Fueling is changing, and right amid this transformation is the Mini Fuel Dispenser Machine. Bringing efficiency, convenience, and precision in fuel delivery, this technology is transforming sectors and changing how business is conducted. Whether it’s a construction site, a logistics fleet, or a farm, the Mini Fuel Dispenser Machine offers a more efficient and streamlined way to refuel compared to traditional methods. In this blog post, we will walk you through how this device is revolutionizing fuel delivery, the benefits it offers, and why it’s becoming an indispensable tool for several sectors. Buckle up to experience how this miniature but potent invention is fueling the future!

Understanding the Mini Fuel Dispenser

This Mini Fuel Dispenser is a compact system designed for easy fuel delivery and efficient operation. It provides portability coupled with accuracy, making it suitable for industries where equipment needs to be refueled on-site. This is a simple device that accurately measures fuel, thereby preventing wastage and ensuring the dispenser operates at its optimal performance. Its sturdy construction allows for working in harsh environments; hence, one can always rely on it and find convenience in its use. By focusing on efficiency and convenience, the Mini Fuel Dispenser promotes contemporary refueling methods.

What is a Mini Fuel Dispenser?

The mini fuel dispenser is a compact and portable refueling system that ensures efficient and accurate delivery of fuel. It is typically used in construction, agriculture, mining, logistics, and other industries to provide on-the-spot refueling of vehicles and machinery, thereby reducing downtime and improving productivity.

The latest mini fuel dispensers are equipped with features such as digital flowmeters for precise fuel measurement, auto-shutoff nozzles to prevent spills, and fine, built-in filters to ensure fuel cleanliness. They can dispense diesel, gasoline, or biodiesel with flow rates that mostly range between 20 and 60 liters per minute, depending on the models. They work on electricity, batteries, or sometimes manually to meet the demands of different users placed in varying working environments.

Durability is a crucial element that must be considered in mini fuel dispensers. Mostly, these are made with corrosion-resistant materials, which therefore ensure reliability in adverse operating conditions. They are also ergonomically designed for easy transport and installation at different sites. As aspects of efficient resource use and environmentally conscious practices are being given prime consideration now, some models of mini fuel dispensers integrate fuel considerations and techniques to reduce waste as part of environmental and cost-saving initiatives.

Mini fuel dispensers serve as a comprehensive solution for the portable and efficient management of fuel resources. Regardless of whether in remote sites or busy industrial settings, the dispensers continue to make a significant impact in enhancing the efficiency of the entire refueling process and ensuring operations run smoothly.

Key Components of a Mini Fuel Dispenser Machine

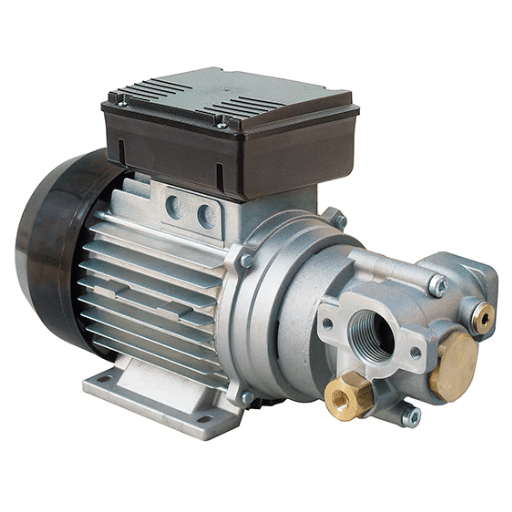

Pump System: The pump is the core component inside the mini fuel dispenser. Fuel is drawn from the storage tank and pumped to the nozzle. It purveys steady fuel flow at efficient and reliable rates.

Flow Meter: It features an exact flow meter that measures the quantity of dispensed fuel, enabling precise fuel distribution and maintaining transparency for scrutiny.

Nozzle: The dispensing nozzle is an excellent device for dispensing fuel to either a vehicle or a container. Nozzles are provided with automatic shut-off devices to avoid overflows and spills.

