Fuel dispensing equipment, in a way, really powers industries, transportation, and, indeed, the daily operations that occur across the globe. It is essential to have sound, reliable systems whenever you manage fleets, operate a fuel dispensing station, or coordinate industrial fueling needs—ensuring smooth execution. This article delves into the global realm of high-tech fuel dispensing systems, examining new developments and innovations in their design and operation, and how these advancements enhance fuel management. From a technological standpoint, there is considerable potential to capitalize on, along with significant safety improvements, ensuring that these systems continue to evolve for the benefit of both businesses and consumers. Follow along as we discuss the factors that make the best fuel dispensing solutions stand out from the others.

Understanding Fuel Dispensing Equipment

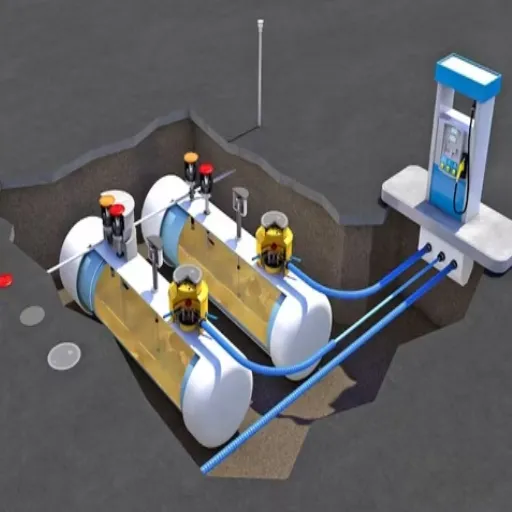

Fuel dispensing equipment includes all tools and systems used for the safe and efficient transfer of fuel from a storage tank to a vehicle or any other machinery. Generally, these include pumps, hoses, nozzles, and meters to initiate, stop, and measure the quantities of fuel discharged. Today, fuel dispensers are made with digital interfaces, automated controls, and safety devices to improve their ease of use and accuracy. Designed to meet industrial acceptance procedures, these systems ensure precise fueling with minimal wastage and compliance with safety regulations, making them essential for both businesses and consumers.

What is Fuel Dispensing Equipment?

The term “fuel dispensing equipment” encompasses all systems and devices designed for the efficient and safe transfer of fuel from storage tanks to vehicles or other machinery. Contemporary fuel dispensers are equipped with advanced technology, including metering systems, electronic payment docks, and software that tracks fuel use and related transactions. This means that many fuel dispensers are currently equipped with flow meters that measure fuel with an accuracy of +/-0.5%, thereby rendering fuel deliveries precise and minimizing errors. Globally, trends are also moving toward more environmentally friendly features, such as vapor recovery systems used to reduce harmful emissions during the refueling process.

Based on industry analysis, the market for fuel dispensing equipment is projected to experience a compound annual growth rate (CAGR) of approximately 5-6% in the coming years, driven by increasing fuel consumption and technological advancements in dispensing systems. Key developments are observed in sensing applications and the Internet of Things (IoT), where their usage enables real-time monitoring and predictive maintenance, thereby minimizing downtime and maximizing operational efficiency. With the aforementioned features and capabilities, fuel dispensing equipment plays a crucial role in advancing the distribution of transportation, logistics, and energy infrastructure on a global level.

Types of Fuel Dispensers

Fuel dispensers are generally classified into various types based on their function and compatibility with different types of fuel. The main ones are:

Standalone Dispensers – Considered the most basic type of fuel dispenser, they are typically used in smaller fuel stations or facilities. These function independently and dispense fuels such as gasoline, diesel, or kerosene without advanced monitoring or control systems.

Multi-Product Dispenser (MPD) – Allows for the dispensing of multiple fuel types from a single installation. These innovatively modern stations thereby save on real estate space while offering their customers an option of different fuel grades.

High-Flow Dispensers – These are designed for commercial and industrial purposes, serving vehicles that require large volumes of fuel, such as trucks, buses, or heavy equipment, and are therefore designed to deliver fuel at a much faster rate than conventional dispensers.

