In the vast spectrum of moving liquids, transfer pumps undoubtedly remain a valuable utility. Should water flood your basement or need to be transferred between tanks, they offer a trusty pump for almost every kind of liquid. However, selecting the best type of transfer pump can be a daunting task, considering all the options available. The following text details the basic functions of transfer pumps, describes the different types of transfer pumps available, and provides use cases that demonstrate the real value of these pumps. By the end of this, you will have a clear understanding of how these pumps work and how they can facilitate liquid transport for both daily and specialized purposes.

Introduction to Transfer Pumps

Because they are primarily used for moving liquids, transfer pumps are highly versatile. They operate using a flow mechanism that draws in liquids through the inlet and pushes out alternatives for draining, filling, or transferring liquids from the outlet very quickly. The prevalent types are manual, electric, and gas types, each best suited for its applications. These transfer pumps have a wide range of applications in various industries, including agriculture and domestic settings, such as emptying water tanks or transferring fuel. Easy to operate and flexible in use, they remain a must-have for every liquid-moving process.

Definition of a Transfer Pump

Transfer pumps are versatile machines working efficiently in transporting liquids from one place to another. They are used to pump out water in floods and to transfer fuel, water, and other fluids from one container to another. A transfer pump creates pressure variations to push a liquid through an inlet and out of an outlet.

A variety of pump types exist in the modern era, including manual, electric, and gasoline models, each of which is used depending on the task at hand. Electric pumps have become one of the most popular types of transfer pumps due to their convenience of use and efficiency. A transfer pump can be used to transfer anywhere from a few hundred to a few thousand gallons per hour, depending on its type. However, most electric transfer pumps have a flow rate of about 5 gallons per minute for smaller residential units, up to 20 gallons per minute or more for industrial-grade units.

Flow rate, power, and chemical compatibility are all factors that must be considered when purchasing a transfer pump, particularly if it will be used for transferring chemicals or fuels. Additionally, new technology has led to the development of lightweight yet highly durable materials, which has increased portability over time, making transfer pumps increasingly practical for all applications.

How Transfer Pumps Work

Transfer pumps work by creating a pressure difference that causes liquids to flow from one place to another. Various mechanisms are involved, including centrifugal force, diaphragm movement, and positive displacement. For example, in pump operation, the liquid is allowed to enter through the inlet side, while the outlet side directs the liquid toward its intended destination. The internal mechanisms may include impellers, rotors, or diaphragms, with or without associated movements, to facilitate the actual movement of fluids, depending on the type of pump used.

These transfers have undergone significant efficiency improvements recently. For example, in centrifugal transfer pumps, the liquid is moved by the high-speed rotation of energy, with industrial models having flow capabilities of up to 450 gallons per minute. Diaphragm transfer pumps are widely used for transferring viscous liquids or chemicals, as they are capable of maintaining steady pressure without leakage. Modern transfer pumps can also feature variable-speed control and self-priming capabilities, thereby reducing or eliminating the need for manual interventions.

Usually, factors such as lift height and viscosity affect the performance of transfer pumps. For instance, most pumps are designed for lift heights of approximately 10-25 feet, although some heavy-duty types can handle lifts exceeding 30 feet, which is necessary for specialty industrial applications. Also, their materials allow these pumps to withstand abrasive or corrosive fluids, such as stainless steel and corrosion-resistant polymers. Consequently, transfer pumps become highly versatile and capable of meeting a wide range of operational requirements.

Common Applications of Transfer Pumps

Due to their versatility and ability to efficiently transfer liquids, transfer pumps are utilized in numerous industries. A key sector, however, remains agriculture, wherein pumps need to pull water from reservoirs, wells, or rivers for irrigation purposes. For example, transfer pumps, which transport thousands of gallons of water per hour, support the cultivation of crops through modern irrigation systems.

Another prominent application is construction, where transfer pumps are used for dewatering excavations, removing unwanted fluids, and transferring concrete mixes, among other purposes. Heavy-duty transfer pumps operating in construction sites transfer thick liquids or fluids that carry solid debris.

In the chemical and petroleum industries, transfer pumps are used to ensure the safe transfer of volatile or corrosive liquids, such as acids, solvents, or fuels, in accordance with regulatory standards. The study reveals that the global chemical transfer pump market is growing steadily and is projected to exceed $4 billion by 2027, primarily driven by increasing demand for improved and robust designs.

