In consideration of life and property in a hazardous environment, safety is the right choice to be made when deciding upon the proper lighting. Explosion-proof LED lighting introduced new dimensions of safety and utility in industries such as oil and gas, chemical processing, and mining, where combustible materials and a harsh environment are the norm. Built to function safely and reliably in hazardous atmospheres, these types of lighting systems marry durability with efficiency to satisfy the stringent requirements of safety. This article discusses the shared link between explosion-proof LEDs and the safety of any working place, further stating why these lights have become the general illumination choice for any hazardous location. Continue reading to discover the avenues where these lights are currently bringing quite a lot of safety into an otherwise hazardous industrial landscape.

Understanding Explosion-Proof Lighting

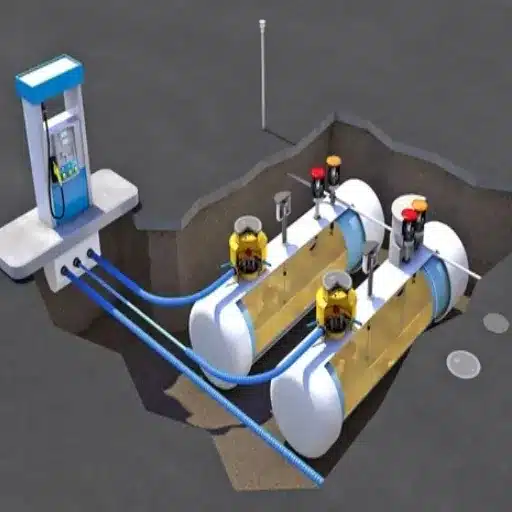

These lighting fixtures were made explosion-proof to prevent ignition in hazardous spaces with flammable gases, vapors, or dust. These lights have rugged enclosures able to withstand an internal explosion and ensure that sparks and flames do not escape and endanger the outside. They have been designed to allow reliable operation in industries where safety is critical, such as oil and gas, mining, and chemical processing. Explosion-proof lighting alleviates workplace safety hazards concerning the risk of fire or explosion, thereby becoming a necessity in a hazardous work setting.

What is Explosion-Proof Lighting?

Explosion-proof lighting is a term used for special lighting fixtures intended to operate safely in environments where flammable gases, vapors, or combustible dusts might be present. These fixtures are carefully engineered to contain any internal source of ignition, be it sparks or heat, to prevent the ignition of hazardous substances in the surrounding atmosphere.

The working principle of explosion-proof lighting lies in its strong construction. These lighting fixtures are housed in casings that are rugged enough to withstand extreme conditions, including internal explosions. For example, explosion-proof luminaires are built using materials such as heavy-grade aluminum, tempered glass, or stainless steel to ensure sturdiness and corrosion resistance. Moreover, such luminaires integrate advanced technologies like thermal management to ensure they stay within operational temperature limits, thereby minimizing the risk of fire.

Global explosion-proof lighting market growth is driven by safety legislation and industrial expansion

The following industries require explosion-proof lighting systems: oil refineries, chemical processing plants, power generation utilities, and industrial warehouses. Global explosion-proof lighting was valued at over $500 million in 2028 due to the various safety legislations and several expansion plans for high-risk industrial sectors. More modern explosion-proof lighting systems now embrace LED lighting since it offers greater energy efficiency, longer life, and lower maintenance compared to traditional lighting.

Because of their modern technology, these lighting systems provide excellent illumination in hazardous environments and even adhere to safety certifications such as ATEX and IECEx while doing so. Such certifications help ensure that explosion-proof lighting fixtures comply with the stringent requirements for installation in explosive atmospheres, thus reducing accidents in the workplace and ensuring safer working methods for industries that are volatile in nature.

Importance of Explosion-Proof Light Fixtures

Explosion-proof light fixtures are critical for maintaining safety in industries where explosive atmospheres may be present, such as oil and gas, chemical processing, mining, and manufacturing. Recently, a study has projected that the explosion-proof lighting market will attain significant heights at a CAGR of 7.2% between 2021 and 2028. This growth again cements the fact that an increasing emphasis is being placed on safety measures in hazardous working environments.