Alternative fuel dispensers – This category encompasses dispensers for alternative energy sources, including compressed natural gas (CNG), liquefied petroleum gas (LPG), and electric charging stations. They are increasingly being marketed as contributors to sustainable transport.

Smart Fuel Dispensers – Integrated with IoT technology and advanced sensors, these fuel dispensers enable real-time monitoring, payments, and analytics. These systems provide greater convenience to users and improve operational efficiency for fuel station operators.

Each type performs specific duties to provide maximum flexibility and adaptability for various industries and applications.

Key Components of Dispensing Equipment

Dispensing equipment comprises several essential components that have ensured precision, efficiency, and quality in various applications. The following are some of the key elements, along with their functions and significance.

Pumps and Actuators: The dispensing equipment operates by transferring accurately measured quantities of liquids, gases, or chemicals using pumps and actuators. Actuators are responsible for controlling the movement of the dispensing mechanism, ensuring consistent output in terms of volume dispensed or time duration. Recently, electric actuators have gained prominence, as they allow for a greater degree of precision, thereby reducing output waste and maximizing operational efficiency.

Nozzles and Valves: While nozzles control the flow and distribution of the material being dispensed, valves must bear the task of on/off flow control under harsh working conditions with utmost accuracy. These new-age designs of nozzles, such as multi-pattern or automatic types, see wide applications ranging from fuel dispensing to industrial adhesive dispensing, among many others. Researchers have found that optimizing the flow in new-age nozzles leads to a 15% reduction in material wastage.

Sensors and Flow Meters: These sensors maintain an internal parameter monitoring system, which counts temperature, pressure, and flow rate, among several other sensorial values, for safe operations. Flow meters complement the sensors in measuring the actual quantity of material dispensed. The innovations in ultrasonic and turbine flow meters, which reduce the error margin to within 0.5%, have contributed significantly to accountability enhancement in sensitive industries.

Control Systems and Interfaces: Advanced dispensing systems were the fusion of a control interface for monitoring or operating the machine. The interfaces ranged from straightforward analog panels of display to very sophisticated touchscreens coupled with IoT connectivity. With cloud-based systems in place, operators can access data remotely, improving response times and enabling predictive maintenance.

Housings and Frames: The structural or framework components of dispensing equipment provide a secure and durable base for the system. Modern materials, such as stainless steel and reinforced polymers, enhance longevity and compatibility with corrosive or hazardous materials. Studies show that in harsh environments, stainless steel housings have a 30-40% longer equipment life.

Automation and Integration through Robotics: Many dispensing systems now incorporate robotic arms or automation to perform precision tasks. With such integration, dispensing could be carried out quickly, repeatedly, and with high precision in manufacturing or healthcare applications. A report on robotics in dispensing points indicates an operational time reduction of more than 20%, accompanied by increased accuracy.

Together, these ensure that modern dispensing equipment meets the needs of various applications, ranging from healthcare to food service, transportation, and manufacturing. Using advances in design and technology, these systems have become even more durable, accurate, and efficient.

The leading choice of fueling equipment

Due to their inherent reliability, precision, and speed, modern fueling equipment consistently ranks as the top choice among fueling systems. The apparatus is designed to ensure that fuel is delivered safely and accurately in the demanding applications of transportation, aviation, and fuel retail. Features include advanced flow control, mechanisms to prevent leaks, and simple-to-use interfaces, making it a highly trusted solution for these applications.

Top Brands in Fuel Dispensing Equipment

Tokheim: In the fuel equipment sector, Gilbarco Veeder-Root boasts heavy recognition. By focusing on technical innovation for reliability, the company has provided tailor-made solutions to petroleum stations, convenience stores, and retail outlets. Such dispensers are advanced in that they offer secure payment processing, comply with EMV standards, and enable data analysis for enhanced operational efficiency and security. For Gilbarco, trusting a product means that it is well-proven and durable in the markets.

Tokheim: Tokheim is a world-renowned supplier of fueling systems and related equipment for gas stations. Its fuel dispensers are manufactured using precision engineering and modern technology to deliver fuel with extreme accuracy. Additionally, Tokheim has developed fuel station management software solutions that enable operators to manage their operations efficiently using real-time data. A focus on sustainability and energy efficiency keeps the brand at the forefront of industry innovation.

