LED lights sometimes explode with immense force, sending shockwaves through the otherwise calm aura of unexpected occurrences. Primarily celebrated for their energy conservation and longevity, there have been rare incidents of these exquisite devices blowing up into a hundred pieces. What could have made this hearty, dependable device go to such catastrophic extremes? This article aims to explain the reason behind any LED light explosion, be it a manufacturing defect, incompatibility, improper usage, mishandling, or electrical intricacies. Once you gain insight into these reasons, you will know how to protect yourself in the future, take care of the LED lights, and prevent such situations from recurring. We will illuminate this terrifying yet intriguing phenomenon and light the way toward safe and efficient lighting practices.

What Causes a Light Bulb to Explode?

Several factors cause a light bulb to explode, whereas the most common reasons are overheating, manufacturing defects, or electrical faults. Overheating occurs when the bulb works beyond its wattage rating or is fitted inside a closed fixture. A manufacturing defect, having something like thin glass or weak construction, would make the bulb susceptible to cracking under pressure. Electrical faults, such as power surges or loose connections, can suddenly increase the current, causing a sudden molten failure in a filament or some other internal part of the light. Keeping the bulb installed correctly, employing the correct wattage, and preserving a steady power supply would help avert the above incidents.

Understanding Common Causes of Bulb Explosions

Environmental factors may also prove to be a victim, causing the explosion after all, manufacturing defects, or electrical issues. Extremely high humidity or moisture may enter the bulb, forming condensation. This, with rapid expansion occurring when the filament heats up, forms such a temperature difference between the inside of the bulb and its outside that cracks the glass, causing the explosive reaction. Data show that such occurrences are more frequent in humid-climate regions, especially where ventilation is ad hoc.

Another major cause is the usage of incompatible and often counterfeit bulbs. Non-certificate bulbs—these are said to be produced without proper or quality control—have been reported to fail during use. Thus, consumers are advised to check and ensure that a bulb or the bulbs they buy carry a certificate like UL [Underwriters Laboratories] or CE marking.

The heat created by enclosed fixtures impedes cooling around the bulb far beyond thermal limits. The findings indicate that bulbs on average failed 20-30% faster where ventilation was poor than in settings where airflow was adequate. Checking one’s fittings regularly and never putting in a bulb of wattage more than specified for that particular fixture will substantially reduce this risk.

Can Voltage Fluctuation Cause a Bulb to Explode?

Yes, voltage fluctuation can cause bulbs to explode. Power surges, sudden spikes in electric current, overwhelm the melting of the filament or some internal components, thus heating up so quickly that they fail structurally. For instance, beyond exceeding the voltage rating for a bulb, the filament may be heated so fast and furiously that it will physically snap. In more severe cases, some shards of the enclosure may be released.

According to electrical safety data, even a 10-20% voltage variation above the prescribed supply can rapidly deteriorate a bulb’s lifespan and increase the possibility of failure. Over-voltage conditions can also destroy the integrity of LED drivers or capacitors in contemporary LED bulbs and ultimately induce an explosion. Surge protectors, coupled with bulbs rated for your outlets’ voltage, will reduce any such dangers.

On the other hand, more gradual or slight voltage dips or variations strain the bulb’s components, especially those with fragile or poor workmanship. To preserve lighting systems for both durability and safety, a stable power supply through voltage regulators or with advice from an experienced electrician in areas prone to fluctuations needs to be maintained.

How Wiring Issues Lead to Light Bulb Explosions

One of the most critical factors in the explosion of light bulbs is wrong or bad wiring. Loose connections may be one common problem; when they are present, partial electricity contact is made intermittently. This intermittent flow of current generates heat, which may cause the overheating of a bulb just enough to destroy it in an explosion. Other causes include old or damaged wiring, which cannot handle the voltage requirements of modern lighting appliances. Recent statistics indicate that thousands of electrical fires start annually because of faulty wiring, with many beginning with small but preventable failures in the lighting system.

