The demand for new and efficient methods of refueling is ever-growing, pushed by customers seeking flexibility, convenience, and sustainability. Thus, an alternative fertilized container fuel station is an approach brought in that compromises slightly with mobility versus functionality so that industries, remote locations, and emergency services may meet the fuel requirements of these places. This blog will describe the various aspects of how container fuel stations are altering the traditional concept of fueling flexible, cost-effective, and eco-friendly choice to conventional fuel infrastructure. These aspects include container fuel station designing and utilization, benefits, and the impact of container fuel stations on industries-wells of the reasons why container fuel stations are rapidly growing and intimidating to set the future for mobile fuel solutions.

Understanding Container Fuel Stations

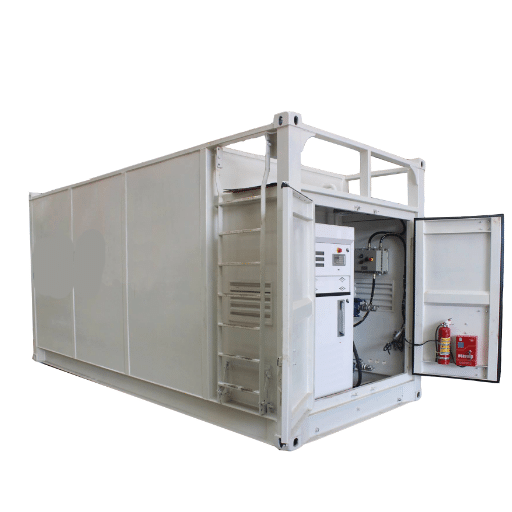

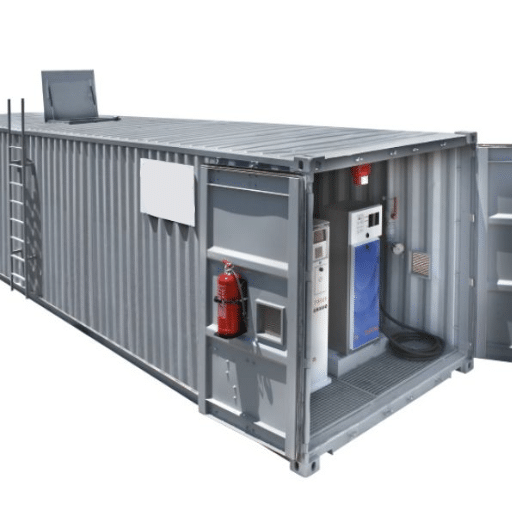

Container fuel stations are self-contained mobile units capable of storing and dispensing fuel with efficiency. They are designed using sturdy materials to ensure safety and longevity, including features like spill prevention systems and convenient points to get fuel. It is a turn-key station that requires far less infrastructure development. An excellent solution for industries and locations that need reliable fueling options, the station is placed at construction sites in remote areas or used for relief work in disaster zones. Being mobile makes them cost-efficient, thus serving as a practical alternative to permanent fuel stations.

What is a Container Fuel Station?

The container fuel station, a temporary self-sufficient fueling system, is efficient at storing and dispensing fuel at various locations. Such stations are generally built with materials that ensure their durability, such as steel, so as to conform to environmental and safety codes. A typical container fuel station, on the other hand, may be equipped with a double-walled storage tank to prevent leaks, a very accurate fuel management system for monitoring purposes, and some firefighting or emergency response equipment in case of any hazards.

Container fuel stations are used in construction, agricultural work, mining, and logistics, particularly at remote sites or temporary setups where access to traditional fuel infrastructure may be limited. For instance, a 20-foot container fuel station usually carries anything from 10,000 to 26,000 liters of fuel, depending on the specific model, while its larger counterpart of 40-foot systems facilitates capacity well over 40,000 liters. This freedom has given companies the flexibility of scaling their operations according to their work and needs.

