Technological advancements have been occurring rapidly today, influencing tomorrow very much. The global petroleum markets are among the industries that voice these changes. On the gas station front, the introduction of the latest innovation, automated fuel dispensers, heralds the biggest change in the distribution and sale of gasoline, whereby customers and retailers are supposed to realize efficiencies, security, and comfort, hitherto never experienced. The article discusses in detail the role the automated fuel dispensers play in shaping the way operations are run, as these machines set a new standard and the system of provision in the field of petroleum business operations. Whether any professional within the fuel industry, an investor, or a curious column of technical experts affecting developments could read a rather complete description that breaks into the very depths of considering automation in a sector so far dominated in its most important processes by human labor.

Understanding Automated Fuel Dispensers

High-precision digital sensors combined with secure payment systems and human-machine interfaces enable up-to-date AFDs to work with complete autonomy. After selecting the grade, the customer can interface with the screen to pre-pay and subsequently fuel on his or her own, while more precise metering technology ensures safety mechanisms such as auto-shutoff remain set to avoid spillage. On the digital side, besides that, these machines operate on hugely robust software networks that offer impregnable transaction security, instantaneous monitoring, and maximal operational effectiveness. This makes them a truly dependable gas station solution in the new era.

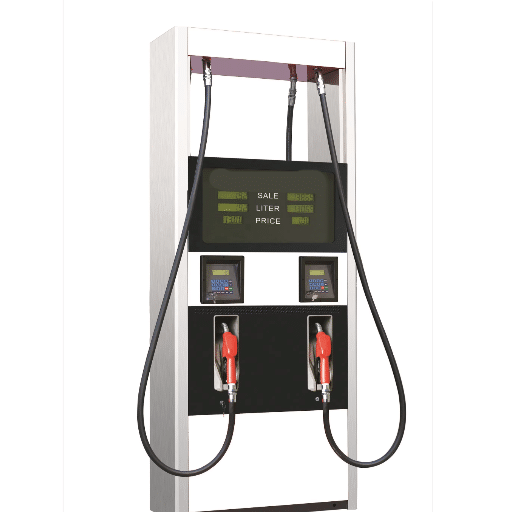

What is an Automated Fuel Dispenser?

An Automated Fuel Dispenser (AFD) is essentially a self-serve station where clients are able to fuel their vehicles without the mediation of an attendant. These dispensers are endowed with top-end metering and control systems that guarantee the accurate delivery of the fuel along with the fulfillment of appropriate safety requirements. Touchscreen interfaces for user interaction, secure payment options within card mode and mobile payments, integrated software solutions, and real-time monitoring and transaction management are some of the features of these automated fuel dispensers. By efficiently fueling the combustion process, automated fuel dispensers bring about consumer convenience, short waiting periods, and an overall efficient operational aspect from both the customer and the fuel station’s point of view.

Types of Fuel Dispensers

Fuel dispensers could be grouped broadly by their functionality, fuel type, and design specification. They include:

Single-Product Dispensers

Single-product dispensers are designed to dispense a single fuel type, such as gasoline or diesel. These dispensers usually operate at a small-sized fueling station where such priorities are paramount.

Multiple Product Dispensers

Multiple-product dispensers are designed and modified to be able to pump and handle more than one kind of fuel type, like gasoline, diesel, ethanol blends, or CNG from a single machine. These are commonly used in today’s fueling environment to satisfy various consumer requirements.

High-Flow Dispensers

Designed for a heavy flow of fuel, high-flow dispensers are engineered to meet the time demands of fleet and commercial vehicles. That is mostly fueled by high levels or flow rates, making the operation suitable for heavy equipment such as trucks and buses.