Grounding faults will present another hazard. If a fixture or an outlet is not grounded correctly, the accumulated excess electrical current will have no path to be discharged safely. Thus, the bulb gets overloaded, overheats, and pops. Transporting foreground issues include incorrect bulb usage, high-wattage bulbs placed in fixtures not rated for them, exacerbating the problems that the building can cause. Adhering to wiring that fulfills national electrical codes (such as the National Electrical Code standards in the U.S.) and engaging the services of a licensed electrician to do periodic inspections will dramatically reduce these dangers and keep your home or office safe.

How Does Overheating Affect LED Light Bulbs?

LED light bulbs are seriously affected by temperature constraints, and the lifespan of a light bulb increases with lower heat. The faster the temperature, the faster the deterioration of the inside parts, such as the driver and diodes, eventually lowering the bulb’s brightness and efficiency. And such a situation can cause a bulb to start flickering and eventually die off after acquiring heat discolouration. To avoid such situations, the fixture must provide good ventilation, and LEDs must not be placed in enclosed or poorly ventilated areas unless they are expressly made for the job. The proper heat management will guarantee the reliability and long life of the LED light bulbs.

What Happens When an LED Bulb Overheats?

If an LED bulb gets heated way above its standard operating temperature, its performance and life expectancy can be seriously affected. High temperatures lead to the early deterioration of the sensitive internal components of the LED, such as the phosphor coating and semiconductor diodes. For instance, overheating can cause an LED bulb’s efficiency to be dramatically reduced by as much as 70%, which means it produces less light while at the same time consuming more power. Long-term overheating is detrimental to the quality of illumination because the bulb may start flickering or just inconsistently shine, and if it’s awful, the bulb may even fail.

New LED technologies typically combine heat sinks and thermal management systems that effectively dissipate heat to cure this. Typical heat sinks might be made of aluminium or ceramics so that the heat can be quickly carried away. This is very important since LEDs work well only below 185°F (85°C), with rapid deterioration in performance occurring as they exceed this temperature.

Proper ventilation in lighting fixtures is essential for preventing LED bulbs from overheating. Enclosed spaces can trap heat, worsening the problem. If the situation calls for it, always choose an LED bulb rated for use in enclosed fixtures. Also, dimmer-compatible LEDs and dimmer switches should be used in tandem to curb excess power and consequently heat output. Following these suggestions will greatly help extend the life of LED bulbs and provide excellent service.

Factors Contributing to Excessive Heat in LED Lights

Several factors contribute to excessive heat generation, impacting LED lights’ durability and efficiency. Improper thermal management is perhaps the principal one. LEDs require heat sinks to eliminate heat; if these heat sinks are blocked or poorly designed, heat buildup results. Even though modern LED fixtures incorporate advanced thermal management concepts, they may overheat if abused or overloaded.

The ambient temperature within the LED installation adds to the heat generation. Higher ambient temperatures work against the heat dissipation cycle, especially in confined or poorly ventilated locations. Consider, for instance, some studies finding lowered operation life by over 50% for LEDs used in temperatures exceeding those for which they were rated.

An almost equally important factor is overcurrent. Using dimmers that are incompatible with LEDs or driving excess current to the LEDs causes overheating. Higher heat means deterioration of the components.

Dust and dirt accumulation further aggravate the heat dissipation problem. LEDs face this problem mostly when installed outdoors or in industrial environments, where the reduced airflow is yet another thermal force. Routine cleaning of the fixtures and maintenance of airtight fittings will at least thin down this burden.

Hence, by addressing these parameters and executing the installation and operation of LEDs in favorable climatic conditions, users are generally assured of their optimum working and lifespan.

Preventing Heat Dissipation Issues in Light Fixtures

While the problems related to heat dissipation are being prevented, it is essential to study the effects that design, material, and environmental factors may have on the heat dissipation process. The highest-quality heat sinks should be given priority for efficient thermal management solutions nowadays. For example, aluminum and copper heat sinks are premium materials of high thermal conductivity, and studies prove that they may decrease fixture temperature levels by 20-30%. Using these materials means proper heat transfer away from the vulnerable LED components, thus minimizing LED failure risk. Face-to-face interaction with other approaches would optimize airflows around the light. Open designs and placement in ventilated areas provide better cooling. Research revealed that proper ventilation could increase fixture efficiency by up to 25%, notably where high heat is present, like in an industrial workshop or outdoor installations that get direct sunlight.