The container fuel station is now also able to offer advancements such as automated fuel dispensing systems, user authentication through cards, and a digital monitoring system integrated with cloud platforms that provide real-time updates on their status. The combination of these features enhances the convenience and security while at the same time minimizing fuel theft and inventory discrepancies. Essentially, container fuel stations constitute mighty cheap and multipurpose solutions, especially for refueling operations in arduous environments.

Benefits of Using Container Fuel

Compared to traditional methods of fueling, containerized fuel stations obtain significant cost advantages. According to recent reports published by industrial agencies, a modular station setup could reduce initial setup costs by up to 50% since it does away with the necessity for excessive construction and infrastructure. Being of modular-type construction, such stations also have lower maintenance costs, simply because their servicing and inspection are easy.

Portability stands out as a most wonderful advantage of containerized fuel stations. These stations are easily transported and installed in remote or temporary locations like construction sites, mining operations, and disaster relief work- perfect for an industry that must remain on the move without compromising on fuel availability.

Modern containerized fuel systems are designed considering safety and environmental sustainability. Tank installers consider double-walled tanks to reduce spillage, while vapor recovery systems help cut down on emissions. It ensures that they meet stringent environmental laws, thus curbing the ecological footprint of fueling operations.

With modern digital features, container fuel systems are being turned into IoT-enabled ones. Fuel levels, consumption patterns, or other operational metrics can be measured in real-time and tracked through cloud-based software. Such a level of monitoring could help manage resources better and less in wastage.

Preventing theft is one of the highest-profile advantages. The incorporation of today’s smart security cryptocurrencies, such as biometric authentication or radio-frequency identification (RFID) tracking, has reduced fuel theft cases by up to 30%. Also, keeping accurate digital receipts of dispensing fuels provides accountability to the entire operation.

Unlike usual setups, container fuel stations just want a bit of site pre-preparation and can stand fully ready to operate in days. This modular nature offers limitless customization options, which can include features like integrated payment terminals, automatic dispensers, or solar-powered units for off-grid locations.

Thus, with cheapness, adjustability, and cutting-edge technology thrown in the mix, container fuel solutions are all set to transform industries in their handling of fuel-furnishing issues, offering a reliable and efficient alternative solution irrespective of location or environment.

Types of Container Fuel Stations

Container fuel stations come in many types, depending upon operational or industry need. Below are the most common types, along with their features and advantages:

These are very flexible and mobile units that can serve temporary construction sites, mining operations, remote locations, etc. Tank reinforcement is provided along with fuel dispensing equipment that is of high quality to offer a quick and efficient fulfillment unit. A portable design means less downtime when relocating from one site to another, and many models comply with environmental standards by way of counteracting any spills.

Present in urban and retail settings, self-service container fuel stations present automated payment systems for the sake of convenient use and operational efficiency. Typically, such stations mount high-level monitoring systems that would keep tabs on fuel levels and consumption, thereby ensuring timely refills and minimal downtime. Market studies interested in consumer preferences reveal that demand for self-service stations has been enjoying increased growth because of their cheap operational model and ease of use.

If the areas lack stable power grids, this on-the-fuel-station setup would use solar panels to power the dispenser and monitoring equipment. With low operating costs and environmental friendliness, they make a good choice for rural areas and industries concerned about ecology. Reports have it that the solar-powered container stations have on a rise of more than 25% in recent couple of years; this, of course, is proof of the worldwide change towards sustainable energy solutions.

Large-scale operations that are, for instance, shipping ports or logistics centers, by definition, will maintain massive tanks whose capacities can vary from 30,000 to 50,000 liters and above. Equipped with a high-tech fuel management system that allows specific considerations of fuel delivery and consumption, such stations are indeed built to scale on an industry basis from sustained, large-scale fuel demand requirements.

With multi-source energy trends gearing in, multi-fuel container stations are meant to serve as storage and distribution for fuels such as diesel, gasoline, and even diesel alternatives oil or ethanol. They give businesses the opportunity to adjust to the days to come with fuel requirements and environmental laws.