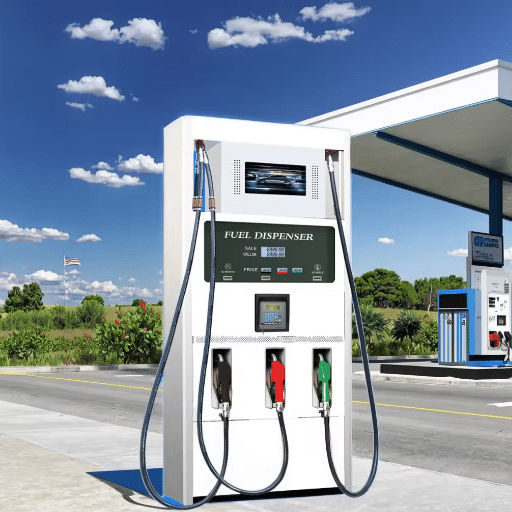

Retail Fuel Dispensers

Retail fuel dispensers have widely installed payment systems and digital displays often interfaced with marketing promotions to cover a variety of public fueling scenarios. This is where the service meets efficiency.

Commercial and Industrial Dispensers

Designed primarily for private fleets, construction yards, or industrial use, they have significant importance in dependability, accuracy, and integration of considerations towards larger storage tanks. Retailer comforts are secondary, while the next page of emphasis is on the ingenious fuel management system for effective tracking.

Each dispensing system is technologically outfitted to fit likely fuel outflow, technology integration, and end-user context in a well-tailored manner, and serves as the best option with respect not only to best adaptability but also to best optimization over varying operational landscapes.

How Automated Systems Work

Automated systems follow predefined tasks with minimal human intervention, and they are governed by the integration of hardware and software components. Essentially, these systems collect real-time data via sensors; control algorithms interpret that data and make decisions. The control mechanism of actuators can then execute a wide range of physical actions to help a system deliver its intended functionality.

An important area of application is in industrial fuel dispensing systems, where things like flow rates of the fuel to monitor, inventory levels to maintain, and dispensing operations to ensure are all controlled through direct control of flow meters, Electronic Control Units (ECUs), and communication networks. These systems normally incorporate IoT technology to promote information sharing and allow operators to keep track of performance from remote locations. This end-to-end automation reduces errors, improves operational efficiency, and helps maintain the high safety and regulatory standards, indicating the central importance of these systems in today’s industrial processes.

Benefits of Using Automated Gas Dispensers

Automated gas dispenser in the industry has several attractive features. They increase the precision, which enables them to deliver just the right quantity of gas, thereby reducing waste and adding reliability. Automation also eliminates human error, thereby improving the safety of the operation system. Automation enables real-time monitoring and remote control, allowing problems to be detected and handled immediately. In this manner, compliance with standards develops as well, so that compliance with regulations required for audit and report processes is facilitated. In sum, automated gas dispensers increase the efficiency, safety, and reliability of business operations in accordance with standards in industrial environments.

Improved Customer Experience

Gas vending machines reduce the wait time for a customer due to faster and easier interaction with them, giving a much-improved experience. Through these intuitive processes, the Machines make buying gas an easy and quick process; transactions are performed quickly, and customers wait just a little for the completed purchase. And for every payment, in step with the technical response to the modern customers’ expectations, advanced payment methods are set up with full contactless payment and mobile-based options at NoSurro. There is a possibility, in addition to these attractions of a loyalty program and a very flexible receipt configuration, to have an entirely personalized vending experience. Automated units, therefore, prove to be trustworthy for customers as the systems that reduce their level of difficulty grant efficiency by enhancing them with hardly any room for failure.

Increased Efficiency and Speed of Refueling

These unique smart systems immensely enhance efficiency by reducing the extent to which humans are involved while improving the fueling process. Maximum precision is ensured along the dispensing system its way with the multitude of modern technologies, when the flow rate is optimized and real-time monitoring is kept a close watch over the scenario. Furthermore, pre-payment and digital e-payment reduce the wait time, speeding up transactions and increasing throughput during peak-hour rush. Automated solutions bring uniformity to operations while reducing the downtime due to manual errors in changing conditions. All these measures ensure enhanced workflow efficiency and guarantee a seamless user experience.

Risk Management in Fuel Dispensing

Fuel dispensing is a high-risk sector when it comes to managing risks through identifying, evaluating, and managing various hazards associated with stored fuels, such as flammability of fuel, environmental contamination from spills, and human health risks associated with long-term exposure to the VOCs.

