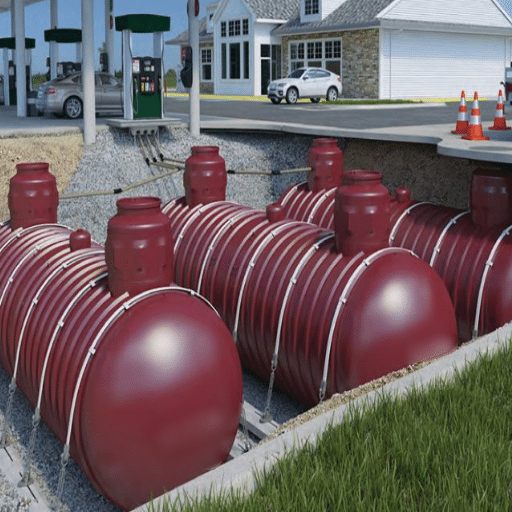

Understanding Underground Storage Tanks (USTs)

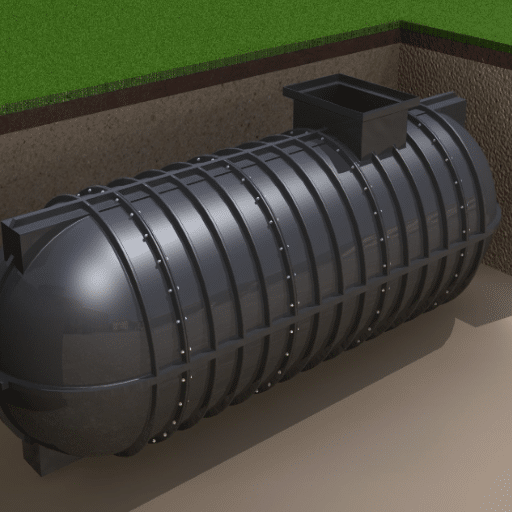

Underground Storage Tanks (USTs) represent a type of container designed for keeping liquids or gases concealed below the surface of the earth, primarily for industrial, commercial, or residential uses. Usually, these systems comprise a tank and any connected underground pipes that are primarily designed to prevent the leakage of liquids such as petroleum, chemicals, or hazardous materials. USTs play a significant role in those industries that need to store large quantities of substances while also complying with environmental regulations. Proper management ensures that no leakage occurs, thereby protecting public health and protecting the environment.

Definition and Purpose of USTs

The primary purpose of Underground Storage Tanks (USTs) is to keep the regulated materials underground and thereby help those industries that store large quantities of liquids such as petroleum, hazardous chemicals, or other regulated materials. These systems typically consist of one tank with underground piping connecting it to the dispensing area. USTs are important because they reduce the need for space on the surface, and they also protect the stored materials from the external environment. However, their main function goes beyond environmental efficiency since properly managed USTs are designed in a way that prevents leaks, ground contamination, and substance loss. In the United States, following regulations like the Resource Conservation and Recovery Act (RCRA), USTs are considered safe for operation and maintenance practices, which in turn protect public health, groundwater, and ecosystems.

Common Types of Underground Storage Tanks

There are several different types of Underground Storage Tanks (USTs) depending on their physical characteristics, such as material, content, and application. USTs can be grouped into three broad categories:

| Tank Type | Material | Primary Uses | Key Advantages |

|---|---|---|---|

| Steel USTs | Coated or cathodically protected steel | Petroleum products (gasoline, diesel, jet fuel) | Durable, widely used, equipped with protective coatings and cathodic protection systems |

| Fiberglass-Reinforced Plastic (FRP) USTs | Fiberglass-reinforced plastic | Ethanol blends, corrosive chemicals, and water | Excellent corrosion resistance, lightweight, easier transport, and installation |

| Composite USTs | A combination of steel and fiberglass | Fuel storage, hazardous chemicals | Combines strength and corrosion resistance, highly durable and versatile |

Steel USTs

The majority of these tanks are made from coated or cathodically protected steel, which is why they are very popular as storage tanks for petroleum products such as gasoline, diesel, and jet fuel. Moreover, such tanks are sometimes fitted with special protective coatings or cathodic protection systems to fight off rust and, thereby, extend the period of service.

Fiberglass-Reinforced Plastic (FRP) USTs

FRP tanks are the most durable in terms of corrosion and chemical resistance; they can be kept for the storage of ethanol blends, corrosive chemicals, or even water. Their lightness, however, not only makes their transport and installation easier than steel tanks but also reduces the cost of installation.

