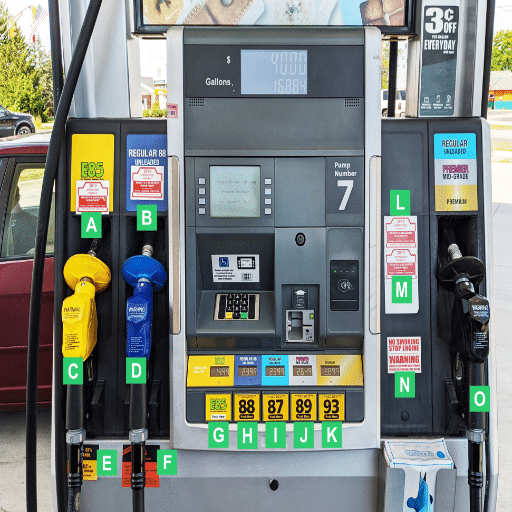

A pump is a device designed for transferring fuel from dispensers into automobiles safely and economically. It generally includes the metering system, nozzles, and hoses for precise delivery of fuel. New-generation dispensers boast futuristic articulations such as a digital display, contactless payment system, and fuel-management console to increase the ease and efficiency at service facilities. The choice of a proper model is influenced by the kind of fuel used, the size of the station, and the scope of customer demand–thus requiring reliability and durability for better performance over a longer period.

Types of Fuel Dispensers

The fuel convenience store attendant classifies them either as submarine-pump systems for use inside a fuel storage tank or as topping systems for use outside the storage. Submarine pumps enjoy fast fuel speeds as they allow the incorporation of the fastest fuel flows across gas stations that experience heightened traffic. Furthermore, vapor locks take place at a decreased frequency with submarine pumps. They provide unique capabilities for large-scale operative bursts, particularly in setting up several dispensers into an interconnected single system.

In dispensers that use suction pumps, a pump, as its name implies, is located inside the dispenser to pull the fuel out of the storage tank. Such systems are typically deployed at small or low-volume stations due to a simplified design and lower maintenance requirements. That said, the suction systems are cost-effective for infrequent operation but are rather slower in fuel delivery as compared to those fitted with submersible turbines.

Advanced models of dispensers, in addition to offering designated fuel types for gasoline, diesel, and alternative fuels such as ethanol and CNG, have been made to support advanced technology such as multi-product dispensing systems, vapor recovery systems, and point-of-sale solutions to cater to the needs of modern service stations.

Importance of Quality and Service in Fueling Solutions

Quality fueling solutions are more significant in the effective and safe operation of fuel dispensing systems because superior components-robust pumps, metering systems with precision, and safe nozzles-require very little maintenance and allow performance optimization. The use of substandard equipment poses a risk of fuel contamination, inaccurate metering, and potential safety risks, thereby bringing about clashes in all operations, thus incurring higher costs.

Equally important to the fueling sector is service provision, which encompasses maintenance, service, and support. With this service, regular checks and timely operations will diminish downtime impacts and ensure that all environmental standards are upheld, like emissions and incompatible vapor recovery requirements. Service programs in full do nothing but help prolong the life of the equipment and improve operational effectiveness.

Again, a premium service will foster new and invigorated customer experience, which is only furthered by easy-to-use interfaces and the integration of the payment systems. By the same token, excellence and service are the result of several different things through which various solutions actually increase their functional habits and service levels from self-preservation to customer satisfaction to business sustainability.

Industry-Leading Brands in Gas Pumps

Some companies have set a benchmark with consistency in their innovative, reliable, and brilliant performance in gas pump technology, which are surveyed to be the top of industry-leading brands. The industry majors that come to mind include:

1. Gilbarco Veeder-Root

The world-renowned company for fuel dispensing technologies and integrated payment methods is Gilbarco Veeder-Root. Street Encore and FlexPay are expected to deliver maximum precision, durability, and the most updated gas pump technologies ever seen, having all the feathers of perfection in fuel management. Gilbarco can also focus on information management, giving a glance at operational insights.

2. Wayne Fueling Systems

Seems Wayne Fueling Systems marks a distinctive identity with concern for sustainability and technological advancement. Wayne Helix’s setup is identified by modular engineering, user-friendly design, and impressive environmental conservation measures. In distant regions, Wayne provides remote monitoring and operational control via cloud-based communications systems essential in the present-day petroleum retail marketplace.