To mitigate these risks, all fuel-dispensing systems must be guided under stringent legal frameworks as set by the OSHA and EPA regulatory standards. What is more, the regular upkeep and checks on equipment- dispensers, storage tanks, and pipelines- serve as part of preventing possible equipment failures. Additionally, the introduction of highly safety-technological components such as a leak-detection system and an automatic shutoff mechanism engine ensures that opportunities for accidents as well as environmental damages are minimally accommodated. There is also extensive training for the employees concerning the emergencies ahead and how the relay the operational process to guarantee maximum employee safety.

Finally, robust spill response plans in place, coupled with containment measures, placing secondary barriers around storage areas, greatly reduce the risk of environmental harm. A combination of technological advancements and strict safety practices allows for the improvement of safety standards on fuel-dispensing operations, along with a reduction of the inherent risks.

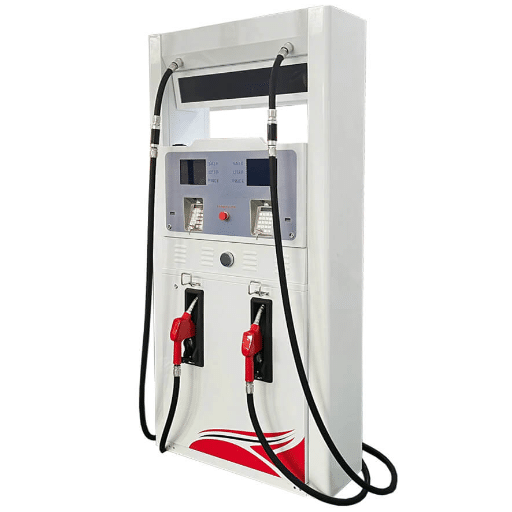

Components of Automatic Fuel Dispensers

A group of components is tantamount to the creation of fuel sucked from storage and taken to the nozzle, all this in a design of the flow that enjoys both efficiency and consistency.

| Component | Function |

|---|---|

| Nozzle | The nozzle is the first membrane through which hoi polloi use to spill the fuel into the tank of an automobile. In recent times, advanced nozzles are available and will provide an automatic cut-off feature to stop possible overflow. |

| Metering System | One of the more important components of accurate billing is a precision meter that will measure exactly how many liters of fuel will be dispensed. |

| Controlled System | There are electronic processors and software to manage operations. They monitor the quantity of fuel dispensed and may also work with other systems like pay terminals. |

| Hoses and Piping | As these entrenched tubes are long, they can traverse a long distance between the motor and nozzle. They have to deliver fuel in a substantial quantity and premium quality to the device. |

| Display System | The display system provides the buyers with crucial information, such as the volume of fuel drawn, price per unit, and total volume of fuel stored, thereby ensuring transparency. |

Automatic fuel dispensers provide accuracy, safety, and convenience. Propelling these components are inclusive of automatic fuel dispensing system components, greatly reducing the cost of fueling downstream for cheers.

Nozzle Types and Their Functions

Fuel dispenser nozzles are crucial components that have been designed to enable safe and proficient fuel dispensing. There are several types of fuel nozzles designed for specific applications:

Automatic Shut-Off Nozzles

These nozzles have a mechanism to stop fuel flow when the tank is full, hence the largest Spurs! outlets can’t overflow, preventing even a significant loss of fuel. Most have a back-pressure-sensitive system for detecting any back pressure from the fuel tank.

High-Flow Nozzles

Widely used in situations, be it commercial or industrial, there are high-flow nozzles that are meant to deal with large quantities of fuel in a short time. These are employed mostly in the refueling of heavy-duty vehicles such as trucks or buses and are highly efficient.

Vapor Recovery Nozzles

Vapor recovery nozzles are utilized to prevent the violation of environmental laws that require fuel vapors to be recovered during fuel offloading, since these discharge chemicals into the atmosphere.

Manual Nozzles

Like those other orders, these order vectors seemed to have great potential behind them. Correspondingly, one would find oneself most influenced by them, while others find their respective medium strength being manifested, some back and forth.

