Fuel storage tanks serve essential functions in multiple industries because they function as critical systems that store liquid fuels, including gasoline, diesel, and all other needed fuels. Organizations need to select appropriate tank types through learning about their specific uses and following recommended operating procedures because this process protects their operational success and their ability to meet safety standards and legal requirements. The blog post will examine different fuel storage tank types while showing their actual uses and delivering practical guidance to successfully operate and maintain these tanks. The comprehensive guide will help you make informed decisions, whether you want to upgrade your storage systems or learn about the best storage practices used in your industry.

Types of Fuel Storage Tanks

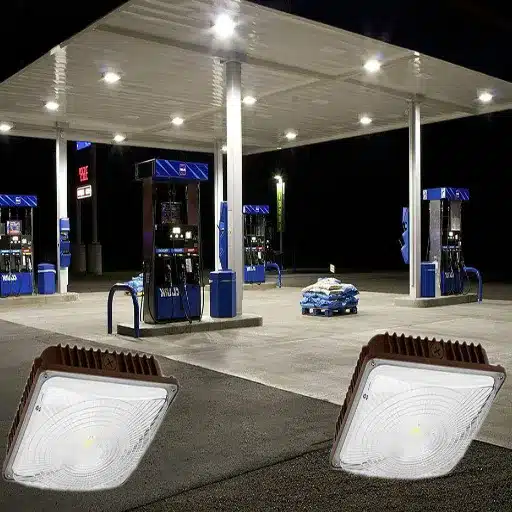

Above-Ground Fuel Storage Tanks

ASTs serve as the primary solution for fuel storage needs because their design enables use in areas that cannot accommodate underground tank systems. The industrial sector, together with fueling operations and agricultural facilities depend on ASTs because these storage tanks enable their fuel supply operations to run smoothly. Fuel operation teams and staff members need access to fuel storage tanks for their daily work needs and equipment checks, which take place during operating hours.

The above-ground fuel storage tank market will expand because customer requirements for environmentally compliant storage systems drive demand for these tanks, according to recent industry reports. The above-ground fuel storage tank market will generate USD 4.29 billion in revenue by 2031, according to 2023 market data, which shows a compound annual growth rate (CAGR) of 4.7% during the forecast period.

ASTs provide three main benefits, which include their lower maintenance requirements, faster installation process and cheaper total expenses when compared with underground storage systems. The product development process for manufacturers involves creating new technologies, which include spill-containment systems, liquid-level gauges, and corrosion-resistant coatings. Businesses can use these advancements to achieve safety compliance while they work to decrease fuel spillage hazards.

Businesses can use their knowledge about above-ground fuel storage tank functions, market developments, and technological progress to choose and implement suitable solutions that fulfill their distinct operational needs.

Underground Fuel Storage Tanks

Operators who need to keep large volumes of fuel in secure underground facilities use underground fuel storage tanks (USTs) as their standard storage solution. The tanks provide three main benefits: they preserve vital surface areas and decrease potential environmental hazards, and they protect fuel from dangerous weather changes, which could cause fuel degradation. The global UST market will experience approximately 4.3% compound annual growth rate (CAGR) until 2030 because rising fuel demand meets the growing regulatory requirements of transportation, aviation, and energy sectors.

Modern UST systems now use double-walled systems, which include state-of-the-art leak detection technology and fiberglass-reinforced plastic material for their leak detection needs. The system innovations provide a solution that protects against leaks and spills while maintaining safe operations through its long-term handling capabilities. Modern UST systems can identify leaks at an early stage through their ability to measure tiny pressure fluctuations, which helps avoid serious operational threats. The U. S. Environmental Protection Agency (EPA) has established new regulations that require businesses to implement strict inspection and maintenance procedures for their operations.

Underground fuel storage systems provide two main advantages to businesses, which include meeting environmental compliance needs and storing fuel in safe and effective ways.

Portable Fuel Tanks and Skid Tanks

The industry relies on portable fuel tanks and skid tanks because these tanks deliver both adaptable and safe solutions for their fuel storage requirements at different times. The tanks come with a design that enables easy transportation to all locations, including construction sites and agricultural fields and remote work areas, while they fulfill the requirements for environmental protection.