Composite USTs

Tanks that have been constructed from a combination of steel and fiberglass materials have gained their popularity because they satisfy the requirements for strength and corrosion resistance at the same time. That is why these Composite USTs are being increasingly chosen for their durability and versatility, which can be applied in various fields, including the storage of fuel or hazardous chemicals.

Key Consideration: Every UST type is particularly designed to address the diverse operational needs of the installations and to comply with the most stringent safety and environmental regulations. The right choice of a tank depends on a number of factors, such as the nature of the stored substance, site conditions, and regulatory requirements.

Importance of UST Programs

The Underground Storage Tanks (USTs) programs, which prevent the release of toxic materials through leaks, mainly but not exclusively protect the groundwater and air that we breathe. These programs entail the application of rigid regulations that USTs be designed, built, and blueprinted assuredly and in cooperation with the federal and state governments. The primary elements of these regulations include routine tank inspections, leak-detection systems, and spill-prevention procedures. Environmental monitoring and extensive documentation are indeed part of the process by which the degree of contamination that might affect soil, water, and the surrounding nature is brought down to the lowest possible level.

The UST programs treat environmental clean-up whenever there is contamination underground as a priority—that is, they conduct an early detection operation and take corrective actions that lead to reduced long-term cleanup costs and liabilities. The UST programs require the latest technology, such as double-walled tanks and advanced monitoring systems, to be used, thereby increasing the reliability and safety of the UST systems. Thus, they not only provide the industries that store fuel and chemicals with the ability to comply with regulations but also help them to operate in an environmentally sustainable manner.

Regulatory Framework for Underground Storage Tanks

In the United States, the Environmental Protection Agency (EPA) mainly controls the regulatory framework for USTs through the Resource Conservation and Recovery Act (RCRA), Subtitle I. The EPA prescribes leak prevention performance standards that are comprehensive in tank design, installation, operation, and maintenance. On top of that, the operators have to provide release detection and arrange financial support for the cleanup and damage liability. Many states have their own UST programs that are required to comply with or exceed the federal standards, thereby allowing local enforcement and oversight to take place. This system not only supports the environment but also ensures that public health is safe, and at the same time, it makes the tank owners responsible for compliance.

Overview of UST Regulations

Key Federal UST Requirements

The federal regulation that the Environmental Protection Agency (EPA) has established for Underground Storage Tanks (USTs) has determined the minimum standards that need to be complied with in order to keep the environment and the population safe from the danger of leaking tanks. The regulation has dictated a very high level of performance for UST systems since they have to be properly installed and constructed in such a way that corrosion will not occur and the failure of the structure will be prevented. In addition to that, the provision for spill and overfill prevention has to be such that the systems for leak detection will be able to identify the occurrence of even the smallest releases very quickly. Besides this, UST systems will have to go through regular inspections, testing, and maintenance as a part of their compliance assurance activities over the long term.

State-Level UST Enforcement

States with EPA-approved UST programs are allowed to operate under the authority delegated by the federal agency, which not only ensures that the local conditions are taken into account but also makes the compliance measures adapted accordingly. Even though the state programs are required to meet at least the federal standards, they are still allowed to introduce extra requirements, such as increasing the number of inspections or adopting special technologies for monitoring the tanks. The localized method results in more efficient monitoring, and at the same time, the federal aims are aligned with the particular state’s environmental concerns.

Financial Responsibility and Cleanup Protocols

Underground storage tank (UST) owners and operators must not only be accountable but also be ready with the financial means to clean up the pollution and pay for the third-party damages in the event of a spill as part of their financial responsibility obligations. Some of the approved methods for compliance by the EPA are through insurance, trust funds, and surety bonds. The proper cleanup sequence will be quick.

EPA Regulations and Their Impact

The Environmental Protection Agency (EPA) has generated quite a stir in the industry with its strict regulations that offer nothing less than a total transformation of the polluting practices. These regulations require the use of the latest technologies, which would otherwise remain behind the scenes in laboratories, like its high-tech leak detection systems, and double-layered containment, along with strict maintenance protocols, all incorporated in a plant or in an industrial area. The Resource Conservation and Recovery Act (RCRA), for example, imposes stringent monitoring and proper disposal of hazardous waste, which implies that the whole workflow would be accounted for in the final reckoning.