Pump Mechanisms in Automated Systems

Pump mechanisms are preferred in automated systems for applications in which precise, dependable, and efficient fueling is mandated. Positive displacement or centrifugal pumps are the systems most commonly used. Which type of pump to use depends on their application.

Positive displacement pumps are those pumps that use a diaphragm or gear-type mechanisms to capture a fixed volume of fluid and get it through the system. These could be accommodating varied pressures from there; the consistent flow rates in an automated fueling dispenser stand to gain. On the other hand, centrifugal pumps, with their rotors serving as impellers for converting rotary motion into fluid motion, are highly efficient in applications of very high volume flows.

Integrating with automated setups generally includes having sensors and controllers that keep an eye on the functionality of the pumps, adjust their flow rates, and make sure they meet the safety requirements in place. Some advanced safety mechanisms are given the features of emergency shutoff functions for pump requirements, pressure control valves for injection system operation, and anomaly detection diagnostics to increase pump uptime and decrease environmental risks. These technologies enable precision, safety, and environmentally friendly capabilities for fuel pumps in these highly automated refueling stations.

Integration with Management Systems

The pumps must be integrated with management systems to optimize both the operation and decision-making, for they give a basis for data. The best hand-in-hand relationship that pump systems and management systems can have. These days, a range of fuel management systems is brought in to interface pumps efficiently, facilitating real-time monitoring, automated reporting, and the control of pumps remotely. Fuel usage, inventory levels, and machinery performance- all are carried out tracking work with the help of IoT-based sensors and software, to say the least. The integrated processing node itself plays the role of providing predictive maintenance such that it might analyze data trends and predict when some equipment may need maintenance work done, hence curbing possible downtimes and loss of earnings. An integrated alert system ensures impeccable compliance with standards, together with an automated process-optimization algorithm, followed by ensuring-operation personnel a standby on which to operate at full attention with boosted operational efficiency. Integrated monitoring technology opens the door to real-time management data collection and accurate operating expense accounting to help with judicious cost analysis.

Different Types of Fuel and Their Dispensers

Fuel types commonly used in various industries include gasoline, diesel, natural gas, and ethanol blends. All these types necessitate the establishment of purpose-specific dispensers made to safely and effectively supply the fuel to any particular passenger or equipment.

Gasoline

Most used in cars, it can be dispensed through the dispenser that usually includes a vapor recovery system to decrease fuel emissions back into the air during refueling.

Diesel

Diesel is used in heavy-duty vehicles and equipment. Usually, they would be characterized by pumps with a higher flow rate, which helps in accommodating large fuel tanks, and high complexity top filters to maintain fuel quality.

Natural Gas (CNG/LNG)

Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG) are dispensed through special pumps, treating gas storage and delivery with high pressure and cryogenic technology to attain a safe passage.

Ethanol Blends

Ethanol-blended fuels and E85 need dispensers that are compatible with the ethanol content so as to prevent corrosion or damage to equipment. Typically, these dispensers are labeled to show the particular blend of ethanol they are aligned with.

To fulfill these standards, one should always ensure that the correct dispenser suitable for each type of fuel has been used.

Gasoline vs. Diesel Fuel Dispensers

The purpose of the provision of these gasoline and sedimented-dispensing machines is to ensure complete rationality to meet the powered vehicles that they service, reduce breakdowns related to safe care, and additionally entertain low or high impurity. Gas dispensing units are rated as the highest flow rate in order to save the combination of capability tanks of a vehicle; diesel dispensing units, in contrast, are relatively low flow rate due to the reason that diesel fuel is less consumed by a vehicle, which must be efficiently injected.

Other variances include the length and shape of the nozzle. For example, gas station equipment is fitted with very small diameter nozzles to match the standard gas inlet ports of any gasoline vehicle to ensure correct fueling. Diesel nozzles, on the contrary, have wider diameters to ensure they can never fit into the fuel port of any gasoline vehicle, thus being in compliance with both design and safety laws. Finally, diesel has a higher density and viscosity than gasoline, necessitating pumps specifically built to handle such physical properties.

