In servicing the world in the moving process, dispersing fuels essentially uses the gas pumps. Be it an operator wishing to install a new modern refueling system into his business or an obsessive tourist wishing to find out about the industry’s top leading players, knowledge of the top manufacturers’ crucialities cannot be overstated. This guide takes on the major and innovative gas pump manufacturers in the market nowadays. From latest technology to reliability and efficiency, these companies sculpt our refueling mechanism and provide gas stations with an easy refueling process. So what follows is an insight into the major key players that propel the workings behind the gas pump industry and a glance at what each can offer in value.

1. Shandong Shengrui Intelligent Equipment Co.

Founded: 2011

Introduction: Shandong Shengrui Intelligent Equipment Co., Ltd., is one of the leading manufacturers of intelligent fueling equipment, emphasizing evolving solutions for gas station operations. Located in China, the company enjoys an enviable reputation for quality products and advanced technology.

2. Gilbarco Veeder-Root

Founded: 1865

Introduction: Once a pioneer in fuel dispensing technology and integrated fueling solutions, Gilbarco Veeder-Root is now considered an eminent legacy with a long tradition of innovation.

3. Dover Fueling Solutions

Founded: 2017 (part of The Dover Corporation, established 1955)

Introduction: Dover Fueling Solutions is a relatively younger outfit, sprouting out of the names of several well-acknowledged fuel and automation brands.

4. Tatsuno Corporation

Founded: 1911

Introduction: Quintessentially Japanese in its commitment to precision and quality, Tatsuno Corporation has a long history in the design and manufacture of fuel dispensing equipment.

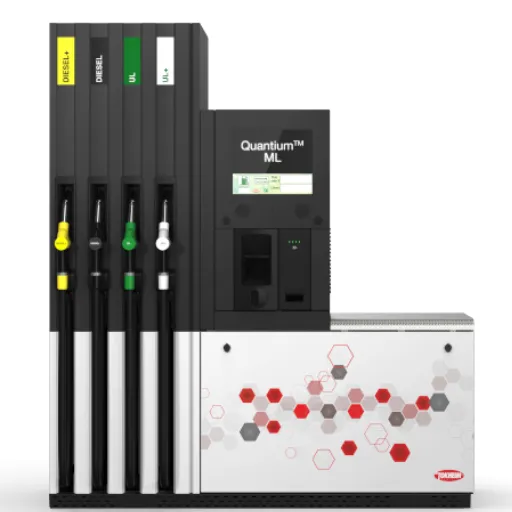

5. Tokheim

Founded: 1901

Introduction: More than a hundred years of existence positions Tokheim as probably the oldest and most respected name among the fuel dispensing authorities.

6. Wayne Fueling Systems

Founded: 1891

Introduction: Wayne Fueling Systems is among the most recognizable names in fuel technology and has been a catalyst for change and innovation in the industry.

7. Piusi S.p.A.

Founded: 1953

Introduction: Piusi S.p.A. has been in the business of fluid handling since 1953 and is based in Italy. They manufacture diesel and gasoline fuel pumps.

8. Scheidt & Bachmann

Founded: 1872

Introduction: Scheidt & Bachmann is a company based in Germany, providing global solutions in fuel retail systems and technological applications.

9. Beijing Sanki Petroleum Technology Co., Ltd.

Founded: 1995

Introduction: Sanki, as the Chinese juggernaut in fuel dispensing equipment, veers toward energy-efficient and eco-friendly types.

10. Bennett Pump Company

Founded: 1919

Introduction: The United States-based company Bennett Pump is identified with quality work and provides products that meet the needs of contemporary fueling stations.

Frequently Asked Questions (FAQs)

Which are the leading gas pump manufacturers in North America?

The leading gas pump manufacturers in North America include Gilbarco, Bennett Pump, and Tuthill. These companies generate innovative fuel dispensers and oil transfer pumps for various applications in oil and gas.

In what ways do gas pumps from big companies differ?

Fuel dispensers could be different in various ways depending upon the technology they use, their flow rate, and what fuelling options they serve, such as diesel or CNG. Some only focus on high-precision metering pumps, and others might be heavy-duty pumps designed for industrial purposes.

What kinds of pumps do oil and gas manufacturers produce?

Oil and gas manufacturers list a myriad of pumps they manufacture-ranging from rotary to diaphragm and gear pumps to reciprocating pumps. These pumps are used essentially for fluid control in many petroleum equipment applications, facilitating the movement of oil efficiently and leakage detection.

How do gas pump manufacturers make sure their products are safe?

Regarding safety features, all gas-pump manufacturers must comply with the ISO standards and perform tests. Some of these manufacturers incorporate design features such as leak control and pressure control mechanisms to avoid explosions and to ensure safe working pressure of up to 2000 psi.

What importance do headquarters locations hold for pump manufacturers?

Headquarters locations for pump manufacturers could play a very important role in deciding supply chain or distribution prowess. For example, the companies having headquarters scattered across North America could have better access to commercial fleet operators and industrial applications to improve in the markets.

What role do gas pump companies play in the petroleum industry?

Gas pump companies are of supreme importance in the petroleum industry as they provide all kinds of filling solutions and equipment to the retail outlet stations. Their products enable them to provide for a smoother transfer of various fuels, which include crude oil and American gasoline, to the end-user and businesses.

How do manufacturers of fluid control systems participate in the gas applications market?

Manufacturers of fluid control systems enhance the gas applications market by bringing technology-based improvements that could give better performance to fuel dispensers and oil transfer pumps. Their innovations get more fuel sold by increasing the reliability and efficiency of the pumps that operate in commercial and industrial sectors.

What are the benefits of high-precision metering pump usage in fuel dispensers?

Some features that will be provided by the high-precision metering pumps in fuel dispensers include very accurate measurement of the fuel dispensed and a reduction in wastage. These pumps become essential to ensure that regulatory standards are met within the petroleum equipment field and that retail fueling facilities maintain the honor of serving the customer.

Can you describe the different types of fuel options for commercial fuel dispensers?

Commercial fuel dispensers allow multiple fuel options-gasoline, diesel, liquefied natural gas (LNG), and compressed natural gas (CNG). This flexibility allows fleet operators in operational mining industries to select the fuel type that best suits their requirements.