3. Tatsuno Corporation

Tatsuno Corporation truly belongs to the greatest future in the field of petroleum technology. The company is famous for its precision in the design of its production machinery, and its quality control system offers a huge range of choice for fuel pumps, ranging from various fuel options. So far, their constant quest for sustainable and ecological design has earned them a worldwide reputation as the choice of firm.

The three companies above have been consistent frontrunners in offering trustworthy and innovative solutions, and they have become vanguards as well as the most preferred choice for fuel retailers who look for performance as well as sustainability.

Popular Models of Fuel Dispensers

Wayne Helix Series

Bearing resilience and user-friendliness as their main themes, the Helix series focuses further on simple operation and highly complicated security settings ideal for very busy high-traffic locations and smaller ones.

Gilbarco Veeder-Root Encore 700 Series

Focusing on high energy-saving ability and a user-friendly intrinsic design, the Encore 700 Series has nuanced fuelling for meeting different customers’ needs.

Tatsuno Sunny G-Series

The Sunny G-Series is closely tailored to perform well and be fully adaptable to alternative fuels, thus ensuring long-term compatibility and easy maintenance.

These models contribute to displaying the systematic progress in fuel vending, ensuring reliability, efficiency, and versatility in the modern-day fueling environment.

Gilbarco Encore 700 Overview

The Gilbarco Encore 700 series is a paragon of dispenser technology, meant to optimize both operational efficiency and user experience. The modular design of the passel of items allows the flexibility of growth or shrinkage, depending on market need. The product family demonstrates the ability to work with alternative fuels such as E15, B20, and compressed natural gas that support transitioning to sustainable energy. The Encore 700 provides ease of operation and heightened security, with a user-friendly interface combined with an encryption feature. Capable of remote management, real-time diagnostics ensure that high-stress environments are empowered with very low downtime and maintenance costs, giving the best return on investment. The dispenser range is cited for compliance with the current laws, and the ready configuration conforms to pressures for future changes, thereby saving money as part of a pioneering investment in fuel businesses.

Comparison of Dual and Single Dispenser Models

Two-herded dispensers are structured to underpin the dispensing of product from more than one nozzle at a time, thereby easily meeting the fueling demands of throughput in high-volume operations. A model of two sides has two of each, rendering operators able to assist in filling two vehicles at once. Such an arrangement is acceptable at ideal sites like busy fuel stations or commercial ones in need of high turnover rates, and until the station is up and running, the time is money for the company. However, the two-nozzle system generally comes at a higher price and at an additional cost, with more maintenance needs.

Models with one head per side are easier to manufacture and have less cost than those with two heads. This in itself should be good enough to want one system for those not needing intense mobilization. Slower in operation than this legend would have it, the model with two sides allows customers to switch at will to a single head system for prior-to-business head thereafter.

Business requirements, together with customer requirements and available budget, decide whether the operator shall use dual or single dispenser(s). In high volumes, the double dispenser is highly effective, but smaller sites, adapted to lesser throughput demands, would be more suitable with single dispensers. Both models should stem from their legal and technological requirements and comply with the sphere of intelligent technology to induce many expansion capacities.

Used Gas Dispensers: Pros and Cons

Advantages

Cost-Effectiveness

One of the biggest advantages of acquiring used gasoline dispensers is the low cost due to no initial expenditure. Used dispensers can be bought for a fraction of what even the most modest-priced new model would cost and leaving room for deployment of funds for operational purposes. You will find that, vis-à-vis the same brand and condition, there is a huge margin of discount that may go up to 50%.

Immediate Availability

Second-hand dispensers are ready for the take-away, with no waiting time for supply, without the long spells that newly bought equipment requires. This is particularly appreciated by businesses that need to replace or increase their dispensers at short notice to meet any demand.

Sustainability

Reuse conserves the environment by curtailing waste, and keeping a gasoline dispenser alive lengthens its life. Consequently, the need for fabricating new equipment is minimized: energy conservation and raw material conservation.

Compatibility with Older Systems

Some of the used dispensers can accommodate legacy systems and are ideal for companies operating on fairly old technology. This enables them to avoid upgrading these older systems due to new technology.

Cons

Service History Unknown

Used gas dispensers are often sold without any documentation concerning the maintenance and repair history. This scenario increases the risk of buying equipment that will need constant servicing or one with some concealed fault.

Repair Costs

The price may be right until one needs to keep the repair costs in mind. The used dispensers may involve considerable repair, such as the replacement of a certain part, due to wear and tear. Such is the case in replacing a fuel flow meter, which can go up to hundreds of dollars and therefore offset the savings.

