Siphoning gas is a method that has different practical applications, like emergency fuel transfer and keeping small engine equipment running. Although the concept might sound simple, doing it properly and safely requires a good understanding of the procedure to prevent accidents or damage to your car. This guide aims to explain in detail how siphoning works, what tools you will need, and what precautions you should take to guarantee safety and efficiency. If you’re stuck without gas or just need to move some for regular checking, this article will give you the knowledge to carry out the job responsibly and effectively.

Understanding the Siphon Process

Siphoning is based on the law of gravity and the pressure difference. At first, one end of the siphon hose is put in the fuel tank to let the lighter liquid flow from the tank (the higher point) down to the container (the lower point). The liquid starts its journey either by the manual creation of suction in the hose or by a pump. Gravity is the driving force behind the flow, which lasts until the end of the hose in the container is lower than the fuel level in the tank. To keep the flow going, the hose has to be properly watched to be sure no air gets into the system, as that will bring the flow to a halt. It is always the best practice to use approved siphon equipment and never to suck with your mouth, as that would lead to the inhalation of toxic gases or liquids.

What is a Siphon?

A siphon is a device or a technique that is employed to move liquids from one receptacle to another by means of gravity and atmospheric pressure. A siphon usually has a tube or a hose that is first filled with liquid in order to establish a steady flow. The end of the tube that takes in liquid has to be at a lower level than the liquid at the source, for the siphon to work correctly. The atmospheric pressure then pushes the liquid into the tube, and at the same time, gravity keeps pulling the liquid down through the tube as long as there is no interruption of air in the tube or hose. Siphons can be found in many applications, such as draining of fuel tanks, fish tanks, or simply moving water through barriers without a pump. For safe and effective siphoning operations, it is important to have the right tools and the necessary expertise.

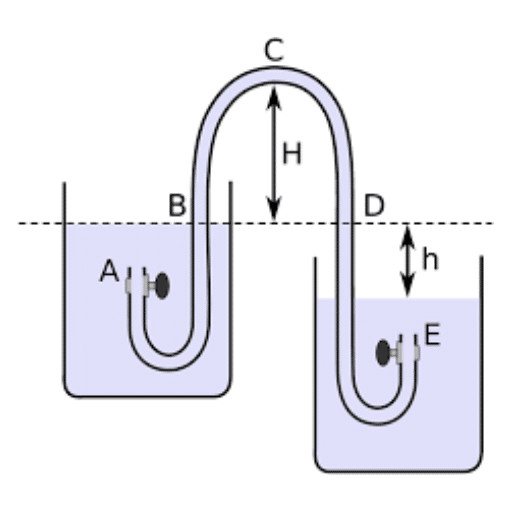

How Does a Siphon Work?

A siphon works on the principles of atmospheric pressure, gravity, and the cohesion of the liquid. If the siphon is set up such that one of its openings is placed in the liquid source while the other one is kept at a lower level, the liquid will flow by itself from the higher point to the lower point. To start the siphon, it first needs to be filled to eliminate the air and thus form a continuous liquid column. The corresponding liquid column is pushed up by the atmospheric pressure on the intake side and kept flowing down the discharge side quite smoothly by the force of gravity. The liquid molecules are pulled together by their cohesive forces, which keep the column intact. This simple but efficient mechanism makes it possible to transfer liquids over the barriers without using pumps.

Importance of Gravity in Siphoning

Gravity is the main force in the siphon mechanism by making the liquid flow through the discharge side. The liquid column is under the gravitational force; thus, the intake and discharge ends are subjected to different pressures. The pressure difference is the one that drives the liquid from the higher place (intake) to the lower one (discharge). To make it more efficient, gravity combines with atmospheric pressure so that the liquid on the intake side is pushed up to the receiving side due to a lessened pressure caused by the height of the liquid column. If there were no gravity, then the siphon would not work at all since the liquid would not be going down the discharge side, creating a backflow. The interplay of gravitational force, atmospheric pressure, and liquid cohesion is crucial for maintaining a smooth and efficient siphoning.