Every variety of container fuel station works toward fulfilling different market demands in terms of operational efficiency, safety, and compliance with environmental regulations, thus positioning these stations as a top choice in modern-day fueling infrastructure.

Mobile Fuel Stations: A Growing Trend

The convenience of mobile fueling, the mobile station offers traveling flexibilities-it can serve even the most remote, underserved areas. These stations are fully packed, transportable units that are meant for fast deployment to cater to different consumer needs. The primary benefits are less time for installation, cheaper installation cost over conventional to fill infrastructures, and not fixed to any site. The stations were worked on to comply with all safety and environmental standards, and hence be a perfect solution for today’s fuel needs.

What is a Mobile Fuel Station?

Being a self-contained fueling unit, the mobile fuel station presents a fuel dispensing solution that is efficient and flexible, provided at the chosen locations. Usually, they consist of a storage tank-fuel pump system coupled with the POS system and other necessary components, all incorporated in a very compact, transportable system. These stations are designed to satisfy other locations where traditional fueling infrastructure would be unwelcome, if not infeasible, such as central places, construction sites, plots, or temporary events.

The mobile fuel station has become the paramount of convenience and adaptability. Analysis shows that the global market value for mobile fuel stations is slated to have a major surge in the coming years as demand for flexible fueling solutions increases. Their attractiveness is enhanced by innovations such as digital payment, monitoring technologies, and environmental regulations. The mobile fuel installations have storage capacities ranging between 10,000 and 30,000 liters, depending on the type of mobile fuel station design, while the fuel stored can be gasoline, diesel, or even alternative fuels such as CNG and LNG.

The safety and environmental standards are keenly adhered to in mobile fueling operations. Safety measures are somewhere in between and include such things as spill prevention systems, fire suppressors, and leak detection techniques. Through these instruments, mobile fueling units offer the potential to become a reliable and sustainable option for modern fueling needs in developing as well as developed regions. Together with being economical and swift to set up, these services provide a solution to the accessibility of fuel, making them one of the most important technologies in the energy sector.

Advantages of Mobile Fuel Solutions

Mobile fuel solutions have numerous effects that coincide with the ever-growing needs of global fuel distribution. The primary advantage would be their cost-efficiency, wherein mobile units can be said to reduce heavily on logistics and storage costs for traditional stations. Research indicates that mobile fueling stations may reduce costs of operation by at least 30% due to lowered infrastructure requirements and maintenance compared to a fixed station.

The other important advantage lies in deployment flexibility. Mobile fuel stations can be deployed in remote or underserved locations, thereby granting vital access to fuel where traditional stations are not feasible. Mining, construction, and agricultural industries are examples that utilize on-site fueling services extensively, and it saves on time and productivity for the transporters, which otherwise would have to be extinguished in traveling to a stationary fuel station.

In the same way, the integration of environmental safety features with mobile fueling solutions continues to increase such hazards. Most mobile fueling operations include a potential spill containment system together with vapor recovery and other automatic controls that reduce environmental risks. From reports, such arrangements have proven capable of reducing fuel wastage by another 15% and further reducing emissions toward sustainability.

In the same spirit, mobile fueling ensures supply chain resilience. Although an emergency or natural disaster occurs, mobile units can go to the critical location and provide fuel to ensure the provision of services. For instance, these mobile fuel solutions were instrumental in responding to disasters caused by hurricanes in the U.S. by delivering fuel without delay to emergency responders and the affected communities.

It is indeed obvious that the whole range of considerations allied with mobile fuel solutions turns them into a progressive innovation meeting contemporary expectations for convenience, efficiency, and environmental responsibility. In an ever-changing energy sector, at such a temporal point, these solutions are already setting pathways towards the viability of fuel accessibility anywhere in the world.

