When viewed from on high, a minute fuel pump might well be classified as a producer of life in a car’s fuel system. Without it, the engine would not be able to receive fuel to power a car efficiently. How much do you really understand about that often-forgotten part of your vehicle? This article will walk you through the essential components of a fuel pump and their functions, making it easier for you to understand how it works and keep your vehicle running smoothly on the road. For the experienced enthusiast or the curious, this is valuable insight into the working system of fuel delivery to your car. Get ready to delve into the smooth intricacies of a fuel pump that will increase your appreciation for it on your daily commute.

Introduction to Fuel Pumps

Fuel pumps are vital parts of a car’s fuel system. It is their primary function to move fuel from the gas tank into the engine at the required pressure for the engine to operate efficiently. Most modern vehicles use electric pumps, which are nearly always located inside the fuel tank. These pumps are designed for efficiency and reliability, ensuring a constant fuel flow to meet the engine’s demand. Without a fuel pump, the engine would not be able to receive fuel, which is necessary for operation. Therefore, this component is crucial for the vehicle’s performance and drivability.

What is a Fuel Pump?

To make the fuel pump operation seem human, one might state that it is a fundamental component or assembly joining a variety of interrelated systems of fuel delivery inside a vehicle, moving fuel from the tank to the engine at the required pressure. Generally, an internal combustion engine-powered vehicle needs a fuel pump to render good performance and efficiency. Regarding the misses, there are typically two types of fuel pumps used: mechanical fuel pumps, which are considered an older generation, and electric fuel pumps, which are more contemporary.

Key Fact: Electric fuel pumps are typically located inside a fuel tank, and their operation maintains a relatively high and steady fuel pressure required by fuel injection systems, normally operating between 30 and 80 psi, as specified by the engine design and manufacturer.

For example, more advanced fuel injection systems on contemporary sedans and SUVs demand elevated pressures for accurate fuel atomization and combustion.

The durability of the fuel pumps is another primary consideration. Essentially, the best elevated electric pumps typically last between 100,000 and 150,000 miles and beyond. Depending on the quality of the fuel loaded, driving conditions, and maintenance, the lifespan of a fuel pump can vary significantly. A good example of maintaining a pump is changing the fuel filter periodically, as it prevents dirt from entering the pump and causing premature wear.

In the past, fuel pumps were simply gasoline dispensers, but the new ones are designed with electronic controls that maximize their efficiency and safety. A few models come equipped with pressure regulators and control modules that actually adjust pump output in response to engine demand. So, not only do they improve fuel economy, but more importantly, they enhance engine performance by ensuring a consistent and steady fuel supply.

The fuel pump, by each reckoning, is said to be one of the most critical components, ensuring that the engine receives a constant and reliable fuel supply under conditions conducive to perfect combustion.

Importance of Fuel Pumps in the Fuel System

A crucial component for keeping machinery in modern internal combustion engines running is the fuel pump. It is designed to deliver just the amount of fuel specified in various driving situations, thereby maintaining the car’s fuel efficiency and performance. Recent studies on automobiles reveal that advances made in electric fuel pumps do go a long way towards improving mileage and reducing emissions. Modern fuel pumps can pressurize the fuel delivery system beyond 60 psi, which is an essential requirement for high-performance engines to function correctly.

On the other hand, the fuel injection methods in particular experienced an immediate decline in interest with the advent of direct injection systems, which utilize fuel at the highest pressures to achieve the most accurate injection. This technology provides quicker throttle response with a power-peaking effect, while reducing fuel consumption by up to 15%. These pumps, partnered with sophisticated sensors and control units, dynamically adjust the fuel delivery according to changes in load and driving conditions.

Key Benefits of Modern Fuel Pumps:

- Improved fuel economy

- Reduced emissions

- Enhanced engine performance

- Dynamic fuel delivery adjustment

- Longer operational lifespan

Fuel pumps built with materials capable of withstanding everyday wear and tear are designed to have longer working lives. In corrosive environments, it is made of corrosion-resistant alloys to resist longer, even in the present vehicle environment. Ensuring proper maintenance and operation is crucial; loss of pump function can cause irregular fuel delivery, resulting in reduced engine performance or, perhaps worse, complete stalling. On one end, fuel pumps enable the engine to reach its full potential by delivering fuel efficiently, and on the other, they help mitigate environmental consequences through improved fuel economy.

