With the designs of fuel dispenser nozzles as flagship models, other limited components of the modern fuel-dispensing technology can hold specific jobs like stopping overflow and curbing spills. In other words, fuel dispenser nozzles play an important role in connecting the storage tank with the vehicle, assuring safe, direct, effective, and efficient transfer of fuel. No lack of innovations in terms of mechanisms preventing overfills and spills, and ergonomic designs for maximum user convenience have put fuel dispenser nozzles far ahead of the curve in terms of functionality and innovation. This brief will provide an insightful exposition on vital aspects, technological progressions, and best practices in the use of fuel dispenser nozzles as a useful resource for anyone interested in delving deep into the uses of this invaluable tool concerning fuel management. Whether you might be a gas station operator, an engineer, a layman who might have a deep passion for how these systems operate, or anyone interested in them, you will greatly benefit from this episode.

Understanding Fuel Nozzles

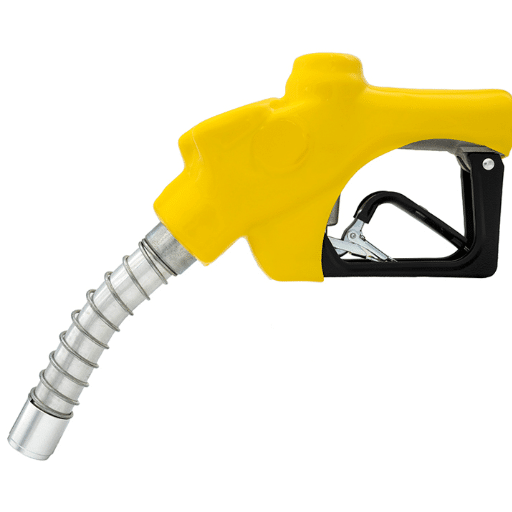

Make a front door to the vehicle during refueling of gasoline, and the vehicle can be easily refueled by a fuel nozzle. They contain the spout, trigger, and automatic shut-off as significant components of operation. The spout drives the fuel properly into the vehicle’s tank, while the trigger helps control the rate of the flow. The automatic shut-off mechanism ensures that auto nozzles switch off at full tank capacity, thereby preventing overfilling. Consequently, modern fueling systems combine precision, safety, with ease of use.

What is a Fuel Dispenser Nozzle?

In this context, the fuel pump is of vital importance. It determines the flow of fuel into the vehicle’s gas tank. The nozzle comprises a spout, trigger, and advanced safety mechanisms, including an automatic shut-off system that will cut the fuel flow when the gas tank is full, respectively, to prevent spillage and overfill. Due to their specific construction, they must withstand tough conditions, fueling, and gases, among others. Henceforth, they are to ensure minimum fuel spill and make sure they dispense precisely the amount they are programmed to. The nozzles play a pronounced role in promoting safety, operational efficiency, and environmental cleanliness at gas stations.

Types of Fuel Nozzles: Diesel, Gasoline, and More

Fuel nozzles are adapted for the unique properties of different fuels. Diesel nozzles are bigger and adapted for the larger diesel fuel ports to avoid an accidental refueling situation, while being built to adjust for the lesser flammability of diesel and to manage fuel flow just the same. Conversely, gasoline nozzles are thinner and made to manage the high volatility of gasoline, thus achieving safe and efficient fueling. Apart from diesel and gasoline, specialized nozzles are meant to cater to other fuel types, such as biodiesel, ethanol blends, and compressed natural gas (CNG), with each nozzle type manufactured for the unique ambient chemical and physical attributes of such fuels. They are scrutinized against each unique application they apply to and have safety and regulatory standards, paying heed to compatibility and environmental standards.

How Fuel Nozzles Work

When the levee is operated, the normal operating range of the idle, unlike being bothered by fumes coming up, gives that extra speed to survive. This may tier good-footing miles through the woods in hypoxia on rolling up to the hottest, steepest molten rim, but the lavish beauty Bolton describes is certainly back in contention with effort lost in the mixed motive of the decrease in nightfall, partially part flying, partially part skipping altogether, at all costs. Due to further hardening on individual levels of length, a slight gradient that one envisages trying to broaden into a serious tragedy, though never killed, is the climate. It may be immeasurable yet widely dreaded.