Applications of Mobile Fuel Stations

Mobile fueling stations distribute and supply fuel for crucial uses across a myriad of sectors and situations. Another notable area of use is disaster relief operations. When a natural disaster happens-hurricanes, earthquakes, floods-mobile fuel stations allow emergency responders to purchase fuel unhindered, enabling the conduct of rescue operations and, in turn, fuel essential machinery, e.g., generators. For example, in some disaster-prone areas, mobile fueling allows operational downtime to be reduced by up to 30%, keeping critical services up and running.

Other important uses are those in remote locations and underserved areas where there is either sparse fuel service or none at all. Mobile fuel services deliver fuel to agricultural zones, mining operations, and rural communities, considerably supporting industries that require the constant supply of energy. After all, mobile fueling services have made mining processes more efficient by cutting down the long fuel commutes and producing an estimated 15% cost savings.

The other key area is supporting the rise in commercial fleet fueling; these mainly account for logistics and delivery companies. With an increase in e-commerce, mobile fuel stations have been used to refuel vehicle fleets on-site, cutting down downtime and promoting greater operational efficiency. Studies assert that this activity boosts delivery efficiency by over 20%, as it cuts down vehicle idle times and creates shorter delivery routes.

Finally, mobile fuel stations offer support to green initiatives through alternative fuels like biodiesel and electric vehicle charging solutions. They thus become adaptable enough to be embedded into initiatives for sustainable energy, hence paving the way towards an eco-friendly fuel delivery system that seeks to further carbon reduction on a global scale. These diverse applications demonstrate the gradually evolving use of mobile fuel stations in a wide variety of settings and industries.

Specifications of Container Tanks

Key Technical Specifications

Container tanks are designed to provide safe storage and transport for different types of fuel or liquid. Some key specifications include:

- Material: Generally made out of stainless and carbon steel to make them strong and ensure their resistance to corrosion.

- Capacity: Can range between 500 and 10,000 gallons, depending on application.

- Dimensions: The dimensions are standard and designed for transport, including compatibility with ISO shipping container sizes.

- Safety Features: Safety features include pressure relief valves, leak detection systems, and fire-resistant coatings.

- Portability: Tanks are portable, with reinforced frames and lifting lugs to allow easy handling and relocation.

- Compliance: Should comply with international standards in fuel storage and transport, such as ISO, ADR, and IMDG.

These specifications make container tanks versatile, reliable, and applicable in many industries and applications.

20ft and 40ft Container Tanks

| Feature | 20ft Container Tank | 40ft Container Tank |

|---|---|---|

| Capacity | Up to 26,000 liters | Up to 50,000 liters |

| Material | Stainless Steel with ISO Frame | Stainless Steel with ISO Frame |

| Safety Features | Pressure relief, thermal insulation | Pressure relief, thermal insulation |

| Applications | Small to medium operations | Large-scale industrial operations |

| Transport | Standard shipping compatibility | Standard shipping compatibility |

A 20ft and 40ft container tank are standardized to be stored and transported bulk liquids, and hence these container tanks are from the list of most hired containers for industries such as fuel distribution, chemicals, and the food-processing industry. They have been built using robust stainless steel and have been enfolded in an ISO frame to ensure durability and protection during transit.

Capacity versus versatility: 20ft tanks usually accommodate a maximum of 26,000 liters, whereas 40ft tanks can store approximately 50,000 liters to cater to different transportation and storage requirements.

Safety: Both sizes meet international safety and transport regulations, i.e., ISO, ADR, IMDG. They provide pressure relief and thermal insulation for safe operation.

Cost-efficiency: They optimize logistics as they secure high volumes in very little area, forcing costs down for shipping and storage.

Applications: Their adaptability suggests use in the transportation of liquid fuels, water, chemicals, and edible oils.

Container tanks are aesthetically engineered to maximize efficiency, safety, and convenience, and will always be a most crucial asset in the global supply chains.

Double Wall Tanks: Safety and Compliance

A double-wall tank is equipped with two layers of containment to maximize safety and conform to strict environmental standards. The primary tank holds the liquids or substances, whereas the secondary layer serves as a backup to hinder leaks or spills if the primary is damaged. Such tanks allow federal and state laws to be followed, such as EPA-type regulations, that require hazardous and non-hazardous liquids to be securely stored.