Wayne Fueling Systems: A leader in fuel dispensing technology, Wayne Fueling Systems is committed to environmental solutions for fuel dispensing. Wayne dispensers are designed to minimize fuel loss and vapor emissions, which makes them eco-friendly. The company also prioritizes customer convenience, incorporating wireless payment systems and interactive user interfaces. All of these bring innovations that place the company among the favorites in the field of fuel dispensing equipment.

Bennett Pump Company: With over a hundred years of existence, the Bennett Pump Company is renowned for its dependable and customizable fuel dispensers. Among its offerings are products for retail, commercial, and fleet fueling applications. Bennett distinguishes itself by producing equipment that can be used for alternative fuels, such as E85 and Biodiesel, thereby meeting the new demands created by the transportation industry.

Piusi: Piusi is a company that makes fuel dispensing equipment designed for versatility and performance, especially outside the retail setting (e.g., agriculture and construction). Their compact, portable units ensure efficient fuel transfer in various locations. Piusi is gaining popularity for its durable and user-friendly products, particularly in areas where remote refueling options are necessary.

These brands represent the cutting edge of fuel dispensing innovation, forging ahead with reliability in design, technology implementation, and sustainability. Their vast product array meets the varied needs of both commercial and private users, while adapting to the changing trends in the industry and shifting energy requirements.

Innovative Features of Modern Fuel Dispensers

Thus, modern fuel dispensers come with technologies that are highly focused on enhancing efficiency, safety, and the end-user experience. The main features provide advanced metering systems for the actual dispensing of fuel, ensuring that fuel is neither wasted nor inaccurately billed to the consumer. In many of these devices, payment solutions were integrated, including contactless and mobile payments, which further facilitated transactions and eliminated the need for physical contact.

Other significant innovations include cloud-based monitoring and management systems. Such solutions allow operators to remotely monitor fuel usage, inventory levels, and receive real-time alerts for any maintenance issues that may affect operational efficiency. Furthermore, today’s fuel dispensers are increasingly designed with sustainability in mind and incorporate vapor recovery systems to reduce environmental impact by capturing and reusing vapors arising from the refueling process.

Some models utilize IoT technology for data analytics and predictive maintenance, enabling the prevention of failures and minimizing downtime. Dispensers today are often equipped with additional safety features, including emergency shut-off systems for hazardous situations, leak detection sensors, and the capability to dispense alternative fuels such as biodiesel, ethanol, and even hydrogen. These advancements ensure that modern-day fuel dispensers meet the growing demand of a dynamic energy market while complying with stringent environmental and safety regulations.

Comparison of Fuel Dispensing Solutions

Depending on the application, fuel types, and technological features, fuel dispensing solutions can vary significantly. Here follows a microscopic comparison of standard offerings:

Traditional Mechanical Dispenser: These systems are mechanical and therefore preferred for their durability and lower initial cost. They can be ideal for smaller fuel stations or locations where advanced digital systems may not be necessary. The absence of modern features, such as real-time monitoring and calibration, may, however, result in inefficiencies over time.

Electronic Dispenser: By incorporating data interfaces and advanced metering systems, these gas dispensers are designed for high-traffic fuel stations. Accuracy in fuel measurement, improved data logging, and integration with payment systems are among the key features. Several of these systems also offer the option to dispense alternative fuels, supporting green energy initiatives. They require comparatively greater investment, yet their operational efficiency and adaptability render these systems long-term solutions that can cater to the dynamic needs of the market.

Smart IoT-Enabled Dispensers: Intelligent dispensers are IoT-based technologies that enable remote management and provide real-time data analytics on their operations and the performance of the fuel stations. Some of their functionalities include detecting leaks, automatically sending maintenance alerts, and providing comprehensive reports for station operators. Although not inexpensive to set up, due to their ability to streamline fuel station operations and minimize maintenance costs, these dispensers prove to be financially beneficial and environmentally friendly.

By evaluating these different types of solutions, a business can determine the most suitable fuel dispensing system for itself, based on its budget, operational priorities, and commitment to sustainable development.