Control Panel: The control panel is used to set and control the dispensing process. New systems typically feature digital displays that show transaction details, including the amount of fuel, price, and total cost.

Hoses and Piping: The nozzle is connected to the pump by a flexible and durable hose, through which fuel is transferred with minimal resistance. Piping is used to provide structural integrity and distribution.

Filtration System: During dispensing, filters remove impurities from the fuel with the end goal of delivering cleaner fuel to the recipient. This lessens engine wear on vehicles in general.

Power Source: Mini fuel dispensers utilize an electric, battery, or solar system as their power source, enabling them to operate in diverse environments and support mobile applications.

The components work in tandem to ensure that fuel dispensing is convenient, accurate, and, most importantly, safe.

Types of Nozzles Used in Dispenser Machines

The common types of nozzles used in mini fuel dispenser machines include automatic shut-off nozzles, manual nozzles, vapor recovery nozzles, and high-flow nozzles.

|

Type |

Feature |

Purpose |

Flow Rate |

Special Use |

|---|---|---|---|---|

|

Auto Shut-off |

Hands-free |

Prevent spillage |

Standard |

General use |

|

Manual Nozzle |

Simple control |

Basic fueling |

Adjustable |

Versatile |

|

Vapor Recover |

Eco-friendly |

Reduces fumes |

Moderate |

Environmental |

|

High-Flow |

Fast delivery |

Fuel trucks |

High |

Heavy vehicles |

Applications of Mini Fuel Dispenser Machines

Mini fuel dispenser equipment is typically used in locations where fuel must be dispensed efficiently and adequately. This includes smaller fuel stations, construction sites, farms, and any other places where traditional fuel setups would be impractical for one reason or another. A refueling dispenser is particularly beneficial to have nearby, as it can quickly and conveniently refuel vehicles, agricultural equipment, and machinery. Portability, ease of functionality, and the ability to operate from physically weak infrastructure zones, such as construction sites, are a few attributes that make it an excellent instrument to pack along.

Mobile Fuel Stations and Their Benefits

The mobile fuel stations provide on-the-go refueling services with options for flexibility and efficiency, adaptable to various environments. They are what the remotest places need to run: agriculture, construction, others in materials procurement, loading/unloading, logistics, and mining. With the search, they would fill a significant gap in unfavorable downtimes.

Modern mobile fuel stations feature the latest technology, including automated fuel dispensing and real-time monitoring. For example, operators can track fuel consumption in real-time and optimize act distribution while preventing waste using an IoT-based tracking system. Additionally, fuel stations prioritize safety with features such as double-walled tanks, spill containment, and fire prevention systems, ensuring compliance with all relevant environmental and safety regulations.

These figures show rapid growth in the global mobile fuel station market. Expected to continue at a rate of over 5% CAGR in the coming years, the increasing demand for efficient fuel solutions in developing regions is encouraging. Industries operating in isolated areas (mining in Africa or agricultural fields in Southeast Asia) emphasize the importance of the systems for sustaining productivity and supply chain continuity. More portable and convenient, mobile fuel stations are essentially saving organizations that depend heavily on machinery and vehicle fleets the cost of prefabrication.

With technological advancements and an increasing focus on sustainability, mobile fuel stations are being progressively adapted to CNG and hydrogen, becoming active participants in the transition to cleaner energy solutions. Their versatility and reliability give them importance in modern-day industrial and commercial situations.

Usage in Petrol and Diesel Delivery

The advent of mobile fueling stations has altered the traditional delivery of petrol and diesel to various sectors, providing considerable convenience and efficiency. These stations are implemented for industries such as agriculture, construction, and logistics to offer on-site fueling, thereby reducing downtime and optimizing operations. Recent industry reports indicate that the global mobile fueling market is poised to grow at a compound annual growth rate (CAGR) of approximately 6-8% over the forthcoming decade.