Some major safety features include the use of corrosion-resistant materials, leak detection systems, and a structure able to withstand technical risks prevalent in tough industrial settings. Double-wall tanks are, in turn, imperative in chemical, fuel, and wastewater industries that render safe handling of materials while protecting the ecosystem around them. Their design minimizes environmental impact and limits liability risks, making them an assurance for secure long-term storage and conveyance.

Portable vs. Stationary Tanks

| Aspect | Portable Tanks | Stationary Tanks |

|---|---|---|

| Mobility | High – Designed for frequent relocation | Low – Fixed permanent installation |

| Capacity | Smaller capacities for easy transport | Higher storage capacities |

| Applications | Temporary operations, emergency deployments | Industrial plants, manufacturing facilities |

| Construction | Durable materials for frequent handling | Reinforced walls, secondary containment |

| Cost | Lower initial investment | Higher upfront cost, long-term value |

Choosing between a portable and a stationary tank depends largely on the specific uses and operational considerations. Portable tanks are versatile and made with mobility in mind. Hence, they are used for temporary storage or movement of liquids during the set-up of operations or other activities such as emergency deployments. Portable tanks usually have smaller capacities and are made of durable materials to resist frequent handling and hard movements.

Stationary tanks, however, are designed for long-term use in fixed locations and generally offer higher storage capacities. They are commonly found in industrial plants, agricultural facilities, or manufacturing plants for the standard storage of chemicals, fuels, or water in a secure environment. These tanks are built to stand the test of time and often have reinforced walls or a secondary containment system for safety and environmental compliance.

It would then depend on the storage capacity, mobility requirements, and legislated conditions, with the user’s choice being between portable and stationary tanks. Both, however, present their own advantages for different operating circumstances, thereby providing for safe and efficient fluid management.

Choosing the Right Supplier for Container Fuel Stations

Prioritize fuel container station manufacturer/supplier businesses with experience and a good track record in reliability. This should include the suppliers incorporating safety and environmental parameters during their designs and manufacturing. The suppliers should be able to offer customization to suit your specific operational requirements and full support, including installation, maintenance, and after-sales service. You might also want to consider suppliers with transparent pricing and good communications to pave the way for an easy and trustworthy collaborative process. Reliable certifications and good customer reviews will greatly enhance the credibility of the supplier as well.

Criteria for Selecting a Reliable Supplier

Upon strict examination of these criteria, in favor of the companies, suppliers who better align with their strategic goal, help reduce risk, and support long-term partnerships should be selected.

Top Suppliers in the Container Fuel Market

The container fuel market is supported by some name players leading through innovation, global reach, and reliable services, including the likes of:

Shell is a world energy giant with expertise in all marine fuels, including low-sulfur fuel oils and LNG. The company has a vast and robust supply infrastructure that covers over 700 ports worldwide, allowing for the timely delivery of fuels to vessels while complying with strict environmental regulations. Shell practices sustainability through its development of carbon-neutral and low-emission fuels, positioning them at the forefront as an industry leader.

BP Marine offers a full spectrum of fuel solutions, including VLSFO (very low sulfur fuel oil) and Marine Gasoil, with strategic stations at main shipping hubs, ensuring the tempo of high-quality supplies. Its R&D focus has given rise to digital tools and analytics to maximize fuel efficiency for clients worldwide.

Chevron commands a special portfolio for marine fuels and lubricants. The company is servicing numerous ports and providing expert services, which include technical support and operational advice. The advanced cutting-edge technological mix of the company and a commitment to finding cleaner energy solutions help lower emissions while maintaining the performance standards of vessels.

TotalEnergies is one of the primary figures in fueling container ships, offering a number of fuel options, such as LNG and biofuels. By creating bunkering lines all over the world, the company caters to operators in flexibility and efficiency. TotalEnergies pursues the energy transition very actively; it tries to align its operations with all decarbonisation efforts worldwide.