Types of Fuel Pumps

Fuel pumps are crucial components in any modern automotive system, ensuring a consistent supply of fuel to the engine. They come in many types, depending on their designated systems and applications:

| Pump Type | Location | Best Application | Pressure Range |

|---|---|---|---|

| Mechanical | Engine-mounted | Older vehicles | Low pressure |

| Electric | In-tank/External | Modern vehicles | 30-80 PSI |

| Inline | Fuel line | High-performance | Variable |

| Rotary Vane | Various | Diesel engines | High pressure |

Mechanical Fuel Pumps

Mechanical fuel pumps are named as such because they rely on mechanical activity from the camshaft or crankshaft of an engine. These pumps literally suck fuel from the tank to the engine through a diaphragm. Though reliable, they are now almost phased out in favor of more advanced systems in modern vehicles.

Electric Fuel Pumps

Such pumps are found in most modern vehicles and are mounted either inside or outside of the fuel tank. These pumps deliver fuel to an engine at both higher pressure and with greater accuracy, both of which are essential for fuel injection. Unlike mechanical pumps, these electronically ask the engine how much fuel it needs, delivering only that quantity, thereby enhancing the vehicle’s efficiency and performance.

Inline Fuel Pumps

Located in a fuel line, inline fuel pumps are often found in the presence of high-performance or peculiar vehicle modifications. Together with the in-tank fuel pump, this pump increases pressure and flow, ensuring adequate fuel delivery for high-horsepower applications.

Rotary Vane Pumps

Common in diesel engines and heavy-duty applications, the rotary vane pump draws and transfers fuel using rotating vanes, which are known to be very durable under high-pressure requirements.

Each type of fuel pump comes with its own advantage; it depends primarily on the engine type, the configuration of the fuel system, and how one intends to use it. Carefully selected and maintained, fuel pumps will keep a vehicle performing optimally and lasting longer.

Components of a Fuel Pump Assembly

The fuel pump assembly incorporates several key elements that help ensure an efficient journey for the fuel delivery system:

| Component | Function |

|---|---|

| Pump | This is the primary element that transfers fuel from the tank to the engine. |

| Filter | It filters out any dirt and impurities in the fuel that could harm the engine. |

| Pressure Regulator | Maintains a constant fuel pressure, ensuring the engine runs properly. |

| Strainer | Acts as a precursor filter, preventing larger particles from entering the pump. |

| Electrical Connections | These connections transmit electricity that makes the pump work. |

| Hoses and Connectors | To ensure a good flow of fuel and to make secure connections within the system. |

Each piece is of utmost importance to the reliable delivery of fuel when requested by an engine.

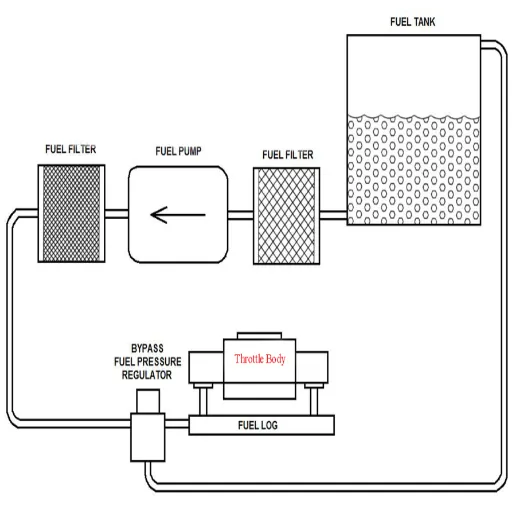

Fuel Pump Module Overview

The fuel pump module is a crucial component of a vehicle’s fuel delivery system, ensuring the engine receives the required amount of fuel at the correct pressure. It is composed of several integrated parts, including the pump, pressure regulator, strainer, and electrical connections. These components work together to draw fuel from the tank, filter out impurities, and deliver the fuel at a pressure suitable for smooth engine operation.

