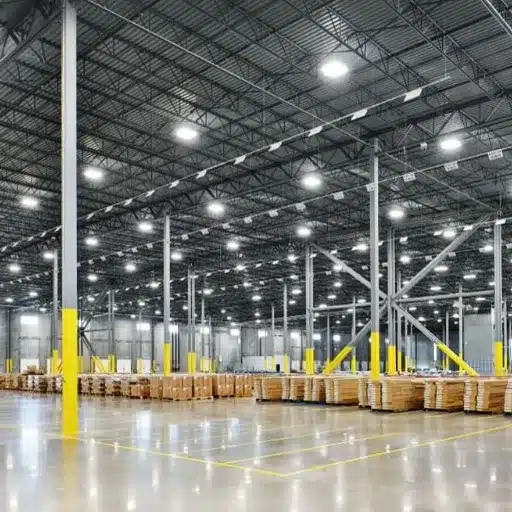

It has been recognized that improved lighting is of great importance, especially in the workplace, due to the use of energy and workers producing output. In all technological lights that are commonly manufactured, it is the downlights for industrial high bay LED lights that are modern devices in that they offer performance enhancement and cost-effectiveness of a light source in the long term. The purpose of this expository essay is to point out the high bay device in industrial usage as a preference, after considering the aspects of increased production, operations, and aspects that are so basic in a traditional setting of lights will be got in the high bay LED lights. In the case where a person wants to create more light in the warehouse, working areas, or sporting complex floors, it is worth stating that this remains very difficult without the use of the industrial high bay LED radiance growing lighting system.

Understanding High Bay LED Lights

What are High Bay LED Lights?

The industrial high bay LED lights are a type of lighting device. Installing these in such a space is important, bearing in mind the fact that the ceiling in question is about 6.1 meters or even higher. In a case like this, shallow beam short base or an opaque deep beam hone shade enhancers are of little help, and this is where the use of high bay lights comes in handy.

As opposed to the old school lighting options like the tube lights, halogen football stadium lights, high bay illuminations, etc., these come enhanced with LED chips, which have replaced the old style of incandescent bulbs thanks to their efficiency and effectiveness. The lights of an LED type (Light Emitting Diode) light equally in that they are capable of lasting over 50,000 hours, hence a low maintenance cost in the long run. They are also efficient as they can use as little as 60 percent or 80 percent of what the common metal halide or high-pressure sodium luminaire will consume.

It is owing to the fact that most high bay LED lights provide high-quality light with good coloration (a CRI of usually 80 or above), for such light, most objects and spaces appear alive. Besides, many of them are dimmable, compatible with motion sensors, and the heat output is low, which complements both energy efficiency and workplace safety. There is also operational industry statistics, and it is characterised by the fact that companies that have begun using high bay LEDs report a return on investment (ROI) within 2 to 4 years because of energy and maintenance cost reduction.

Modular and smart lighting systems development has spurred the introduction of various elements attached to high bay LED lights and systems. These elements include the control over these LEDs from a distance, scheduling, and performance monitoring. An example of operational industry systems may be given where industrial high bay LED lights are concerned. They are a firm response to the increased call for green methods of production by many industries hoping to increase their efficiency levels.

Types of High Bay LED Fixtures

- Linear High Bay LED Lights

These spaces are industrial in nature and are often tall and wide, such as shopping malls and sports facilities. This is more because they are an enclosed fixture that needs to provide an even spread of light, so as not break the light big extent, unlike circular fluorescent tubes to be placed on the aisles or shelves available for rectilinear fluorescent lamps. As per available statistics, these fixtures can achieve a maintenance solution of up to 150 lumens of light per square foot. This goal was achieved by allowing consumers to get much light using less energy. For example, it can be energy saving upto 60% on the consumption by replacing the Linear High Bay LEDs over the customary incandescent lights, metal halide, or fluorescent. - UFO High Bay LEDS Lighting

UFO high bay LED fixtures are disc-shaped and most often found in open spaces with high ceilings like gymnasiums and factories. These lighting fixtures are extremely tough and usually carry a waterproof IP65 rating, which enables their installation in more demanding applications. In the context of the new generation of UFO LEDs, they typically achieve efficiency rates of over 130 lumens per watt, ensuring the reliability of the performance specifications. Such figures present that using UFO LEDs is economical and can result in savings of a few hundred dollars every year in maintenance and power costs, especially if the said lights are used with motion or smart controls. - Smart High Bay LED Systems