Even more advanced thermal interface materials (TIMs), such as graphene and phase-change materials, are emerging, offering greater even heat distribution. In industrial tests, these are said to increase the thermal performance of LEDs by 50%. Maintaining the fixtures, such as regularly cleaning dust from vent openings or checking on thermal paste or TIM wear and tear, also supports efficiency over the long term.

Static sensors are then used in bright lighting for temperature monitoring. These sensors allow for autonomous dimming when temperatures pass above safe thresholds, preventing overheating and thus running without the need for manual operator intervention. Studies show that this proactive thermal management can reduce LED lifespan by more than 40%, proving an economical application in residential and commercial realms.

The use of this array of advanced technology and materials in LED systems goes a long way toward solving heat dissipation concerns and ensuring reliability, energy efficiency, and applicability to a variety of uses.

Is It Safe to Handle an Exploded Bulb?

Bulb explosions can be dangerous if adequate care is not maintained. First, ensure that the power is switched off, lest one be exposed to electric shocks. Gloves should be put on to protect one’s hands from sharp glass fragments while removing the remaining pieces from the socket with pliers, if necessary. Glass shards comprising the shattered bulb should be dropped into a strong bag and disposed of. One should use gloves throughout the procedure and avoid touching the bulb with bare hands. Some bulb types might contain dangerous substances such as mercury. If such hazardous elements are present within the bulb, follow your local instructions on safely disposing of the bulb.

Steps to Take After a Light Bulb Explosion

Safety First: Immediately after a bulb explodes, electrical power should be turned off at the wall switch or circuit breaker so that one is not subjected to an electric shock while cleaning up the debris. Ensure that no one nearby, including animals, can touch the shattered glass or debris, as they might get injured. Ventilate the room for about 15 to 20 minutes, more so if the bulb type is fluorescent, since it can emit minute amounts of mercury vapor.

Wear Protective Equipment: Wear gloves, safety goggles, and a dust mask to protect yourself from irritation by acceptable debris or, even worse, getting cuts and inhaling hazardous particles.

Get Cleaning Supplies: Use stiff paper or cardboard to collect big pieces of glass. Sticky tape will pick up the smaller fragments. Disposable wipes or a damp paper towel will collect any finer dust. Lastly, use a sealable container such as a glass jar or heavy-duty plastic bag for disposal.

Cleaning Up Broken Glass and Debris: Use cardboard to gently scoop away large pieces of glass and dispose of them in a corked container. Use sticky tape to pick up remaining tiny shards of glass and dust from the surface. Do not vacuum to prevent the potential spreading of mercury-containing particles, if any, into the air.

Check for Mercury (CFL or Fluorescent): Compact fluorescent lamps (CFLs) and some fluorescent lamps typically contain between 4 and 5 milligrams of mercury. After the vial is broken, these fine powders in the vial debris must be collected carefully, with the room remaining ventilated. Dispose of the material properly as set forth under the hazardous waste regulations in your locality.

Double-Bag the Debris and Properly Dispose of It: Place all collected materials into a sealed bag or glass container, including gloves and wipes. Double-bag if necessary, and label it hazardous waste if the bulb contains mercury. Ask local waste disposal services or hazardous material facilities where to dispose of it properly.

Safety Inspection and Bulb Installation: Before installing a new bulb, check the socket for damage or residue. Using a clean, dry cloth, wipe the socket gently. Check the bulb packaging to ensure the replacement bulb has the correct wattage and specification.

Prevent any Future Occurrences: To prevent light bulb explosions, do not exceed the fixture’s rated wattage, make sure the bulb is installed correctly, and always buy bulbs from reputable brands. Energy-efficient and shatter-proof bulbs such as LEDs should be considered, as they do not contain hazardous materials like mercury.