Last but not least, these immerse themselves in wastewater treatment plants, where they help pump sewage, sludge, and treated water from one process to another. The installation of advanced pumps with up-to-date automation systems further enhances efficiency and reduces downtime in these critical operations. They are somewhat able to act as a demonstration to highlight the transfer pump’s presence where versatility and performance count in multiple establishments.

Types of Transfer Pumps

Transfer pumps can be broadly classified according to their design and working principle. Some common types are:

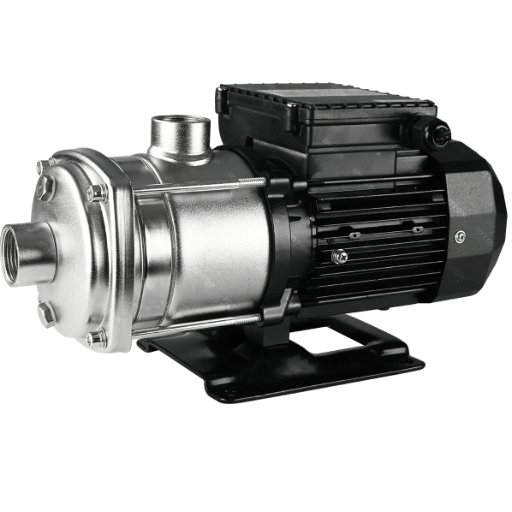

Centrifugal Pumps

They are best suited for transferring clean liquids of low viscosity, featuring an impeller that rotates to generate flow. Thus, these are generally used in water supply and irrigation.

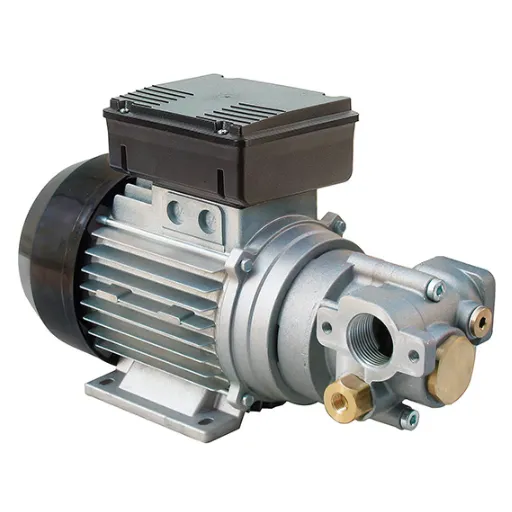

Positive Displacement Pumps

These pumps act upon viscous materials and provide accurate flow; hence, the movement of liquid is in a definite quantity. They are commonly used in industries such as oil and gas or food processing.

Diaphragm Pumps

These pumps are capable of handling liquids containing solids or slurry-based liquids and are often associated with applications such as chemical transfer and wastewater treatment.

Peristaltic Pumps

These pumps work by rotating a roller to compress a hose or tube; hence, they are suitable for delicate fluids, such as pharmaceuticals or corrosive chemicals.

Submersible Pumps

Specially designed to work underwater and are used for various purposes, including dewatering, sump pumping, and sewage handling.

Historically, pumps of each type have been designed for specific applications, ensuring the reliable transfer of any kind of liquid for which they are intended.

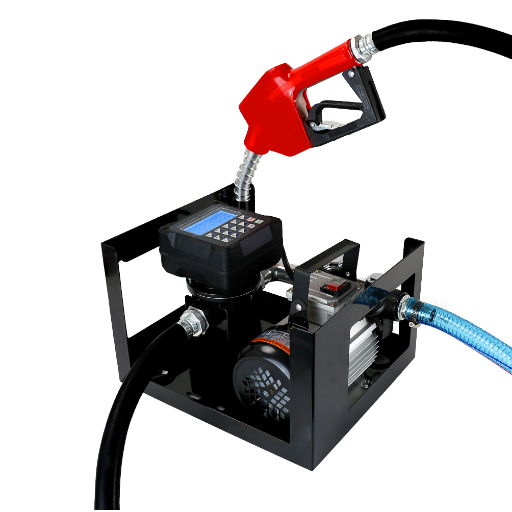

Fuel Transfer Pumps

Fuel transfer pumps are essential equipment that help move fuel safely and efficiently from one location to another, such as from storage tanks to vehicles or equipment. They are used in various industries, including agriculture, construction, transportation, and the petroleum industry, among others. Typically, manual or electric pumps are used to ensure the accurate delivery of fuels such as diesel, gasoline, and kerosene.