The most current versions of high-bay lighting possess smart features, for instance, motion sensors, dimmers, and remote control, for easier management. With which it utilizes Internet of Things (IoT), corporations can track how much energy each facility uses in a day or a week and make provisions on how best they can operate. A study sourced from depicts that such mechanisms can increase energy efficiency to 20% over the ordinary LED fixtures – a gain that is both environmental and economic. - Economic and Environmental Impact

Installing high bay LED fixtures not only cuts down the associated costs of operations but also improves the social responsibilities of the organization. The Lifespan of these Fixtures is Way Longer Than 50,000 hours, which limits a Lot of Waste on Replacement. Moreover, companies that have replaced their lighting with LEDs have reported savings in energy costs of up to 75%, with ROI, in this case, being relatively shorter, between 1.5 and 3 years. Therefore, it is an investment that’s vital for any intending company concerned with improvement through energy saving.

Applications in Commercial and Industrial Settings

The advent of LED lighting technology has expanded the application of industrial high bay LED lights for numerous reasons. Industrial high bay LED lights are commonly used in factories and other industrial buildings because they provide intense lighting, enabling the light to cover a wide expanse. This offers improved illumination and safer conditions for the employees and contributes to lowering electric energy expenses. Statistics show that it is possible to reduce the costs of lighting that involves LED in a guesthouse, a business center, a trading center, or any other big building to 30% of what it would otherwise be.

Offices benefit from more and more LED lighting tailored for workstation use, whose color and intensity can be varied, as it is known to improve an employee’s productivity. It has been demonstrated that the proper interior lighting can improve work performance up to 23%. The application of LED lights is not only confined to the four corners of a house, but also to stores, for example, by allowing light emitters to be aimed at various sections of the store to enhance product displays, to make it more attractive, and increase the store’s rate of sales.

Streetlights, parking areas, and similar locations best support the use of Smart LEDs due to their robustly built structure and rainproof features. There are many instances of local governments replacing traditional lamps with LED lamps, where it is claimed that consumption of energy is reduced by about 50%, up to 60% in some cases. Moreover, taking into consideration the extremely long service life of LED lighting without needing even a single movement or change, this allows for fewer servicing costs, therefore more savings to businesses, global and small alike.

This is what, in fact, makes overall efficiency and flexibility in these aims achievable and possibly a driver behind the need for businesses and industries to have LEDs.

Benefits and Efficiency of Using Industrial High Bay LEDs

Energy Savings and Cost Efficiency

To start with, the main intention of industrial high bay led lights is to increase energy efficiency by an enormous margin compared to other lighting in practice, which includes metal halide or fluorescent lighting. For instance, newer studies indicate the superiority of an LED light as it consumes no less than 75 percent less energy than an incandescent light and lasts more than twenty-five times an incandescent light. In these big factories, this allows for a cut in electricity consumption along with the replacements, which are usually avoided, as this helps in improving the system availability.

Moreover, these high ROI high bay LEDs are most often fitted with added advantages such as dimmers and motion sensors, which all help the management strategize in terms of energy conservation lighting. For instance, buildings with motion sensor lighting utilize an additional 30 – 50 % less power as the lights are only in use when there is a need to do so.

Recent reports show that annual energy spending can be reduced by up to 60% by simply replacing common, outdated fixtures with new industrial high bay LED lights. Thus, if it is a 100,000-square-foot warehouse, tens of thousands of dollars can be earned every year. This improvement is not only cost-effective but helps reduce the greenhouse gas emissions of the facility and, for the bigger picture, meets world demand for energy saving.

Improved Lighting Quality and Performance

Conventional fluorescent and metal halide lights have been surpassed in light quality by industrial high bay led lights. The LED technology advancement has enabled these lights to provide brightness and uniform illumination in a structure without causing glare or flickering. The CRI rating of LED lights, according to Isaiah, ranges from 80 to 90, which is close to the intensity of the sun and improves the understandability and appreciation of objects and colors, respectively. The idea behind such robust and effective illumination is that the workers were able to complete their tasks with more precision in industrial operations, no errors were made, and more activities in the process were carried out.