Fuel Types and Their Dispensing Requirements

Dispensing systems must be tailored to different fuels, taking into account safety, efficiency, and regulatory requirements. The significant types of fuel and their dispensing requirements are:

Gasoline: To ensure gasoline is treated safely, pumps must be highly sealed with vapor recovery systems to reduce emissions and prevent spills. Being highly flammable, pumps must certainly comply with safety standards.

Diesel: Diesel dispensing requires pumps with strong seals, hoses resistant to corrosion, and generally higher flow rates compared to gasoline, to accommodate vehicles endowed with larger fuel tanks.

Compressed Natural Gas (CNG): CNG systems utilize high-pressure dispensing equipment to transfer the gas safely and efficiently. Proper connections and pressure regulators are essential for their operation.

Electric Vehicle Charging: EVs are charged through charging stations equipped with connectors designed for a specific vehicle model. The charging speed depends on the charging level (Level 1, Level 2, or DC fast chargers).

Each fuel type has systems specifically designed for the safe and effective distribution, by environmental and safety parameters to be achieved.

Gasoline Dispensing Solutions

In recent times, the gas has attracted a multitude of buyers/drivers, which has led to the creation of new technologies for dispensing the product that optimize operations in terms of safety and compliance with environmental norms. This contemporary design of gasoline dispensing units is equipped with an environmentally friendly vapor recovery system, which minimizes emissions during refueling and thereby reduces air contamination. According to independent industry studies, the vapor recovery system can capture up to 95% of the harmful hydrocarbons released during fueling.

The provision of petrol metering utilizes electronic systems that ensure accurate metering, with an accuracy of 99.5% or more, thereby providing the correct measure to the customer. Maximally, such dispensers now offer a user interface for security, integration for payments, and remote monitoring capabilities. While the operator is alerted for maintenance checks, this innovative technology ensures reduced downtime.

According to the data, global gasoline consumption is closely tied to regional fuel economy standards and the growth of alternative fuel sources. With over 1.4 billion vehicles worldwide, gasoline dispensing systems are considered a critical infrastructure element in transportation networks.

Diesel and LPG Dispensing Equipment

Diesel and LPG (Liquefied Petroleum Gas) dispensing equipment would undoubtedly enable the fueling of various industries, including transportation and agriculture. From a utilization perspective, various heavy vehicle systems, agricultural machinery, and industrial equipment benefit from diesel oil due to its greater energy efficiency and improved engine reliability. Advanced diesel dispensing systems now feature high-flow pumps, enhanced filtration systems to protect engine performance, and digital metering systems for precise dispensing.

LPG, however, is becoming increasingly popular as a cleaner alternative to conventional fuels, with reduced carbon emissions and a lower environmental impact. The LPG dispensing equipment has undergone a transition in response to increasing demands, with a focus on safety, efficiency, and versatility. Modern-day LPG dispensers feature vapor recovery technology to minimize gas emissions and are equipped with safety features, including automatic shut-off valves.

Data highlights shifts in consumption influenced by regional policies and market demands affecting diesel and LPG. For instance, the global LPG market size was valued at approximately $130 billion in 2022 and is estimated to increase at a compound annual growth rate (CAGR) of 5% post-2030, owing to its increased adoption in the automotive and domestic sectors. Concurrently, there is significant diesel consumption, with regions such as Europe and the Asia-Pacific accounting for large shares due to their reliance on commercial transport and industrial activities.

Innovative fuel dispensing systems for these two fuel types are thus essential to navigate the crossroads posed by the ongoing energy transition while further supporting sectors that depend on it.

Hydrogen and Compressed Natural Gas Dispensing

Hydrogen and Compressed Natural Gas (CNG) have become increasingly viewed as cleaner alternatives to fossil fuels, and they therefore play a significant role in the global transformation of the sustainable energy system. Hydrogen dispensing systems are crucial to supporting the continued growth of FCEVs globally, with tremendous investments being made in hydrogen infrastructure. The industry’s reports have stated that the hydrogen market will surpass $200 billion by 2030, and substantial resources will be allocated for the creation of efficient and scalable dispensing systems.