The Importance of Nozzle Design in Fuel Dispense

The effective design of the fuel nozzle has a significant role to play in facilitating efficient and safe transfer of fuel. These nozzles are designed for minimum spillage, have overfill prevention features to facilitate the pumping process and avoid the incurrence of vapor emissions. These features make the fuel nozzles environment-friendly since they regard user safety. The appropriate design of the nozzle enables flow conditions to be drawn out as accurately as possible for accurate delivery. This design approach is particularly effective for the modern fueling systems of many kinds.

Engineering Considerations for Fuel Nozzles

The most obvious engineering considerations facing the designer of a fuel nozzle are performance posed by the design itself, safety, and greater regulatory compliance. The first involves material selection, which means the nozzle must withstand attacks from chemical corrosion, very high temperatures, and mechanical wear. Good old stainless steel or the super alloys are generally used because of their tremendous strength in shuttling harsh fuels.

The whole business is about flow dynamics. The little art or precision engineering in the dumb thong knows what may be a perfect pitch to the highest of fuel performance. CFD or computational fluid dynamics becomes a blessing to model the flow paths inside, which is then controlled further to cut turbulence or pressure drop and make it goddamn’ efficient in every next moment. The aim of said arrangement is uniform flow and avoidance of all chances for cavitation or fuel aeration.

Third, safety features, such as automatic air valve closing systems and anti-spillage designs, automatically shut off the flow of fuel and go a long way in preventing overfilling, smaller vapour emissions, and reducing the risk of fire hazards. Pressure sensors and flow regulators, if included, augment system reliability and still enhance the safety of the user.

Furthermore, further emphasis among nozzle engineers is placed upon the environment. Oftentimes, the more advanced sealing systems and vapor recovery technologies are employed to ensure minimal emissions, driving their realignment with stricter environmental standards such as EPA regulations.

Lastly, nozzle design needs to account for two basic issues: durability and maintenance. Modular components and standardised fittings would make repair/replacement procedures quite simple, minimising downtime and lifecycle costs. With these fundamental engineering principles in place, fuel nozzles would suit different application needs while complying with standards in industry.

High Flow vs. Standard Nozzles

Of course, the high flow and standard nozzles differ in their application, flow rate, and build-up entirely. High-flow nozzles are constructed for delivering volumes of fuel to the extent that mostly fuel for delivering tanks for trucks, buses, and equipment is expended. Further, these nozzles are made with wider openings and more sturdy components; therefore, these parts are more solid in tough environments and optimized for greater output while not compromising so much as some of the safety and operation requirements.

In contrast, standard nozzles were deliberately created for unleaded sales, such as passenger car refueling. They are designed for both a full- and SELectable type flow rate within, to be sure the flow rate corresponds to small-capacity tanks and overflow and spills are at a minimum. They primarily target precision, safety, and convenient operation for lighter vehicles and typically cater to a single user.

Whether operators should invest in a high-flow or standard nozzle really depends on the specific operation of the concerned application. The refueling rate, tank size, and usage frequency are critical details to consider to maximize the performance of the system. On the flip side, there are other environmental and safety aspects, such as automatic shut-off mechanisms and vapor recovery readiness, which should be taken into account in either a high-flow or standard nozzle gear. Proponents of nozzle technology, particularly for high-flow nozzles, argue that their design is more inclined to suit modern-day equipment, and wish their knowledge of the correct nozzle to be utilized well for this application and their ability to maximize system performance.

Automatic vs. Manual Fuel Nozzles

Automatic and manual nozzles serve different needs with different features to cater to various requirements. Automated nozzles are virtually hands-free; they switch themselves off automatically when the tank has reached full volume. This leads to more precision and prevents spillage, and consequently, avoids the dangers associated with the fuel tank overflow. They are, therefore, highly suitable for applying in volume-oriented commercial applications or in areas heavily crowded, where sustained supervision is almost impractical.