Typically, contemporary fuel transfer pumps feature inline filtration systems to capture impurities before they enter the nozzle, automatic shutoff nozzles, and digital flow meters for accurate measurement. High-capacity electric fuel transfer pumps are rated at 20-30 GPM, providing fast refueling for large machines. In contrast, a manual pump is great for small-scale use due to its portability and ease of use.

The material used for the manufacture of fuel transfer pumps is designed to ensure durability and safety, with cast iron or aluminum housings that are suitable for the demanding conditions imposed by fuel handling activities. Moreover, they are trusted to meet critical regulatory standards such as UL (Underwriters Laboratories) and ATEX (explosive atmosphere certification), thereby protecting the operator and ensuring reliability of the product. Moreover, regarding environmental and safety regulations, the pumps facilitate a safe working environment and operational efficiency. Thus, they earn a spot on the indispensable list in several industries.

Water Transfer Pumps

Designed to transfer massive quantities of water with relative ease, water transfer pumps find several applications. These pumps are primarily used in agriculture, construction, firefighting, and flood control to irrigate fields or pump out excess water, and may also be used to transfer potable water. It all depends upon the flow rate and the head pressure when we talk about performance in water transfers. Modern-day pumps deliver quantities ranging from 50 to well above 500 gallons per minute (GPM), while their head can reach heights of up to 150 feet or even more.

These water transfer pumps get powered from fuel sources such as gasoline, diesel engines, or electric motors. Depending on the requirements, water transfer pumps come in various shapes and sizes. Portable pumps are used for flood emergencies, while fixed-type pumps with high capacities are designed for use in industrial and agricultural systems. Recent advances in technology have enabled manufacturers to build energy-efficient and durable pumps. Most models available in the market now boast corrosion-resistant materials and newer sealing systems designed to maximize pump life in hostile working conditions.

Self-priming, lightweight, and adaptable to different hose sizes are some of the features these water transfer pumps should provide to enhance ease of use. Thermal protection is provided for specific units to prevent overheating during extended use. Knowing the specifications and requirements of the task will guide one in choosing the pump that guarantees free and reliable water management.

Septic Transfer Pumps

Used in the treatment of pond water, septic transfer pumps serve various purposes at both residential and commercial levels: for instance, treating wastewater from septic tanks or discharging multiple liquids. They play a vital role in maintaining hygienic conditions and preventing system overload. High durability and clog-resistant impellers, which prevent objects larger than a specific diameter from passing through, typically around 2-3 inches, depending on the model, are some features advertised for these pumps.

Today’s seismic transfer pumps are fitted with specially designed motors to provide high flow rates, reliability, and efficiency. These pumps generally produce flow rates ranging from 70 to 200 gallons per minute (GPM), with discharge heads ranging from 10 feet to well over 200 feet. The majority of them are constructed from heavy-duty materials, such as cast iron and stainless steel, which provide excellent corrosion resistance and a long lifespan, even with continuous operation.

Equipped with a float switch for level detection and activation, this feature is only used when required for fully automated operation. Energy efficiency was improved while maintaining performance. Matching the pump’s capacity and environmental requirements to the system ensures efficient waste management and lasting reliability.

Choosing the Right Transfer Pump

Choosing the proper transfer pump is mainly dependent on your specific needs and system requirements. Is the waste or material thin or abrasive? This aspect will be relevant to the pump. Establish the flow rate and head height required for the application, ensuring the pump can manage the necessary volume over the specified length. Consider energy efficiency and durability: these two parameters will affect how the pump performs over time and the cost you will incur. Perhaps there are corrosion-resistant features and maintenance methods that make the pump easy to maintain and repair. Consider that a pump that meets these criteria will work effectively and efficiently.

Factors to Consider When Buying a Transfer Pump

Key Considerations

The selected transfer pump must be suitable for the purpose, which begins with determining the substance to be transferred, ranging from water to chemicals or fuel. Estimate likewise the flow rate required for the operation, generally expressed in gallons per minute (GPM), to ensure the pump can adequately satisfy the task at hand. Lastly, head height or maximum lift should be determined, thus dictating the distance over which the pump can move the liquid vertically.