A diesel delivery system often includes materials to withstand the corrosive and abrasive effects of diesel’s chemical properties, which are vital for durability and adherence to fuel standards. On the other hand, gas outlets have been designed with vapor-tight components in compliance with environmental regulations. The use of proper dispensing equipment to handle fuels ensures practically efficient equipment maintenance and protection, enhanced workplace safety, and the prevention of costly misjudgments like cross-fueling in different types of fuels or equipment failure.

Portable Fuel Dispensers for Various Needs

Portable fuel dispensers are designed to offer flexibility, efficiency, and safety in the context of fueling operations across different industries such as agriculture, construction, or even transportation. Generally compact and easily transportable, these dispensers are furnished with precision pumping systems that guarantee accurate dispensing. Several models incorporate advanced parts like digital flowmeters, automatic shut-offs for nozzles, and integrated filtration systems to retain the purity of the fuel.

The most important catch to watch out for in a choice for portable fuel dispenser concern: fuel compatibility, mostly: would it serve gas, diesel, or kerosene usage, the capacity for storage and discharge; presence of accessories such as hoses and nozzles are also other deciding factors. Compliance with environmental and safety guidelines is a must to prevent spills, leakage, and vapor emissions, and other foreseeable hazards. With the new, robust design being chosen to withstand harsh working conditions and resist corrosion, materials are obviously judged for durability. This, paired with flexibility in terms of acceptability in the hands of quite stringent operational considerations, puts portable fuel dispensers on top of other fueling requirements in the field or at remote sites.

Mobile Fuel Dispensing Solutions

Modern mobile-fuel-dispensing systems have tremendously changed the fueling process by providing extra convenience, efficient fuel unification, and adaptability throughout several industries. Today’s technological systems generally use digital flow meters, automatic data logging, and real-time monitoring to ensure correct fuel volume. Such technology, in turn, ensures ideal management of inventories through accuracy in measurement while preventing discrepancies and maintaining operational set standards.

New data asserts that mobile systems usually enhance fueling delivery efficiency by up to 30%, especially in instances when essential to prompt on-site refueling, construction, agricultural, logistics, et al. This has come to incorporate GPS tracking and IoT connectivity, because suppliers are allowed to keep an eye on their fuel consumption patterns and, in turn, optimize their delivery routes.

The growth reflects support for the view that the mobile fuel solutions market is in a position to extend and expand at a compounded yearly growth rate (CAGR) projected at around 7 percent for at least the next 10 years. A global surge is going to be evoked owing to the demand for flexible refueling capabilities in areas that are averse to easy access to traditional refueling points. There has been increased interest in developing materials and battery technology that will facilitate an improved system design, ever ready to perform in challenging environments and loaded with lower maintenance costs and eco-friendly features for a greener tomorrow.

All of these improvements underscore the mobile fuel solution providers’ aptitude in meeting the requirements of today’s emerging industry while simultaneously promoting sustainability via increased efficiency on a myriad of different application fronts.

Challenges and Considerations

Mobile fuel dispensing encounters a number of crucial challenges—regulatory milieu, safe fueling during transfer, and its operational readiness in remote or most arduous terrains. Compliance with environmental prerequisites and safety standards calls for close monitoring and a sufficiently robust system design. Logistic challenges should also be met, for instance, ensuring chain management and putting into place the technology now available to best optimize functionality. Having proper maintenance of mobile fueling equipment and operator training is essential in reducing downtime and avoiding accidents. Addressing these factors is imperative for the establishment of the feasibility and sustainability of mobile fueling solutions.

Transitioning from Manual to Automated Systems

Fueling the shift from manual operations to automation is the utilization of high-tech resources toward improved precision, efficacy, and scalability within operations. Automation removes repetitive and error-creating tasks as robots-over programmable systems, sensors, and machine learning algorithms-Make operations easier. Transitioning towards automation necessitates a systematic implementation approach, including evaluating current processes, which may yield areas applicable to automation initiatives and metrics to deliver a bespoke action plan. The reliable functioning of interoperable software, operationalizing robust data collection standards, and ensuring secure connectivity are the most important drivers toward effective system integration, preventing potential data breaches; corporate training and change management are critical in ensuring employees adapt to the new tools throughout the process, pushing to ameliorate resistance and boost productivity. The increase in automation improves operational efficiencies and pushes businesses into lower operating costs by offering higher advantages associated with their increasingly varied technology landscapes.