Today, modern fuel pump modules also focus on efficiency and durability. Some designs come equipped with a sensor to monitor fuel level and system operation. Symptoms of a leakage or failing fuel pump module include engine sputters, hard starts, and loss of performance. Maintenance and replacement of the unit at the right time ensure the proper functioning of the fuel delivery system, which in turn guarantees consistent smoothness in vehicle operation.

Fuel Tank and Its Role

One such element in the vehicle’s fuel delivery system is the fuel tank that stores fuel until the engine needs it. Fuel tanks are often made of metals like steel or plastics that are now heat-resistant and do not encourage leakage. The tank has baffles inside to hinder the fuel from sloshing about during motion and venting to balance the pressure change. Along with the fuel tank, fuel pumps, and fuel lines, these components bring the fuel to the engine smoothly. They must be inspected frequently to protect fuel tanks, fuel pumps, and fuel lines from contamination, corrosion, or damage, thereby maintaining optimal performance and safety levels.

Fuel Filter Functionality

The fuel filter keeps the fuel clean before it gets to the engine. It filters out contaminants such as dirt, rust, and debris, which might otherwise clog the fuel injectors or cause damage to other engine parts. Typically, the filter is positioned on the fuel line, preventing dirty fuel from reaching the engine and ensuring smooth functioning and optimal efficiency. The filter may become clogged over time, restricting fuel flow and potentially hampering engine power or causing the engine to stall. Replacing the fuel filter according to the vehicle manufacturer’s recommendations will help prevent these issues from otherwise shortening the engine system’s lifespan. Regular maintenance of the fuel filter helps keep the engine running smoothly and reduces the risk of expensive repairs.

Understanding Fuel Pressure and Regulation

Fuel pressure and regulation are crucial in ensuring the engine receives the correct amount of fuel for optimal efficiency. The fuel pump is responsible for pressurizing the fuel as it flows from the tank to the engine, while the fuel pressure regulator maintains a constant pressure level by adjusting the fuel flow. If the pressure falls below a certain threshold, the engine will hesitate or stall; if it rises above a certain threshold, fuel inefficiency or engine damage may occur. It is essential to periodically inspect and maintain the fuel pressure system to ensure smooth and efficient engine operation.

What is Fuel Pressure?

Fuel pressure is the pressure created as fuel moves from the fuel tank to the engine, allowing for adequate combustion and efficient engine operation. The fuel pump creates this pressure, while a fuel pressure regulator controls it to the levels necessary for engine operation. Fuel pressure in present-day gasoline engines typically exceeds 40 but remains under or near 70 PSI (pounds per square inch), depending on the design and type of fuel injection. High-performance engines or those using direct fuel injection will require higher pressure values.

Pressure Requirements by System Type:

- Standard Fuel Injection: 40-70 PSI

- Direct Injection: Up to 2,000 PSI

- High-Performance Applications: Variable, often exceeding standard ranges

Maintaining the fuel pressure within an optimal range is vital to ensure the engine’s good performance. Insufficient pressure can cause symptoms such as sputtering, a lack of acceleration, or misfiring. In contrast, excessive pressure can lead to incidents of overly rich fuel mixtures, increased emissions, or damage to engine components. These days, modern vehicles with highly advanced fuel pressure systems contain sensors that monitor the pressure and adjust it in real time to ensure that the fuel is delivered perfectly under varying loads and operating conditions. Periodic checks and maintenance of the system can prevent several issues with the fuel delivery system, which in turn guarantees the system’s safe & efficient functioning.

Role of the Fuel Pressure Regulator

The fuel pressure regulator is a core component that controls the flow and pressure of fuel through the fuel delivery system within an engine. It regulates the optimal amount of fuel entering the fuel injectors consistently, regardless of changes in engine speed and load conditions. Their steady pressure ensures that there is never any scenario where too much or too little fuel is fed into the engine, thus compromising engine performance through misfiring, poor acceleration, or fuel economy.

The design of a newer fuel pressure regulator ensures operation within a specific pressure range. For example, countries that use fuel-through-port implementations usually operate within a 35-65 psi range, whereas fuel-through-direct systems almost always demand much higher pressures, sometimes exceeding 2,000 psi. Hence, these pressure values offer greater atomization efficiency of fuel and its combustion in the chamber, resulting in both power and emission control improvements.