The use of CNG has broadly been adopted due to its greener status compared to diesel and gasoline, in addition to being more cost-effective. Currently, over 30 million vehicles powered by natural gas are in operation worldwide, with the Asia-Pacific and Latin America regions having the highest rates of adoption. Modern CNG refueling facilities are equipped with sophisticated safety features, pressure management systems, and rapid resupply capabilities to meet the demands of the rapidly expanding personal and commercial transportation sectors.

These two fueling technologies are thus evolving into hybrids, incorporating new technology that serves both hydrogen and CNG through hybrid dispensing systems. With such systems, cost efficiencies can be achieved, along with improved infrastructure utilization, making them desirable solutions for fueling stations transitioning to alternative fuels. Greater efforts are now being made to standardize, enhance safety, and expedite refueling to meet consumer needs and facilitate the widespread adoption of hydrogen and CNG technologies worldwide.

Installation and Maintenance of Fuel Dispensing Equipment

Keeping fuel-dispensing systems in good working order by proper installation and maintenance guarantees safety, efficiency, and the equipment’s long-term usability. During installation, it would be a breach of all regulations, safety principles, and manufacturer’s instructions to disregard any one of them. Certified professionals must perform installations to minimize the risk of problems arising during operation.

General maintenance will involve periodic inspections to detect any leaks or signs of wear and tear, while ensuring that the dispensing systems are properly calibrated to the required level of accuracy. When in use, servicing all components promptly will solve any malfunction issues and ultimately increase the average lifespan of the equipment. Keeping records on hand for inspections and repairs will help personnel identify trends of recurring problems, ensuring compliance with regulatory requirements. The extreme benefits of prioritizing preventive maintenance over correctness can translate directly to reduced downtime for systems and improved overall operational efficiency.

Best Practices for Installing Fuel Dispensers

Site Preparation: Before the installation begins, verify that the installation area complies with local regulations and safety standards. Remove all obstructions from the area and ensure the ground is level to provide a solid base for the dispenser.

Electrical and Plumbing Set-up: Engage professionals to establish electrical connections and underground piping systems. A critical consideration will be to ground the dispenser properly to avoid static discharge. Additionally, pipe systems must be checked for leaks before final installation.

Regulations with which to Comply: Become familiar with environmental, health, and safety standards (such as those for underground storage tanks and vapor recovery systems). Meeting these standards ensures operational safety into the distant future while avoiding costly penalties.

Calibrating the Equipment: For the efficient operation of the dispenser, calibration must be done first to ensure accurate measuring of fuel. This must be done using certified calibration tools and verified by the local authority, where applicable.

Testing and Quality Control: Conduct a thorough test of the fuel dispenser, including pressure tests, flow rate checks, and leak tests on all connections. Documentation must be maintained for the tests carried out for future use.

Ongoing Training: Provide training to installation crews and operating staff on correct usage, maintenance, and safety protocols. Awareness of operating procedures can considerably reduce misuse and mechanical failure.

Using the method mentioned above, a fuel dispenser installation can ensure safe, efficient, and fully regulatory-compliant operation, providing reliability and customer satisfaction.

Routine Maintenance for Optimal Performance

Routine maintenance ensures the efficient working condition of fuel dispensers, promoting safety and minimizing downtime. Thus, a planned maintenance schedule enhances the performance and extends the equipment’s lifespan. The following are some key points that one should consider when planning for routine maintenance:

Weekly Inspection and Cleaning: Visual checks should be done for leaks, worn-out seals, and damaged nozzles. For cleaning, an allowance should be made to ensure that dirt and debris do not interfere with the accurate readings of fuel flow. This applies to the cleaning of dispensers, nozzles, hoses, and even exterior surfaces. Having such clean dispensers would certainly enhance customers’ confidence in the product.

Calibrations of Flow Meters: The flow meters must be regularly tested and recalibrated to ensure their accuracy in measurement. Studies have shown that even minor deviations can result in significant financial losses and customer dissatisfaction. Calibration checks are required in most jurisdictions to be performed at least once annually for all flow meters. For dispensers, more frequent adjustments are necessary for those used more heavily.

