Overview of Fuel Dispensing Systems

These systems are designed to transfer fuel efficiently from storage tanks into vehicles. The basic components of a fuel dispensing system include a fuel pump, a dispenser unit, hoses, and nozzles. The purpose of the pump is to move the fuel, while the dispensing unit measures and displays the quantity being delivered. The nozzle either directs the controlled release of the fuel into the vehicle tank or ensures an uncontrolled lapse in the transfer. More sophisticated versions may integrate safety mechanisms, payment terminals, and monitoring systems to enhance the accuracy and operation of the system. Fuel dispensing systems ensure the smooth operation of civil transportation and fuel distribution networks.

What is a Fuel Dispensing System?

A fuel dispensing system refers to all mechanisms used to ensure that fuel is transferred efficiently and safely from storage tanks to vehicles or equipment. Generally, it will include components such as storage tanks, a fuel pump, a dispenser unit, a hose, and a nozzle, each playing an integral part in the dispensing process. The fuel pump draws fuel from the tank, and the dispenser unit controls and measures the amount dispensed, displaying it to the user. Some systems also feature built-in safety, payment, and monitoring systems to ensure precision, safety, and convenience. Industries in transportation, agriculture, and energy rely on these systems for their fuel needs.

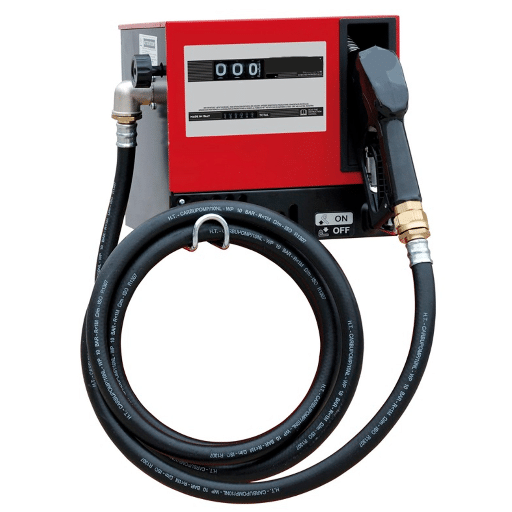

Components of Fuel Dispensing Equipment

Fuel dispensing equipment combines several critical components to ensure efficient and accurate fuel delivery, while also prioritizing safety considerations. Below is a detailed breakdown of the elements.

Fuel Pumps

They are the central element of the system, extracting fuel from underground or above-ground storage tanks. Modern pumps move fuel while maintaining constant flow rates, typically ranging from 10 to 40 gallons per minute (GPM), serving a variety of applications, from standard vehicles to enormous commercial demands.

Metering System

Modern metering apparatuses dispense fuel with absolute precision, ensuring accurate volume measurement. Typically, positive displacement meters or mass flow meters are employed that adhere to strict metrological standards, having an accuracy of ±0.3% commonly required in many countries for verification purposes.

Hoses and Nozzles

Fuel delivery nozzles regulate the fuel flow into the truck’s receiving tank, utilizing a design that employs leak-proof technology to prevent spillage. The automatic shut-off type is most commonly used: The moment the tank is filled, it stops any further flow of fuel to avoid overflow. Hoses are designed to withstand the harshest environmental conditions and constant use; they derive their strength from flexible materials, such as nitrile rubber or polyurethane.

Filtration Systems

The filtration system is incorporated to filter out contaminants such as water or sediments from the fuel before delivery. The higher-performance fuel filters are crucial for maintaining fuel quality and engine performance by capturing particles down to the 10-micron size range.

Dispenser and Display

Fuel dispensers feature controls that regulate the flow and quantity delivered. Most systems nowadays are computerized with digital displays and touchscreens, providing users with real-time information, such as price, volume, and grade of fuel. High-end models include features such as multi-language capabilities and integrated payment systems to enhance the user experience.

Safety and Monitoring Technology

Safety remains paramount in fuel dispensing systems. The latest model units feature vapor recovery systems to reduce emissions, automatic shut-off systems in the event of an emergency, and sensors for detecting leaks. Moreover, smart-monitoring systems with IoT technology enable operators to check fuel levels, system integrity, and performance from anywhere, providing better control over operations and mitigating downtime.

This amalgamation of components ensures reliable, precise, and secure fuel transfer processes across various industries, meeting the needs of customers and operational requirements. With every period, technological advancements boost the efficacy and environmental sustainability of these systems.