Warranty Or Help With Technical Issues

While new gadgets usually come with both comprehensive guarantees and a variety of support services, the used machines are sold on an “as-is” basis. In other words, businesses are holding all risks with respect to unforeseen mechanical breakdowns, post-takeover.

The Disappearance Risk

Old dispensers might not feature the technologically advanced systems, for instance, the EMV (Europay, Mastercard, and VISA) compliance and contactless payment schemes. That would ice off potential future modifications from the system and put the operator at a disadvantage vis-à-vis the morphing consumer expectations.

The Checklist

The company should carry out a thorough survey on the gas dispensers’ condition before purchasing them used. They might even want to get an overview of a technical examination. They need to look toward their own operational specifications and ensure any used dispensers adhere to compliance rules as well as customer necessities. It is the proper weighing of cost savings versus functionality and future-proofing that should guide you in making a wise and strategic move.

Used Gas Dispensers: A Cost-Effective Solution

Used gasoline dispensers increase the concrete chances of disinvesting from stored-equipment assets, less the risk of reversing their practical functions. One may have a wishlist dispense from a pre-owned supplier of gas dispensers. Preceding, one may have the best machinery that thrives inside the organization. The gas dispenser may be as good as new, for a charge! The main console should indicate maintenance and testing, furnished to the required certification standards for safety and operational standards. Then, you will reap long-term benefits along with a significant level of satisfaction from your customers, who are the ultimate source of wealth for the maintenance of these standards. In short, maintenance of high standards enables optimally favorable margins for your operations.

Benefits of Purchasing Used Equipment

Cost Savings

One of the major advantages of buying used equipment is that highly involves the cost savings than buying new machines. With used equipment, businesses can generally acquire high-quality models, free up capital for other critical investments, and at a reduced purchase cost.

Appreciating Asset

New equipment depreciates very rapidly during its early years of use, and it loses its value to half of its value. Buying used is buying after the optimization of depreciation, when the value can be maintained for a longer time.

Immediate Availability

Used equipment is usually available in comparison to the long lead time for manufacturing and delivery of new units. Rapid availability is most important for a business that is trying to deploy an asset quickly.

Sustainability and Environmental Benefits

Going the used route significantly cuts the environmental impact associated with producing new machines with respect to energy requirements and raw material consumption. This option is favorable to the environment and stretches the service life of a durable product.

Proven Reliability

Many other used machines come with records of proven performance. Used machines, in proper condition, from good sources, would have maintenance records and operational certifications that ensure reliability.

By utilizing second-hand equipment in an intelligent way within an operational context, businesses stand to reduce costs and keep performance at competitive levels.

Inspection and Maintenance of Used Gas Pumps

Inspecting and keeping in good condition the used gas pumps is best achieved through a carefully planned approach. Some of the key steps are:

Visual Inspection

First of all, do a visual inspection; try to see any wear or damage, whether there are cracks, rusting, or worn-out parts. Often, the leaks and corrosion around seals, hoses, or fittings play a great role in the eventual failure of the equipment.

Check and Inspect Pump Calibration

Calibration becomes the critical part in anticipatory fuel disbursement, then goes the foremost duty to verify whether this calibration meets the industry standards or not. Test the outflow rate of the gas to ensure consistency with the manufacturer’s specifications. In cases where this is not possible, recalibrate the meter to meet regulatory requirements.

Powering Up the Electrical System

Inspect, assess, and verify all wiring, connectors, and control panel components, all of which must be sound and well. Verify the state of their operation.

Replace Worn Components

To prevent mishaps and to prevent any further breakdowns in the future, the parts—such as washers, tubing, and nozzles (among others)—should be replaced. Proper detailing of the replacement parts in consideration of pump performance is an excellent regimen to follow for the sake of safety during operation.

Compliance and Certification

It needs to be confirmed whether the gas pump complies with local and national regulations, along with looking for any required certification stickers, and making sure that operational conditions are up to the specified control standards for the industry at large.

An implementation of a routine maintenance schedule should prolong the useful life of the machine and ensure that the equipment remains functional non-interruptedly. When it is carried out properly, inspection and maintenance routines improve the reliability and safety of used gas pumps, providing for better fluid gain for a business.

