Our fuel dispenser pumps represent the solution that is reliable, efficient, and accurate for retail fueling operations. These pumps, made of tough materials and equipped with advanced metering technologies, provide not only accuracy in fuel delivery but also the ability to withstand high-usage conditions for a long time. They meet the safety and performance standards set by the industry so that you will not experience any disruptions in your business operations. We manufacture both single and multi-hose dispensers, which are designed to cater to the different fuel dispensing needs and, at the same time, reduce maintenance requirements.

Understanding Fuel Dispenser Pumps

Components and Functionality of Fuel Dispenser Pumps

The fuel dispenser pumps consist of several essential components, whereby each of them contributes to the functioning and the precision of the machine. Among the primary parts are the metering unit that guarantees the exact measurement of the volume of the fuel; the valve that controls the flow of fuel and sets the rate of the flow; and the spout that is made for delivering the fuel safely and efficiently. The modern dispensers have merged the cutting-edge technology with electronic systems, like the digital displays and point of sale machines, which in turn boost the convenience and the efficiency of the user and the dispenser. Moreover, some of the pumps come with vapor recovery systems that help to lessen the impact on the environment during the refueling operation. All these components together are also able to keep the accuracy, safety, and adherence to the industry standards.

The fuel dispensers are connected to an underground tank from where they suck the fuel through a pump that can be either a suction pump or a submersible one. Then, the fuel is metered where its volume is measured correctly, and after that, it is put into the vehicle’s tank through the nozzle. This entire process is very strictly calibrated so that there is no wastage, no leakage, and the reliability of operation is assured.

Types and Applications

The fuel dispensers are mainly divided into two types, suction-type dispensers and submersible-type dispensers. Suction systems are perfect for small-scale fueling stations since they are less complicated; whereas, submersible systems, because of the high flow rate, serve big stations with high demand. In addition, these pumps provide different configurations, for example, the single-hose or multi-hose alternatives to be used for several types of fuels like petrol, diesel, and even biodegradable ones like biodiesel or ethanol blends. Their sturdy construction makes them apt for use in such diverse places as commercial service stations, industrial refueling facilities, etc.

Fuel dispenser pumps have become an indispensable part of the whole distribution chain by taking the risk of being heavily regulated, safe, efficient, and eco-friendly.

What is a Fuel Dispenser Pump?

A fuel dispenser pump is a highly advanced instrument that performs a safe and precise delivery of fuel from the storage tanks to the cars or other machines. Its operation is based on the use of specialized pumping mechanisms, meters, and hardware to measure and control the fuel flow. The systems are capable of dealing with a wide range of fuels such as gasoline, diesel, ethanol blends, and biodiesel, while being compliant with strict calibration and safety norms. Modern fuel dispensers utilize features like vapor recovery systems for lessening the environmental impact, as well as digital interfaces for a better user experience. Fuel dispenser pumps are found at service stations and industrial refueling sites and form the backbone of the fuel distribution network, making sure that the fueling operations are always reliable and accurate.

Types of Fuel Dispenser Pumps

Fuel dispenser pumps can be classified into two major types, mainly based on their purpose and application:

Submersible Pump Systems: These systems consist of a submersible pump placed at the bottom of the storage tank to transfer fuel to the dispenser. Submersible pumps are efficient and reliable, hence they are frequently used in high-traffic fuel stations. They are designed in such a manner that the fuel does not have to travel a long distance, hence energy loss is reduced and consistent flow rates are maintained even under demand-intensive conditions.

Suction Pump Systems: Suction pumps create a vacuum to draw fuel from the storage tank to the dispenser. They are less complex than submersible systems, hence cheaper and easier to maintain. Suction pumps are typically found in small-scale refueling sites and places with low fueling demands where the distance to be pumped is not great.

Each type has unique benefits depending on the operational requirements, costs, and site infrastructure, allowing companies to choose the best alternative for their individual needs.

Key Features of Retail Fuel Dispensers

Fuel dispensers at retail gas stations are indispensable devices that always deliver accurate amounts of fuel and, at the same time, facilitate efficient customer service. Here are the most important characteristics that set modern fuel dispensers apart:

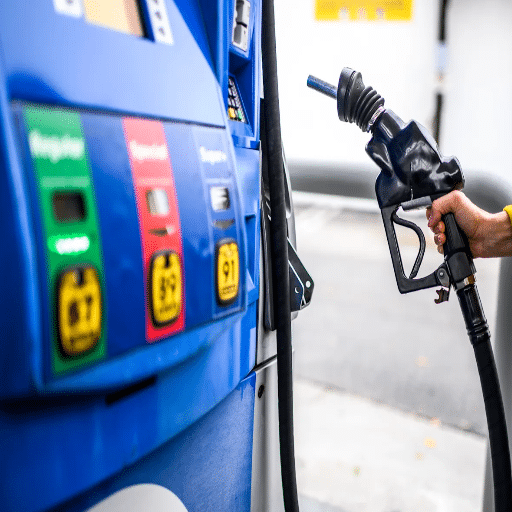

Measurement Accuracy: Fuel is measured precisely by integrating advanced meters and calibration systems into dispensers. Along with the reduction of discrepancies, these systems comply with metrology standards and hence, do not cause losses for either customers or operators.