Types of Fuel Dispensers

There are several varieties of fuel dispensers designed/service to serve particular needs in different industries. The prevalent ones include:

| Dispenser Type | Description | Best Use Case |

|---|---|---|

| Suction Pump Dispensers | Suction-type systems pull the fuel from the storage tank into the nozzle | Smaller installations or when the tank is located above ground and positioned directly next to the pump |

| Submersible Pump Dispenser | The submersible pump dispenses fuel by pushing it from inside the storage tank to the nozzle | Large-volume refueling stations, provides faster fuel transfer and feeds multiple dispensers from a single tank |

| Standard vs. High-Speed Dispenser | Standard-speed dispensers are used by regular vehicles, while high-speed dispensers are required for heavy-duty vehicles | Trucks or buses, where capacitors need to be moved quickly in large volumes |

| Multi-Product Dispenser (MPD) | A series of fuel dispensers designed to dispense different types of fuel from a single unit | Fuel stations serving diverse needs with gasoline, diesel, and alternative fuels |

| Electronic Dispensers | Equipped with the latest electronics for accurate measurements, digital displays, card payment systems | Modern fuel stations requiring optimal usability and customer convenience |

These fuel dispensers cater differently to specific operational and customer requirements, providing efficiency, safety, and reliability in managing fuel systems.

Mechanical Aspects of Fuel Dispensing

Fuel dispensing shall be regarded for its mechanical side with several pieces of equipment, the chief being the one who safely and efficiently transfers the fuel from one place to the other. It includes pumps that draw fuel from storage tanks, hoses that deliver it, and dispensing nozzles with automatic shut-off valves to prevent overfilling. Another primary function is that of valves, which regulate flow, while filters eliminate impurities from the fuel itself and maintain its quality. All such pieces of equipment operate in unison, executing dispensing operations accurately and reliably, with the highest priority given to ensuring safety for both the end user and the equipment.

How Fuel Pumps Operate

Fuel pumps are crucial equipment for dispensing fuel and transferring it efficiently between storage tanks and vehicles or machinery. These pumps function by the combined action of mechanics and electronics. Modern fuel pumps initiate their operation with an electric motor that drives the internal mechanism to create suction, drawing in the liquid fuel. Based on the type of pump (submersible or above-ground), it then pushes the fuel through pressurized pipelines.

Flow meters inside the system measure the volume of fuel with very high accuracy to dispense the correct amount. Advanced pumps are being equipped with sensors and digital technologies for real-time monitoring of levels, temperature, and flow rates. For example, some fuel pumps are equipped with electronic pressure regulators that maintain a constant flow rate, even when demand is high.

Safety is the paramount goal in the operations of a fuel pump. Risk minimization provides for emergency shutoffs under conditions such as power surges, leaks, or abnormal flow rates at the pump itself. The pipes also contain an excellent filter preventing any kind of contamination from passing through; a process that meets strict regulatory standards for fuel quality. These advances demonstrate how fuel pumps continue to evolve with technology, as well as in response to industrial demand.

Mechanical Components in Fuel Dispensers

Fuel dispensers are complex machines consisting of various mechanical components that work in unison to accomplish their intended purpose: fuel delivery with a certain degree of accuracy and efficiency. Among these components is the metering unit, which measures fuel in the minute volumes dispensed. Modern meters, equipped with fine and sometimes high-precision gear or turbine metering technology, typically have an error margin of ±0.5%, ensuring accuracy within industry standards.

The following essential element is the pump unit, which draws fuel from underground tanks to the nozzle. Such systems typically employ vane or gear pumps, which are advantageous due to their ability to handle various fuel types efficiently. These pumps usually deliver fuel at flow rates ranging from 10 to 40 gallons per minute (GPM) for retail dispensing; flow rates can be as high as 90 GPM for commercial and industrial applications.

The hose-and-nozzle assembly is meant to be durable and user-friendly. Nozzles may incorporate automatic shut-off features to prevent overfilling and spilling, ensuring safety during operation. A high-flow nozzle may provide greater filtration, allowing for the handling of larger volumes without compromising quality.

Pressure regulators maintain flow uniformity and regulate pressure variation between the storage tank and the nozzle. This, in turn, ensures the end delivery under any environmental conditions, considering operational conditions.

Fuel dispenser components, in general, are designed to work in synergy to enhance operational safety, accuracy, and dependability across a diverse range of environments where fueling activities occur.