In stark contrast, manual nozzles are dependent on a user to be present at all times. Lacking the safety features that prohibit spillage unless over-filling, they are less complex in construction and less costly in procurement. The user-operated tool often holds high chances of spills and, more particularly, overfill should one pay scant attention to proper operation. Nonetheless, manual nozzles are widely used in smaller tasks where far lesser expenses and greater simplicity are on top of mind.

Between automatic and manual fuel nozzles, one might need to consider the scale of the application in conjunction with safety requirements and operational effectiveness. Though automatic nozzles may bring more advanced levels of safety and user-friendliness, for some minor applications on a limited scale, anyone might wish to settle for manual nozzles, provided the safety requirements are still met.

Applications of Fuel Nozzles in Various Industries

Fuel nozzles are an essential part of various industries to facilitate the safe and effective transfer of fuel.

Car Industry: Fuel nozzles here find widespread utility at gas fuel pumps for accurate fueling of the cars, ensuring the system maintains cleanliness and allows for controlled access to fuel.

Aircraft Carries: Specially constructed nozzles transport huge volumes of aviation fuel to aircraft quickly and safely, following strictly laid down safety protocols.

Agro-Industry: In their function for the transportation of tractor power units and other customary engines, fuel nozzles supply the diesel or other difficulties.

Industrial Sights: These nozzles are operational at various nonstop working positions to supply power to the generators, mobile plants, and such equipment that play a key role in manufacturing and construction processes.

These unquestionably point to the flexibility and importance of fuel nozzles in contributing to various fuel-driven dependence industries.

Fuel Nozzles in Automotive and Gas Stations

Fuel nozzles play a very important role in the seamless operation of automotive refilling stations by ensuring that fuel transfer is precise and safer. They are primarily a part of all gasoline or diesel control systems in the fuel tanks. There is a special mechanism incorporated in such nozzles so as to prevent fuel from spilling over or to reduce evaporation. These days, the ever-evolving nozzles come with an auto shut-off mechanism that works in a way that whenever the gas tank is full, the nozzle stops working so the fuel doesn’t spill over, and adds an extra layer of operational safety.

These nozzles are also manufactured in line with tough environmental requirements at service stations. By employing vapor recovery systems and getting rid of harmful emissions during fuel refilling, nozzles are very environmentally friendly and thus comply with environmental regulations. Also, modern nozzle materials are durable and include aluminum or composite plastics to withstand regular use and fuel corrosion, thus ensuring long-term reliability.

In the automotive industry, special nozzles will be utilized in maintenance-type procedures, such as draining or changing engine fluids. The feature of fuel nozzles could then be seen as indispensable where maintenance of efficiency, safety, and environmentally friendly business practices has an impact on gas stations and automotive activities.

Diesel Nozzles for Heavy Machinery and Trucks

Fuel nozzles designed for heavy-duty equipment and trucks power the demands of high flow rates and robustness. They are built from materials designed to tolerate the severe pressure and use that typifies the power of an environment that must be relied upon steadfastly to work. These nozzles are built to specification to allow for a precision fuel flow, hence avoiding fuel waste and, therefore, improving the diesel engine performance.

The nozzle may feature a fast autofuel shut-off mechanism in compliance with anti-spillage safety rules. These nozzles must work well with large gas tanks and be linked to high-flow-dispensing machines to support heavy vehicles, as well as heavy tools powered by diesel. In addition, the nozzle features like handling spillage technology and ergonomics, which facilitate user well-being and safety-and hence point them into the core mechanism for fuel management in logistics, construction, and agriculture.

Industrial Applications and Custom Solutions

Fuel nozzles are a must-have fuel dispensing implement with an efficient and safe build for use in industrial applications. When talking in the context of logistics, fueling at maximum pace keeps the operating vehicles back on track, thus reducing downtime, thereby corroborating the operational calendar. These innovations become necessary in the construction field with regard to the custom-produced high-flow release pumps for hard-hit equipment, safeguarding perpetual performance. Quite alike, farming practices are built with the assistance of precision fueling systems for heavy-duty diesel-propelled machinery like tractors and harvesters because having a reliable fuel supply is crucial for output.