Portable Fuel Tanks use lightweight materials, which include polyethylene and steel, to create tanks that provide mobility through their ergonomic design features. The products include built-in handles, molded tie-down grooves, and integrated fuel pumps. The tanks offer two capacity options through their 12-gallon personal equipment tanks and their industrial tanks, which exceed 1,000 gallons. According to the Occupational Safety and Health Administration (OSHA), portable tanks with capacities exceeding 660 gallons must adhere to additional safety measures such as secondary containment.

Skid tanks operate as permanent fuel storage systems, which keep their position because heavy-duty skids enable movement through the equipment. The tanks provide storage capacities between 500 and 10,000 gallons, which makes them suitable for storing large quantities of fuel. Skid tanks use steel double-wall construction to contain spills while they comply with National Fire Protection Association (NFPA 30) fire safety regulations. Skid tanks serve various industries, which include construction, transportation, and agriculture, because these sectors need to refuel their equipment without delays.

Modern technology now operates portable tanks and skid tanks through the installation of anti-static grounding connections and secure access points, which prevent unauthorized access, and through the implementation of leak-detection systems. Businesses can achieve compliance with EPA standards through their tank investments, which also decrease potential spill and contamination hazards.

Applications Across Industries

Agricultural Fuel Storage Solutions

Farmers require fuel storage facilities because all their vital machinery and equipment, and agricultural vehicles need diesel and gasoline to operate. Modern fuel storage solutions now serve agricultural purposes because portable fuel tanks and skid fuel tanks function as effective storage systems for agricultural fuel requirements. According to recent industry research, above-ground fuel storage tanks enable farm operations to complete refueling tasks 25 percent faster, which helps farm work progress efficiently while reducing interruptions to their daily operations.

The advanced systems within the tanks use GPS tracking technology for two purposes, which include tracking the locations of the tanks and tracking the amounts of fuel that they hold. The systems provide farmers with immediate data, which helps them to prevent unforeseen fuel shortages that occur during essential planting and harvesting tasks. Agricultural enterprises use dual-wall building methods together with secondary containment systems because those technologies enable them to meet environmental protection standards, which help them reduce their environmental impact and assist with compliance requirements.

Research shows that organizations that implement approved fuel storage systems experience 40 percent fewer environmental fuel leakage incidents compared to their previous fuel storage systems. These tanks now support biofuels because organizations increasingly seek sustainable practices that help decrease their dependence on fossil fuels.

Construction Industry Fuel Needs

Construction activities require fuel supplies, which businesses need to maintain their operations for heavy machinery, generators, and essential equipment throughout their working hours. The global construction fuel market achieved a value of approximately $119 billion in 2022, according to recent industry reports, while analysts project that it will grow at a compound annual growth rate of 4.8 percent between 2023 and 2030. The world requires effective fuel management systems to meet increasing consumption needs because this situation creates new chances for developing infrastructure projects.

The construction industry has demonstrated diesel fuel to be its most effective energy source because it delivers high performance for construction equipment, which requires substantial energy input. The construction industry now embraces alternative fuels because companies need to comply with emissions standards that have become more demanding. Biodiesel blends, which combine petroleum diesel with renewable bio-based materials, can decrease greenhouse gas emissions by up to 74 percent when compared to petroleum diesel, according to their environmental impact assessment.

Construction sites use storage solutions as an essential aspect of their fuel management system. The construction industry developed advanced fuel tank designs that establish double-walled tank systems together with security systems that monitor fuel consumption because these systems provide protection against leaks and contamination events. The new technologies support both regulatory compliance and operational management by providing organizations with actual fuel usage information that shows their fuel consumption in real time. The implementation of these solutions has resulted in construction companies achieving a 25 percent decrease in fuel-related losses, according to case studies done within the industry.

The construction sector demonstrates its dedication to building sustainable development projects through smarter fuel systems and renewable energy solutions, which create a better ecosystem approach for all major construction projects.