Electrical Inspection: Electrical inspection encompasses all necessary work to detect and correct potential problems in wiring, control panels, or electronic payment systems before they impact normal function. Any faulty circuits or components that could cause system failure should be repaired immediately. Modern fuel dispensers equipped with IoT systems will automatically perform self-checks and alert operators when real-time electrical problems occur.

Filter Replacement: Fuel filters prevent debris and contaminants from being dispensed to the customer. Changing filters every six to twelve months, depending on the volume of fuel dispensed, maintains the present quality and protects the equipment from internal corrosion.

Keeping Software Updated: Contemporary dispensers often use software to control their automated features and report on their analytic data. Always keep the software updated for optimal functionality, security, and compliance with ever-changing regulatory requirements.

Safety Mechanism Testing: Safety features, such as the automatic shut-off system, vapour recovery unit, and emergency stop buttons, are to be tested periodically to ensure their proper functioning. A failing safety system poses a risk to both clients and staff.

Detailed Record Keeping: In the maintenance field, it is best to maintain detailed records regarding all maintenance, inspections, and repairs. One can document issues along with their resolution and then use this information to pinpoint repeating problems and work to enhance their operation method over time.

Incorporating a comprehensive maintenance schedule to cater to these critical components can essentially help reduce equipment failures and ultimately lead to enhanced customer satisfaction. For instance, studies have shown that proactive maintenance can save around 30% on total operational costs compared to reactive repairs. Investment in preventive maintenance should be strongly considered as one of the key approaches towards guaranteeing smooth and uninterrupted operation of fuel dispensers.

Common Issues and Troubleshooting Tips

Fuel dispensers are essential for smooth operations, but face numerous issues that can disrupt fuel delivery or cause inefficiencies. Below are the frequent dispensers’ problems and tips on how to effectively troubleshoot them:

Slow Fuel Flow: The most common complaint is slow fuel flow, which aggravates customers and delays service. Typically, clogged fuel filters or restrictions in the fuel line are the cause. Filters need to be checked and changed regularly, say every 6 months to a year, depending on usage. Monitoring sediment buildup in the storage tanks is also crucial, as it directly affects the flow rate.

Meter Errors and Calibration Issues: Incorrect fuel measurements can lead to inaccurate bills and revenue loss. Some studies indicate that calibration drift may occur gradually over time due to the wear and tear of the internal gears. For accuracy, meters should be checked and calibrated periodically, with the industrial recommendation being every three to six months or as dictated by local laws. It is therefore best to use Certified Calibration Equipment for proper measurement and adherence to standards.

Leaky Nozzles: A leaky nozzle indicates that it is worn out due to lost sealing and other issues, which waste fuel and could pose safety hazards. Check nozzles periodically for any signs of wear, cracking, or loose fittings. Replacement should be made with OEM parts to ensure compatibility and durability. Proper training of personnel to handle nozzles safely can also help reduce premature damage.

Display Errors: Faulty displays can pose issues for transactions, causing suspicions amongst customers. These arise from a myriad of causes, such as electrical issues, circuit board failures, or extreme weather conditions. In such situations, ensure that all connections are correctly made and protected, with damaged circuit boards replaced immediately. Regular cleaning of the displays, combined with weather-proof enclosures, may help prolong their lifespan.

Pump Motor Failures: The best possible moment to detect a fault in a motor supplying a pump is when it causes the pump to stand still. This can occur due to overheating, excessive running, or damaged bearings. A maintenance schedule that includes lubrication of the motor parts and online monitoring for unusual noises can help avert motor failure. On the other hand, many of the new motor systems also incorporate a thermal overload protection system, which shuts down a pump if it is approaching overheating and may cause damage.

Clogged Vapor Recovery Systems: Vapor recovery systems designed to minimize environmental impact are susceptible to clogging, which can adversely affect their performance. Ensure regular maintenance of these systems, which includes cleaning vents and filters to promote proper airflow. Following manufacturers’ instructions for inspection frequency and component replacement will provide better results.

Be proactive in troubleshooting and performing all necessary maintenance to minimize interruptions to operations. Keeping records continuously will highlight persistent problems, making it possible to target the purchase of parts and system upgrades to raise system reliability ultimately.