With the demand for fuel efficiency rising and more fleet vehicles being used for regular refueling, growth would tend to increase. An example is the mobile fuel stations of today, which are equipped with advanced tracking technologies and automated systems to ensure that an accurate amount of fuel is both delivered and consumed. This also provides lower operational costs compared to traditional methods of refueling, such as making frequent trips to the gas station.

As stringent emission requirements are enforced worldwide, companies are adopting mobile fuel to streamline their operations and comply with regulations. Mobile fuel stations must be flexible enough to dispense both standard fuels and alternative fuels, such as biodiesel, to retain their versatility and indispensability in the fuel service industry.

Portable Fuel Solutions for Various Scenarios

With their flexibility, convenience, and efficiency, portable fuel stations have become increasingly important in various situations. When securing fuel is not possible on-site, portable fuel solutions enable remote construction sites to maintain all heavy machinery and equipment in optimal working condition. Industry reports suggest that such solutions have reduced downtime during refueling by up to 30%, thereby significantly increasing output levels.

Emergency response operations can benefit greatly from it. During emergencies, such as hurricanes or wildfires, fast on-demand fuel can be provided for emergency vehicles, generators, and rescue operations. For instance, after major hurricanes, portable fuel units played a crucial role in restoring basic power to the affected areas following massive outages.

Finally, portable fuel delivery services facilitate the power needs of large-scale outdoor events, such as music festivals or sporting events, where generators provide temporary infrastructure. Recent data highlight that portable fuel delivery to the event site can reduce logistics costs by 20% compared to conventional refueling methodologies.

Agriculture also utilizes portable fuel for machinery, such as tractors, harvesters, and irrigation systems, in areas distant from centralized fuel sources. Minimizing fuel wastage while ensuring maximum operation during peak seasons is therefore guaranteed as industries adopt greener practices. Portable fuel systems that can deliver alternative fuels such as renewable diesel are also receiving attention as the world strives to reduce carbon emissions.

As portable fueling solutions cater to various needs in construction, emergency response, events, and farming, they provide a critically essential service that supports efficiency and emergency operations across different contexts.

Features of Modern Mini Fuel Dispenser Machines

Compact and Portable Design: Modern mini fuel dispenser machines are designed for portability, making them suitable for installation in remote or confined areas.

Support Alternative Fuels: Many models are compatible with alternative fuels, including biodiesel and renewable diesel. Hence, this feature fulfills the demand for greener energy solutions.

Advanced Metering Systems: By having accurate flow meters, the machines ensure fuel is dispensed accurately, minimizing waste and enhancing operational efficiency.

Higher Safety Features: These machines incorporate automatic on/off shut-off valves and leak detection systems to minimize the risk posed by fuel handling.

Ease of Operation: User-friendly touch interface panels and digital display screens make fuel dispensing quick and easy for operators of all skill levels.

Durability and Weather Resistance: Constructed with tough materials, mini fuel dispensers ensure endurance plus consistent performance under the harsh environmental conditions.

These characteristics make mini fuel dispenser machines a dependable and efficient solution for various industries that require portable fuel management.

Digital Displays and User Interface

Modern mini fuel dispensers are equipped with advanced digital displays and an intuitive user interface, providing ease of operation. Fuel type, quantities dispensed, total cost, and pump status would typically be displayed information to allow operators to keep track of and manage the entire fueling procedure. In terms of quality, many displays feature high-resolution LED or LCD screens, which make them visible in both daylight and low-light conditions.

Before I describe advanced enhancements with interface features, let’s consider a few key issues: multi-language support, touchscreen functionality, and compatibility for an integrated payment system, among others. Such enhancements include simplified operations, a reduction in the training period required for new users, and an increase in fuel management accuracy. Some systems also include connectivity features that enable remote monitoring and syncing of data, allowing the fleet manager to access fuel consumption data from multiple locations for informed decision-making purposes. These innovations lay claim to functionality and convenience set within reasonable bounds for an extensive range of users and applications.