By following these detailed steps, you can ensure that safety measures are adopted and the bulb is correctly disposed of, minimizing health risks while improving the chances that similar incidents will not happen.

How to Safely Dispose of Shattered Bulb Fragments?

Disposal of shattered bulb fragments is essential from a safety point of view and to protect the environment. In some compact fluorescent lamps or CFLs, the room should be ventilated for 10 to 15 minutes, especially if the bulb contains hazardous substances, such as mercury. Don gloves to protect from injury and, along with stiff paper or cardboard, gather the larger shards of glass. Do not vacuum or broom because this will only disperse smaller particles or residues into the air. For the tiny pieces or powder, sticky tape works well.

Once all fragments are collected, seal them in a big garbage bag or glass jar to prevent leakage. If the broken bulb contains mercury, consider it hazardous waste. Contact your local hazardous waste disposal contractors or recycling facility for assistance, as most municipalities offer programs to dispose of bulbs and other dangerous materials safely. Check for local electronics recycling programs for bulbs other than those now mentioned, as some parts can be recycled.

According to recent data, improper disposal of hazardous materials contributes to the 60 million tons of waste that enter the environment each year. By disposing of dangerous materials responsibly, you can reduce your footprint and ensure your safety and the environment.

When to Call a Qualified Electrician?

For complicated or dangerous electrical problems, there is no alternative to getting in touch with a professional electrician if everything is to be done according to safety standards and local codes. This situation involves frequent tripping of circuit breakers, lights flickering or dimming, outlets heating up from touch, and upgrades of wiring in the home. If installing new appliances, dealing with unsafe or outdated wiring, or having exposed wires, a professional ensures the work is done correctly and safely. Any electrical job for which permits are needed should always be handled by a reputable electrical company, including adding new circuits and rewiring. If you doubt your electrical issues, never try to fix them yourself, as this could mean an electrical fire or physical harm.

Could Manufacturing Defects Lead to Light Bulb Explosions?

A light bulb can explode in the presence of manufacturing defects. The wrong assembly, weak glass, or faulty materials during production cause the light bulb to fail during everyday use. For example, a poorly sealed bulb might let air in, which reacts with the filament to induce overheating or breaking. To lessen the risk, buy bulbs from reputable manufacturers that abide by safety standards and quality control methods.

Identifying Defects in LEDs and Traditional Light Bulbs

Manufacturing, design, and usage-related factors could cause defects in conventional and LED light bulbs. Defects more common to incandescent bulbs include fragile filaments, improperly sealed glass enclosures, and poor raw materials. These defects, in turn, bring about a relatively shortened life, flickering, and sometimes an abrupt cessation during use. Studies from the field show that almost 10% of incandescent bulb failures occur prematurely due to defects caused by improper manufacturing quality checks.

While more energy efficient and longer-lasting, LED lights are not exempt from defects. Poor heat dissipation is a common defect in LED lights. LED lights use heat sinks to dissipate heat, and if the heat sink is poorly designed or installed, it causes the LED to overheat, reducing its brightness and lifespan. Overheating accounts for about 20-30% of early LED failures. Bad drivers that regulate the flow of electrical current to the LED can make it flicker, dim, or outright fail; the driver can be the cause of the defect.

Manufacturers continue to develop better materials, heat management designs, and quality standards to combat these issues. However, consumers should also take precautions, such as buying from brands of proven reliability, looking for certifications like Energy Star or UL, and verifying compatibility with their fixtures and voltage requirements. Identifying the above problems early on and opting for high-quality lighting goes a long way to ensure safety, performance, and durability.

The Role of Capacitors and Resistors in Bulb Explosions

Capacitors and resistors are essential components of lighting technology, representing the functionality and safety of current light bulbs, mainly in LED and CFL designs. Capacitors stabilize voltages and suppress power surges, while a resistor limits current flow. The failure or mal-design of these components can contribute massively to the risk of bulb explosions.