Moreover, several types of LEDs are developed with a variable temperature of the color temperature, the most frequently used range being 3000K (yellow light) to 6500K (white light), and these applications also have their specific aspects to be considered. Research shows that optimal conditions concerning the amount of exposure to important lights can improve employees’ performance in production and storerooms by up to fifteen percent, which is a practical proof of the benefit of LEDs in any kind of tasks. Also, and more crucially, a considerable amount of concentration and efforts were focused on lowering the heat output through the LEDs in comparison to the conventional metal-light, more specifically, working during such hours when people are allowed to come to a great many office spaces, for instance, in many warehouse spaces.

Longevity and Maintenance Advantages

The industrial high bay LED lights are one of the best alternatives to incandescent lamps, fluorescent lamps, and other fittings, as they have a very long lifespan. Generally speaking, a single LED bulb can burn for 25000 to 50000 hours, whereas traditional types of lamps are designed to last only upto may be 1000 hours or so, while CFLs are projected to last about 8000 to 10000 hours. One of the reasons for this is the increased swap intervals and, therefore a reduction in the maintenance costs and work time consumption in connection with this kind of apparatus. Research from the United States showed that the mere substitution of existing light fixtures with LED lights could help to reduce the electricity bill by almost 30 billion US dollars per year in the next couple of decades.

In addition, LED lights are a more favorable option for these areas as they are able to withstand extreme conditions. For example, while incandescent lamps have fragile filaments and CFLs are enclosed in thin glass, LED lamps can handle vibrations, shocks, and extreme temperatures. This is an advantage of LED lighting as it is totally unrealistic to allow such lighting systems, incorporating such as, industrial and outdoor lighting as well as commercial lighting and advertising, be built in any inconsistent form.

Apart from that, long-term savings are inevitable in the sense that there is very little standing ecosystem service and investment. For example, in countries where street lighting is more widely used, there has been evidence of a 50 percent reduction in the budget allocated to public lighting due to the consumption of energy-saving LEDs, not just for energy expenses, but also in that replacements and maintenance activities are far and few in between.

However, in the case of industrial high bay LED lights, the situation is getting more complicated, because thirty meters is the lowest level suitable for products labelled as high bay or low bay.

This is the most sought-after when it comes to efficiency. Further development on this is to list the first objectives regarding practicality and cheapness, virtue of these useful light resources, and explain the reasons why municipalities and companies have replaced the systems with LEDs.

In regions where there are industrial high bay LED lights, not only does the load factor of the structure’s illumination come down, but the maintenance element ensures that the cost of such trip cans does not arise, and remains low since the activity takes place for a longer block of time without the need to replace them.

Choosing the Right High Bay LED Lights for Your Facility

Factors to Consider for High Ceiling Spaces

With every intention to optimally reduce the energy consumption, you must, amongst other measure remember the following: if not, then very simple considerations when purchasing industrial high bay LED lights for a room that has a high ceiling;

- The Height and the Lumen Efflux

Very high luminous products normally require very high ceilings. Say, for instance, even thin LED lumineers that have a quality of 10,000-40,000 lumens can be applied to ceilings that are more than 20 feet high, depending on the outcomes of the lighting effect. It would be necessary to highlight that a 300-500 lux level is the minimum allowable for such areas as warehouses and gym halls for proper illumination. - Angle Of Beams

The above table explains the variance between the various beam angles of the bulbs. Higher ceilings require 60° or 90° beam angles, as these angles provide light downwards. Conversely, wider beam angles, for instance, 120° and beyond, are recommended for low ceilings or places where there is a need for flooding light. - Color Temperature

This is in relation to the color temperature of the LED lights, which is mentioned in Kelvin scale and has some impact on the amount of efficiency of the area. Very high temperatures, like 5000 K and 6500 Kelvin give a daylight effect, and it is used mainly in stores and factories. Cooler temperatures close to the 3000-4000k range are more appropriate for stores and restaurants looking for relaxation. - Power Usage And Life Span

It is worth saying that the latter optimizes energy costs, especially when implemented in industrial high bay LED lights, as possible reductions of energy consumption up to 70 % relative to fluorescent light sources or metal halide lights are possible. It is common for a light-emitting diode’s luminous intensity to last in excess of fifty thousand hours, which significantly cuts down on cost and incidence of replacement. - Revised and Instructional.

LED high bay fittings, a newer version, come with motion sensors and dimmers, which are more localised and control light levels according to the facility’s nature of activity and occupancy. Conversely, the situation is further supported by information, suggesting that the inclusion of motion sensors and a smart electricity system slashes electricity costs by an additional 30%. - Rating and Strength

In the case of working in industrial areas, it is recommended to fit electrical fitments with a high IP rating of and beyond IP65 to minimise dust and water entry. Because much of the manufacturing work is carried out inside the factory and also in such places as ‘sports and exercise facilities’, juice lights will be needed; the lights will need to be robust.