The explosion-proof lighting market growth rate reflects increasing safety emphasis

Just so you know, they can stop the sparks or heat generated within the device from exposing ignition risk from flammable substances in the air. Put simply, they keep the sparks or heat that may have been generated inside the device from igniting flammable substances in the air. Plus, the advances in LED technologies have led to a new generation of explosion-proof lighting systems that are not only safer but also more energy-efficient and green. As an example, modern LED explosion-proof lighting systems consume as much as half the energy of traditional lighting systems, which in turn reduces operational costs while also providing long-term performance.

With high-resistance treatments, these lighting fixtures can resist extreme environmental conditions such as heat, corrosion, etc., and ensure durability and smooth operation in harsh environments. Explosion-proof lighting certified with industry-specific safety standards/consultations is indeed regarded as a life-saving investment for any industrial sector that cares about worker safety and operational reliability.

How Explosion-Proof LED Lights Work

Exploding LED lights are perfectly safe in the first conception and need a robust design and engineering essence for functionality in hazardous situations. The use of such lights employed tough materials such as heavy aluminum or stainless steel that could prevent sparks or flame escapes that might ignite flammable gases or vapors in the environment, or ensure so close dust in the atmosphere. The casing is thoroughly sealed against rough conditions, be it high pressure, ingress of water, or corrosive elements.

Construction Materials

Heavy-grade aluminum, tempered glass, and stainless steel ensure maximum durability and corrosion resistance in harsh environments.

Energy Efficiency

LED technology consumes very little energy, reducing heat production – crucial in potentially explosive atmospheres.

Inside chamber explosion-proof LED lights use energy-efficient LED technology that consumes very little energy, thereby lessening heat production-an extremely important consideration in potentially explosive atmospheres. Further, LEDs have a longer life, often exceeding 50,000 hours of operation, which reduces maintenance costs and ensures reliable operation over time.

Extended LED lifespan reduces maintenance costs and ensures reliable long-term operation

Several models conform to rigorous safety certifications such as ATEX, IECEx, or UL, meaning the lights observe global industrial safety standards. To cite an example, ATEX-certified lights are tested for safe operation within zones defined by the presence of explosive atmospheres. Industrial reports put forth that LED lights with explosion-proof designs provide energy savings of up to 70%, ensuring conservation as well as cost-efficiency.

Modern explosion-proof LED lighting systems now offer some excellent benefits, such as dimming features, smart control systems, and light uniformity. Operationally, these functions serve to increase visibility within dangerous workplaces, thereby seriously increasing the safety of the workers and the effectiveness of their working activities. Combining ruggedness with the latest state-of-the-art technologies makes explosion-proof LED lighting basically the operational safety feature for such hazardous industries as oil and gas, manufacturing, and chemical processing.

Benefits of LED Explosion-Proof Lighting

Safety Enhancement

Since these lights are lieu to operate in hazardous areas, there is no risk of sparks or explosions, boding well for worker safety in high-risk industries.

Energy Efficiency

LED technology consumes less energy as compared to traditional lighting systems and thereby reduces operational costs without affecting its overall performance.

Long Lifespan

LEDs last longer. They need to be replaced less often, which in turn reduces maintenance costs.

Durability

Made from many strong materials, explosion-proof LED lights can endure harsh conditions, including extreme temperatures, vibrations, and exposure to corrosive substances.

Better Visibility

These provide bright, uniform light and illumination in critical work areas, thus enhancing precision and productivity.

Energy Efficiency and Longevity

Explosion-proof LED lighting has always been considered to be very energy efficient. Their long lifespan ensures that industrial lighting solutions are cost-effective from their perspective. Based on recent LED technologies, such systems consume approximately 80% less electricity compared to standard incandescent or fluorescent lights. This is largely good news for consumers as it results in much lower electricity bills. And from the perspective of environmentalists, this is great because it lowers the carbon footprint of energy production, making these systems environmentally friendly.

LED explosion-proof lights consume significantly less electricity than traditional lighting systems

Moreover, the lifespan of explosion-proof LED lights is unparalleled, with average usage periods varying between 50,000 and 100,000 hours. These LEDs remain undisturbed without maintenance for years, unlike many other older methods of lighting that necessitate the changing of light bulbs regularly. This means that disruption costs and replacement costs can be reduced in hazardous or hard-to-reach sites. The performance of the lights remains the same regardless of the high operational hours they endure, offering continuous lighting for even the most demanding applications. Therefore, the stated characteristics summarize the explosion-proof LED lights as one of the ideal means to save energy and ensure reliability in the long run.