Step-by-Step Guide to Siphoning Gas

- Safety First

Always make sure to work in a very well-ventilated place so that you do not inhale any fumes. Do not siphon gas close to open flames or heat sources to cut down on the risk of ignition. - Collect Required Tools

Acquire a siphon pump or a clean hose. Choose the tools that are specifically manufactured for fuel transfer so that you can avoid contamination or spilling. - Examine the Fuel Tank

Uncap the fuel tank and check what is inside. Make sure that no blockages or impurities are there before moving on. - Position the Siphon Hose

Insert the hose into the fuel tank with one end and make sure it touches the gas at the bottom of the tank. With the other end of the hose, locate it in a proper vessel for the fuel to be collected. - Trigger the Flow

In case of the siphon pump, adhere to the manufacturer’s directions for opening up the gas flow. If going manual, start the siphon by generating suction until the gas starts flowing without interruption. Do not put your mouth on the hose directly because of safety concerns. - Keep Watching the Process

Monitor the fuel being moved so as not to overfill the container. As soon as the amount of fuel you want has been collected, halt the process. - Detach the Hose and Close the Openings

Gently detach the hose from the fuel tank and container, trying to avoid spilling at all. Close the fuel tank cap and container lid tightly. - Get Rid of the Spilled Gas and Keep the Tools

If any gas was spilled, clean it up at once so that the risk of fire is minimized. Keep the siphoning tools in a place that is safe and marked for them. Properly dispose of waste or leftover fuel.

Important: Never siphon gas without first checking the relevant laws and regulations to be on the safe side and properly comply with them.

Tools Needed for Siphoning Gas

For the purpose of siphoning gas safely and effectively, the following tools and supplies are generally required:

- Siphon Pump or Kit – It consists of either manual or electric pumps that have been specifically made for the safe transfer of fuel. Pumps with transparent tubing allow you to see the flow and confirm the correct working conditions.

- Clear Tubing – Sturdy, fuel-compatible pipe fittings to assist the gas transfer operation without breakage or leakage.

- Gas Container (Approved) – A leak-proof and certified container for receiving the siphoned fuel, for instance, those that conform to DOT/OSHA standards.

- Protective Gear – Gloves and eye protection to keep accidental skin contact or fuel irritation of the eyes from happening.

- Rags or Absorbent Material – Handy for the cleanup of small spills and the creation of a safe working environment.

- Funnel (Optional) – To facilitate the pouring when transferring fuel to another container or vehicle in a controlled manner.

Make sure that all the tools are in proper condition and follow the local regulations regarding the handling and transporting of fuel.

Preparing to Siphon Gas Safely

Before starting the siphoning process, make sure you the local laws and regulations on fuel transfer are in place so you don’t get entangled in legal issues. Try to find a spot that has good ventilation and is absolutely away from flames, sparks, or any other heat sources, as this will significantly decrease the chances of fire or explosion. Lay out your tools in an orderly fashion and check them for cracks or worn-out parts.

To begin, place the containers in an arrangement where the receiving container is lower than the source tank, and it is safe. This positioning is very important because siphoning makes use of gravity to move the liquid. Take the hose or siphon pump and put it into the source tank, making sure it goes down under the fuel level, while the other end is firmly placed in the receiving container. For manual siphons, create suction using the method recommended by the manufacturer, such as pumping a bulb, to start the flow of gasoline. If an automatic pump is being used, the device should be turned on according to its operating instructions. Always keep an eye on the transfer process closely in order to avoid overflow or spills.

After the process is done, carefully withdraw the siphon hose to prevent drips, tightly close all containers, and clean the fuel-exposed area. In the event that a spill takes place, immediately clean the area with rags or absorbent material and make sure you dispose of the waste in accordance with the environmental regulations. Following these steps guarantees not just a smooth fuel transfer but also a minimization of the health and safety risks linked to it.

Executing the Siphoning Process

In siphoning, one of the first steps is always to have all the necessary and proper tools ready, such as a siphon pump or hose plus a couple of suitable containers. After that, place the container receiving the liquid at a lower height than the one containing the liquid in order for the liquid to flow through gravity. Now take a siphon hose and plunge one end of it into the liquid inside the source container; make sure it is completely underwater. Place the other end of the hose securely over the receiving container so that nothing spills.