With these in mind, the other stakeholders, among them the lighting coordinators and planners of the lighting schemes, need to include the lighting designer professional, in order to consider maximizing the effectiveness, the fit, and the cost consideration when dealing with high ceilings. All thanks to the external and internal supporters, leaders, such as managers, who taught and encouraged you, and to the industrial high bay led lights, because these lights change the picture inside the premises.

Installation Tips for Optimal Performance

Multiple considerations or aspects need to be taken into account in the case of industrial high bay lights to perform to the maximum.

- Mounting Height: A necessary reduction in the skill required and involvement of personnel is obtained because lighting for high-bays is used for high ceilings, ranging from 20 ft to 40 ft. Setting these lights too low can lead to discomfort in the eyes, while setting them too high reduces the Light Efficiency and the quantity of light reaching the desired areas. Research points to the optimal height of installation of high bay lights, giving even light distribution, which makes it more convenient to see.

- Spacing for Lights: Meticulously positioned and angled luminaires will help avoid any over- or underlit spaces. For example, with the ceiling height ranging between 20 and 30 foot, it is advisable to maintain the luminaries at between 15 and 20 feet spacing in normal lighting condition whereas lower lighting condition allows a greater interval between luminaries i.e., 20 to 30 feet.

- The Relevance of Beam Angle: Beam angles influence where the light will be thrown. Where the aims are to avoid unnecessarily throwing light, a high-efficiency luminaire with a beam angle of 60° is the default. Generally, lighting with a beam angle of 120° would be appreciated in large spaces such as rooms, relaxation, and reception areas. a Insertion of a comment on the usage of beams to enhance effectiveness.

- Energization Manufacturing and Evaluation: Consumer energy reduction technologies; Use of such high-construction installed lights might as well energies result in energy consumption reduction of up to 70%. When comparing metal halides and fluorescent lamps. Moreover, LEDs’ proven useful life of 50,000-100,000 hours greatly cuts through the glass to their replacement cost and, more importantly, the downtime.

- Use and Interface Technologies: Attempts have been made to develop systems that assist in enhancing energy usage through motion sensors and control systems as well. For instance, the manufacturing of these industrial high bay led lights entails special wiring that utilizes earth coupling assistance, together with other electrical devices, which provides a reduction in the utilisation of energy ranging from 20-30%.

- Environmental Factors: Confirm the selected fittings are suitable to the operation conditions. In hot or low temperature areas, only consider using L. E. D’s suitable for those environments. It is recommended that for fixtures that are located in dusty or damp environments, the enclosures used are rated IP65 or above.

Adhering to the comprehensive suggestions listed above, it is possible to provide the reliable, effective, long-lasting lighting that meets the demands of any particular industrial or commercial space.

Maintenance Best Practices for Longevity

Taking care of any industrial and commercial lighting systems is more than a maintenance task. One has to ensure they can perform at maximum capacity for a prolonged period of time. It is crucial to ensure that all the systems are maximizing their lifespan and the energy efficiency of light fittings and bulbs is constant. There are several best practices you can use:

- Regular Cleaning.

Dirt and other deposits on light fixtures can have a negative impact on their performance and light output. Therefore, the lamp, lenses, and fixtures should be washed with a non-abrasive cleaner.

For instance, research carried out has shown that fixtures that are in the dirt increase the usage of light by 30 % and that indicate that those cleaning computer schedules have to be changed according to the surrounding environment. - Inspection and wear Part Replacement.

To combat the strange cases of lights going out during operation, or where lights aren’t in full power, inspection services should take on abnormal lights, flickering lights, dimming, as well as color changes. Replace the drivers or LED modules, which are the initial failures, and prevent any other failures. For example, LEDs are typically rated between 50,000 hours and 100,000 hours, but the drivers have an average life span of only about 40,000 hours; hence, replacing the driver is necessary. - Temperature Management

Keep the environment under which the fixtures are operating as recommended. Interior fixtures may be overheated, leading to their reduced durability or poor performance, even before the LED lights start to deteriorate. For response or any other needs, ensure that heating or cooling solutions are applied. - Improves in Controls & Firmware

For lighting systems that are intelligent, remember to install all the drivers and other control settings. Improvements usually tend to contain several areas, such as performance enhancements, bug fixes or what is called practical energy-saving. For example, the different packages inside these updates can save power consumption by about 20%. - Efficient Facilities and Remaining Procedures

We recommend, at this point, the use of energy management tools to take charge of the repayment study within the scope of the lighting system. Knowing about potential problems can let you know when it’s better to service equipment before something occurs–repair rather than maintenance. There is evidence that predictive maintenance can decrease the incidence of repairs by a rate of up to 15%, saving money.