Customization Options for Fuel Pump Dispensers

The contemporary fuel pump dispensers come with customization that different businesses and clients can apply depending on their needs. Some of the main customizable features include interfaces, such as touchscreen displays, that can be customized with company branding, logos, or promotional messages. These interfaces typically come with multiple language options, allowing them to be used by diverse groups of users.

Furthermore, fuel pump dispensers can be integrated with advanced payment methods, utilizing RFID readers for contactless payments and supporting mobile wallets. By doing so, they can expedite the payment process, enhance its convenience, and reduce the customer’s waiting time. Safe access control can be integrated into any dispenser for fleet management, allowing only authorized personnel to dispense fuel.

Another custom feature, especially popular, is compatibility, which allows dispensers to work with various fuel types, including gasoline, diesel, biofuels, and CNG. More advanced ones, therefore, allow for multi-product nozzles where the station caters to a large number of vehicle types.

Data-driven insights are becoming increasingly critical. Dispensers with their integrated monitoring systems track fuel consumption, pump performance, and maintenance schedules, enabling businesses to optimize their operations and address issues proactively. With energy efficiency technologies, such as vapor recovery systems and LED lighting, incorporated, customized dispensers are providing businesses with a helping hand in reducing costs and environmental impact.

Versatility ensures that fuel pump dispensers are adaptable to the diverse needs of various industries, ranging from retail fuel stations to large commercial fleets.

Specifications to Consider When Choosing a Machine

When purchasing a fuel pump dispenser, it is essential to inspect various specifications that ensure efficiency, reliability, and cost-effectiveness for the intended operation. Consider these key factors:

Flow Rate Requirements: Flow rate refers to the speed at which fuel is dispensed. Retail fuel stations typically operate within standard flow rates of 5-10 gallons per minute (GPM), depending on the type of fuel. Commercial or industrial applications, however, may require higher flow rates, ranging from 15-50 GPM and above. Making an appropriate flow rate selection may help reduce the time a customer must wait while being served.

Compatibility with Fuel Types: These dispensers are designed to dispense a variety of fuels, including gasoline, diesel, ethanol blends, and biodiesel. It must be ensured that the dispenser will be compatible with the fuel types used in one’s operation and with regulations covering the handling of alternative fuels.

Meter Accuracy: Always consider precision in fuel metering; it ensures neither loss is created nor customer inconvenience is caused. Select one that meets or exceeds minimum calibration standards and offers an accuracy rating of ±0.2% or better. Typically, modern dispensers are equipped with automatic calibration features to enhance their reliability over an extended period.

Durability and Material Quality: The dispenser’s construction material should resist harsh weather conditions, possible chemical exposure, and heavy use. Models made from corrosion-resistant materials, such as stainless steel or composite materials, ensure durability for more extended periods and reduced maintenance costs.

Technological Integrations: Some of today’s dispensers are fully equipped with various technologies, including integrated digital displays, barcodes, wireless connectivity, and IoT capabilities. These technologies enable real-time monitoring, transaction management, and predictive maintenance alerts, ensuring minimal downtime.

Energy Efficiency: Systems equipped with LED lighting and efficient motors reduce power consumption, therefore saving on costs. Selecting a machine certified for low energy use can also help achieve the goal of sustainability.

Safety Features: Key safety features to consider include emergency shut-off valves, vapor recovery systems, and fire protection mechanisms. The presence of these features reduces risks and safeguards against violations for fuel dispensing.

Cost of Ownership: Besides considering the initial purchase price, also consider the long-term operation, maintenance, and repair costs for the dispenser. Machines that are easy to maintain, with service warranties for parts and labor, add greater value to the client over time.

By properly considering these specifications, companies can select fuel dispensing systems that meet their operational needs, increase efficiency, and promote safety and environmental consciousness.

Maintenance and Safety of Fuel Dispenser Machines

Proper maintenance and safety of fuel dispenser machines are vital to their operation and to prevent accidents. Inspections need to be made to identify any wear and tear and confirm that all components are performing as they should. Preventive maintenance involves activities such as cleaning or replacing filters, checking hoses for leaks, and calibrating meter gauges to retain accuracy and efficiency.