If you are working with a manual siphon pump, turn it on according to the manufacturer’s instructions, which usually involve squeezing or pumping to begin the movement of liquid. Create the initial vacuum for hoses that need it, very carefully, so that there is no accidental swallowing or inhaling of fumes. When the liquid starts to flow, then watch it very closely and make adjustments so that there will be no leaks, overflows, or hose displacements.

To finish off the transfer, lift the siphon hose above the containers’ level to stop the flow. Then take out the siphon hose very gingerly so as not to let any drips fall. After that, dispose of any liquid left in the hose correctly, and make sure that all the containers have been sealed tightly. It is best to clean up the tools and any spillage immediately and follow the local environmental rules on disposal of fuel or other hazardous materials. Thus, by using these elaborate steps, one can ensure not only the safe but also the effective siphoning of liquids during the siphoning operation.

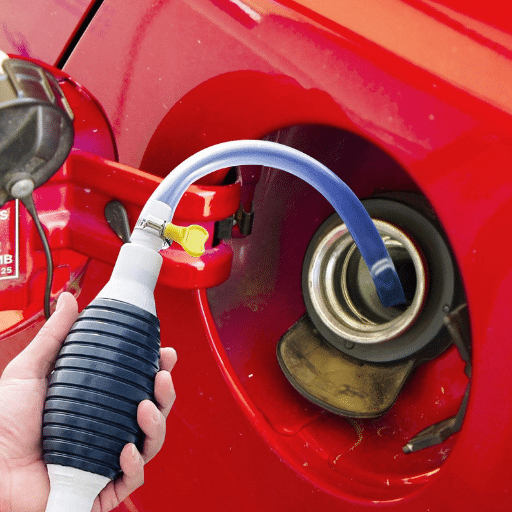

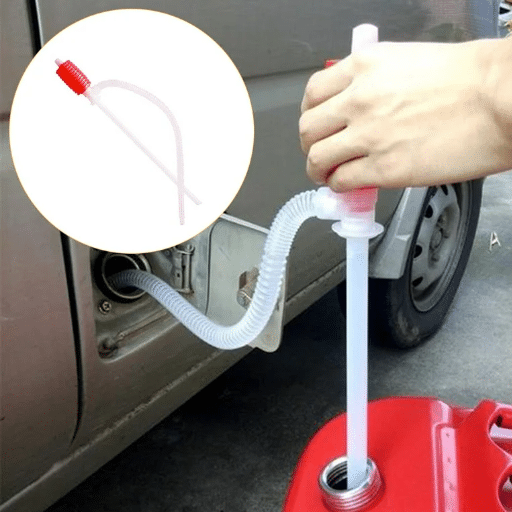

Using a Siphon Pump for Gas Siphoning

A siphon pump makes it easy to move gas from one place to another, and it’s a safe way of doing it. First, make sure the pump is clean, and there are no impurities. Put the pump’s intake tube into the container where the gas is and the outlet tube into the container where you want the gas to go. Follow the pump’s operating instructions, which usually involve squeezing or priming, to get the gas flowing. When you have transferred the amount you want, stop the pump and slowly remove the tubes so no gas spills. Always do this under proper ventilation and far from fire, and follow the safety rules for combustibles.

Benefits of Using a Siphon Pump

The siphon pump is a tool that comes with a lot of benefits and is the best option for the transfer of liquids when safety and efficiency are paramount. To begin with, they greatly lessen the chances of spills and contamination, thus allowing very precise control during the whole liquid transfer process. Hence, they are perfectly suited for fuels, chemicals, or any other sensitive liquids. In addition, they require no electricity to operate, and this makes them portable and cost-effective tools, especially in remote or emergencies. Thirdly, the siphon pump was designed to be very friendly to the users with its simple assembly and operation. So, it can be used by both professionals and amateurs with little or no expertise in the field. Also, their ability to work with different types of liquids and containers of various sizes adds to their flexibility for industrial, automotive, or household uses.