It is highly possible to ensure that the lighting system of a building stands the test of time and is usable most of the time, thanks to the availability of modern maintenance policies. Such measures have direct positive effects, extending the durability of the equipment in use as well as supporting energy savings for operational costs by reducing wastage.

Recent Technological Advancements in High Bay Lighting

Smart Lighting Solutions for Industrial Applications

The increasing need for new lighting technologies also extends to industrial high bay LED lights aimed at enhancing productivity, energy consumption reduction, and regulation of handling processes. For example, many systems employ all of these amenities, such as motion control, daylight, and IoT optimization. Consequently, almost half of the illumination energy with a great number of industrial high bay LED lights installed can be cut off due to such smart lighting, where energy is saved. The major solution is supplemented with presence-energy sensors, where presence sensors detect the extent of people, so that the energy does not need to be used as per the brightness level.

In addition, if lights are connected to the internet, the user is able to manage the lighting system from any location. Deleted materials based on the presented information are also of great importance. Utilization changes patterns are easily detected as such systems are able to monitor the power in use and how it is used at different levels. Some studies have pointed out that maintaining a normal lighting setup by incorporating IoT drops the costs by at least a fifth to a sixth. This is achieved due to the self-correcting methods, which address the issue beforehand, more like in predictive analytics.

These and many other new technologies have consumable industrial equipment beneficial as it reduces energy costs, improves green design, and increases the output. Smart lighting systems are not a matter of choice with the contemporary power saving and energy competition, especially in industrial high bay LED lights and other spaces.

Innovations in Linear LED High Bay Lighting

In recent years, research and development activities in the field of Linear LED High Bay Lighting Fixtures have reached an advanced extent as a result of new technological and conceptual advancements. These Industrial High Bay LED Lights are red with a high level, such as 140 at the lowest and 160 at the highest, and are more energy-efficient than fluorescent or metal halide lights of the same purpose, since they don’t consume a lot of electric energy. The industry asserts that, inasmuch as current research shows that recycling these linear LED lights can reduce energy-related costs to almost sixty percent, this has greatly solved the associated problem in large-scale industrial settings like warehouses, factory complexes, and gymnasiums, thanks to our easy gym entry.

To add on, there are some lighting installations which have the feature panel lights, motion sensors or sunshine-collecting lanterns for the purpose of energy saving. Another finding established that it could be possible to add more “industrial high bay LED lights” with smart control devices, which limit system load to 20 – 30 percent. Besides, the incorporation of LED lights that have a lifespan of over 5000 hours greatly helps by preventing expensive repairs since it is no longer a must to change the bulbs frequently.

Given that the IoT technology support is already built into the design of linear LED high bay light fixtures, there is again a very supportive pattern for the market. The lamps improve modern-day lighting by being able to connect to the internet to allow users to access information on the energy consumed and the subject rate of the lamps in real time, which in a way enables their efficient operation management by the facilities managers. But still, it is understood that more government and organizational interests are on policies addressing every sector that deals with renewable energy. Some hockey stick forecasts predict a market growth that will see the penetration of industrial high bay LED lights rise by at least 7.6 percent, Compound Annual Growth Rate or CAGR, between 2023 and 2030.

This project’s goal is to implement linear LED high bay structures efficiently while ensuring the enterprise’s stable operation for a long time without losing the quality of management work, and while increasing attention to environmental issues, promoting such solutions.

Energy-Efficient Features in Modern High Bay Fixtures

The levels of brightness capable of use, especially as far as metal halides and even other traditional types of light sources such as fluorescent tubes, can be generated by industrial high bay LED lights, utilizing far less energy. For instance, it was found that the distribution of LED bulbs ranged from 130 to 150 lumens per watt, which makes them some of the most efficient light fixtures in the market.