Energy efficiency must be given high importance to reduce operating costs, followed by selecting a pump power source suitable for the intended use, whether electric, gas, or manual. A pump must be made of corrosion- or wear-resistant material, especially if it will handle downright harsh chemicals or abrasive substances. A significant consideration is how easily the pump can be maintained; pumps containing easily accessible parts and simple servicing requirements reduce downtime and increase operational life. Based upon this selection of features, the buyer can make an informed decision that is most appropriate for their particular needs.

What to Look for When Buying a Fuel Transfer Pump

When purchasing a fuel transfer pump, keep these essential features in mind while making your decision:

- Flow Rate: Select a pump with a flow rate that matches the amount of fuel you need to be transferred daily. The flow rate is typically measured in gallons per minute (GPM). Pumps with low flow rates are suitable for small projects, whereas for large operations, pumps should have high flow rates to save more time.

- Power Source: Fuel transfer pumps can be powered by electricity, a battery, or manual operation. Electric pumps are preferred for high-volume fuel transfers. Portable pumps run on batteries, while manual pumps are suitable for small needs or where a power supply is scarce.

- Compatibility: Ensure that the pump material is compatible with the type of fuel to be transferred, whether gasoline, diesel, kerosene, or any other liquid. It should be corrosion-resistant, using materials such as stainless steel or certain plastics, so that the pump’s working life is not compromised and safe operation is ensured.

- Portability and Mounting Options: If the pump needs to be moved around, being lightweight and portable will make it a lot easier to handle. If it’s for stationary use, ensure it has secure mounting options.

- Safety Features: Opt for sturdy safety features, such as automatic shut-offs, bypass valves, and explosion-proof motors, to prevent accidents during operation and meet regulatory requirements.

- Ease of Maintenance: Pumps should have easily accessible parts and simple maintenance instructions to facilitate easier maintenance, thereby decreasing downtime and extending the pump’s lifespan.

Considering these factors will make it easier for you to select a fuel transfer pump that is both time-efficient and durable, tailored to your specific needs.

How to Select a Water Transfer Pump for Your Application

Using these factors to select a water transfer pump requires careful consideration of one’s specific application and working conditions. The following factors must be looked into:

- Flow Rate Requirements: Knowing the amount of water that needs to be transferred and the time it takes to do so is crucial. In gallons per minute (GPM), this indicates the pump’s size and power.

- Pump Type: Select a pump type based on the water source and intended end-use. Centrifugal pumps are well-suited for clean water, trash pumps for water with debris, and diaphragm pumps for high-viscosity liquids.

- Power Source: Select the power source to use (electric, gas, or diesel) based on availability and practicality. Things are better and easier to handle when electricity is not present.

- Vertical Lift and Pressure: The height of the vertical lift, the water is supposed to travel (head height), and, if possible, the required pressure expected to be served in the job.

- Durability and Materials: When transferring water with chemicals, select pumps made from materials that resist weathering and corrosion for use in outdoor environments.

- Portability and Size: If frequent movement is a must, opt for designs that are lightweight and easily carried.

By working on these specifications, you can gain an understanding of a water transfer pump that will perform optimally and suit the application. Checking the product specifications and comparing brands can help narrow down the choice.

Transfer Pumps and Fluid Types

Different transfer pumps are designed for various fluids. Centrifugal and utility pumps are used for water or other non-corrosive liquids due to their simplicity and efficiency. The chemical transfer pump is used with corrosive materials such as acids or solvents, or where the equipment needs to be made of materials resistant to chemical attack. For thicker or viscous fluids, diaphragm pumps are preferred since they can pump high-viscosity fluids without aggressive performance loss. Check for the pump chemistry compatibility at all times to ensure safe and efficient operation.

Fluid Transfer Pumps Handle

Fluid transfer pumps are general-purpose pumps used to transfer liquids in various industries, with different types of pumps being suitable for specific purposes. Recently, developments have positioned pumps to be more efficient, intermittent, and durable. For instance, centrifugal pumps with impeller designs aimed at better energy efficiency, thereby reducing their operational cost. Data suggest that centrifugal pumps can achieve efficiency as high as 90% under optimal conditions, implying that these pumps perform well in large-scale operations where reliability is crucial.