Additionally, sophisticated fuel pressure regulators on the market today comprise an electronic control system, integrated with the engine management system, allowing the pressure to be dynamically adjusted in response to real-time driving conditions. The regulator may hold a lower pressure during an idle state or increase it to a higher level during hard acceleration. This caliber of precision can enhance engine performance while reducing emissions by maintaining the optimum state of the air-fuel mixture. Inspection and servicing of the fuel pressure regulator can enable this component to function efficiently and help avert problems such as erratic idling, difficulty starting, and excessive fuel consumption.

Check Valve Functionality in Fuel Pumps

Primarily, the check valve in a fuel pump ensures that fuel pressure is maintained at the right level and that fuel flow is directed in the proper path. The check valve is either located inside the fuel pump or, in some cases, installed as a separate component within the fuel system assembly. It performs its duty by preventing fuel from returning to the tank when the engine is off. Proper functioning helps keep the fuel lines primed, allowing the engine to start quickly and efficiently.

In general, when encountering high-pressure systems, modern automotive check valve design allows them to withstand pressures between 30 and 60 PSI. High-performance vehicles may even operate at higher pressures, where the performance and reliability of the check valve become critical factors. When the check valve fails, the pressure in the system drops, which can cause problems such as hard starts, stalling, and the pump failing to hold pressure during acceleration.

During any fuel system maintenance routine, it is recommended that regular checks be performed to ensure the proper functioning of the check valve for optimal performance. A faulty check valve will either cause loss of pressure after the engine is shut down, longer cranking times, or intermittent spurts in the fuel system. Immediate replacement of a damaged or worn-out check valve is crucial to prevent further damage to the fuel pump or injectors, thereby increasing the efficiency of the overall fuel delivery system.

Fuel Delivery Mechanism

A fuel delivery ensures that fuel is transported effectively and at the appropriate pressure to the engine. It primarily consists of the fuel pump, fuel lines, fuel filter, and fuel injectors. The fuel pump forces the fuel through the system, the fuel filter removes impurities, and the injectors spray the fuel with utmost precision into the engine for combustion. All these elements must be in working order for the engine to operate correctly and efficiently. Regular maintenance, such as changing the fuel filter and ensuring the fuel pump is functioning correctly, ensures the fuel delivery system operates reliably.

How Fuel Injectors Work

Having a precise mechanism to deliver fuel to the engine is crucial for maximizing engine performance and efficiency. The injectors spray atomized fuel directly into the combustion chamber or the intake manifold of the engine through an electronic valve, which opens and closes in rapid succession, delivering a specified quantity of fuel at the required time during the engine cycle. Nowadays, fuel injectors are far more complex, featuring sophisticated engineering that enables varying spray patterns for efficient combustion, reduced fuel consumption, and lower emission levels.

| Engine Type | Operating Pressure | Reason for Pressure Difference |

|---|---|---|

| Gasoline Engines | 30-100 PSI | Lower-density fuel requires moderate pressure |

| Diesel Engines | 30,000+ PSI | Denser fuel characteristics require extreme pressure |

Atomization is necessary in fuel combustion, as finer droplets mix more effectively with air, allowing the fuel to burn more completely and cleanly. Direct-injection systems, which extend the fuel injector technology efficiently, inject fuel directly into the combustion chamber, allowing for better control over the air-fuel mixture.

Regular maintenance is essential for keeping fuel injectors at their best performance. With the passage of time, deposits can build up on the injector nozzles, which causes incorrect spray patterns and inefficient fuel burn. Through the process of ultrasonic cleaning or the application of fuel injector cleaners, these deposits are removed, restoring injector performance. With the help of advanced diagnostic tools, technicians can now also accurately ascertain flow rates and identify faulty injectors, thereby maintaining the efficiency and power output of engines.

The Role of Valves in Fuel Systems

In an internal combustion engine, valves prime the room for fuel and air. The intake valves within the fuel system meet the combustion chamber with the proper amount of air-fuel mixture, whereas the exhaust valve expels the burnt gases. These components must operate in sync with the entire engine cycle so that the opening and closing actually occur at the right time, thereby achieving their maximum performance.