Maintenance of Mechanical Equipment

Proper maintenance of mechanical equipment ensures optimal efficiency throughout its operational life and helps reduce downtime in machinery. A good maintenance plan would thus include annual inspections, periodic servicing, and replacement of substandard parts. A recent industrial research states that routine preventive maintenance contributes 25% to making equipment more reliable and reducing unplanned downtime by almost 45%.

Critical Maintenance Statistics:

- 70% of machinery failures are attributed to bad lubrication practices

- Vibration monitoring can predict bearing faults six months before failure

- 30% of process failures across industries are caused by negligence in calibration

Lubrication is one of the most critical processes that should be in place to reduce friction and wear on moving parts. The findings also indicate that almost 70 percent of machinery failures were attributed to bad lubrication practices. Proper care must be taken to ensure that the correct lubricant is applied in the correct quantity to optimize the equipment’s optimal functioning.

Additionally, predictive maintenance now utilizes vibration analysis and thermography. These methods can detect the causes of imbalance or overheating before they become significant problems. For example, vibration monitoring can predict bearing faults six months before failure, allowing for timely correction.

There is maintenance calibration for pressure gauges, valves, sensors, and other components, which ensures that operations perform accurately and by safety standards. Statistics indicate that 30% of process failures across industries are caused by negligence in calibration.

Maintenance capable of achieving the highest percentage, with the adoption of modern diagnostic techniques, improves mechanical equipment, thereby significantly reducing operational risk and cost.

Electronic Fuel Dispensing Systems

Electronic fuel dispensing systems are advanced mechanisms designed to effectively dispense fuel into vehicles. Typically, they comprise equipment such as fuel pumps, nozzles, and meters to ensure accurate measurements and safe operation. These systems offer the advantages of greater precision, reduced fuel wastage, enhanced safety through automated operation, transaction monitoring, and other features. They find applications in gas stations, fleet management, and industries that require a dependable and uncomplicated method of fuel dispensing.

Introduction to Electronic Dispensing Equipment

Electronic dispensing equipment has remained a vital tool for efficient fuel management and distribution, particularly in industries that demand accuracy and rely on reliability. Modern facilities are equipped with more advanced technologies than before, including digital flow meters, computer-controlled dispensing, and real-time monitoring. In this way, considerable accuracy in measuring fuel is assured, while simultaneously preventing discrepancies and wastage.

With IoT technology integrated into specific systems, one can track and diagnose remotely. Knowing usage patterns, detecting anomalies, and the ability to address these problems promptly and minimally all ensure that downtime is reduced and preventive maintenance maximized.

By now, data analytics systems are generating detailed fuel consumption reports to maintain transparency and support businesses in making informed decisions. The incorporation of safe payment mechanisms and automated tracking systems further builds user confidence and ensures safe operation. Features such as these make electronic dispensing equipment a viable option for various industrial sectors, including transportation, agriculture, and logistics.

Advantages of Electronic Fuel Management Systems

Electronic fuel management systems offer numerous advantages to enhance operational efficiency, cost management, and environmental stewardship across various industries. They, however, provide a real-time view of fuel consumption, allowing businesses to identify inefficiencies and reduce fuel wastage. For example, some studies have shown that companies employing advanced fuel management solutions have gained fuel savings of up to 15%, resulting in a decline in operational costs and increased profitability.

- Data Accuracy: Electronically recorded and reported fuel consumption reduces, or rather eliminates, the possibility of errors introduced through human recording. The most significant value of this level of accuracy lies in operations on a large scale, such as fleet management, where even minor discrepancies can have substantial financial consequences.

- Enhanced Security: These systems enhance security through features such as driver authentication, which prevents unauthorized fuel access. Research reveals that implementing such measures can reduce fuel theft by as much as 20%, ensuring resources are used responsibly and safeguarding assets.

- Environmental Sustainability: By optimizing fuel usage, businesses can reduce their carbon footprint and comply with increasingly stringent environmental regulations. This commitment to sustainability not only benefits the planet but also enhances a company’s reputation in the marketplace.

- Flexible Integration: Many systems are designed to be scalable and adaptable across various industries. From agriculture to logistics, electronic fuel management systems cater to the unique operational needs of organizations of all sizes, making them a versatile solution.