Improper capacitors are a significant and common culprit responsible for exploding bulbs. One instance being that if an electrolytic capacitor is cheap or old, in the presence of high temperatures, it begins to leak and eventually might burst, manifesting itself in the abrupt disintegration of the bulb. Studies have shown that these failures occur with capacitors that were not specified for high-temperature tolerance, prolonged use, or were oversized- capacitors can store an excessive amount of charge, creating a power imbalance that can damage other internal components.

In contrast, improper resistance to current flow causes overheating and contributes directly to a lack of stability in the bulb. Overheating in a resistor may result if it is undersized for the current power it needs to dissipate or is subjected to high-voltage spikes. According to investigations, thermal failures in resistors accounted for a considerable number of electrical circuit failures in an industry environment where voltage fluctuations are common.

Good-quality bulbs can reduce these risks by using advanced design features. For example, metallized film capacitors should be used whenever possible—they are more durable and provide better thermal stress resistance. Flame-resistant resistors can considerably improve appliance safety. Manufacturers may also install other protective circuits, such as thermal fuses and surge protectors, further protecting the appliance from the failure of a given component.

Therefore, understanding how capacitors, resistors, and other electrical components work together is essential for manufacturers and consumers. Preventing potentially hazardous failures such as bulb explosions requires careful design and engineering choices, raw material selection, and adherence to strict safety standards.

How to Prevent Future Bulb Explosions?

To prevent any future bulb explosion, safety and quality must be prioritized in all production and use phases; manufacturers must use only high-quality materials, implement strict safety standards, and build protective elements such as thermal fuses and surge protectors into the bulb design. Consumers, conversely, need to guarantee that bulbs are being used according to specified wattage values and protect power surges with surge protectors, fulfilling their responsibility by removing any damaged or faulty bulbs. From regular maintenance to proper handling, all of these aspects contribute to eliminating bulb explosions, thus allowing safe and reliable use of bulbs.

Inspecting Your Home’s Electrical System

Regular checks of your home electrical installation will ensure that it remains safe from hazards, malfunctions, and gains in energy efficiency. Start with the circuit breaker panel, ensuring there is no wear or corrosion, and that the breakers do not trip with standard loads.

The panel must always be in top condition to minimize the risk of electrical fires, which total about 51,000 residential fires in the United States annually. Looking at an outlet and switch may reveal discoloration, buzzing noise, or overheating, which might be symptoms of bad wiring or an overload. It is best to update worn-out outlets to modern types, such as GFCI outlets, in the kitchen, bathrooms, and other wet locations to prevent shock hazards.

Check appliances and cords for exposed wires or frays; faulty wiring is a considerable risk that accounts for almost 20% of electrical fires every year. For homes with 20-30 years of wiring, fix the wiring to comply with the current modern electrical codes, as older materials like aluminum wiring might prove to be even more hazardous.

Using energy-efficient LED bulbs and having surge protection in the house adds extra safety measures against power spikes. Having a professional licensed electrician inspect the home every five years can uncover hidden issues and ensure that your electrical system will continue to live longer and conform to current safety standards.

Choosing the Right Wattage and Voltage for Your Lamps

When selecting a wattage and voltage for my lamps, I always make sure to check the manufacturer’s specifications on the lamp or its packaging; this ensures the highest performance and prevents it from being overheated or damaged electrically in any way. Besides matching the bulb voltage with that of the home electrical system, I select a wattage that gives the brightness I seek and still falls within the safe limits of the fixture.

Regular Maintenance and Inspection of Bulbs and Sockets

Maintaining your lamps extends their utility and ensures safety and energy efficiency. Flickering or dimming lights should be replaced immediately; these may be signs of aging or impending failure. Electrical safety guidelines state that sockets and connections should be inspected every six months for wear, corrosion, or loose contacts. Dusting the fixture and cleaning the bulb with a dry, soft cloth increases brightness and reduces the heat build-up risk. These LED bulbs that are energy efficient have been tested to last from 15,000 to around 25,000 hours, consuming less energy than a standard bulb in myriad ways, and are therefore excellent candidates for use in most homes. If one follows consistently through with the above, they can keep their functionality while avoiding electrical hazards.