How to Operate a Siphon Pump

To operate a siphon pump in a safe and effective manner, it is very important to follow the procedure step by step. First of all, put the siphon pump’s intake end into the source of liquid, making sure it is completely dipped in the liquid to prevent air pockets. After that, put the pump’s discharge end in the recipient container, making sure it’s at a lower height than the source container because siphoning depends on gravity. A lot of pumps include a priming feature, like a bulb or a manual pump; squeeze or activate this to start the flow of liquid. When the liquid is moving, the siphoning process will depend on the gravity force, and it will be sustained as long as the tubing is free of air and the flow is uninterrupted. Keep a close eye on the process to prevent overflows and spills, and make sure the liquids are not being transferred through incompatible materials that would damage or contaminate them. Follow the manufacturer’s instructions at all times to get the best performance and safety.

Common Issues with Siphon Pumps

| Issue | Description | Solution |

|---|---|---|

| Air Bubbles in the Tubing | Air getting stuck in the siphon tubing breaks the liquid flow | Check if the tubing is fully underwater during priming and look for leaks that might let air in |

| Clogs or Blockages | Debris can cause blockage in the tubing, resulting in loss of flow efficiency | Keep the pump regularly clean and inspected; use a filter when working with liquids that have particulate matter |

| Material Compatibility | Using incompatible liquids can lead to material degradation or pump failure | Always check if the pump parts are chemically resistant per the manufacturer’s specifications before transferring liquids |

| Loss of Prime | Siphoning stops suddenly due to improper initial setup or flow disruption | Reprime the pump by establishing suction anew and ensure all connections are airtight |

| Leakage or Cracks | Repeated stress or chemical exposure can cause the tubing or pump body to crack or leak | Conduct regular inspection, maintenance, replacement, and proper storage of the pump |

Being through with solving these problems, you will be able to keep the efficiency and trustworthiness of your siphon pump, and also its operational life will be longer.

Safety Precautions When Siphoning Gas

Essential Safety Measures

- Avoiding Direct Contact: It is always advisable to wear gloves and safety goggles in order to avoid skin or eye contact with gasoline; both can be harmful and irritating.

- Working in a Well-Ventilated Area: The fumes of gasoline are very flammable and poisonous. Make it a point to be outside or in a place with good ventilation to lessen the risks of inhalation.

- Using Approved Equipment: In the case of gasoline transfer, do not use anything else than siphon pumps that are specifically made for this purpose, as they prevent leaks, spills, or accidental ignition.

- Staying Away from Open Flames: It is very important to ensure that there are no heat sources, open flames, or sparks in the area, as gasoline vapors are an extremely flammable substance.

- Dealing with Spills Immediately: In the event of a spill, absorbent materials should be used for the cleaning process and disposed of accordingly to local regulations.

- Gas Storage: Gasoline should be transferred into safe containers, properly labeled, and then stored in a cool, dry place that is neither near heat nor direct sunlight.

If you take these precautions, you will be able to handle gasoline safely and at the same time reduce the risks involved with siphoning.

Avoiding Spills and Hazards

Gasoline handling entails a lot of precautions, and for that reason, it is important to follow certain rules if one wants to avoid spills and hazards. One of them is transferring fuel with the right tools, for example, a siphon pump; on the other hand, it might seem to use a suction hose and manual methods, but this certainly raises the risk of accidents and also inhalation. Check that the gasoline container is secure on a flat surface and opened in the right way so that it does not get knocked over or seep through. It is preferable to be in charge of the flow when pouring gas into the tank or the transfer container and to pour it slowly so as not to cause splashing or overfilling. Then, inspect all containers and equipment before using them to make sure they are in good condition and free from cracks or damage that could let liquid escape.

Nevertheless, it is important that all fueling activities be done in well-ventilated areas to minimize vapor build-up, since they can easily cause fire and health problems. At the same time, cleaning up any spills should be considered very important, and this should be done by using non-flammable absorbents like sand or commercial spill kits and always wearing gloves to prevent skin contact. Last but not least, make sure to properly label and store fuel in certified containers that are specifically designed to hold gasoline and keep them away from ignition sources, children, and pets. If you are alert and follow safety protocols, then spills and hazards will be effectively reduced.