Common Issues in Electronic Systems

Despite the fact that electronic systems work to near perfection, they do face certain challenges. Inaccuracy in data or loss of data is one such problem. Hardware failures may sometimes result in it; software glitches are equally guilty, as are power interruptions. For instance, there is a strong indication that unexpected power outages cause nearly 45 percent of data corruption incidents, as reported by IT professionals working in various sectors.

| Common Issue | Impact | Statistics |

|---|---|---|

| Data Corruption/Loss | System downtime and operational disruption | 45% caused by power outages |

| Cybersecurity Threats | Financial loss and data breaches | Average cost: $4.45 million per business (2023) |

| System Integration Issues | Implementation delays and increased costs | 70% of projects delayed due to incompatibilities |

| Component Degradation | Reduced system reliability | 30% of failures due to inadequate maintenance |

Another such problem is cybersecurity threats, especially for internet-connected systems. Due to the surge in cyberattacks worldwide, it has become essential, now more than ever, to address this issue. It is estimated that cybersecurity breaches had an average cost of $4.45 million per business in 2023.

Third, system compatibility and integration issues become hurdles to operational efficiency. Many companies encounter challenges when integrating new electronic systems with their existing legacy infrastructure, resulting in outages and increased implementation costs. Almost 70% of system integration projects are delayed due to unexpected incompatibilities.

Lastly, another consistent issue is the maintenance and degradation of components. Consumables such as printed circuit boards, sensors, and processors tend to wear out or degrade under harsh conditions, including excessive temperatures and high humidity. According to a report by McKinsey, approximately 30% of electronic system failures are attributed to inadequate preventive maintenance.

Addressing these issues requires constant investment in system upgrades, stringent cybersecurity measures, and preventive maintenance to ensure their viability and long-term performance.

Business Considerations for Fuel Dispensing

In managing fuel dispensing operations, firms should prioritize the reliability and operational efficiency of the equipment. Reducing downtime through scheduled maintenance is crucial to preventing costly downtime and repairs. Greater accuracy and less human error are achieved through modernization toward automation, a win for customer satisfaction. Industry standards will be complied with when cybersecurity measures are employed to protect transactional data. A sustainable financial plan would encompass, among other things, environmentally friendly technologies for adoption as green alternatives continue to gain consumer appeal.

Choosing the Right Fuel Dispensing Equipment

The correct choice of fuel dispensing equipment requires a careful evaluation of factors to ensure proper applicability across operational, regulatory, and environmental spheres. Firstly, one must consider what type of fuel they will dispense, as specific equipment is designed for specific fuel types, including gasoline, diesel, or alternative fuels such as CNG or biodiesel. Ensuring that it fits correctly with these fuels is crucial for safety and optimal performance.

Secondly, flow rate requirements should be met with business needs. In high-volume applications, dispensers should be able to dispense quickly to minimize wait time; lower-volume applications may favor accuracy over speed. In addition to that, it must consider advanced metering and monitoring applications to increase operational efficiency and offer the ability to track data in real-time.

Durability and ease of maintenance go hand in hand. Raw materials should be rugged and high-quality to tolerate attempted or actual abuse under real harsh conditions and to endure continuous daily usage. Equipment with easy access to parts will permit quick repairs and reduce downtime for the gas station. Look for dispensers that observe an industry standard or certification, and also local laws to lessen the risk and liability.

Finally, aim for green technologies. The design of modern fuel dispensers emphasizes environmental protection through energy conservation and vapor recovery, meeting a growing consumer demand for eco-conscious practices. By considering the above, a business will be able to evaluate and select fuel dispensing equipment that strikes a balance between efficiency, safety, and sustainability.

Cost Analysis of Fuel Dispensing Systems

An analysis of the price of fuel dispensing systems for consumers will consider both the initial investment and the long-term operational expenses on-site. For increased flow rate, better material of construction, or integrated technology, the price will be anywhere between $15,000 and $25,000 per dispenser. A less restricted high-end dispenser might easily cost over $30,000, featuring digital display, card payment (point of sale system) integration, and advanced data tracking.

| Cost Category | Price Range | Description |

|---|---|---|

| Standard Dispensers | $15,000 – $25,000 | Basic functionality with standard flow rates |

| High-End Dispensers | $30,000+ | Digital displays, payment integration, advanced tracking |

| Annual Maintenance | $500 – $1,000 | Per dispenser, varies by usage and environment |

| Energy-Efficient Models | Higher Initial Cost | Lower operational costs due to reduced electricity consumption |

Another set of costs is incurred in the operational provision, including maintenance, calibration, and repair options. Maintenance is estimated to cost between $500 and $1,000 per dispenser annually, depending on usage frequency and environmental conditions. These costs are particularly important for maintaining compliance with standards regarding safety and accuracy.