Chemical transfer pumps remain the most popular choice for handling corrosive materials. Advances in materials technology have strengthened this status quo, with modern materials such as polypropylene, PVDF, and stainless steel offering excellent resistance against aggressive chemicals without degradation. Studies show that pumps do not lose performance when subjected to either highly acidic or alkaline solutions, thereby almost doubling the lifespan of the pump body.

Diaphragm pumps have been designed to move viscous fluids and have thus been improved by the advent of air-operated double-diaphragm pumping. This improvement significantly enhances the control and adjustment capabilities of the pumps when handling highly viscous liquids or those containing solids. Data reveal that their capacity extends to managing fluid viscosities of up to 20,000 cP, making it the most sought-after solution in the industry for oil, adhesives, and other thick substances.

This, therefore, implies that the primary focus in the area of fluid transfer pump technology has centered on efficiency and materials that can withstand and adapt to a wide range of operational requirements across agriculture, food processing, chemical manufacturing, and wastewater treatment.

Special Considerations for Diesel Transfer Pumps

Safety First: To ensure the safe and efficient operation of diesel transfer pumps, several considerations must be taken into account, particularly the flammability and density of diesel fuel. Material compatibility is a crucial factor, as seals, hoses, and pump bodies must be chemically resistant to diesel to ensure long life and prevent leakage. For example, for this application, pumps made of cast iron or stainless steel are highly recommended.

A diesel transfer pump is selected based on its flow rate and efficiency. The flow rate for models available on the market for small-to-medium operations ranges from 10 to 30 GPM, while large industrial-grade pumps may have a flow rate of well above 100 GPM. Flow rate consideration is application-dependent, for instance, recording fuel for agricultural machinery or industrial fuel transfer.

Safety features are just as important. Any diesel transfer pump should be equipped with automatic shut-off nozzles, explosion-proof motors, and thermal overload protection to minimize the risk of accidents. On the other hand, pumps with a filtration system prevent contaminants from entering fuel tanks or machinery, thereby maintaining optimal engine performance and extending engine longevity.

Finally, portability and power supply options are other characteristics that need to be considered. Most pumps for diesel transfer offer lightweight, compact designs and power options, such as 12V or 24V DC, which are suitable for use in remote locations or on vehicles. Such features enhance versatility and assure performance under different working conditions.

Comparing Transfer Pumps for Different Fluid Types

The transfer pumps must be suitable for various types of fluids. All these possibilities need to be judged for compatibility, efficiency, and the requirements of usage. For instance, diesel fuel transfer pumps are specially designed to accommodate the viscosity and composition of diesel, preventing contamination and ensuring smooth operation. On the other hand, pumps for oils or lubricants having a thicker consistency are built with stronger seals and materials that resist wear. On the contrary, water transfer pumps are primarily concerned with flow rate and tend to wear out when used for any fuel or corrosive liquid.

Consider materials of construction and safety features as other distinctive parameters. Chemical or corrosive fluid pumps may be made of corrosion-resistant materials, such as stainless steel or specialized plastics, to prevent corrosion. Additionally, many chemicals necessitate the certification of a pump as ATEX or UL to meet safety regulations in hazardous areas.

Portability and power sources also differ among pumps. Those used in remote areas may be battery- or manually powered for portability, whereas larger, powered units are preferred for stationary or high-capacity applications. Ultimately, one should choose a pump based on having explicit knowledge of the fluid’s individual properties and ensuring that those properties are compatible with the pump’s capabilities to ensure safe, effective, and reliable operation.

Maintenance and Troubleshooting of Transfer Pumps

Regular maintenance helps sustain the efficiency of the transfer pumps and minimize breakdowns. Maintenance tasks may involve checking and cleaning filters, inspecting seals and gaskets for wear, and applying proper lubrication to moving parts. Periodically, keep an eye out for leaks and abnormal sounds that may indicate early signs of failure. Troubleshooting can begin by confirming power connections, verifying if the pump is primed, and inspecting for any clogs or blockages within the system. Addressing these common issues will prolong pump life and maintain reliable operation.