Future Trends in Fuel Dispensing Technology

The future of the fuel dispensing industry weighs heavily on sustainability, efficiency, and digital capabilities. Alternative fuel types are very much in trend nowadays, with EV charging stations and hydrogen fuel dispensers becoming increasingly commonplace as the global shift towards cleaner energies continues. Increased automation also ties into the innovative systems aspect, which integrates IoT for real-time monitoring, predictive maintenance, and greater operational efficiency. Payment options, such as mobile and contactless, are being incorporated and streamlined into the user experience. All of these factors contribute to the advancement of environmental issues and the evolution of consumer expectations.

Advancements in Fuel Dispensing Equipment

Fuel dispensing technology has experienced a recent surge in development to meet the growing demand for efficiency, sustainability, and an enhanced user experience. Among other things, modern dispensers incorporate increasingly sophisticated electronic systems for metering that grant utmost accuracy in measuring fuel, limiting losses on one hand, while ensuring that consumers and businesses are treated fairly on the other. These systems are made to comply with far more stringent global norms of fuel measurement and emission standards.

Notable modern improvements bring alternative refueling solutions, such as CNG and hydrogen fuel dispensing, to the forefront of construction, representing a step in line with the global trend toward green energy. Hydrogen dispensing, for example, now refills a car in less than five minutes, surpassing traditional gasoline pumps in refueling speed, and operates safely.

The smart fuel dispenser with IoT capacity is another advanced technology. These systems enable the real-time monitoring of dispenser performance using data collection and predictive analytics. They can identify faults and plan maintenance to minimize downtime and improve operational efficiency. Industry reports suggest that maintenance costs can be reduced by up to 30 percent for IoT-enabled dispensers, and system reliability could be improved by addressing issues before they impact mundane operations.

The customer’s user experience is being further improved by integrating contactless payment methods and digital interfaces. Payment and services will remain seamless for the user. For instance, some fuel stations can now connect to a mobile app, where customers can reserve a pump, monitor lubrication consumption, and access loyalty programs through their smartphone.

Fuel dispensing equipment serves as an umbrella term encompassing different devices for dispensing fuel into an automobile or for other purposes, of which there are several. Equipment for the dispensing of petrol must meet a range of requirements at the State level, in addition to other Standards, Codes of Practice, and regulations. This is intended to implement necessary controls aimed at ensuring measurement reliability, safety, pollution accounting, and customer protection, among other objectives. Fuel dispensing equipment is primarily the means through which fuel reaches the consumer. Hence, any technological advancement in this field cascades directly to the end-user. Equipping consumers with improved and more reliable equipment enhances the customer experience, safety, and fuel quality on the ground.”

Impact of Environmental Regulations on Dispensing Solutions

Since the subject of environmental regulations has been foisted upon the dispensing solutions, one that few considered, I choose to see it differently. In response to demonstrations for lower emissions and higher standards of fuel cleanliness, such regulations have driven the enhancement of dispensing equipment aspects of design and functionality. Features such as vapor recovery and sophisticated monitoring have now become standard, thereby significantly reducing environmental harm while ensuring compliance with regulations. In my opinion, these regulations protect the environment and also steer the industry toward a more sustainable and forward-thinking footing.

The Shift Towards Sustainable Fuel Dispensing

Green fuels received significant attention in response to the worsening environmental conditions and changing regulatory landscapes. For example, alternative fuels such as biodiesel, ethanol, and hydrogen are being integrated into fuel station infrastructure as part of a transition toward cleaner energy systems. In 2023, it was reported that revenue generated from alternative fuel-dispensing systems worldwide is expected to grow by more than 10% annually, driven by the widespread adoption of renewable energy policies.

Establishing EV charging stations and hydrogen refueling stations is a new-age element of fuel dispensing. In 2022, the International Energy Agency (IEA) emphasized that, since the number of vehicles surpassed 26 million globally, the subsequent need was for the rapid expansion of EV infrastructure. This transition has led to investments in ultra-fast chargers, charging stations powered by renewable energy, and smart grid integration, making these solutions convenient and efficient for consumers.