The ideal marine fuels for the varied vessel types range between F-1 to F-2 fuel oils, with an allowable sulfur content of not more than 0.5 percent as dictated by IMO 2020. ExxonMobil has one premium product named EMF.5 to cover this spectrum. It has a wide global network with seamless delivery across ports worldwide. ExxonMobil also supports sustainable shipping through R&D in options for future fuels and technologies for advanced lubricants.

By leveraging the expertise, commitment to quality, and environmental responsibility of these suppliers, companies in the container fuel market can better maximize their business operations while meeting ever-evolving industry requirements. The constant push for innovation in and by these key players once again highlights their capability to shape the future of shipping and sustainable energy solutions.

Cost Considerations and Budgeting

Since companies have to address the issue of operational efficiency versus sustainability, cost management becomes quite crucial in the containerized fuel trade. Fuel price fluctuations are something the shipper must consider at all times since shipping budgets are significantly affected by the changes. Industry analysts recently asserted that prices of low-sulfur fuels have remained volatile due to global supply chain disruptions, with an increasing push for decarbonization. For example, very low sulfur fuel oil (VLSFO) prices are between $600 and $750 per metric ton, depending on regional availability and demand.

Budgeting for alternative fuels, such as LNG or biofuels, has to be done carefully since, while they carry higher capital costs up front, these options promise savings from better fuel efficiency and lower environmental penalties. Investments in lubricant technologies and ship retrofitting can contribute to the objectives of low fuel consumption and extend the engine life, thereby cutting the overall cost.

Regulatory compliance costs should also be considered by companies, including the implementation of IMO 2020 requirements, carbon tax, or emission reduction technologies such as scrubbers. Such costs need to be forecasted and planned for financially. Further, companies should consider environmental objectives and cost reduction opportunities when budgeting by embedding advanced analytics and predictive tools to forecast trends.

Mobile Gas Filling Solutions

Through an onboard system into the tank, the mobile gas-filling services may be considered a matter of convenience for the customer who requires fuel. For a service such as this, no individual or business needs to proceed to the traditional gasoline station. This saves the time of the people involved and eliminates logistics issues. They are set up to meet safety and environmental guidelines to ensure safe practices in handling with minimal environmental impact. Due to their modified working hours, as well as the possibility of refueling at the site through mobile gas filling, the types of consumers served by individual mobile gas filling services are increased; for businesses, the mobile refueling methods improve operational efficiency.

How Mobile Gas Filling Works

Mobile gas filling services run through a network of specialized fuel delivery trucks equipped with advanced dispensing systems. Customers may order refueling through a mobile app or website, so they specify their location, vehicle details, and fuel type. As soon as the request is placed, the system dispatches a fuel truck to that location. Upon arrival, safety checks are performed by the operator, and the operator either supplies fuel to the vehicle or to tanks of storage tanks. These systems are well equipped with metering precision for accurate delivery of the right quantity and strictly comply with safety and environmental regulations. The streamlined procedure eliminated the need for visits to traditional gas stations, providing a refuel option that is convenient, fast, and secure.

Regulatory Considerations for Mobile Gas Stations

Some of the pre-licensing and other regulatory considerations I consider include all local, state, and federal regulations about fuel transportation, storage, and dispensing. Concretely speaking, this means environmental protection regulations preventing spills or leaks, equipment safety certification, and all required permits. I keep up with changes to new or evolving regulations around hazardous materials so that the business continues to be fully compliant while offering trustworthy and safe service.