Flow Rate Options: A wide range of vehicle types, from regular passenger cars to heavy-duty trucks, can be accommodated by the adjustable flow rates provided by fuel dispensers. The high-flow nozzles are specifically for faster tank fills of such vehicles.

Robust Construction: Dispensers are made to endure the very rough conditions of the environment. Materials that resist corrosion, weatherproof panels, and durable hoses are some of the features that add up to the longevity and reliability of the dispensers in different climates.

Advanced Payment Systems: Modern payment terminals at fueling stations come with card readers, contactless NFC systems, and mobile payment compatibility, thereby becoming more efficient and user-friendly. Additionally, these systems use secure encryption to keep customer data safe.

Integrated Safety Features: Automatic shut-off nozzles, pressure relief systems, and anti-leak mechanisms are standard safety features. In addition to reducing risks associated with fuel dispensing, these features ensure safety during operations.

User-Friendly Interfaces: Digital displays show the details of fuel transactions clearly, such as the volume, cost, and price per gallon/liter. Accessibility is further improved by touchscreen options and multilingual interfaces.

Connectivity and Data Management: Modern dispensers are capable of IoT integration, which allows monitoring and diagnostics to be performed remotely and in real time. For station operators, this connectivity results in very little downtime and better maintenance planning.

Customizable Configurations: Retail fuel dispensers can be customized in terms of tanks and nozzle setup, which makes them perfect for stations that deal with different kinds of fuel like gasoline, diesel, ethanol blends, and even alternative fuels such as hydrogen or CNG.

Thus, the features of today’s retail fuel dispensers reveal not only their technical superiority but also their flexibility to the ever-changing requirements in the industry, hence ensuring reliable performance and customer satisfaction.

The Importance of Choosing the Right Fuel Pump

Choosing the appropriate fuel pump is a very important step to ensure that the fuel dispensing system works efficiently, is cost-effective, and will last a long time. The right pump should be determined by considering such aspects as compatibility with the fuel type, desired flow rate, and strength against wear caused by changing operating conditions. For gas stations that provide more than one kind of fuel, it is very important to select pumps that allow for multi-product dispensing. Also, energy efficiency, as well as safety and environmental compliance, should be ranked as the highest priority in order to meet regulatory requirements and minimize operational costs. If businesses undertake a thorough examination of these criteria, they will be able to make the most of their fueling operations and, at the same time, increase customer satisfaction.

Factors to Consider When Selecting a Fuel Dispenser

Choosing a fuel dispenser requires careful evaluation of various main factors that contribute to operational efficiency, compliance, and customer satisfaction:

Flow Rate and Pumping Speed: The dispensing speed of fuel becomes the main criterion for efficiency in high-volume stations. Regular fuel retailing stations have set flow rates of 40-50 liters per minute; however, in the case of commercial or industrial applications, there is a need for higher speeds. These pumps can deliver 90 liters per minute or even more to cater to large vehicles.

Compatibility with Fuel Types: Compatibility of the fuel dispenser with the designated fuel types, whether gasoline, diesel, biofuels, or other alternatives such as compressed natural gas (CNG), is a must. For the stations selling multiple fuel types, multi-product dispensing (MPD) units help the operators save floor space and provide the customer with convenience by amalgamating different fuel types under one dispenser.

Accuracy and Metering Standards: The users of high-precision meters are to keep the fuel measurement accurate, losses minimized, and customer confidence guaranteed. Certified accuracy that is in accordance with national weights and measures regulations should be the primary selection factor.

Durability and Environmental Resilience: In the design of the fuel dispensers, it is necessary that they can endure tough environmental conditions without degradation. Among others, extreme temperatures, humidity, or prolonged UV exposure. The use of stainless steel and anti-corrosive coatings for dispenser casings are the materials that are highly recommended.

Integration with Modern Payment and Management Systems: The advanced fuel dispensers come with point-of-sale (POS) systems, fleet management platforms, as well as contactless payment solutions. Such interoperability leads to smooth transaction processes and enhances operational oversight.

Safety and Compliance Standards: Following local and international safety rules, like explosion-proof certifications and leak detection systems, ensures both regulatory compliance and operational safety. Besides, the dispensers have to be in accordance with the environmental regulations that prevent spillage and vapor emissions.

Once the above traits are appraised in accordance with the business needs, the operators can pick a fuel dispenser that guarantees the fueling operations to be efficient, accurate, and environmentally friendly.

Benefits of Portable Fuel Dispenser Solutions

Portable fuel dispensers, as a solution, in terms of their benefits, versatility, efficiency, and cost-effectiveness, come out as the winner. Due to their small and mobile design, they are capable of supplying fuel to places that are very difficult to access or are located very far away. Thus, they are best suited for agricultural, construction, and fleet vehicle operations. The high-precision metering technology that is a part of these dispensers assures accurate fuel measurement, thus cutting down wastage and raising accountability. The portable fuel dispensers are, in addition, equipped with user-friendly features like digital displays and automatic shut-off systems that are very helpful in enhancing operational efficiency. Besides, these systems lead to cost savings through the elimination of the stationary infrastructure and lessened downtime that is associated with centralized fueling. Moreover, the dispensers that are portable dispensers are always in compliance with the required safety and environmental standards and thus preventing accidents of spillage and emissions; hence, they are an eco-friendly option. The blending of functionality and mobility in portable fuel dispensers has made the distribution of fuel more efficient in various operational environments.