Where to Find Reliable Used Gas Dispensers for Sale

Productive responses, or feedback, on where to buy dependable used gas pumps state that buyers should go for the suppliers who have a reputation for giving high-quality equipment and dependable services. The consigning website Gas Pump Exchange provides a variety of cost-effective, examined options that meet the industry’s acceptable standards for refurbished gas pumps. Another reputable site, Petro Supply, features sources where one can pick from a sizeable supply of inspected used fuel dispensers newly fitted, along with all the accessories and parts needed to establish a complete outfit. The Central Equipment Co. competes by providing numerous used fuel dispensers, giving the network detailed pictures and product descriptions, and offering after-sales support. Stay well away from those with a bunch of cover-up policies, no warranty-put in attention, and substantiate reviews only after so many investigations, would these ensure a well-supported financial investment!

Installation and Retrofit of Fuel Dispensers

The installation and retrofitting of pump dispensers need initial advanced care; mainly, this practice must be in accordance with safety bylaws and operational profitability. A place should be chosen in compliance with recent zoning laws and environmental standards when needing installations. Necessary modifications to electrical contact, piping, or structure to satisfy regulations and manufacturers’ codes will have to be accomplished. Retrofitting aims at replacing certain outdated features with newer devices, such as enriched meters or system payments, for more accurate readings and services. Satisfaction in the prompt and especially career services will be obtained by modifying such machines from the beginning in such regard.

Steps for Installing a New Gas Dispenser

1Site Preparation

Start with preparations for the site. Ensure that the site adheres to the local safety standards and any pertinent safety regulations. Clear the area of debris and check the mobility of the dispenser units and their location. Verify the upkeep and compliance of existing fuel storage tanks and piping.

2Foundation and Anchoring

You’ll now need to build or inspect the dispenser island foundation so you’ll know the ultimate restraint. Directly attach the dispenser using the anchoring hardware specified by the fabricator, and to the best with applicable codes.

3Electrical and Piping Connection

Coordinate with licensed professionals for fuel supply lines and electrical systems. Inspect all grounding, piping, and wiring for compliance with local building codes and industry best practices, ensuring all connection guidelines for all the piping have been followed during construction.

4System Integration

They will install and configure system elements like flow meters, payment terminals, and communication systems, and link them to the existing fuel management system for smooth integration, which necessitates additional software setup for systems to remain compatible with one another.

5Calibration and Testing

The next stage involves calibrating the dispenser to the desired fuel flow rate. All hose connections need to be checked for leakages, and site-based merchants must comply with all necessary safety standards. Any tests, analyses, alignments, and calibrations need to be observed and passed.

6Inspection and Certification

With inspections conducted by an authorized institute and certifications showing to be in compliance with any planned governmental sanctions for safety, the dispenser becomes officially operational. Any issues identified during the audit need to be resolved before the unit becomes operational.

7Training and Deployment

Provide adequate training for operators in the safe use and handling of the fuel dispensers. After all system verifications are made for functionality, the dispenser is put into operation.

It requires going through each step with a great deal of care to ensure compliance, prevent environmental risks, and maintain operational efficiency. It is always advised to consult with a certified professional and follow regional guidelines for gas dispenser installations.

Retrofitting Existing Stations with Modern Equipment

First, it could be upgrading to more advanced equipment that the existing pumps would allow for. For this transformation to take place, extra plans must be designed that involve, among other things, a total overhaul of the dispensers through more modern technology, like enhanced monitoring capabilities, greater ease of use, the capability to charge an electric vehicle, or compatibility with a hydrogen fuel dispenser. This is done in congruence with the industry standards and the consumption requirements of customers.

Issues to consider include compatibility with the present underground storage tanks, observance of local environmental laws, and inclusion of safety measures to avoid leaking and spilling of fuel. One of the fuel vapor recovery systems or an automated tank gauge is implemented in strict compliance with environmental requirements. Also, a standard routine maintenance program of full cleaning and checks will ensure that these retofitted parts have no problem with long years of service.

Selecting the proper contemporary equipment means a detailed value vs. benefits analysis to grasp probable gains in efficiency and savings in operation, and scalability in the future. Additionally, seeing to your retrofit like a responsible steward from start to finish, with licensed contractors and compliance requirements weighed, is a must. In other words, by working this way, the existing station extends its life in such a way that it can accommodate new developments in fueling technology as well.