Also, the industries are required to have financial guarantees that will fund environmental rehabilitation, which will serve as a strong deterrent against possible negligence or the like. The requirements from the Clean Air Act and the Clean Water Act mean health monitoring, technology for reducing emissions, and treatment of wastewater, even if it means keeping the environment clean. However, the law’s compliance requirement adds to the total operational cost. The EPA slowly changes the industries’ attitudes toward green technologies by its policies of fining and rewarding eco-friendly practices, thus protecting nature as humans’ culture. The laws of the EPA are indeed strict and tough to follow, but at the same time, they promote the use of the official pollution control methods, hence keeping the ecologically rich areas for the future.

State-Specific UST Regulations

UST (Underground Storage Tank) regulations that differ from state to state are organized in such a manner that they meet federal criteria while considering the unique ecological circumstances and challenges of the area. These regulations are typically accompanied by more detailed specifications regarding the construction of the tanks, leak detection, corrosion resistance, and technical operators’ training. As an example, there are states that mandate both the tanks and the pipes to have a second containment so that in case of a leak, it will be contained, whereas in other states, similar monitoring technologies are to be employed, such as automatic tank gauging systems or regular tightness testing. Furthermore, many of the states require inspections to be carried out more frequently and have also created financial responsibility mechanisms to help offset the cost of cleanup if a leak or spill occurs and the state mandates such cleanup. Therefore, to avoid problems, operators will need to be well-informed about the local regulations, carry out preventive maintenance regularly, and maintain very precise records so that they do not face any fines, and at the same time, the groundwater resources are safe.

Inspection and Maintenance of USTs

Proper inspection and maintenance of underground storage tanks (USTs) are essential to leak prevention and environmental resource protection. UST operators shall conduct regular visual inspections to identify corrosion, damage, and other signs indicating the potential for structural failure. Monitoring systems, leak detection alarms, and automatic tank gauging should undergo regular testing to ensure they are operating correctly. Scheduled maintenance will incorporate the inspection of spill buckets, overfill protection devices, and double-walled parts for integrity. Environmental regulations compliance will presuppose keeping inspection, testing, and repair records up-to-date. Implementation of these practices lessens the risks and ensures safety in operation.

Regular Inspection Requirements

Constant validation of storage facilities is an absolute necessity in order to get the operational guarantee and environmental compliance. The entire system should be visually inspected for any signs of corrosion, leaks, or structural damage. The regions where the risk of leakage is the highest, such as spill buckets, sumps, and pipe fittings, should be inspected with special care. Leakages can be detected through monthly inventory checks and reconciliations. One year should pass before more updated and exact tests, like pressure tests for tanks and lines that use electronic monitoring systems, are performed for the integrity of the system. The testing of overfill prevention devices is another requirement of compliance, which also involves the keeping of records that show adherence to these requirements. Regular maintenance set by the authorities, together with proper documentation, made storage operations reliable and safe.

Performance Measures for USTs

To comprehensively assess the performance of Underground Storage Tanks (USTs), it is imperative to make the application of monitoring and testing methods uniform in a given manner. The first mentioned criteria for evaluation are leak detection, corrosion protection, and system integrity. Regular leak detection can be done through the use of automated tank gauging (ATG) systems, interstitial monitoring, or statistical inventory reconciliation, which is a combination of these methods. The data provided by the methods used is very accurate and can even identify the leaks or failures in the system.

Corrosion control is another important concern that has to be taken into account, especially when it comes to metal components. The UST systems must provide either cathodic protection or non-corrosive materials to avoid metal parts. This measure not only helps in meeting environmental regulations but also extends the life span of the tank infrastructure.

In addition, testing of tank and pipe integrity should take place no less than once a year. Tightness testing or pressure monitoring are examples of methods that are applied to prove that the containment system complies with the regulations. Keeping track of inspections and maintenance activities is a useful tool in assuring conformity with the requirements of both federal and state regulations.

Important Note: Picking UST performance measures as a strict routine will not only end up being cross-cutting environmental risks but also provide UST operators with a legal backing to run their operations and maintain them.