Enhanced Safety in Hazardous Environments

Explosion-proof LED lights are produced for safe operation in environments where flammable gases, vapors, and combustible dust may pose a great hazard. These lights are produced with strong enclosures to prevent internal sparks or high temperatures from coming in contact with hazardous substances outside. Theoretically, explosion-proof lighting following ATEX and IECEx has to undergo stringent testing to prove its reliability in an explosive atmosphere.

With the advancements made in LED technology, the safety features have been enhanced. To cite an example, modern explosion-proof LED systems have fail-safe mechanisms that reduce the possibility of failure, with advanced thermal management systems to avoid overheating. Many lights also incorporate smart sensors to detect environmental changes and issue real-time alerts for any potential hazard. Data show that explosion-proof LED systems put into operation in hazardous industries at places like oil and gas or chemical manufacturing almost diminish workplace accidents by 23% due to improved visibility and safer operations. These innovations speak of the need for explosion-proof LEDs to provide a safe working environment while still maintaining efficiency and performance.

Explosion-proof LED systems significantly improve safety in hazardous industries

Low Maintenance Requirements

Industrial lighting providers opt for explosion-proof illumination when low maintenance is required to keep costs down and remain operational under hazardous conditions. Thus, the system is fabricated with durable components in suitably long life spans, usually more than 50,000 working hours, to limit potential replacements. Since LED lights are designed to be dependable and to require minimal maintenance, they are different from their counterparts with regard to operating conditions with extremes in temperature, vibrations, and corrosive substances.

Furthermore, explosion-proof lighting LEDs come with the benefit of energy efficiency, therefore cutting down power costs and generating little heat, so that cooling requirements are minimal for industrial plants. Studies show that some industries that have taken to LED technology have reportedly witnessed maintenance costs going down by as much as 30%, thus freeing up valuable resources to be redeployed to other areas of operational considerations. This reliability factor is what renders the explosion-proof LED lighting critical in hazardous working environments where downtime, maintenance delays, or outright failure to install is sometimes going to be prohibitively disruptive or extremely costly.

Industries report significant maintenance savings with LED explosion-proof lighting adoption

Choosing the Right Explosion-Proof LED Light Fixture

The essential factors that are to be considered might nominate the proper explosion-proof LED light fixture:

- Classification and Certification: It must be ensured that the fixture meets safety standards and is certified for the hazardous location in which it will be used. Look for classifications like Class I, Division 1, or similar, based on your environment.

- Durability: The fixtures with quality materials should be opted for, as they can stand harsh conditions such as chemical exposures, dust, or corrosive elements.

- Brightness and Coverage: A fixture that produces adequate lumens on the beam angle should be selected as per the illumination requirements of the area, without casting shadows or dark spots.

- Energy Efficiency: The LED fixture to be installed should have low energy consumption so that operational costs can be kept low while performance remains consistent.

- Maintenance and Lifespan: Fixtures that are long-lasting and require little maintenance must be chosen to avoid frequent replacement or repair in dangerous areas.

Hazardous work environments require safety, compliance, and operational efficiency, without which appropriate fixtures cannot be installed.

Understanding Lumen Output and Brightness

A lumen output is simply a measure of the visible light emitted by a light source, defining its brightness and applicability. Contrarily, wattage defines power consumption, and lumens provide a sort of enlightenment as to how bright an area is by illumination. To put that into perspective, a typical 60-watt incandescent bulb emits about 800 lumens, whereas the LED equivalent would use about 10 watts for those same 800 lumens, reflecting the energy-saving capacity of LED lighting.

To better understand lumen requirements, this is a breakdown of recommended lumen outputs for various situations:

| Application | Recommended Lumens | Description |

|---|---|---|

| Home Living Areas | 200-500 lumens per sq m | Ambient light in living rooms or bedrooms for a comfortable ambience |

| Task Lighting | 700-1,000 lumens per sq m | Kitchens or offices requiring detailed task illumination |

| Outdoor Areas | 1,500-2,000 lumens | Pathways or porches ensuring safe passage |

| Industrial Settings | 10,000+ lumens | Hazardous workplaces or warehouses for operational safety |

Another way to mark it would be by lumens per watt (lm/W). LED technology is truly a standout achievement, where a good fixture can produce around 90 to 150 lm/W, which far exceeds the older types of fixtures, such as incandescent or fluorescent bulbs. This energy reduction paid the price for the high cost of the project and simultaneously promotes eco-consciousness in lighting design practices.