Therefore, dispensers that conserve energy are initially more expensive, but their operational costs are lower due to reduced electricity consumption. Equipped with a vapor recovery system, the system would have minimized fuel loss and environmental impact, resulting in savings. Another benefit for such companies would be that, in return for the sustainability of their operations, it might open up opportunities for grants or tax incentives, thereby reducing initial expenses.

Understanding the total lifecycle cost of fuel dispensing equipment enables businesses to make informed decisions that best meet their financial goals as well as operational needs.

Regulatory Compliance and Safety Standards

It is the utmost priority for a business operating fuel dispensing systems to adhere to the provisions established by government agencies regarding regulatory compliance and safety standards. Following stringent guidelines, governments and regulatory agencies, such as the United States Environmental Protection Agency (EPA), establish regulations regarding emission reduction, spill prevention, and equipment safety measures. For example, to protect air quality and reduce the health hazards posed by volatile organic compounds (VOCs), EPA regulations mandate the installation of Stage I and Stage II vapor recovery systems.

Key Regulatory Bodies and Standards:

- EPA: Emission reduction, spill prevention, vapor recovery systems

- OSHA: Safety in handling flammable liquids, grounding and bonding requirements

- ISO 9001: Quality management for operational reliability

- ISO 14001: Environmental responsibility and emissions reduction

While OSHA emphasizes safety in the environment where flammable liquids are handled, operating procedures are given the utmost importance. The methods include grounding and bonding all equipment to prevent static buildup, implementing proper maintenance and inspection programs to identify and stop any leaks, and establishing systems for employee training to respond efficiently to emergencies. These studies provide evidence that accident rates drop significantly once these measures are implemented, thereby enhancing both safety and operational effectiveness.

Overseas bodies like ISO provide standards to regulate the sustainable and safe management of fuel systems. The ISO 9001 deals with quality management to ensure operational reliability, while ISO 14001 addresses environmental responsibility, focusing on reducing emissions and effective resource management.

By ensuring safety, companies that use compliant systems remain within the limits of the law, avoiding heavy fines and lawsuits. Thus, remaining current with laws will enable them to operate efficiently and remain environmentally conscious.

Future Trends in Fuel Dispensing Technology

Fuel dispensing technology in the future aims to make the operation more efficient, sustainable, and user-friendly. Major citizen early-witness enhancements would be automated payment systems for seamless and contactless transactions. The other significant shift is accommodating alternative fuels, whether hydrogen or biofuels, for greener energy solutions. With IoT connectivity now added to the mix, bright dispensers offer real-time data monitoring and predictive maintenance, minimizing downtime. All these technologies are being developed to bring fuel dispensing technology in line with modern consumer expectations and sustainability goals.

Innovations in Fuel Dispensing Equipment

One of the many fields that has undergone significant advancement to meet changing consumer demands and the evolving energy industry is the fuel dispensing equipment. One of the important inventions is the use of mobile payment technologies to facilitate smooth, contactless transactions, thereby providing users with convenience and security. A second considerable advancement was adapting dispensers to alternative fuels, such as hydrogen and biofuels, as well as EV charging systems, to support the transition to a more sustainable energy source.

Mobile Payment Technologies

Facilitating smooth, contactless transactions for enhanced user convenience and security

Alternative Fuel Adaptation

Dispensers adapted for hydrogen, biofuels, and EV charging systems for sustainable energy transition

IoT Integration

Smart fuel dispensers with real-time data insights for maintenance optimization and reduced downtime

Advanced Metering

Enhanced accuracy in fuel measurements, waste minimization, and regulatory compliance

Through the IoT, bright fuel dispensers introduced new ways of maintenance and optimization by providing real-time data insights into system performance, allowing for more accurate maintenance scheduling and minimizing operational downtime. Furthermore, these advanced metering systems enhance the accuracy of fuel measurements, minimize waste, and comply with regulations. In this way, these technologies embody a futuristic view on dispensing, aligning with environmental concerns and the ever-increasing need for user-friendly technology.