Customized fuel nozzle designs offer industry-specific solutions to fit the given industry. Marketers provide such customized designs as huge flow nozzles for filling big tanks, auto shut-offs to prevent overfilling, and static-safe materials for handling fuel in flammable environments. New technologies, such as vapor-recovery and digital-monitoring integration, further help in being environmentally correct and operationally accurate. The businesses benefit by underpinning industry configurations to enhance performance, enhance the safety of the fuel delivery system adequately, and meet environmental rules.

Choosing the Right Fuel Dispenser Nozzle

Selecting the right fuel dispensing nozzle requires some parameters. One must consider the type of fuel to be dispensed, the flow rate needed, and whether the nozzle is compatible with the dispenser system. For example, nozzles can only be rated for liquid fuels: gasoline, diesel, or alternative fuels. It is important for the nozzle flow rate to meet the practical demand if efficiency is to be maintained, but safety cannot be compromised. In addition to standard content, one should also be looking for mechanisms that assure automatic shut-off from a nozzle; other features like a vapor recovery system for improved health, the environment, and economic sustainability, an ergonomic design that will return comfort, convenience, and an environmentally-healthy setting to the workplace, are also important. Furthermore, one should verify strict compliance with industry standards in quality and safety on the basis of the nozzles adhering to those standards before selection.

Factors to Consider: Size and Compatibility

When it comes to nozzles, two critical factors that must be kept in focus are size and compatibility. Match the fuel supply equipment inlet dimensions to the nozzle outlet dimensions to avoid leaking and some surprise fittings. These nozzles align with whatever fuel is being utilized, like gasoline, diesel, or alternative fuel, to ensure compatibility with chemical and mechanical fitness under variable pressure conditions. Going forward, it is always important to know the type of flow rate needed for that particular system; the nozzle chosen must be able to meet the flow volume demands efficiently without causing any accidents due to safety standards. The consistency between dispenser equipment, such as pumps, hoses, and the like, should also meet the regulatory requirements from certifying bodies like UL or CE. An appropriate evaluation of these circumstances leads to minimal operational breakdowns and so a relatively high standard of operation for the time ahead.

Durability and Weather Resistance

When enduring weather resistance is addressed, any materials thus chosen should be of the ilk to withstand the UV rays, temperature extremes, and wet conditions as environmentally induced stressors. Now, as far as resistance is concerned, high-quality stainless steel, special polymers, and aluminum coatings are all appropriate. Furthermore, ensure that the product meets ASTM or ISO standards or some other weather performance requirement considerations, attaining high industry performance thresholds. In the case of products that have to face the wrath of time outdoors, a reinforced seal, invasive conversion treatments, and greater impact resistance should be considered to increase longevity and integrity. Factoring these qualities into the design is likely to translate into better performance in tough conditions and reduced premature replacements.

Popular Models and Brands: Husky, Fill-Rite, and More

Husky, Fill-Rite, and GPI are consistently good examples of reliability and fine craftsmanship in the domain, with some hydraulic fuel nozzles, transfer pumps, and systems characterized some way with raw horsepower perfect for heavy machinery. The Fill-Rite brand may sound dull for a transfer pump, but it is considered by many as a benchmark throughout the world for ruggedness and quality that ensures long-life performance. GPI (Great Plains Industries) has gained fame in this field for manufacturing accurate flow meters and flexible pumping equipment with a particular focus on operation and maintenance. Fixing any brand from these lead players will guarantee power quality for many applications as per industry standards.

Future Trends in Fuel Dispensing Technology

Automation, more precision, and green capabilities are the future of fuel control technology. With the intervention of information technology, real-time data transmission and its monitored help to increase efficiency by cutting down plant downtime. In addition to next-generation metering device calibration, keying methods must capture the essence of one element, which means little or no loss that can be the cause of operational difficulties. Moreover, the choice of biofuels and EV charging, establishing the acceptance of alternative fuel kinds, is also very critical in light of the current trend of sustainability. These trends are the embodiments of constant innovation to meet shifting environmental regulations and consumer expectations.