Protective Gear and Equipment

When working with poisonous substances or in places where there is a risk of contacting them, the wearing of the right protective clothing and the use of the right equipment are a must. Personal Protective Equipment (PPE) should consist of gloves made from synthetic materials resistant to chemical penetration, such as nitrile or neoprene, so that hand protection is assured. Safety goggles or face shields are needed to protect against splashes or airborne particles, and respiratory protection, such as masks or respirators, should depend on the kind and concentration of hazardous fumes or vapors present.

Moreover, wearing fire-resistant clothing (if working with flammable substances) reduces the risk of fire, and strong, closed-toe footwear protects against spills or falling objects. In extremely dangerous situations, full-body suits may be necessary so that exposure can be minimized. Certifying by regulatory standards, such as OSHA or ANSI, and inspecting regularly for damage or wear, is the best way to keep safety at the highest level. Proper usage and maintenance of protective gear have a huge impact on the number of accidents and on compliance with workplace safety regulations.

What to Do in Case of an Emergency

In the event of an emergency, it is very important to respond swiftly and continue with the prescribed protocols to guarantee safety. Start by evaluating the situation to discover the hazards that are most urgent and find the best way to handle the situation. Contact the respective emergency services by calling 911 or the local helpline that is relevant, and give them information that is straightforward and succinct about the type of emergency, the place, and whether anyone is injured or not.

If it is safe, evacuate the area through the routes and places that have been designated by your workplace for evacuation. Train yourself to use any emergency equipment at your disposal, like fire extinguishers, first aid kits, or spill containment materials. Always remember to put your safety and that of others over that of the property. Provide first aid only if you are trained, and the situation demands it; otherwise, let the professionals take over.

After the incident is under control, the next step is to report it to the supervisors or safety officers and write down all the details. The reviews that are done after incidents are very important because they help determine the causes and ways to stop similar emergencies from happening again. Being calm, knowing what to do, and being prepared will make a big difference in the effective management of any emergency.

When You Might Need to Siphon Gas

There are circumstances in which siphoning gas becomes a necessity, for example, if a car runs out of gas in an isolated place or during a power outage that cuts off gas station access. Besides, there are cases of siphoning, such as when transferring fuel from one piece of equipment to another, like from a car to a generator, or when draining a car’s tank for maintenance or disposal. Before you start siphoning, make sure to check the regulations in your area, as in some places this activity is outright banned. Also, always practice safety first and foremost, which means using only approved siphoning equipment that will not only prevent spills but also hazardous exposure.

Common Scenarios for Siphoning Gas

Siphoning gas is quite often crucial in many situations that require the best possible fuel management or emergency response. To illustrate, one of the situations when siphoning is done is the refueling of small engines or appliances like lawnmowers, ATVs, and portable generators, for which a gas can is not available. Also, one common siphoning situation is during vehicle maintenance, where draining of the fuel tank is needed to carry out replacing, fixing, or preparing a car for long-term storage of its components. Moreover, siphoning can be indispensable in emergencies like getting stuck without any petrol station in sight; in such cases, transferring fuel from one car to the other can be a lifesaver. In any case, it is very important to observe safety procedures and also to be familiar with local laws to avoid accidents and legal problems.

Alternatives to Siphoning Gas

If you’re looking for alternatives to siphoning gas, then I suggest opting for safer and more effective methods. A hand-operated fuel transfer pump is one of the best options, since it reduces the danger of manual siphoning to a great extent and gives you the possibility of better control. Moreover, in the case of cars equipped with advanced fuel systems, the gas can be accessed through the fuel line using specialized equipment, which can be an option. Always make sure that you have the right tools and that you are following the manufacturer’s guidelines to keep safety and efficiency.

Legal Considerations for Siphoning Gas

Understanding the Legal Implications

Gas siphoning is a method that greatly varies with the area of law enforcement and the intention of the perpetrator. It is regarded as theft and hence illegal in most places if one siphons gas from another’s car or property without their permission. The punishments are quite harsh and may even include fines, restitution, or jail time. On the other hand, siphoning gas from one’s car or with the owner’s consent is basically okay as long as it is done in a safe manner and according to the local rules. In addition, some states or municipalities might have environmental regulations in place regarding the handling of fuel to the extent that they prevent spills or contamination; therefore, the right tools and techniques should be used. It is very important to consult local laws and ordinances so that you are not caught up in legal issues when doing this.