Maintenance of Automated Fuel Dispensers

Regular fuel pump maintenance is the key to keeping them performant and durable. But I attach great importance to a disciplined system of inspection that’s able to flag up potential mechanical and software errors, endeavoring to correct these hitches before they evolve into something worse for service interruptions. Certain key features that ensure operational efficiency can be achieved by cleaning the nozzle, filter, or keypad. While software updates strengthen system performance and enhance protection, I cannot afford to neglect the regular maintenance schedule as provided by the original manufacturer, or to ignore the use of diagnostic tools to track system health in response to reducing downtime and to guarantee operation.

Reference Sources

“Measuring Radon in Soil Gas and Groundwaters: A Review”

Frequently Asked Questions (FAQs)

fuel station: How do automated gas dispensers provide real-time data on fuel and help gas station operators?

By using telemetry and analytics, automated dispensers can provide real-time information on fuel levels, the total cost of sale, and fueling activity. With this information, gas station operators are able to then schedule deliveries, organize inventories, detect and stop leaks, and even potentially prevent an intended skim. The system also allows operators to be alerted about any problems with their submersible pumps or tank sensors, so that quickly available service guarantees that the unit stays compliant. Components of a fuel dispenser, for example, must follow environmental and safety guidelines.

vehicle automation: Will automated fuel dispensers work with mobile apps and mobile wallets for now?

Yes. Various automated systems count amongst mobile app support and mobile wallets for quick authorization. Using a mobile app or tapping the card at the pump activates the fueling process, displaying the total cost in real time with digital receipts. This has shortened the queuing time, made fueling faster than inside manual payment. Provisioning also facilitates the fueling process for both fleets and individuals.

Gas station: Are automated gas dispensers safe in preventing leaks or skimming?

The automated-enabled machines are integrated with a slew of sensors and analytics to notice any wrongdoing, like leaks or skim devices. Fuel dispensers are advanced machines with meters joining shut-off valves that greatly minimize the risk of fuel from the tank or submersible being spilled. That and because of transaction monitoring to authorize payment through a sale, the likelihood of skimming in the pump is reduced, protecting both payment information and the reputation of the petrol station.

Automation of fuel stations: Is it possible for the automation facility of the fuel dispensers to make way for the dispensing of alternate fuels and thus compare the fuels?

Automated fuel dispensers are often configured with the added convenience of multiple fuel types: traditional petrol, alternative fuels like ethanol blends, or biodiesel. Fuel dispensers are built to measure distances in terms of liters and gallons. Various advanced models offer dedicated hose systems that are coupled with disguise nozzles to help prevent the leakage of cross-contaminants. Operational performance indices enable fuel traders to measure actual consumption of different types of fuel and use this information to refine pricing strategies and better manage stock.

vehicle petrol: incision makes the overall cost and efficiency for gas station operators machine-like?

Automated dispensers beat down costs substantially by simplifying the fueling and paying processes. This may lead to a reduction in the expenditure of labor while cutting down the volume of fuel left unaccounted due to theft or skimming. Furthermore, the prediction of maintenance requirements based on real-time data may contribute to the maximization of uptime. To clear these benefits, the overall cost of station operations is drastically lower, nonetheless. At the same time, throughput at the station is inflated along with those ancillary benefits mentioned above, hence supporting customer satisfaction and gross profitability.

AFDS Fuel Station Automation: What about maintenance and regulatory considerations with respect to the automated gas-dispensing machines?

Machines must remain in compliance with local safety, environmental, and regulatory standards. These standards include periodic inspection of the hoses, nozzles, and seals for submersible pumps, as well as the electronic authorization modules. Putting in place a reliable electric supply and grounding is always a good practice, while updating the software is a good idea for better security. Gas station owners should set up monitoring and analysis aimed at early detection of malfunctions, such as leaks would create. It is imperative to allow for manual service at the proper time for improved compliance and threat-free operations.