Ensure that staff is trained in the proper methods of operation and the safe handling of fuel, including measures for spill containment, and that safety signs are prominently displayed. Emergency shut-off systems should be tested at regular intervals to ensure they can be relied upon in the event of an emergency. By complying with procedures as laid out by manufacturers, alongside industry safety standards, machines become effective and safe for daily use.

Routine Maintenance Tips for Longevity

Regular Inspection: Cleanliness Is Next: On-Timing inspections serve as preventative maintenance against costly repairs through early intervention for any signs of wear and damage. Cleanse the filters, fuel tanks, and nozzles regularly to maintain optimal performance. Clogged filters, for instance, have been said to cause a fuel efficiency drop of almost 25%, thereby deepening the need for regular cleaning.

Lubrication: Unlike cleanliness, Lubrication of moving parts minimizes friction and prevents premature wear. Usually, manufacturers recommend lubrication programs tailored to their specific machines, which, if followed, can add a few years to the machine’s life.

Replacement of Worn-Out Components: To prevent vulnerable components from failing, belts, hoses, or seals must be replaced on a proactive basis. It is noteworthy that instances of equipment downtime generally correlate with ignoring indicators of early component fatigue. A spare inventory may reduce unplanned delays.

Monitor Fluid Levels and Quality: Regularly check and change engine oil, coolant, and hydraulic fluids to prevent overheating and mechanical breakdowns. The use of high-quality fluids, specifically designed for the equipment, further enhances the machine’s performance and longevity.

Software Updates and Calibration: For modern and high-tech machinery, it is essential to keep the software up to date and calibrate sensors at regular intervals to ensure better accuracy and optimal output from the machine. It is recommended that equipment requiring high precision be calibrated every 6 to 12 months.

When these steps are considered, the machinery will work at optimal efficiency, resulting in downtime and a longer lifespan. Adhering to maintenance schedules will not only secure the investment but will also increase production.

Safety Protocols for Fuel Handling

An effective fuel handling procedure is essential for ensuring safety in industrial settings and operational environments. Fuel is always to be stored in approved containers, subject to industry standards that include safeguards against leaks and spills. Storage tanks must be placed in ventilated areas, away from direct sunlight and heat sources, to be free from all fire hazards, as per global safety regulations.

Persons handling the fuel should wear protective personal gear, such as gloves and goggles, to prevent direct contact with it. Studies have shown that the vapors of fuel are harmful to humans upon inhalation; therefore, it is essential to ensure that there is an effective ventilation system in fueling areas to minimize such exposure. Spill kits for emergency purposes and fire extinguishers suitable for use on flammable liquids should be made available, and the staff should be trained in their use so they may deal with incidents promptly.

When fuel is transferred between containers and equipment, it is imperative to use anti-static tools to avoid sparks. Several studies have demonstrated that static electricity is a common ignition source during fuel transfers, particularly in dry conditions. Regular inspection of the fuel storage and delivery system to detect signs of wear, corrosion, or leaks would reduce the potential for an incident to occur.

Following these measures ensures that employees, equipment, and facilities are protected while also fulfilling the conditions stipulated by safety regulations, thereby cultivating, in essence, an atmosphere of risk prevention and awareness.

Common Issues and Troubleshooting Techniques

Static Electricity Build-Up: Another issue in fuel handling is the build-up of static electricity, which can produce sparks and lead to an ignition hazard. When transferring fuels, ensure the equipment is properly grounded and bonded to prevent this issue. Grounding cables should be checked periodically for continuity to avoid failure. If antistatic additives are incorporated into fuels, studies have shown that they can reduce the risk associated with spark generation, especially under dry or low-humidity conditions.