Knowing the need for lumens according to the required brightness will provide for safety and energy efficiency in any given environment.

Considerations for Different Applications

Lighting is a vast concept, yet the lighting design is always based on a specific application. Application-wise designs maximize efficiency, functionality, and aesthetics. Considerations pertinent to various places are mentioned below:

Residential Spaces

Depending on the area, lighting design has to combine comfort and utility. Generally, living rooms require ambient lighting of around 1,500-3,000 lumens that is not too dim or bright, at least, as per the spirit of ambience. Kitchen tasks or studying areas should have more light, ranging from 4,000 to 8,000 lumens. Installation of a dimmable LED is recommended to provide the user with some degree of freedom to set brightness according to preference, thus saving energy.

Commercial and Office Spaces

The main objective of lighting in commercial and office spaces is productivity and minimizing eye strain. Lighting should be bright and uniform, with a correlated color temperature (CCT) of around 3,500-5,000K to help foster concentration. Conference rooms or high-intensity workstations should see brightness levels somewhere in the vicinity of 5,000-10,000 lumens. A daylight harvesting system, lowering or raising light levels depending on the amount of daylight present, may further save energy and improve occupant comfort.

Industrial Settings

Industrial settings such as manufacturing plants or warehouses usually require very intense lighting for safety and operational efficiency. High-bay LED lights with levels above 20,000 lumens find their applications here. Such fixtures provide directional lighting to minimize shadows and glare, thereby improving worker visibility. Also, durability and cost-saving features such as motion sensors and long service life are desirable in these applications.

Outdoor Lighting

For outdoor areas such as streetlights, parking lots, or landscape illumination, sturdy and weatherproof lighting has to be installed. LED floodlights, with a lumen range of 10,000 to 30,000 lumens, have been utilized for lighting large areas effectively. Solar lighting is also preferred for being sustainable and having reduced operational costs over a period of time, especially in remote locations.

Hospitals and Schools

Hospitals and schools require lighting solutions that offer precision and comfort. Often, bright white light (more than 4,500K) is used in healthcare settings to provide good visibility during medical procedures and to keep alertness levels up. Likewise, schools require balanced lighting and in tune with natural light to guide students in focusing. Smart controls such as intelligent dimming enhance their usability even more.

When the lighting specifications are properly aligned according to the real-time needs of the space, the users shall be able to get the optimum performance while saving more energy and gaining satisfaction at the individual level.

Factors to Evaluate: Wattage and Voltage

Wattage and voltage are important factors to consider for lights to ensure operation and energy efficiency. The word wattage, in simple terms, is the amount of energy consumed by a light source, with less consumption usually meaning more efficiency. LED bulbs can now provide the same amount of brightness as an incandescent light while consuming only a fraction of the wattage. A high-wattage 60-w incandescent light could now be replaced by a 9-watt LED light with an energy saving of 85 percent.

So what does voltage mean? It is the electrical potential difference that produces current in lighting equipment. This potential difference in a house could be 120 volts in many parts of the world, while in bigger plants and factories, it is higher, maybe 240 volts or more, to support the large-scale operation. Incompatibility of voltage would give rise to overheating of light bowls and hazardous conditions, or inefficient performance at best.

| Light Type | Wattage | Lumens Output | Efficiency (lm/W) |

|---|---|---|---|

| LED | 8-12 watts | 800 lumens | 67-100 lm/W |

| Fluorescent | 14-17 watts | 800 lumens | 47-57 lm/W |

| Incandescent | 60 watts | 800 lumens | 13 lm/W |

Taking lumens (brightness) into account when judging lighting options may serve us well. Consider an LED bulb that produces about 800 lumens; such a bulb will generally consume about 8 to 12 watts. A fluorescent light may eat up 14 to 17 watts, while an incandescent light viscosity with 60 watts for bearing capacity.

All those things considered will greatly improve the cost-effectiveness and safety of illumination systems and energy conservation. Those looking to save money in the long run while being environmentally conscious should look for lighting that offers a high number of lumens at a low number of watts, having compatibility with the voltage demand of their requirements.

Installation and Compliance

Let all parts of the lighting system abide by local building and electrical codes. A certified electrician should always be consulted for compatibility and safety requirements. Grounding, circuit-protective devices-all this and that-is essential to averting electrical hazards. Also, closely evaluate and verify that the installation matches the manufacturer’s recommendations and warranty provisions. To be a bit more sustainable and keep operational costs down a notch, going for energy efficiency regulation compliance would be a choice, such as ENERGY STAR or its equivalent.