Going beyond traditional technologies, modern engine developments include variable valve timing and direct injection systems to increase efficiency and reduce emissions. For example, VVT can adjust the timing of valve opening and closing according to the engine’s demand, thereby improving fuel efficiency by up to 15% and substantially reducing exhaust emissions. In direct injection systems, electronically controlled injectors and intake valves work in coordination to inject fuel directly and precisely into the combustion chamber, resulting in increased power and improved fuel efficiency.

For temperatures and pressures soaring high enough in engines, so-called valve designs have to be made with the utmost steel defined as titanium alloys or nickel-based superalloys, exceeding any high heat resistance. Continuous advancements in valve seating and sealing techniques shall certainly prove beneficial for preventing fuel leakage and maintaining engine performance consistency over time, a feat of great durability and seal.

The keep-up-and-inspection procedure for valves is crucial for addressing performance-related issues, such as valve sticking or leaks, which can result in power loss or reduced fuel economy. While the diagnosis is even further advanced, sensors and other advanced diagnostic equipment embedded within a fuel system allow for the real-time monitoring of valve functioning. This, of course, translates into increased vehicle reliability and efficiency.

Monitoring and Maintaining Fuel Pressure

For the engine to be efficient and produce consistent output, the fuel pressure must be maintained at the desired level. The fuel pressure ensures that the correct quantity of fuel is fed to the injectors, thereby creating the proper air-fuel mixture for combustion. Typically, the fuel pressure should range between 40 and 70 PSI for fuel-injected, gasoline-guzzling vehicles with sufficient capacity. However, this may vary for each car, depending on the make and model.

The fuel pressure regulator and pump should be checked periodically to prevent issues such as hard starts, stalling, or reduced engine power. Some signs indicating abnormal fuel pressure may include strong gasoline odors, poor acceleration, and reduced fuel economy. Modern On-Board Diagnostic Systems even provide real-time warning alerts to drivers and service technicians when the fuel pressure doesn’t meet the recommended threshold set by the manufacturer, averting damage to a greater extent.

⚠️ Warning Signs of Pressure Issues:

- Strong gasoline odors

- Poor acceleration performance

- Reduced fuel economy

- Hard engine starts

- Engine stalling

A fuel pressure sensor, along with other advanced technologies and vehicle diagnostics, helps keep system health in check. High-pressure pumps for direct-injection systems are often rated at pressures as high as 2,000 PSI, especially in modern performance cars. Cleaning the fuel injectors and replacing the fuel filters when they become clogged also helps maintain fuel pressure at optimal levels. Maintaining these critical parts means better engine efficiency and a lower likelihood of costly repairs down the line.

Common Issues with Fuel Pumps

Fuel pumps often experience several common issues, which can prevent the vehicle from functioning correctly. An unusual problem is the pump’s failure due to aging. This can cause an inconsistent fuel flow or complete engine stalling. The fuel filter may also be clogged, restricting fuel delivery and putting extra strain on the fuel pump. Due to electrical causes, the pump may not function, such as in cases of damaged wiring or relays. Regular maintenance, including filter changes and checks for damage, should be performed to prevent the occurrence of these nuisances. If any symptoms, such as engine misfires and hard starts, begin to appear, they must be addressed immediately, or the fuel pump will be further damaged.

Signs of Fuel Pump Failure

A failing fuel pump can show some clear signs, thereby compromising the vehicle’s performance and reliability. Difficulty starting the engine is another prominent symptom. With a failing mechanism, the fuel pump may not build up sufficient fuel pressure for the engine to keep on cranking or to start until it is assisted, so to speak. Engine sputtering at higher speeds is yet another common symptom. This occurs when the pump struggles to maintain a consistent flow of fuel.

Any display of loss of power when the car is subjected to stresses such as acceleration, driving uphill, or towing is yet another big red flag. It occurs due to the pump’s inability to deliver the volume of fuel required by the engine when it is demanded. Another noticeable symptom is sudden engine stalling or surging when cruising at a constant speed.

A defective fuel pump also causes poor mileage. A worn-out pump may be working harder than usual, wasting energy and thereby affecting fuel economy. Other inconveniences may include unusual noises, such as a whining or humming sound from your fuel tank, which can indicate a faulty fuel pump motor.