Corrosion in Fuel Systems: Corrosion often proves to be a significant adversary in fuel storage and delivery systems, as they can become contaminated by water or microbial agents. Tanks and pipelines should be inspected for signs of rust, pitting, and other similar defects. Corrosion-inhibiting chemicals should be used, and drainage measures implemented to safeguard against long-term damage. Reports indicate that the latest advancements in coating technology and materials, such as high-performance alloys, are the most effective at battling this issue.

Fuel Emulsification and Degradation: Fuel degradation, resulting from various processes such as oxidation, microbial contamination, or improper storage conditions, can impair the efficacy and potentially cause blockages in filters or injectors. There yet lies a possibility of resolving this problem by providing proper storage conditions, such as maintaining stable temperatures or conducting periodic tests of fuel quality. Research highlights that employing stabilizers can significantly increase the shelf life of the stored fuels.

Leak Detection Failures: Unmonitored leaks can result in environmental and safety hazards. Modern leak detection systems are equipped with fast-response sensors that give immediate alerts. The operator should conduct regular tests on the operation of the systems and maintain awareness of the early warning signs of leaks, such as sudden, unnatural drops in pressure or an unexplained increase in fuel consumption rates.

Filter Blockages: Clogging by any particulate matter or water contamination in a filter can halt the fuel flow, thereby halting operations. Regularly monitoring the filter condition and replacing the filters as part of a maintenance plan can help prevent equipment damage. The implementation of high-efficiency filtration systems appears to reduce maintenance costs while ensuring optimal performance.

Addressing common issues systematically with up-to-date, modern technologies could thereby secure safety, avoid very costly downtimes, and simultaneously ensure compliance with environmental norms.

The Future of Fuel Dispenser Technology

At the forefront of the future of fuel dispenser technology are efficient dispensing, tireless sustainability, and an enhanced user experience. With digital payments in an age of its own, being integrated here, the generation of increased volumes of maintenance data for analysis, and facilitating alternative fuels, such as hydrogen and electricity, stand as the following technical improvements. Touchscreen displays and mobile app integration, meanwhile, streamline the refueling experience for the consumer. Innovations for fuel dispensers also grease the wheels for energy-efficient designs and intelligent monitoring systems, reducing operational costs and environmental impact, while enhancing the industry’s regulatory requirements in all their ever-changing aspects. Together, these technologies will ensure fuel dispensers keep pace in an increasingly versatile and greener future.

Emerging Trends in Mini Fuel Dispenser Machines

Mini fuel dispenser machines have experienced a significant increase in demand due to the evolution of compact designs and the addition of advanced functionalities. Among the bigger trends is the use of IoT technology for real-time monitoring and better connectivity. This trend essentially means that most modern mini fuel dispensers will incorporate remote controls, data analytics, and automated fault detection mechanisms to enhance efficiency and user experience.

Contactless payment options are the other trend being witnessed. With the surge in digital payment systems, the use of mini fuel dispensers with NFC and QR code scanning capabilities for payment is gaining momentum, ensuring quick, safe, and convenient transactions for the users.

From an ecological perspective, manufacturers are concentrating on energy conservation. Mini fuel dispensing machines are designed to minimize power consumption, featuring efficient motors and power-saving operational modes. Some of the systems are powered by renewable sources, such as solar energy, to reduce their carbon footprint further.

Market analysis reports suggest that the global mini fuel dispenser market will have exponential growth, with a CAGR of more than 5% forecast over the next decade. This growth is fostered by an increased demand in the rural and semi-urban areas, wherein smaller units of dispensing offer an economical and easy method of refueling. With such innovations, mini fuel dispenser machines hold a significant place in the petroleum industry, meeting the dynamic requirements of consumers and the environment.

Impact of Technology on Fuel Delivery Systems

Fuel delivery had been the first area to witness cutting-edge technologies being applied to enhance efficiency, precision, and convenience. I believe that the integration of digital interfaces, automated controls, and enhanced measurement systems has improved operational accuracy and substantially reduced waste. With such amenities, processes are increasingly streamlined and well-managed on the resource side, making businesses, as well as end consumers, better aligned with their requirements for sustainability and convenience.