Routine Maintenance Tips

Keeping your pump systems maintained prolongs their lifespan and ensures that they perform at excellent efficiency. Maintenance activities include regular cleaning or replacement of filters so that proper flow can be maintained; the inspection of seals and gaskets to check for wear so that no leaks occur; lubrication of moving parts, as recommended by the manufacturer, to reduce friction and wear; regular observation for new sounds, vibrations, or leaks that can serve as warning signals; when problems are confronted, begin checking if there is power going into the system, check if the pump has been primed adequately, and if there may be blockages or clogs in the system. Following these maintenance instructions helps keep your pump operationally efficient and minimize downtime.

Common Issues and Solutions

Perhaps it is a common problem for the pump to fail to start. I check, of course, if it is correctly connected to the power source or if the switch is working at all. Then, another issue is the flow or pressure being very low; I then check if there are any blockages in the pipes or if the filter is dirty. In case any abnormal noise or vibration occurs, I feel I must check the pump alignment or fasten any loose parts. For leaks, I inspect the seals and fittings to determine if they need tightening or replacement. Hurrying to do maintenance can often help me solve those problems quickly.

When to Seek Professional Help

Some problems with pumps can be resolved through basic troubleshooting, but other situations require the expertise of professional pump mechanics. One should seek professional help if the motor overheats frequently, as this may denote serious electrical or mechanical problems. If there have been cases of low pressure that never seemed to improve, even after cleaning the filters or checking for blockages, then internal damage or wear could be the culprit, and diagnostic tools are required. Strange noises, such as grinding or screeching, may indicate bearing problems or misalignment that need professional attention. Major leaks, especially those originating from within, must be handled by a professional to prevent further damage. Regular servicing by a certified technician will efficiently keep the pump running and save you from costly repairs in the long term.

Reference Sources

“Designing and Optimizing 10,000 m³/day Conventional SWRO Desalination Plant”

Frequently Asked Questions (FAQs)

What is a transfer pump, and what are its uses?

A transfer pump is a device used to transfer fluids from one location to another, typically moving liquids such as water, fuel, and various other types of fluids. These pumps efficiently move large volumes of liquids and are used in multiple applications, including agriculture, construction, and industrial processes.

What types of transfer pumps exist?

There are many types of transfer pumps available, including centrifugal pumps, diaphragm pumps, and submersible pumps. With various designs and operational modes, each pump type is suited for specific applications and fluids. For instance, centrifugal pumps move water very well, whereas diaphragm pumps are better suited for thicker fluids.

How should I select the right transfer pump for my application?

Depending on the type of fluid being moved, the flow rate, and the distance it needs to be moved, these considerations will help you choose the correct transfer pump for the job. A key consideration would be whether you prefer a portable pump or a mounted installation, as well as the power source for the pump, specifically whether it should be electric or gas-powered.

What are the key parameters to consider when selecting a transfer pump?

When purchasing a transfer pump, consider its flow rate, the construction materials used, and the intended pipe or fluid that will be transported through the pumping process. Also, consider the inlet and outlet port sizes, pump reliability, and maintenance needs to ensure your pump operates at peak efficiency.

How do fuel transfer pumps handle different types of fuel?

The fuel transfer pumps are designed to handle the transfer of various types of fuel, including diesel, petrol, and fuel oils. They have been made with materials that prevent corrosion or distortion from the fuel, allowing the liquids to be transferred safely and efficiently. Proper filtration and care shall also be applied to ensure fuel quality maintenance during transfer.

Could water transfer pumps have been used for septic applications?

Yes, some water transfer pumps are suitable for septic applications; however, be sure to select a pump specifically designed for handling wastewater. Such pumps typically can treat solids and materials found in septic systems, facilitating fluid movement and, most importantly, preventing clogging.

What is the role of suction in a transfer pump?

Suction is an essential element of a transfer pump’s operation. Creating a pressure differential allows the pump to suck up fluid from the source through the intake port. The pump then transfers this fluid through its discharge port to wherever it needs to go. If suction is not working correctly, the pump will have problems functioning efficiently.

Where is a transfer pump commonly used for?

The pump is used for transferring fuel to refueling vehicles, watering irrigation zones, flooding areas, and handling industrial chemicals. Being time versatile, they can be used for both residential and commercial purposes.

How should I maintain the transfer pump to achieve optimal performance?

Ensure optimal performance by regularly checking your transfer pump for signs of wear and tear. Also, take care to clean the filters and replace worn parts as necessary, and inspect hoses for leaks. Use the right pump for the job and operate it within its limitations to maximize life and efficiency.