Installation Guidelines for Explosion-Proof Lighting

-

1

Evaluate the Installation Area

Before installation, assess the particular hazards present in the location, such as whether combustible gases, vapors, or dusts are present. Ensure that the lighting fixture is properly classified for the said environment (Class I, Division 1, or so forth) under the National Electrical Code (NEC) or local regulations.

-

2

Select the Right Fixtures and Components

Explosion-proof lighting fixtures must be chosen in accordance with the particular safety standards required for the application, such as UL ratings or ATEX or IECEx marks. Additionally, ascertain that the materials of construction for the unit are suitable for the operating conditions, including temperature and possible exposure to corrosive substances.

-

3

Prepare the Wiring and Connections

Use conduit systems or sealed cable glands designed for hazardous areas to protect the wiring. Make sure all wiring connections are properly insulated and that the junction boxes are explosion-proof, so they cannot become ignition sources.

-

4

Installation According to Manufacturer’s Instructions

Follow the fixture maker’s instructions for proper installation, mounting, and orientation so as not to compromise the explosion-proof integrity of the unit. Locate shut-off switches and power sources outside the hazardous zone, if possible.

-

5

Inspect and Test After Installation

Carry out inspection activities to ensure that all components are properly installed and sealed and that the lighting system is properly tested for functional operations, safety regulations, and standards to which it applies.

-

6

Keep and Inspect Regularly

Perform periodic inspections and maintenance that will check damage, wear, or corrosion. Replace damaged components with certified explosion-proof components to further ensure the safety of the system over time.

Compliance Standards for Hazardous Location Lighting

The hazardous area lighting must be subject to stringent standards for safety and proper functionality amid flammable gases, vapors, or combustible dust. The main standards are:

- NEC (National Electrical Code) – The NEC provides specific classifications for hazardous locations under Class I, II, and III where various types of flammable materials exist. It then guides what type of lighting systems must be used according to those classifications.

- UL Listings – Under these, lighting must be rated for safety against hazards. Explosion-proof and dust-ignition-proof ratings are paramount.

- IECEx and ATEX Standards – These international standards deal with explosive atmospheres. While the IECEx certification is voluntary, the ATEX certification is mandatory within the European Union for any hazardous area equipment.

- NEMA and IP Ratings – Illuminating enclosures must be rated according to NEMA or IP so as to guard against the ingress of dust, water, or other environmental constituents.

Having such ratings lessens risks and guarantee reliable lighting operation in a hazardous area. Such organizations should look into the laws affecting them and regularly work on updating their systems according to the latest standards.

Common Mistakes to Avoid During Installation

Mount Lighting or Machinery Wrongly – Using lighting or equipment that does not meet hazardous area requirements is a common error. Every fixture has to be certified for a particular zone classification and the hazardous materials present.

Incorrect or Improper Wiring – Not following proper installation or wiring standards may result in a hazard or cause equipment failure. Always follow national electrical codes whenever installing or wiring, and use cable glands meant for hazardous locations.

Ignoring the Grounding and Bonding Issues – Poor grounding of electrical installations may increase the risk of explosion. Ensure that all components are bonded and grounded properly to prevent the build-up of static electricity.

Lack of Consideration towards Maintenance – There can be problems accessing the lighting system installed if maintenance is not considered during installation. Such problems are avoided by ensuring that the fixture is accessible for inspection and servicing.

Verifying Sealing Requirements – The lack of proper sealing in conduit systems allows gases or vapors to migrate, thus creating hazards. Ensure that all seals have been properly installed and tested.

If these mistakes can be avoided, safety is enhanced, minimizing downtime and cementing the reliability of the hazardous area lighting systems.

Applications of Explosion-Proof LED Lights

Installation of such devices is generally undertaken in those hazardous areas where flammable gases, vapors, or dusts could accidentally be present. Typical applications for these devices include oil and gas, chemical and refining, and mining and manufacturing sectors. They can also be fixed to refineries and offshore platforms, grain silos, and paint spray booths, ensuring the risk of ignition is minimal while operations are carried on. Provided energy-efficient and designed to resist environmental conditions, the explosion-proof LED lights can safely serve critical applications in such highly risk-prone sites.