Transportation and Energy Sector Fuel Storage

The transportation and energy sectors are developing advanced fuel storage systems that help them meet rising market demands while they pursue their sustainability goals. Recent research shows that fuel cell technology and hydrogen energy storage systems have reached major technological advancements, according to scientific studies. The hydrogen storage market will expand at a rate of 6.5 percent per year until 2030 because global initiatives aim to reduce carbon emissions while transitioning to sustainable energy systems.

Smart monitoring systems enable fuel storage facilities to gather real-time information, which shows their current fuel content, how their fuel is being used and any possible fuel leaks. The new operational technology enables big operational systems to operate with improved efficiency and safety. Battery energy storage systems (BESS) have become a standard method for renewable energy storage on the electricity grid because this technology provides reliable storage of energy generated by renewable sources. The global battery energy storage market will exceed $20 billion by 2028, according to market research, which indicates renewable energy storage solutions will experience substantial market expansion.

The new technologies create reduced environmental effects while they provide dependable and affordable energy supply chains, which open up fresh business expansion paths within the sector.

Critical Safety Standards for Fuel Storage

Understanding UL Standards: UL-142 and UL-2085

Fuel storage safety operations create the primary safeguard that secures three vital elements, which include legal obligations and operational reliability, and environmental protection. The two safety standards UL-142 and UL-2085 establish essential guidelines for designing and building fuel storage tanks, which protect operational safety and operational performance through their specific requirements. The standard UL-142 establishes requirements for aboveground storage tanks that hold non-corrosive and flammable liquids. The tanks must fulfill stringent construction standards because they require the use of premium steel materials and leak detection systems, and match all stored materials. The UL-142 standard requires extensive testing of tanks to evaluate their strength and durability and their ability to withstand corrosion. The storage tanks that meet the UL-142 certification requirements are commonly utilized by industrial, commercial, and institutional facilities for storing petroleum products and chemicals, according to data evidence.

The UL-2085 standard extends the UL-142 standard through its introduction of extra environmental protections and fire safety features. The UL-2085 standard specifies that certified tanks must function as “protected” or “fire-resistant” tanks, which offer both thermal insulation and secondary containment. The tanks must undergo rigorous performance testing, which includes two-hour fire-resistance assessments, impact resistance tests, and ballistics performance tests. The UL-2085 tanks serve as effective solutions for high-risk areas, which include fuel stations, airports and emergency power systems. The adoption of UL-2085-certified tanks has led to a 40% reduction in fire hazards within high-temperature zones, according to data from the industry.

Both certifications require organizations to maintain high safety standards that protect public safety while developing fuel storage systems that meet current operational requirements. The choice of standard must consider three factors, which include the intended use of the system, the environmental conditions, and the demands of legal requirements. The two standards UL-142 and UL-2085, which protect safety and environmental standards, have become essential elements for sustainable fuel storage systems.

Importance of Double-Wall Fuel Tanks

Double-wall fuel tanks present a crucial technological development that addresses safety challenges and environmental sustainability requirements in fuel storage operations. The tanks consist of an internal wall and an external wall, which create an enclosed space that functions as a secondary containment system. The design protects against leaks because it prevents hazardous materials from contaminating the environment when an internal wall breach occurs.

The latest data shows that double-wall fuel tanks can decrease spill incidents by 95% when compared to single-wall tanks. The people who operate in mining, transportation and agriculture have established double-wall tanks as their preferred solution because these tanks offer exceptional durability and extended operational life. The existing product designs of many models meet both UL-142 and UL-2085 requirements through their combination of fire protection and corrosion defense, and enhanced structural strength.

The typical 10,000-gallon double-wall fuel tank can achieve a 25-year operational lifespan through proper maintenance, which results in long-term cost efficiencies. The tanks feature monitoring systems that detect leaks to enhance their overall safety performance. The global adoption of double-wall fuel tanks demonstrates growing regulatory requirements that aim to protect natural resources and establish safe fuel management practices.

Containment Measures to Prevent Leaks

The effective execution of containment strategies determines the success of both leak prevention and environmental risk reduction efforts. Double-wall tanks function as the industry standard because they provide essential safety benefits through their dual containment mechanisms, which improve operational security. The tanks have the ability to reduce leak incidents by 90% according to current industry research, which shows that they decrease the risk of environmental contamination.