Common Issues Found During Inspections

At UST inspections, different problems can still appear, which may eventually lead to system failure and loss of regulatory compliance. One of the issues is the leak detection system, which is considered perfect, but is not being properly maintained and tested, so the leaks are not being detected in their very early stages. Besides, corrosion protection systems are not maintained properly, and consequently, the materials of the tank and pipe are under the influence of degradation. Poor recordkeeping is another problem that occurs in the full documentation of maintenance logs, testing results, and inspection reports, which are often either incomplete or outdated. Thus, these problems highlight the necessity of routine inspections, adherence to maintenance schedules, and documentation practices, which are good for UST systems to be not only fully operational but also compliant.

UST Release and Spill Management

The foremost techniques employed for underground storage tanks (USTs), which are still proficient in the case of leakages and spillages, are, moreover, the shrinking and also the slow curing of death, which prevents the problem is detained by so that the environment is not harmed. The steps taken are:

- Detection – Through the type of monitoring system used, leaks and spills can, at times, be identified immediately.

- Containment – Reduce to a minimum the spread of the released material by either sealing the place where it is or applying absorbent materials.

- Reporting – Notify local, state, or federal authorities immediately, as it is required by law.

- Cleanup – Soil and groundwater that have been contaminated will be cleaned using tested and approved methods.

- Documentation – Keep detailed and comprehensive records of the incident, including detection, actions taken, and the results.

Make it a point to conduct routine inspections and maintain all equipment in proper working condition in order to diminish the likelihood of future accidents.

Understanding UST Releases

Factors Contributing to UST Releases

Releases from underground storage tanks (USTs) primarily take place due to corrosion, structural failures, and bad upkeep. Corrosion gradually consumes tank walls or piping, and this is most prevalent in the case of old steel systems without any protective coatings or cathodic protection, which then succumbed to the cumulative effect of corrosion over time. A structural failure can be a slow process that sometimes takes years before the leaking part is detected; it is often manifested by cracking, splitting, or rupturing of the tanks and surrounding piping due to various factors like improper installation, natural earth movements, and manufacturing defects. Furthermore, when human errors occur, such as overfilling of tanks or mishandling of materials, the likelihood of releases will still be increased.

Environmental and Health Impacts of UST Releases

Above-ground storage tank (AST) releases are among the main environmental risks that, among other things, can cause direct or indirect harm to humans. The leakages of petroleum, hazardous substances, or other chemicals might penetrate the soil and groundwater. This type of pollution could not only deplete the water quality but also, in the case of the toxins entering the area, could render the non-virgin fauna and flora. That’s why inhaling water, vapor intrusion into buildings, and coming into contact with the ground are all ways that humans can get exposed to these contaminants and thus suffer from a range of health problems like respiratory issues, skin diseases, and cancer, etc.

Preventative Measures and Response Strategies

The leakage of underground storage tanks (UST) requires the full-scale application of monitoring, detection, and maintenance of Tanks and Pipelines. The purchase of modern double-skinned tanks, the introduction of electronic leak-detection systems, and the regular testing of tanks and pipes to locate their vulnerabilities are among the most important and basic measures. Prompt detection and response are essential for the reduction of the impact. The emergency response plans should include rapid containment, soil and water decontamination, and adherence to regulations aimed at minimizing the impact on the environment and public health.

Spill Response Procedures

The measures implemented in case of spills not only serve to minimize ecological damage but also to ensure the continuity of the business in case of safety regulations. The first step is to promptly assess the risky situation. It allows determining the type, amount, and level of hazard of the spilled substance. Firefighters should wear the safest available protective clothing to ensure that there is no harmful exposure. There will be an immediate isolation of the area through the establishment of absorbent barriers or booms in order to limit the spread of the contaminating area due to the spill running into the ground or nearby water sources.

Next, the focus should be on the safe recovery of the spilled material. In general, for liquid spills, either vacuum trucks or absorbing agents are used; solid spills may be treated according to the difficulty, with various disposal setups available. Crews will work under hazardous materials regulations, the Resource Conservation and Recovery Act (RCRA), which governs waste and recycling; thus, proper waste sorting and transfer will take place. Soil sampling or water testing is performed in the area where physical remediation is completed to determine whether the area is safe for use or not.

The documentation of activities has become an essential part of the process of responding to spills. Therefore, the process of documenting every single action taken, including cleaning methods, impact assessments, and correspondence with authorities, guarantees accountability and compliance. In addition, if the staff is trained regarding spills and if regular drills are conducted, it will result in higher preparedness and thus lower risk of both environmental and operational disasters.