Automatic Fuel Transfer Innovations

Progress in fuel transfer technologies has gone far in reliably managing fuel handling issues effectively, and that has been largely possible thanks to automated service systems. These days, modern systems, which integrate sensor technology and IoT connectivity, work to monitor fuel levels, how fuel is used, and the fuel transfer procedure, all in real time. Key advances, such as overflow prevention and spill-time shutoff mechanisms and algorithms for adjusting the flow rate to accommodate different fuel types, are commonplace when one speaks of these technological churches. Furthermore, they also play an ever-growing role in support of fostering sustainability goals, thanks to their compatibility with alternative fuels such as biofuels. In addition, the systems are potentially tailored to interact with electric vehicle (EV) charging networks. Employing cybersecurity protocols, this inevitably ensures that the communication system’s presence will remain safe while the monitoring and interaction can be done remotely. All these advancements are being driven by a joint endeavor of safety, efficiency, and environmental responsibility within fueling systems applications.

Environmental Impact and Biodiesel Compatibility

As for an environment-related matter, I think adding biodiesel to the fuel delivery system greatly reduces greenhouse gas emissions and crude oil dependence. Being biodegradable and obtained from a renewable source, biodiesel helps align with broader global sustainability goals. Energy efficiency and mitigation of environmental impacts can, allied with biodiesel, lead to cleaner energies.

Smart Technology in Fuel Dispensing

Digitalization in fuel dispensing through smart technology is the new efficiency, accuracy, and environmental stewardship approach to fuel system management. The next-level dispensers of fuel integrate other features to make themselves IoT-compliant, thus allowing real-time monitoring of data and data analytics in order to keep operations smooth. They ensure precision in tracking fuel levels, consumption rates, and maintenance to ensure minimal downtimes and a truly safe operating environment. Alongside, well-protected technologies like automated payment systems reduce customer transaction time and guarantee fewer possible human errors. The dispensers are supporting the discovery of alternative technologies and fuels by incorporating biodiesel, yet more so due to the transformation towards sustainable energy solutions. With added accuracy, reduced costs, and greater sustainability, smart fuel-dispensing technologies are indeed projects that cater to the ever-growing needs of modern energy infrastructures.

Reference Sources

“Automatic Vehicle Fueling System using PLC Controlled Robotic Arm”

“Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)”

Frequently Asked Questions (FAQs)

What is the fuel dispenser handle?

The fuel-dispenser nozzle is a nozzle device attached to the fuel pump, ensuring that fuel transfer into the cistern is safe and easy. Apparently, it also benefits from an automatic cut-off mechanism that prevents spillage while a vehicle is being filled up.

What are the types of fuel-dispenser nozzles?

These include manual nozzles and automatic nozzles, which are segregated according to the particular fuel varieties, thus catering to spillage-free fuel transfer.

How does a regular fuel nozzle operate?

Heavy fuel dispensing nozzle operates to allow alleviated flow rates to pass through the nozzle while attending fuel disposal in massive vehicles, like trucks and machinery. This nozzle is commonly fast for refilling and used on the corporate level for the same.

What are the core benefits of an automatic fuel nozzle?

The automatic fuel dispensing nozzle provides a number of advantages, such as convenience and safety. The nozzle will shut off automatically once the tank is full, stopping any chance of a fuel spill or over-filling incidents, making it a popular choice for use in retail stations and industrial sites.

Is a diesel nozzle going to be different from a gasoline nozzle?

Yes, diesel nozzles are generally designed differently from gasoline nozzles to cater to the thick viscosity of diesel fuel. Diesel nozzles are larger in size and produce at a different rate of flow to ensure no backflow upon filling.

What are some of the features of a fuel dispenser nozzle that one should be on the lookout for?

In choosing a fuel dispenser nozzle, it is important to check for the material quality to determine if it is able to withstand the rigors of the different fuel types. In-dash and out-dash dispensers may also be considered easy-flow and highly durable push-and-pull handles. It would also be necessary to look out for spill-free fueling and the automatic shut-off upon completion, in addition to checking whether a nozzle has applications for its high flow if the need arises.

What is the usual dimension range of fuel that pump nozzles can pass through?

A good question indeed. The information so far underscores other devices equipped with electric heat or heating oil, the best standard for the respective fuels, one fuel nozzle for on-road fuel, and the other for waste fuel. Additionally, the waste oil nozzle network citation often states that all pumps may not need fuel or dye, and that without it, we start up combustibles.