Advanced leak detection systems need to be installed as another essential measure, which uses technologies that include ultrasonic sensors, vacuum monitoring, and electronic alarms. Modern monitoring systems can track leaks that occur at a rate of 0.1 gallons per hour, which enables them to provide alerts that prevent extensive damage. The Environmental Protection Agency (EPA) report states that constant monitoring combined with scheduled inspections will lead to a 75% reduction in major leak incidents.

Secondary containment systems use spill containment barriers and drip trays, which function as emergency containment solutions to capture spills that occur around tank systems before the spills can enter the ground. Industries are also adopting impermeable liners and coatings for underground tanks, which provide extra security against corrosion and leakage.

The implementation of these measures requires the execution of necessary maintenance activities, which include pressure testing and corrosion assessment procedures. Tanks that receive routine inspection and maintenance work show a 60% reduction in leak incidents throughout their operational period, according to the research findings from the American Petroleum Institute (API) study.

Organizations can achieve regulatory compliance while safeguarding natural resources and public health through the implementation of advanced technologies and their maintenance protocols.

Best Practices for Fuel Tank Maintenance

Regular Cleaning and Inspection Schedules

Organizations need to execute systematic cleaning and inspection procedures because these processes become necessary for achieving both secure tank operations and extended fuel storage tank operational duration. The existing industry regulations mandate fuel tank inspections to occur at five-year intervals, except when high-use or high-capacity tanks require more frequent assessments. The cleaning process eliminates all tank sludge together with microbial growth and sediment accumulation, which otherwise would result in fuel contamination that creates corrosion and clogging problems within the tank. The U. S. Environmental Protection Agency (EPA) report demonstrates that tanks that operators clean and inspect on a regular basis experience substantially lower chances of losing fuel and contaminating the environment. The inspection process benefits from ultrasonic thickness testing because inspectors can use this technique to identify both existing tank structural weaknesses and initial deterioration signs.

The recent research findings show that 80% of fuel tank failures occur because organizations fail to execute their maintenance duties according to their established maintenance schedules. The implementation of robotic tank cleaning systems enables organizations to achieve their tank cleaning objectives while maintaining safe operations because this technology allows work to take place without halting tank operations. The implementation of these practices enables businesses to achieve operational efficiency while meeting regulatory requirements and decreasing their expenses from repairs and environmental harm.

Leak Prevention Strategies

Industrial storage tank leak prevention requires multiple strategies that involve advanced technologies, together with ongoing maintenance activities and the use of premium construction materials. The materials selected for design projects, together with the methods used to control corrosion represents two essential factors because 67% of tank leaks result from corrosion problems. The application of advanced coatings together with cathodic protection systems represents modern solutions that effectively reduce the occurrence of leaks caused by corrosion.

The use of IoT (Internet of Things) technology through real-time monitoring systems enables organizations to find and address security weaknesses before they become critical problems. Sensors equipped with acoustic emission and ultrasonic tools can detect structural changes or breaches in a tank’s surface before they develop into major leaks. The global tank monitoring system market will achieve a compound annual growth rate (CAGR) of 7.1% according to the MarketsandMarkets report, which forecasts growth from 2021 to 2026.

The combination of detailed inspections together with predictive monitoring systems and advanced material usage allows businesses to decrease their exposure to leak-related dangers. The process not only protects environmental safety but also prevents financial losses and damage to reputation that result from tank accidents.

Extending the Lifespan of Fuel Storage Tanks

The combination of proper maintenance practices together with innovative maintenance techniques serves as the main method to extend the operational duration of fuel storage tanks. The current research establishes that corrosion represents one of the main factors that lead to tank destruction because it causes 40% of all tank failures. The implementation of regular inspections together with corrosion-resistant coatings and cathodic protection systems results in substantial improvements to tank strength. The implementation of cathodic protection results in corrosion rate reductions that reach 80%, which establishes it as a cost-effective method to extend tank operational lifespan.