Innovations in Fuel Pump Design and Functionality

Fuel pump technologies have witnessed key innovations in their pursuit of efficiency, reliability, and environmental sustainability. Hence, modern fuel pumps operate on high-pressure direct injection systems that improve combustion and fuel economy. Enhancements can also be digital and electronic: smart sensors and controllers may monitor fuel quantity in real-time, ensuring exact fuel delivery and better diagnostics of the fuel-pump systems, which in turn reduce the chances of failures.

They also began making the pumps using lightweight, wear-resistant materials to improve their longevity. The design must be environmentally friendly in the sense that it should minimize vapor emissions and fuel leakage into the environment. This aligns with global efforts to reduce environmental impact. These advancements, therefore, essentially enable the fuel-pump systems to respond to the need for performance, and in turn, be both cost-effective and environmentally friendly in both automotive and industrial applications.

Reference Sources

Design and Implementation of a Fuel Dispenser Using RFID

Fuel Automata: Smart Fuel Dispenser Using RFID Technology and IoT-Based Monitoring

Frequently Asked Questions (FAQs)

What is a mini fuel dispenser machine, and how does it work?

A mini fuel dispenser machine is a compact, portable device designed for the efficient dispensing of fuel, such as diesel or petrol, in small-scale settings. It operates using a piston mechanism to deliver fuel through a nozzle, making it ideal for farmers and small businesses in rural areas. The machine often features digital displays for accurate measurement.

What are the advantages of using a portable fuel dispenser?

The advantages of using a portable fuel dispenser include mobility, simplicity in operation, and the ability to refuel in remote locations. This is particularly beneficial for farmers who need to transport fuel to various places without relying on a petrol station. Additionally, these dispensers can be powered by rechargeable batteries, enhancing their usability in areas with unstable power supplies.

Are there any limitations to mini fuel dispenser machines?

While mini fuel dispensers offer many benefits, they also have limitations. They may have a lower fuel capacity compared to traditional petrol pumps, which can be a drawback for larger operations. Moreover, the initial cost might be a concern for some users, despite the long-term savings they provide through automation and efficiency.

How do digital features enhance the functionality of a mini fuel dispenser?

Digital features in a mini fuel dispenser machine enhance functionality by providing precise measurements and easy-to-read displays. Users can monitor fuel consumption in real-time, ensuring accurate billing and reducing the risk of over-dispensing. This automation contributes to better management of fuel resources, particularly in rural areas where efficiency is crucial.

What specifications should I consider when choosing a mini fuel dispenser machine?

When selecting a mini fuel dispenser machine, consider specifications such as flow rate, fuel compatibility (diesel, petrol, or kerosene), and power source (manual or 12V mini electric). It’s also essential to evaluate the machine’s build quality, focusing on high-grade materials for durability and stability during operation.

Can mini fuel dispensers be customized for specific needs?

Yes, many suppliers offer customization options for mini fuel dispensers to meet particular user requirements. This may include adjustments to nozzle types, tank sizes, or the addition of features such as automated shut-off systems. Customization ensures that the dispenser meets the specific needs of different applications, whether it’s for a gas station or agricultural use.

How do mini mobile fuel dispensers contribute to sustainable practices?

Mini mobile fuel dispensers support sustainable practices by enabling efficient fuel management and reducing wastage. By allowing users to refill vehicles and equipment directly at the site of use, they minimize unnecessary transportation of fuel over long distances. This not only lowers carbon emissions but also promotes the use of locally sourced fuels in rural areas.

What is the role of a fuel pump in a mini fuel dispenser machine?

The fuel pump is a critical component of a mini fuel dispenser machine, as it facilitates the movement of fuel from the storage tank to the nozzle. A well-functioning fuel pump ensures smooth operation and consistent fuel flow, enhancing the overall efficiency of the dispensing process. Users should regularly maintain the pump to ensure its longevity and reliability.