The Role of Automation in Fuel Dispensing

It is my conviction that automation enhances fuel dispensing by simplifying operations and enabling greater accuracy. In my view, it is a process simplification with the help of innovative technologies, which make sure that precisely the right amount of fuel is dispensed while, on the other hand, employing multiple checks to avoid errors. Real-time monitoring is also another plus, along with predictive maintenance, which all contribute to increased efficiency and reduced downtime. And I firmly believe that, apart from streamlining performance, automation also stands for the sustainability aspects of employing better fuel management and minimizing waste.

Sustainability in Fuel Dispensing Systems

Unlike fuel dispensing systems that have historically been characterized by pollutant emissions, sustainability in fuel dispensing systems entails their environmental treatment, if not preservation, during operation. In support of this, significant developments in areas of ecological concern have included the use of eco-materials, energy efficiency, and vapor recovery during transfer to reduce emissions. This way, automation ensures efficient, emission-free fuel dispensing, which also reduces the waste generated during the process. Clean energy sources, such as biofuels and electrification, also pave the way for greener alternatives. Apart from that, sustainability in fuel dispensing systems encompasses lifecycle management and maximized recyclability of components, aligning with global sustainability goals. Effectively, all these developments have been implemented to reduce carbon footprints and promote sustainable labor practices in fuel management.

Sustainability Features in Modern Systems:

- Use of eco-friendly materials in construction

- Energy-efficient operation reducing power consumption

- Vapor recovery systems minimizing emissions

- Support for alternative fuels (biofuels, hydrogen)

- Component lifecycle management and recyclability

- Automated systems reducing fuel waste

Conclusion

As we look toward the future, the focus on alternative fuels, automation, and environmental sustainability will continue to drive innovation in fuel dispensing technology. Organizations investing in modern, compliant, and efficient fuel dispensing systems position themselves for success in an increasingly competitive and environmentally conscious marketplace.

Reference Sources

1. Design and Operation of the Hydrogen Supply Chain for Fuel-Cell Vehicles in Expo Shanghai 2010

2. Fuel Cell Electric Vehicles (FCEV): Policy Advances to Enhance Commercial Success

3. Development of a Dimethyl Ether (DME)-Fueled Shuttle Bus

Frequently Asked Questions (FAQs)

What is a fuel-dispensing system, and how does it operate?

A fuel-dispensing system is an electronic device that dispenses fuel, such as diesel fuel or motor fuel, into vehicles. It involves a pump mechanism that automatically transfers the liquid from a storage tank through a nozzle into the vehicle’s fuel tank. Typically, the system is equipped with components such as flow meters and control switches to ensure accurate dispensing and compliance with regulations.

Key components of a reliable fuel dispensing system?

Critical fuel dispensing system components include the fuel pump, flow meter, electric connections, and safety devices such as automatic shut-off valves. Accessories, such as the fuel hose, nozzle, and brackets, are also critical for proper operation. Each component of the dispensing system plays a vital role in providing a safe and efficient fueling experience.

Are there any modifications I can make to my fuel dispensing equipment to ensure it complies with safety codes?

Fuel dispensing equipment must be safe for use and must be periodically inspected and maintained, with all components, including wiring and fuel pump systems, included in the inspection. Staying compliant is facilitated by adhering to all local codes and regulations, such as those issued by the National Fire Protection Association (NFPA) and the Environmental Protection Agency (EPA). Installation with a good kit, along with maintenance, will stand them as close to ideal as possible to safety standards.

What kind of fuel dispensing system can a company use?

There are different types of fuel dispensing systems for business-related activities, sometimes manual and sometimes electronic. Electronic systems can be pretty advanced, allowing dispensing to be automated and enabling real-time monitoring, whereas a more operational approach typically characterizes manual systems. Each company can select systems according to its requirements for manual or automotive-industrial use.

Fuel Dispensing Enhancement in an MC Box of Piusi.

The Piusi MC Box is one of the best electronic devices that enhances the fuel dispensing operation, dispensing fuel in a reliable and accurate method for both diesel and petrol-gasoline. The machine itself comes with an in-built flow meter and LCD for ease of viewing, featuring a compact design that ensures optimal space utilization. In turn, by harnessing modern technology, the MC Box brings some advancements to the fueling experience.

What function do electrical connections perform in a fuel-dispensing system?

Electrical connections play a crucial role in the fuel dispensing system by supplying power to various electronic components of the pump and the control switch. If the electrical wiring is installed well and maintained adequately, it ensures an efficient and safe system. Faulty connections are cumulating malfunctions that make regular inspections quite crucial from the standpoint of system reliability.