The development of robotic tank inspection systems, together with ultrasonic testing systems, enables operators to find weak points in equipment without interrupting operational activities. The use of these technologies enables organizations to meet industry standards while improving efficiency. The oil and gas sector will witness a market growth rate of over 8% from 2023 to 2030 for robotic inspection systems, according to a Global Market Insights report.

The use of double-walled fiberglass together with metal alloy linings as high-performance materials establishes an effective method to prevent leaks while maintaining durability against extreme environmental conditions. The use of composite materials has gained popularity among fuel tank manufacturers because this material combination enables them to reduce equipment damage while maintaining structural strength.

The implementation of these strategies enables industries to achieve substantial reductions in their complete lifecycle expenses while they maintain their fuel storage tanks in a safe and dependable condition.

Reference Sources

-

Ken Research – Global Storage Tank Market Outlook to 2030

This report provides a comprehensive analysis of the storage tank market, including key target audiences such as manufacturers, oil & gas industry executives, and petrochemical corporations. It also discusses market trends, challenges, and opportunities.

Source Link -

Fuel Storage Tank Market Size, Growth & Forecast 2032

A market analysis report detailing the growth and forecast of the global fuel storage tank market.

Explore on Credence Research -

North America Oil & Gas Storage Tank Market Report 2030

Insights into the North American oil and gas storage tank market, including growth trends and projections.

Check on Mordor Intelligence

Frequently Asked Questions (FAQs)

What are the common types of fuel storage tanks?

There exist multiple fuel storage tank types, which include above-ground storage tanks and underground storage tanks. The design of ASTs enables users to monitor and maintain their facilities because the tanks are built to meet both industrial and commercial requirements. USTs offer service stations and sites with restricted land access an efficient solution to meet their space needs. The first category of storage tanks consists of double-walled tanks, which prevent leaks through their additional protective barrier. The second storage tank category consists of composite tanks, which use fiberglass and metallic alloy linings to achieve better protection against environmental corrosion.

Where are fuel storage tanks most commonly applied?

Fuel storage tanks find extensive application across various industries, which include transportation, manufacturing, agriculture, and energy production. They provide essential storage capabilities for gasoline, diesel, and jet fuel, and biofuels, which serve multiple applications. The transportation hubs utilize fuel tanks to provide vehicles, airplanes, and ships with continuous access to fuel. Fuel storage systems enable energy facilities and backup power systems to maintain their operational capacity during power outages and emergency situations.

What materials are best for fuel storage tanks?

The selection of materials for fuel storage tanks depends on the particular needs of each usage case. Steel serves as a popular material because it combines durability with affordable pricing. The market for composite materials, which include special metallic alloy linings combined with protective coatings, is growing because these materials provide leak protection while enduring extreme conditions, resulting in reduced maintenance expenses.

What are the best practices for maintaining fuel storage tanks?

The complete safety and extended lifespan of fuel storage tanks depend on their correct maintenance procedures. The process of conducting inspections should take place at regular intervals to check for any signs of corrosion, leaks, or structural damage. The tank needs periodic cleaning and decontamination because these processes stop sediment build-up and microbial growth, which harms fuel quality. The implementation of a comprehensive monitoring system, which includes leak detection technology, provides two advantages because it helps identify problems quickly and protects the environment from potential risks.

How can fuel storage tanks minimize environmental risks?

To reduce environmental risks, tanks must have secondary containment systems, which include double-walled tanks and bunded tanks that safeguard against leaks and spills. The implementation of spill containment measures through associated drain systems and automatic shutdown valves decreases environmental damage risks. The modern tanks, which incorporate composite materials and advanced coatings, decrease the possibility of chemical reactions and corrosion, thereby providing safer and more environmentally sustainable operations.

How do fuel storage tanks contribute to lifecycle cost savings?

Industries can reduce their future repair and replacement costs through three actions, which include choosing appropriate materials, executing a successful maintenance plan, and adopting leak detection technology. Advanced tanks, which use fiberglass and metallic alloy linings, need less frequent maintenance while delivering extended operational periods. Companies achieve significant reductions in lifecycle costs through their investment in effective designs, which require regular monitoring to maintain fuel and operational efficiency.