Financial Responsibility for UST Releases

Legal and financial obligations regarding the prevention of environmental damage and the safeguarding of public health primarily rest with underground storage tanks (USTs) owners and operators. The federal regulations that govern USTs, which are based on the U.S. Environmental Protection Agency (EPA)’s guidelines under the Resource Conservation and Recovery Act (RCRA), accept UST owners’ claims of financial responsibility for leak-related corrective measures and third-party damage. This financial responsibility guideline places the burden of different measures for addressing the situation and compensating third parties for leak damages on USTs.

In addition to the least costly method of compliance with the Environmental Protection Agency (EPA) regulations, which is insurance for pollution liability, compliance by means of financial sureties, trust accounts, bonds, or the use of a state-specific financial assurance fund are other ways to comply. Polluting insurance is by far the most common method utilized and accepted by the federal regulations. A minimum of $1 million for each case for oil marketers and $500,000 for non-marketers is established in the federal regulations, with limitations on the total amounts allowed for each year. Prompt removal of the contaminated area is the result of good allocation of financial resources; the environmental impact is low, and the concern of all parties is also low.

| Financial Assurance Method | Description | Minimum Coverage |

|---|---|---|

| Pollution Liability Insurance | The most common method accepted by federal regulations | $1 million per occurrence for oil marketers; $500,000 for non-marketers |

| Trust Funds | Dedicated financial accounts for potential cleanup costs | Varies by state requirements |

| Surety Bonds | Financial guarantee from a third-party surety company | Must meet EPA minimum standards |

| State Financial Assurance Funds | State-specific programs for cleanup funding | Varies by state program |

Registration and Compliance for USTs

Owners and operators must register their underground storage tanks (USTs) with the state or local regulatory authority before they can start using them. The registration procedure normally necessitates providing detailed data about the tank, such as its size, type of material, installation time, and its contents. The observance of federal and state laws, consisting of routine inspections, leak detection, and record-keeping, is what secures compliance with the regulations. Not only does proper registration, along with compliance with regulations, minimize risks to the environment, but it also reduces the possibility of incurring fines.

Requirements for UST Registration

The owner of an underground storage tank (UST) has to go through a very tough process to get their permit issued by the federal and state authorities. To begin with, the owner has to submit a full package of relevant documents which would contain not only a detailed description of the tank’s construction (for example, anti-corrosion materials, and secondary containment systems) but also the technical specifications, such as volume and chemical compatibility. Moreover, the owner might need to provide proof of installation certification or documentation of compliance with industry-standard installation practices.

Furthermore, adherence to leak detection procedures is a must. This would entail the installation of approved monitoring systems such as Automatic Tank Gauging (ATG) or interstitial monitoring, logging system performance in detail to ensure leak detection can happen immediately, and maintaining full open communication with the authorities about this matter.

In addition, the owners have to give the financial assurance, proving that they are ready and have the means to control the release, clean up the area, or pay for such activities. Providing compliant insurance, taking part in state assurance funds, or using other credit-worthy methods may entail this. Not fulfilling these extremely high standards might cause the entity to face penalties, or the waiting time for the permit might be prolonged, thus making compliance with UST registration procedures very important.

Compliance with Storage Tank Regulations

To fulfill the obligations for storage tanks, I ensure that proper registrations are done for all tanks, there is accurate keeping of records, and financial assurance is set aside for potential environmental liabilities. There is no tolerance for non-compliance or stoppages in operations. I strictly adhere to the inspection schedules, carry out maintenance work regularly, and address problems at once.

Consequences of Non-Compliance

The consequences of failing to comply with storage tank regulations may be extremely negative in terms of finance, law, and the environment. One main consequence for violating laws is often a hefty financial penalty that may even double if the violation persists. In addition to penalties, law courts might also be invoked, thus putting operators in a situation where they have to litigate and face even the shutting down of their business as a consequence. From the environmental perspective, non-compliance means there is a greater chance of leakage or spillage, which would subsequently cause contamination of soil, groundwater, and even surrounding ecosystems. This would certainly necessitate a very costly clean-up operation. Furthermore, the company’s image may be adversely affected by non-compliance, and the public may lose trust in it, which would also result in a reduction of potential customers. Consequently, it is really necessary for companies to adopt a proactive approach in complying with regulations to effectively reduce risks and make their operations sustainable.

Reference Sources

University of Colorado Law School

This document provides insights into regulations and estimates regarding underground storage tanks.