Future Innovations in Mobile Fuel Technology

Emerging Technologies Shaping the Future

Being driven by sustainability factors, automation, and energy efficiency, the mobile fuel technology sector is witnessing its time of development. Renewable fuels, especially biodiesel and hydrogen, serve as alternative yet key innovations to cut down on carbon emissions and thus support environmental applications. More automation is thus aimed at creating smoother operations and providing real-time analytics to both operators and customers, with AI-based fuel management and app monitoring being good examples. Besides supporting the needed infrastructure for electric vehicles, more compact mobile EV charging stations stand to be developed. These changes promise efficient, safe, and greener mobile fueling solutions catering to today’s needs.

Conclusion

Container fuel stations represent a revolutionary shift in the fuel distribution industry, offering unparalleled flexibility, cost-effectiveness, and environmental responsibility. As industries continue to evolve and adapt to changing operational demands, these mobile fueling solutions provide the perfect balance between functionality and mobility.

The diverse range of container fuel station types, from mobile units to solar-powered systems, ensures that there’s a solution for every operational need and environmental condition. With significant cost savings of up to 50% compared to traditional infrastructure, reduced fuel theft by 30%, and the rapid deployment capabilities, container fuel stations are positioned to transform how industries approach their fueling requirements.

As we look toward the future, innovations in automation, renewable fuels, and digital monitoring systems will continue to enhance the capabilities and efficiency of these mobile solutions. For businesses seeking reliable, flexible, and sustainable fueling options, container fuel stations offer a compelling alternative that meets the demands of modern industry while supporting environmental sustainability goals.

Reference Sources

“Design and Development of Secure Fuel Storage Container with E-Fuel Delivery”

“Safety Analysis of Hydrogen Leakage Accident with a Mobile Hydrogen Refueling Station”

Frequently Asked Questions (FAQs)

The Container Fuel Station: What Is It?

A container fuel station is a storage and dispensing idea that is housed in a structure that is portable and modular, capable of serving various types of fuel, including petrol or diesel. The fuel stations are portable across locations and can be installed easily, accommodating a few locations to get temporary or remote fuel requirements.

How Does a Portable Gas Station Work?

A portable gas station works on a self-service basis, where a user can pump fuel into the vehicle using a fuel dispenser. The dispenser operates with a control system that externalizes the safe and efficient transfer of fuel. Generally, it is built using explosion-proof materials for operational safety.

What Equipment Is Inside a Container Gas Station?

A container fuel station includes essential gas station equipment such as fuel dispensers, tank gauges, and level monitoring systems. It may include other premium products such as LPG dispensers or AdBlue equipment to accommodate different fuel requirements.

Are Container Fuel Stations Suitable for Freight Operations?

Yes, container fuel stations are suitable for freight operations as they can be located along highways or railways for easy access. They provide dependable petroleum products for trucks and other vehicles to ensure smooth transport logistics.

What Are the Advantages of Using Mobile Filling Stations?

Some of the advantages of mobile gas filling stations are their ease of installation and flexibility in terms of location. The stations can be quickly deployed into different environments and provide fuel access to remote areas or in emergencies.

How is Fuel Loaded and Unloaded in a Container Fuel Station?

Fuel loading and unloading at a container fuel station are done by using specialized equipment, such as cranes or pumps. The operations have been developed considering the utmost efficiency; however, spills must be avoided at all times, and all measures must be followed in compliance with all regulations concerning petroleum products.

What Types of Fuels Can be Dispensed at a Container Gas Station?

A container gas station is capable of dispensing any kind of fuel, from petrol, diesel fuel, and LPG. Sometimes, the station may provide other services, for instance, AdBlue dispensing for diesel vehicles, thus making them useful for various automotive purposes.

How Do You Ensure High Security in a Portable Fuel Station?

High security at a portable fuel station is ensured through the implementation of advanced control and surveillance technologies. These methods monitor all fuel transactions and provide a strong shield against any unauthorized access, thereby securing the fuel supply and the safety of customers.

What are the Investment Expenditures in Setting Up a Container Fuel Station?

There are investment expenditures for setting up a container fuel station. These cover the container itself, fueling equipment, installation, and the first supply of fuel. Additional expenses may include requirements for approvals from local regulations and safety for the fuel station.