Reference Sources

This article explores the principles behind how siphons work, including the role of atmospheric pressure and tensile forces.

This paper discusses the mechanics of siphons, including energy due to pressure and elevation, and their applications.

This study investigates the maximum height a siphon can achieve, offering insights into the physical limitations of siphoning.

Frequently Asked Questions (FAQs)

How does gas tank siphoning usually happen by means of suction?

Usually, the process of siphoning gas involves the creation of a pressure difference so that the gas will flow from the gas tank to a lower container. Applying suction or using a pump for the fuel transfer are the ways that this pressure difference is made; once the gas starts flowing, gravity and the tubing length keep it moving until the source is drained or the flow is stopped. Knowledge of basic physics gives an advantage in such a comparison of different methods, as using a hand pump compared to an electric pump to get the fuel transferred.

When it comes to siphoning gas from a car’s gas tank, what hazards would you think of?

Working with gasoline means dealing with a lot of dangers, including gas leaks, fires, and skin/eye exposure if not properly protected. Always do it in an open space, and keep a fire extinguisher handy. Use good ventilation to avoid inhaling gasoline fumes, and do not let gas get into your mouth. Wearing gloves and goggles is essential, and safety measures should be put in place, especially if you are going to be transferring or removing gas from the tank. These precautions will certainly lower the possibility of any major incident happening in connection with gas.

Is it more efficient to use pumps instead of suction to transfer gas from the tank to another container?

Pumps tend to be the rates at which they work more efficiently than mouth suction. By using a hand or electric pump for the gas transfer, you minimize the exposure to gasoline vapors and remove the possibility of swallowing gas. Hand pumps are basic and portable, whereas electric pumps can be highly efficient for transferring large volumes of gas. If you want a specific amount of gas to be transferred or there is a need to move gas from one container to another without risking your health, then opt for a pump.

Is it permissible to remove gas from your own tank or from a tank you need to transfer gas?

The legality differs from one place to another, and depending on the situation. Generally, siphoning gas from your vehicle or from a container you own legally is okay when it is for legitimate purposes like getting rid of contaminated fuel or transferring to the approved equipment. However, stealing gas from someone else’s vehicle or picking it as part of thievery is illegal. If you need to transfer fuel, be sure to check the local laws and, when in doubt, resort to professional services.

What are the safety measures and equipment that I should use while learning to siphon gas and minimize gasoline fumes?

Learning how to safely siphon gas, use a dedicated hand pump or a sealed electric pump for fuel transfer, and the tubing should be long enough to reach from the tank to the container without kinks. Use a fuel-dedicated container as the gas receptor and make sure the tubing and pump are rated for gasoline. Using the right tools lessens leaks, diminishes gasoline fumes, and provides a safe gas transfer method.

What to do to stop the gas inflow that is out of control just after it has started?

One can control the inflow by using a pump that has an on/off valve or by placing the receiving container below the gas tank and watching the transfer closely. Alternatively, if the flow is controlled with a hand pump that has a shutoff or by quickly removing the siphon pump once the amount of gas required has been passed helps stop the flow of gas. Always be ready to cut off the flow before the tube reaches the bottom or the receiving container becomes full to avoid spills.

What are the typical hazards of attempting to get gas using tubing or mouth suction from the tank?

The hazards include swallowing gasoline, inhaling gasoline fumes, causing spills, and resulting fires. Mouth suction can pull gas into your mouth and lungs, which is very dangerous; never taste gas. Using a hose that does not reach the bottom of the tank can leave some fuel behind, and hoses that are not fuel-rated can break down and leak. Hence, always stick to using appropriate pumps and tubing to mitigate such hazards.

Are there other methods still more advantageous than siphoning gas if it is a matter of transferring gas to a different container?

Sure, using a proper hand pump or a certified electric pump for gas transfer can be both effective and safe compared to siphoning. An option is to use a fuel pump that clamps onto the fuel line or a portable transfer pump for gasoline designed specifically for that purpose; they are capable of moving gas from one container to another efficiently. If in doubt, a mechanic or fuelling service can draw off gas from the tank for you, which would mean avoidance of learning how to siphon and handling fuel yourself is no longer necessary, thus minimizing the hazards.