According to figures, the general lifespan of a fuel pump is approximately 100,000 to 150,000 miles, but this depends on one’s driving conditions and the vehicle’s maintenance. Paying attention to these signs and inspecting your vehicle regularly will go a long way in spotting problems with the fuel pump early enough. These checks, therefore, help you avoid more expensive repairs or result in a vehicle that breaks down on you.

Testing Fuel Pump Components

To test the fuel pump components, I would first check the fuel pump relay and fuse. I would then check the fuel pressure with a gauge to ensure it is within the manufacturer’s specified range. If necessary, I would check the wiring and connections for damage or wear. These steps help me identify the problem and determine whether the fuel pump requires repair or replacement.

Preventive Maintenance for Fuel Pumps

Proper upkeep by preventive maintenance ensures the longevity of the fuel pump system. Keep fuel clean: use high-quality fuel, clean fuel injectors periodically, and avoid allowing debris to contaminate the pump. Use the fuel filter as recommended by the original vehicle, so the pump does not put additional strain on the filter. Never run the vehicle or car on a consistently low level of fuel, as this situation makes it difficult for the fuel pumping system to function, which can result in overheating. Check the wiring and electrical connections periodically for any signs of wear, corrosion, or damage. Simple measures like these reduce the likelihood of fuel pump failure, thereby enabling optimal vehicle performance.

Reference Sources

Improving the Characteristics of a Two-Stage Fuel Pump by Optimizing the Blade Geometry

Cavitation Treatment of High-Viscosity Marine Fuels for Medium-Speed Diesel Engines

Frequently Asked Questions (FAQs)

What things can we locate inside a fuel pump?

A few key components of a fuel pump include an electric motor, an impeller, inlet and outlet ports, and a fuel level sender. These all serve to push fuel from the fuel tank to the engine through intermittent pressure application and a relatively constant supply under pressure. Therefore, the electric motor drives the impeller, which in turn moves the liquid fuel through the system.

How does fuel flow from the fuel tank through the fuel pump?

The fuel pump operates by suction, drawing fuel from the fuel tank. Once the electric motor comes into action, it starts spinning the impeller, creating a kind of low pressure that sucks fuel from the tank. This will maintain and direct the fuel supply to the engine, thereby ensuring that poor engine performance does not occur.

What is the function of a fuel pressure regulator in the fuel system?

Fuel pump regulators are components that maintain the correct pressure in the fuel supply line. It needs to pressurize the fuel to a high pressure for optimal engine operation through the fuel injectors, which are working with excessive pressure. Regulating this pressure can lead to fuel flowing backward into the tank, so the regulator ensures that sufficient fuel reaches the engine as needed.

What happens if the fuel pump fails?

If the fuel pump fails, the fuel supply to the engine will be insufficient, resulting in a drop in fuel pressure. This condition may result in an immediate engine stall. Other symptoms of a failing pump include poor engine speed-torque performance, difficulty starting the vehicle, and reduced fuel mileage. Regular maintenance and regular monitoring of the fuel system components would help to prevent such occurrences.

Can the fuel tank be integrated with the fuel pump assemblies?

Many modern vehicles are equipped with fuel pump assemblies that are fitted inside the fuel tank. This arrangement keeps the pump surrounded by fuel, which cools its internal components and extends the pump’s lifespan. It is also worth noting that such an assembly keeps down the number of external fittings for the fuel supply system.

What is the function of the check valve in the fuel pump?

The check valve in a fuel pump serves a vital function, ensuring that fuel does not flow back into the tank once it has been pumped towards the engine. There should always be a sufficient volume of pressurized fuel available for the engine to ensure that the fuel system maintains both performance and efficiency.

What effects does an inhibited fuel pump have on engine performance?

Certain sensitive components, such as the fuel level sender and pressure regulator, found in fuel pumps, ensure the proper delivery of fuel to the engine. When the pressure regulating system operates improperly, fuel is delivered erratically, causing engine performance to fluctuate with bouts of stalling or misfiring.

What is the difference between high-pressure and low-pressure fuel pumps?

High-pressure fuel pumps supply fuel at higher pressures necessary for Direct Fuel Injection systems. Low-pressure fuel pumps, on the other hand, are used in carbureted engines and supply fuel at a lower pressure. Knowledge of these differences helps select the right fuel pump for a specific engine configuration.