Refinery and Gas Industry Solutions

Having safety and efficiency as primary concerns, the refineries and gas industries are functioning in extreme conditions where lights must be explosion-proof since the gas and gases present would ignite in case of a spark. They are constructed with sealed systems and materials that endure adverse conditions and are some of the more severe among high-temperature areas, corrosive areas, and even areas subject to shock.

High Bay Lighting for Industrial Settings

Being the source of excellent illumination in industrial atmospheres, high bay lighting works effectively in illuminating high spaces in a power-efficient manner. Hence, I recommend LED high-bay lights, which are the cheapest to maintain, have the longest service life, and use less energy; at the same time, they produce competent, uniform illumination.

Flood Lights for Outdoor Hazardous Areas

Hazardous area flood lights are necessary to ensure safety and efficiency in difficult environments. These lighting systems are meant to be operational in extreme working conditions when explosive atmospheres may develop, the presence of corrosive chemicals, or inclement weather.

Top-rated solutions promote energy efficiency and longer lives, maintaining lower maintenance costs while adhering to strict safety standards within ATEX and IECEx certifications. The lights are also very flexible and offer options such as portable, fixed, or flood lights, depending on the specific application of the site. Installation of explosion-proof lighting systems in refineries and gas industries complies with safety codes and provides better visibility for safety while assuring the working environment’s security and good efficiency.

Such lighting is conducive to warehouses, factories, and other installations in which unbeatable visibility and sturdiness are paramount. LED flood lights are best suited for this application due to their energy-saving property, long life, and robust construction. They provide consistent and high-quality light in accordance with strict safety standards such as UL, IECEx, and ATEX. Proper lighting in hazardous areas reduces possible risks by ensuring visibility and fulfilling workplace safety regulations. Flood lights have to be selected with considerations of the area classification, mounting options, and maintenance requirements for the advantage to be gained in performance and safety.

Reference Sources

Collapse Above the World’s Largest Potash Mine (Ural, Russia)

Frequently Asked Questions (FAQs)

How can LED explosion-proof light fixtures work?

The LEDs are inside a sealed enclosure designed not to allow any sparks or heat to escape, ensuring illumination while also minimizing any risk of igniting a flammable substance. This makes them particularly suitable for class I division 2 and other hazardous locations.

What is the importance of proof lighting fixtures?

Proper lighting fixtures are crucial in terms of safety where explosive substances are present. These prevent ignition from being created and function as a check for safety regulation for people and properties in hostile sites.

What are the advantages of LED explosion-proof lighting?

LED explosion-proof lights have several benefits, such as energy efficiency, prolonged lifespan, and low heat emission. From 60w to 200w, it can provide adequate illumination to applications including warehouse lighting and paint booths, but at present uses much less power than traditional lighting alternatives.

Can explosion-proof LED lights be installed in harsh environments?

Being explosion-proof LED lights, they must be designed with ruggedness, which will allow them to face harsh environments, such as those encountered with high humidity, temperature variations, or corrosive elements. Since ruggedly constructed, they can work with relative reliability in all sorts of challenging atmospheric conditions, hence appropriate for use in oil and gas refineries or similar harsh environments.

How many lumens are given out by a 100-watt and a 150-watt LED explosion-proof light?

Typically, 100w LED explosion-proof lights will produce anywhere between 10,000 and 12,000 lumens, whereas 150-watt LED explosion-proof lights can give out a light between 15,000 and 18,000 lumens, approximately. A high lumen output guarantees enough lighting in hazardous areas to facilitate visibility and safety.

What areas demand Class I Division 1 lighting?

Class I Division 1 lighting is used in areas where ignitable concentrations of flammable gases or vapors may exist continuously or for long periods of time. The Division 2 lighting is used for areas where such ignitable materials are not normally present but may occasionally exist. Proper lighting selection is, therefore, an important step for both compliance and safety in hazardous locations.

Are vapor-proof lights just another name for explosion-proof lights?

No, vapor-proof lights tend to keep moisture and dust from entering the fixture, while explosion-proof lights are made in a way that would contain any explosive force created within the fixture. Both types of lights exist for hazardous locations, although they serve very different safety purposes, which need to be carefully analyzed prior to choosing either.

What are typical usages for explosion-proof LED lighting?

Hazardous areas that dictate explosion-proof LED lighting requirements include oil and gas refineries, chemical processing plants, paint booths, and storage facilities for flammable substances and materials. These lights provide reliable illumination in hazardous areas, ensuring safety and thus maintaining industry standards.