Also, installation of daylight harvesting controls (e.g., infrared beam sensors, sunlight sensors, etc.) further helps to save electricity by switching on the lights only when there is a need. The incorporation of such even brighter ideas of smart controls enhances energy efficiency gains in lighting by as much as 30% minimization, which could be cost effective more so urban in urban public service buildings or any other structured commercial premises. Information from the recent marketing survey and further statistical analysis indicates that there has been a decline in energy consumption after two years of such strategy facilitation by enabling medium to large-scale industry institutional change, with decreased cost of energy spending by twenty-five percent.

Taking the lead in this revolution are, without doubt, the industrial high bay LED lights that apply cutting-edge technology. Higher efficiency results from both less energy used and greater aches and controls compared with the currently existing lighting system. Another factor that makes LEDs beneficial to providers is longevity, and this is another important aspect of contemporary lighting. The majority of the light fitting systems made from LED are guaranteed to last no less than 50 thousand substance exploitation readmission. This translates to a few years if the client installs it and forgets. This is advantageous to the elimination when preventing users from the same boring procedure, minus the replacement, and lowering the waste significantly.

The capabilities of modern lighting do not only reside in its energy efficiency or energy savings elements. Thanks to recent advances in the application of bright illumination, the functionality and aesthetics of luminaires are also in the process of modernization. Designs that integrate luminaire surfaces designed for high Lumens and efficient usage are generally a good energy-saving mechanism for most organizations, as industrial high bay LED lights consume 30% less energy than the normal fluorescent fittings.

Reference Sources

-

High Bay Lighting Market Effects Study – Final Report

This report, sponsored by the California Public Utilities Commission, explores the market effects and feasibility of high bay lighting in industrial settings.

Read the report -

Integrated Lighting Efficiency Analysis in Large Industrial Buildings

This research evaluates the integration of daylight and LED high bay lighting to enhance indoor environmental quality and energy efficiency.

Read the study

Frequently Asked Questions (FAQs)

How do Industrial High Bay LED Lights work, and how is it beneficial for the modern industry?

Industrial High Bay LED lights are very high-tech fixtures to light up high ceiling places, usually between 20 and 45 feet, which is primarily their use for. They are very effective, especially for modern industries, because they not only provide uniform distribution of illumination but also have high intensity levels, especially for large rooms such as, but not limited to, warehousing, manufacturing, and indoor sporting facilities. This is an assurance of energy-saving resources, long life span replacement, and minimized maintenance expense, which easily beats other lighting systems.

Why are industrial high bay LED lights energy-efficient?

Usually manufactured as high bay LED lamps, it is evident that these have been designed specifically to use much less energy consumes more than the typical mechanisms, for example, metal halide or eight fluorescent lamps. In that regard, the lighting turns more electricity into light as opposed to heat. These fixtures employ modern considerations to not only curb the use of energy but also decrease the cost of operations in an industrial setting.

How is LED lighting technology beneficial to the environment?

When resonating on LED technology, its friendly environmental credence can be seen in the fact that the lamps last quite a long time, consume less power, and production is not harmful to the environment. The lifespan of LED light bulbs ranges from a minimum of 50 000 hours up to 100 000; therefore, there is no need to change them frequently, which leads to less waste. Also, they do not contain any hazardous materials, such as mercury, and another ingredient that contributes to their potential eco-friendliness is that they are recycled very easily.

Is it possible for Industrial High Bay LED lights to be used easily in such hard conditions as those found in factories and industries?

Indeed, Industrial High Bay LED fixtures are made with heavy-duty light fixtures for use in adverse environmental conditions. Most of the fixtures have rugged and shatter-resistant casings to withstand thermal, wet, dry, dusty, and even mechanical forces that are predominant in any work environment. And on this quality, they deliver on their expected performance level and duration even when used in work sites such as factories or godowns.

Is it possible to make Industrial High Bay LED lights to suit particular needs?

This is because almost every type of High-Bay LED lamp available today is adjustable to meet the requirements of any kind of industrial lighting. These are, for instance, the cases where the lighting brightness levels can be varied; the lights possess little to non-existent dimming, or there is a color temperature capability suitable for the type of lighting preferred. Some of these models can also use advanced lighting systems that allow one to home in on epidermal control, telescope bright and adaptable lighting.

How do industrial high bay LED lights help in enhancing the safety of the workplace?

Adequate illumination is of utmost importance with regard to occupational health and safety, especially in relation to industries. The installation of industrial high bay LED lights provides adequate lighting, and it also diminishes both shadows and glare. This goes a long way towards equity and fairness, that is, safe performance of these duties by the workers and an increase in efficiency of the workplace.