Choosing the Right Installation Kit

Choosing the correct installation kit requires compatibility considerations aside from functional and long-lasting performance. Initially, ascertain the compatibility of the kit with the installation in question, thus keeping a safe margin in strict conformity to manufacturer recommendations. The quality of materials must also be given credence, such as corrosion-resistant materials or clean-temp resistance, so that the installation is reliable under working conditions. Kits that come with complete installation instructions and all sorts of bits are definitely the ones to give preference to. Smooth and less total downtime?

Examining certifications and standards compliance, such as the ISO or UL rating, can relieve the uncertainties of many organizations that the solution fits the industry norms. It’s wise to look forward to kits that are either scalable or upgradable to meet future infrastructure enhancements. Real-world performances of kits could either be improved or compromised through technical reviews and user feedback. In this way, organizations could evaluate facts and make a decision that would lastingly appease any costs and operational reliability, respecting the life of the installation.

Future Trends in Fuel Dispensing Technology

Fuel dispensing technologies are centered on sustainable, automated, and better user experiences. New strategies for delivery systems will include a provision for such things as accommodating alternative fuels like hydrogen and EV charging integrations to meet the energy sector’s new demands. In order to reduce transaction time, the use of mobile payment systems has already taken root in the industry. Advanced monitoring equipment is being installed in some of these systems to ensure precision in execution and maintain a check on losses of fuel through real-time data analytics. This marks a trend towards the dual goal of reducing environmental effects in conjunction with greater efficiency.

Advancements in Fuel Dispenser Technology

Fuel dispenser development needs to cater to sustainability more. In this modern world, systems are incorporating IoT capabilities in order to keep an eye on asset location and maintenance through real-time monitoring and predictive analysis. As a result of improving the present technology bearing the issues in measuring technology and, for the first time, removing the problem of uncertain measurement, the adoption of smart fuel dispensers has relieved Fuel retail operators of the need to worry about issues such as transparency, etc. To save the environment against evaporation, thus released into the atmosphere, an agricultural immaterial vapor recovery system permits the evaporation of this vapor, which is then fed back through a combined effort back to the tank as a consumed fuel.

The Hydrogen Fueling infrastructure is advancing steadily, with the dispensers built to meet the high-pressure storage requirements for the next-generation Fuel Cell Vehicles. Furthermore, some of those stations operate in EVs charging co-location arrangements with conventional dispensing facilities to provide some multi-fuel vertical stations, which would also cater to a switch to cleaner energy alternatives. With touchless screens, mobile apps give a techno-functional and user-centric advantage, enabling personalized user experiences and quick transactions, while also embedding rigorous security for the user’s private information. These modern enhancements provide a complete paradigm that brings energy-conditioning systems in harmony with the demands of the world’s diverse transportation landscape.

Impact of PCI Compliance on Fueling Solutions

Payment Card Industry compliance has had a significant impact on the fueling solutions in ensuring that the systems for payment processing are secure and that customers’ financial data is protected. I think the obligation to these standards would at least mitigate data breach risks through consumer confidence in the whole payment infrastructure. By integrating such technologies into our operations, we actually make sure that transactions are smooth, efficient, and in the meantime, under-the-very-crowd latest security threats, and are at the same time fully compliant.

Emerging Solutions for Retail Fuel Stations

The retail fuel sector has undergone a rapid transformation due to technological advancements and changing expectations of the modern consumer. Future solutions emphasize developments in operational efficiency, customer experience, and environmental sustainability. Emerging technologies include the integration of automated payment systems with contactless and mobile payment options to speed up transactions and reduce the time customers spend waiting in line. This comes as sophisticated fuel management systems are being used to optimize inventory tracking, monitor fuel quality, and minimize waste with a focus on ensuring especially fuel-efficient operations at minimum costs.

This was added to by the mounting needs of electric vehicle charging infrastructure as electric vehicles are becoming more common. Retail fuelling stations’ contemporary inclination for developing fast-charging networks off overlapping renewable energies in a holistic effort targets energy sources like solar power, as said fuel solution sustains. They are also leveraging data and AI for predictive studies on customer taste, price optimization, and focused promotional activities. These technologies will certainly enhance operational excellence and bring about a kind of future endurance against market evolution.

Conclusion

Selecting the right gas dispensers and fuel pumps is a critical decision that impacts the operational success, customer satisfaction, and profitability of any service station. This comprehensive guide has explored the essential aspects of fuel dispensing technology, from understanding different types of dispensers and industry-leading brands to evaluating the pros and cons of new versus used equipment. Whether you’re establishing a new station or upgrading existing infrastructure, careful consideration of factors such as fuel type compatibility, station size, customer demand, and budget constraints will ensure optimal performance and long-term reliability.