Reference Sources

1. Evaluation of Balloon Cylinder Explosion Incident

2. New Solid-State Technologies and LEDs in Explosion-Proof Equipment

3. On the Highly Stable Performance of Loss-Free Optical Burst Switching Networks

Frequently Asked Questions (FAQs)

Q: What are the common reasons a light bulb might explode?

A: A light bulb may explode due to several factors, such as a sudden surge in electrical supply, pressure imbalance inside the bulb, or spikes in voltage. Poor insulation or hot spots can also cause the bulb to explode. Additionally, improper installation and exceeding the recommended wattage can lead to catastrophic failure.

Q: Can using off-brand bulbs cause a bulb to explode?

A: Yes, using off-brand bulbs can increase the risk of an explosion. Off-brand products may not adhere to safety standards, leading to potential issues like pressure imbalance or poor insulation inside the bulb. It’s advisable to use quality products to ensure safety and longevity.

Q: How can I prevent my LED light from exploding?

A: Always use quality products to prevent your LED from exploding and ensure proper installation. Avoid exceeding the recommended wattage and check for any spikes in voltage. Ensure that your light fixtures are designed to handle the specific bulb you use.

Q: Why does a bulb sometimes make a dramatic pop when it explodes?

A: The dramatic pop occurs due to the sudden release of energy when the bulb explodes. This can be caused by a pressure imbalance or an insulation failure inside the bulb. When the delicate filament or components inside the bulb fail, it can result in a loud, dramatic pop.

Q: Can a light bulb explode due to heat?

A: Excessive heat during operation can cause a light bulb to explode. If the bulb becomes too hot to touch, it can lead to pressure buildup and eventual failure. Halogen bulbs, in particular, are more prone to this due to their high operating temperatures.

Q: What role do current and voltage play in a bulb explosion?

A: Current and voltage are critical factors in a bulb’s operation. A sudden surge or spikes in voltage can cause the bulb to explode. Ensuring a stable electrical supply and using bulbs designed for your fixture’s voltage can mitigate this risk.

Q: What should I do if a light bulb explodes?

A: If a light bulb explodes, turn off the power immediately to prevent electrical hazards. Carefully clean up any broken glass and inspect the fixture for damage. To prevent future incidents, it’s essential to identify the cause of the explosion before replacing the bulb.

Q: Are LED bulbs safer than other types of bulbs?

A: Generally, LED bulbs are considered safer because they produce less heat during operation and have no filament inside that can fail. However, LEDs can still explode if there are issues with electrical supply, pressure imbalance, or poor-quality products.

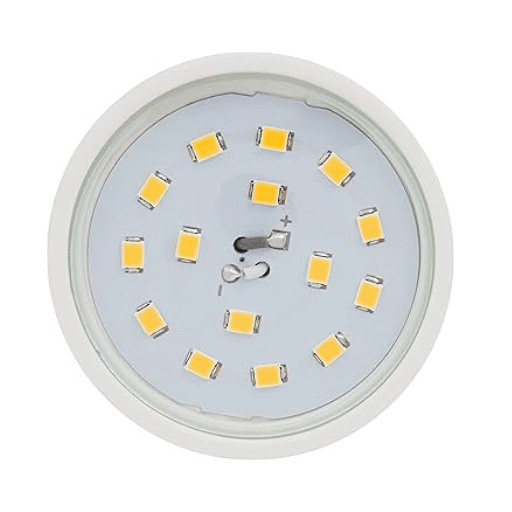

Q: What is an SMD in the context of LED bulbs?

A: SMD stands for Surface Mounted Device, a type of LED technology used in bulbs. While SMDs are efficient and produce less heat, ensuring they are of higher quality and properly installed is essential to prevent potential issues like bulb explosions.

Q: Can light fixtures affect the likelihood of a bulb explosion?

A: Yes, light fixtures can affect the risk of a bulb explosion. Light fixtures must be designed to match the type of bulb being used. Using a bulb with a higher wattage than recommended or fitting it into an incompatible fixture can cause the bulb to explode.