Moreover, these digital technologies also enable bright dispensers to optimize fuel management through real-time data analytics and predictive maintenance, thereby cutting costs while improving environmental responsibility. By harnessing alternative fuels, state-of-the-art technologies, and strict regulatory compliance, fuel dispensing is being steadily redefined for future applications in line with global sustainability goals.

Reference Sources

“Design and operation of the hydrogen supply chain for fuel-cell vehicles in Expo Shanghai 2010”

Frequently Asked Questions (FAQs)

What is fuel dispensing equipment, and how does it work?

Fuel dispensing equipment refers to the machinery and devices used at fueling stations to dispense various types of fuel, including gasoline, diesel, and alternative fuels like compressed natural gas and hydrogen. This equipment typically includes fuel dispensers, pumps, storage tanks, and dispensing nozzles, all designed to ensure the safe and efficient transfer of fuel to vehicles. The operation of these systems is crucial in retail fueling environments, where reliability and speed are essential to meet consumer demand.

What are the key components of a fuel dispenser?

A fuel dispenser consists of several key components, including the pump, nozzle, flow meter, and control system. The pump is responsible for moving fuel from the storage tank to the nozzle, where it is dispensed into the vehicle. The flow meter measures the amount of fuel being dispensed, ensuring accuracy in billing. Advanced fuel dispensers may also feature vapor recovery systems to minimize emissions and enhance environmental safety.

What are the advantages of using state-of-the-art fuel dispensing equipment?

State-of-the-art fuel dispensing equipment offers numerous advantages, including increased efficiency, reduced downtime, and enhanced safety features. Modern dispensers are designed to handle multiple fuel types and often incorporate advanced technology for faster transactions. Additionally, these systems can include features such as overfill prevention, which helps prevent spills and ensures compliance with environmental regulations.

How do equipment manufacturers ensure the reliability of fuel dispensing solutions?

Equipment manufacturers prioritize high-quality materials and rigorous testing to ensure the reliability of their fuel dispensing solutions. They often adhere to strict industry standards and guidelines, which include specifications for safety, performance, and durability. Continuous innovation in design and technology also plays a crucial role in enhancing the reliability of fuel dispensers, making them more resilient to wear and tear over time.

What types of fuel can be dispensed using modern fuel dispensing equipment?

Modern fuel dispensing equipment can handle a wide range of fuel types, including traditional gasoline and diesel fuel, as well as alternative fuels such as liquefied petroleum gas (LPG), compressed natural gas (CNG), and hydrogen. This versatility allows fueling stations to cater to a broader customer base and meet the growing demand for cleaner fuel options.

Which are considered the 10 leading fuel dispensing equipment manufacturers?

The 10 leading fuel dispensing equipment manufacturers include recognized names such as Dover Fueling Solutions, Censtar, Tatsuno Corporation, and Scheidt & Bachmann. These companies are recognized for their innovative designs, reliable products, and dedication to advancing fuel dispensing technologies, positioning them as top players in the global market.

What safety features are essential in fuel dispensing equipment?

Essential safety features in fuel dispensing equipment include automatic shutoff valves, overfill protection systems, and vapor recovery systems. These features help prevent spills, reduce the risk of explosions, and minimize environmental impact. Additionally, regular maintenance and adherence to safety regulations are crucial for ensuring the continued safety of these systems in retail fueling environments.

How does fuel consumption relate to fuel dispensing equipment?

Fuel consumption is directly related to the efficiency of fuel dispensing equipment. Accurate dispensing systems help reduce waste and ensure customers receive the correct amount of fuel, thereby supporting better fuel management practices. Additionally, advancements in technology enable more precise measurement of fuel flow, resulting in overall reductions in fuel consumption at the station level.

What are the benefits of using advanced dispensing nozzles in fuel dispensers?

Advanced dispensing nozzles offer several benefits, including improved flow rates, enhanced ergonomics for users, and features such as automatic shut-off to prevent overfilling. These nozzles are often designed for specific fuel types, ensuring compatibility and efficiency. The use of advanced nozzles also aligns with the industry’s push for innovation and safety in fuel dispensing operations.