A guidance document for storage tank owners and operators, focusing on compliance and regulations.

This resource explains the procedures for closing and managing petroleum underground storage tanks.

Frequently Asked Questions (FAQs)

What are the main underground storage tank regulations for petroleum tanks?

The regulations concerning underground storage tanks for petroleum include the federal UST regulations of the US EPA and the state provisions that are implemented by the environmental department or the natural resources department. These regulations impose several obligations, such as those related to the installation of underground pipelines around the tank, registration of the tank, detection of leaks, protection against corrosion, and training of the operators. It is indispensable for the tanks that are regulated as underground storage tanks, together with those that are regulated as USTs for motor fuel or heating oil, to meet both federal and state requirements regarding underground storage tanks to eliminate the risk of contamination of the human population and the environment.

What are the requirements for USTs affected by leaking underground storage tank sites?

The requirements for USTs necessitate immediate reporting and taking of remedial measures when there is a discovery of a leaking underground storage tank. The owners and operators of underground tanks must comply with the underground storage tank program’s procedures regarding investigation, cleanup, and monitoring at leaking underground storage tank sites or leaking UST locations. The federal UST regulations and the state underground storage tank program policies guide the process of funding, risk assessment, and remediation in such a way that the impacts on human health and the environment are minimized.

What are the performance measures of UST for tank system integrity and monitoring?

Ust performance measures consist of the sensitivity, the frequency of testing of corrosion protection systems, and the effectiveness of containment sumps for interstitial monitoring. Measures of performance also assess the piping of the tank and its conditions, and the training of personnel in the facility, all aimed at keeping the regulated and new underground storage tanks compliant. Governments monitor these indicators in order to ensure the tanks meet the standards protecting human health and preventing groundwater and soil contamination.

Who has the responsibility under underground storage tank regulations: tank owners, operators, or the regulated community?

The primary responsibility under the regulations for underground storage tanks rests with the owners and operators of those tanks. The regulated community has to get tanks registered, keep records, train operators, and make sure that they comply with both federal and state UST regulations. Owners and operators of underground tanks must also notify the authorities of any releases, maintain systems for leak detection and containment, and, when the tanks are on a state or federal program, comply with regulations for farm and residential tanks that are similar to those that apply to the tanks regulated by the state or federal program.

What is the effect of underground storage tank requirements on both new tank installations and new tank registrations?

The installation of new underground storage tanks requires carrying out a compatibility assessment (which could be, for example, the filling up or changing over to an alternative fuel compatibility form), proper installation of tanks along with pipes laid underground, and strict adherence to monitoring and containment standards. Initially, new registration and permits for underground storage tanks have to be obtained from the state, which is a part of the underground storage tank program, before a new tank can be put into operation. These requirements make certain that the new tank and piping systems are capable of upholding the utmost performance measures and, at the same time, protect human health and the environment.

In what ways do underground storage tank regulations serve to safeguard human health and the environment?

Managed regulated USTs prevent the release of oil and other hazardous materials and thus keep the populations and surroundings safe. Among the conditions placed on underground storage tanks are leak detection, corrective actions for leaking, secondary containment, and restrictions on the sites of tanks near drinking water sources. The combined volume of underground tanks and the location of the tanks determine the intensity of oversight; hence, regulatory programs aimed at leaking tanks through remediation and monitoring.

Are residential tanks and farm and residential tanks covered by federal UST regulations or state rules?

In most cases, federally regulated underground storage tank (UST) regulations do not apply to some small tanks, such as the heating oil tanks used in homes or on farms, which can still be subjected to state regulations. State programs for underground storage tanks (USTs) sometimes include different kinds of regulations dealing specifically with residential and farm tanks, such as registration, piping standards, and spill prevention. Owners are advised to check with their state’s department of natural resources or department of environmental quality to determine if their tanks are USTs, and to receive information about the regulatory requirements applying to USTs.

What should tank owners and operators of underground storage tanks do about operator training and ongoing compliance?

Tank owners and operators of underground storage tanks must provide the required operator training to the designated operators in accordance with federal and state regulations. Continual compliance includes regular inspections, leak detection system maintenance, containment sump testing for interstitial monitoring, record keeping for tank and underground piping maintenance, and timely registration renewals for tanks. Implementation of these practices minimizes occurrences of leaking underground storage tanks (LUSTs) and creates a healthy and safe environment for humans and animals at ust facilities and tank sites.