The future of fuel dispensing is evolving rapidly with advancements in sustainability, automation, and user experience. From IoT-enabled smart dispensers and vapor recovery systems to hydrogen fueling infrastructure and EV charging integration, the industry is moving towards cleaner, more efficient solutions. By staying informed about technological innovations, maintaining high standards of quality and service, and ensuring compliance with safety and environmental regulations, fuel station operators can position themselves for success in an increasingly competitive and environmentally conscious marketplace. Investment in reliable equipment, whether new or properly inspected used dispensers, combined with regular maintenance and adherence to industry best practices, will ultimately deliver the best return on investment and ensure sustainable business growth.

Key Takeaways

- Quality fuel dispensers are essential for accuracy, safety, and customer satisfaction

- Leading brands like Gilbarco Veeder-Root, Wayne Fueling Systems, and Tatsuno Corporation offer innovative and reliable solutions

- Used gas dispensers can provide significant cost savings but require thorough inspection and evaluation

- Proper installation, maintenance, and compliance with safety regulations are critical for optimal performance

- Future trends focus on sustainability, alternative fuels, and enhanced user experiences through technology integration

- Smart decision-making balances initial investment, operational efficiency, and long-term sustainability goals

| Feature | New Dispensers | Used Dispensers |

|---|---|---|

| Initial Cost | High – Full retail price | Low – Up to 50% savings |

| Warranty & Support | Comprehensive coverage | Limited or “as-is” basis |

| Technology | Latest features & compliance | May lack modern features |

| Availability | Longer lead times | Immediate availability |

| Maintenance History | Clean slate – no history | Unknown – potential risks |

| Depreciation | Rapid initial depreciation | Already depreciated |

| Environmental Impact | Higher manufacturing footprint | Lower – reuse & sustainability |

| Best For | High-volume stations, long-term investment | Budget-conscious operations, low-volume stations |

Final Recommendations

For New Station Operators: Invest in new equipment from reputable brands to ensure compliance, warranty coverage, and access to the latest technology. This provides peace of mind and positions your station for long-term success.

For Existing Station Upgrades: Evaluate your specific needs, traffic volume, and budget. High-quality used dispensers from trusted suppliers can offer excellent value, especially when properly inspected and certified.

For High-Volume Operations: Consider dual dispenser models and advanced features like remote monitoring, real-time diagnostics, and integrated payment systems to maximize efficiency and minimize downtime.

For Future-Proofing: Look for equipment that supports alternative fuels, EV charging integration, and modular design to adapt to evolving market demands and regulatory requirements.

Reference Sources

“Building a hydrogen infrastructure in Norway”

“Electric vehicle waves of history: lessons learned about market deployment of electric vehicles”

Frequently Asked Questions (FAQs)

What gas dispenser types for sale are there?

The sale of a variety of gas dispensers, for example, rebuilt gas pumps and new models such as the Gilbarco Encore series-provides solutions to different fueling needs with specifications/adjustments depending on whether the solution is for retail fuel stations or fleet operations.

What is involved in the process of installing gas dispensers?

Gas dispenser installations often involve site assessments to make sure the machinery is compatible with the existing infrastructure. A kit, electronics, frame, door construction, and all necessary material is given by the dealers to create a fueling environment that is safe and efficient.

What criteria should I consider when going by a gas pump?

Think of electronic control, PCI-compliant security safeguards, and compatibility with CNG equipment for Compressed Natural Gas with your gas pump. The Veeder Root and Encore 700s are more sophisticated platforms that add value and user-friendliness to the benefits scheme ever.

Can I retrofit an existing dispenser with increased productivity?

Yes, providing an upgrade to their existing workstation functionality is very common. Improved technology ensures smooth and safe fueling, safety compliance, and growing customer appreciation.

With fast shipping being so important, what does that mean for gas dispensers?

The swift shipping of gas dispensers is of crucial importance, especially for those that operate on uninterrupted fueling. Quick service ensures that dispensers are installed at the right time, minimizing downtime and allowing customers to have a positive experience from fueling.

What roles can gas dispensers play to support fleet operations?

Gas dispensers designed for fleet operations are filled with characteristics that fully optimize refueling processes, like integrated POS systems and advanced controller technology that streamlines fuel usage tracking and costing with great efficacy, thus accomplishing an appropriate overall management of the fueling experience for the business of fleet business.