Comparing Diesel and Gasoline Dispenser Pumps

Diesel and gasoline dispenser pumps are similar in that they both use the same basic principles; however, they greatly differ in their design, operation, and the laws they have to abide by because of the different characteristics of the two fuels. Diesel fuel dispensers usually have big filters and special pumps because the diesel fuel is more viscous and heavier, which is why it is necessary to ensure smooth flow and correct measuring. Sometimes, they also contain parts that are meant to reduce fuel foaming during dispensing, which is a problem more common with diesel than with gasoline.

Gasoline dispensers, however, are made to get along with a fuel that is lighter, more volatile, and thus has a lower density. They also have to take greater precautions to prevent vapor emissions to meet environmental laws, which include installing vapor recovery systems. Besides, gasoline pumps are generally faster than their diesel counterparts since they are mainly used in retail fuel stations, where quick refueling is essential.

Compatibility between materials is another major factor that distinguishes diesel from gasoline. Diesel dispensers are made from materials that do not react with the oil of diesel, while gasoline dispensers use parts that do not react with the solvent-like properties of gas. The safety requirements also differ, as the risk of ignition due to static electricity is higher with gasoline because of its lower flash point, which calls for more stringent grounding and bonding practices.

The accuracy and dependability of both systems are undoubtedly of a high standard, but the choice of the right pump is still greatly influenced by the application, mode of operation, and regulatory compliance that are peculiar to the type of fuel being dispensed.

Popular Brands and Models

There are a few reliable brands of fuel transfer pumps that are well known for their performance and dependability:

Fill-Rite: Heavy-duty pumps for gasoline, diesel, and kerosene applications are the main products of Fill-Rite, and the company is recognized worldwide. Some of the models it produces are the FR1210H and FR701V.

GPI (Great Plains Industries): GPI is a major company in the market for portable fuel transfer pumps, and pumps like EZ-8 and M-150S are perfect for light to medium-duty applications, and thus the company is regarded as the country’s leading manufacturer of such pumps.

Piusi: A European brand that develops electronic pumps, Piusi has models like the EX50 for diesel and biodiesel that are quite popular.

Tuthill: Manufactures strong pumps such as the Tuthill 12V DC Series geared towards agricultural and industrial fuelling requirements.

These companies are always recognized for their products’ long life, accurate performance, and compliance with safety regulations. Every single model is tailored to specific operational requirements, which gives the user the utmost flexibility in terms of fuel type and application.

Overview of the Encore 700 Series

The Encore 700 Series is a top-tier selection of fuel dispensers fabricated to satisfy the needs of current fueling systems. Gilbarco Veeder-Root, the maker of this series, merges state-of-the-art technology with the sturdiest construction, thus guaranteeing performance that is nothing short of excellent in highly frequented retail fueling places. The dispensers come in different forms that can handle various types of fuels, among them are gasoline, diesel, biodiesel, and ethanol mixes, which give it the highest level of versatility in the market.

Besides, the Encore 700 Series, through its top-notch hydraulics and vapor recovery system that is very efficient and up to date, ensures that very minimal operations are done simultaneously, thus bringing about efficiency and compliance with the very strict environmental standards. These dispensers are equipped with high-quality interactive screens that are user-friendly, and this gives the customers a chance to be involved in the content engagement through multimedia and even promotional activities during the fueling sessions.

Among the unique features is the installation of safe payment terminals that are EMV-compliant, which not only ensures safety during transactions but also lowers the risk of fraud while allowing contactless and digital payments. The modular structure makes it easier to maintain, causes less downtime, and guarantees a longer life span of the equipment. The Encore 700 Series, which is very sustainable, efficient, and user-friendly, has been and will always be the operators’ choice if they want to upgrade their fueling operations.

Gilbarco Fuel Dispensers: A Trusted Choice

Gilbarco dispensers are a class-one long-living fuel dispenser, a trend of technology, set up to improve the running of the facility. It integrates one set of advanced operations and select state-of-the-art EMV-compliant payment systems that ensure secure transactions and minimize fraud threats. They also have a modular design that ensures ease of servicing or replacing components, cutting down on downtime and maintenance costs.

The dispensers are built for extreme performance and reliability by integrating highly advanced metering systems in order to guarantee maximum accuracy in the fuel measurement and to minimize losses through discrepancies. Many models, such as the Encore 700 Series, also permit green fueling with vapor recovery systems and energy consumption-reduction features. Operators also get the added benefit of sturdy cloud-based software for remote monitoring and analytics, providing insight into capacity, maintenance schedules, and transaction data.

The company also emphasizes user-centric design with the incorporation of intuitive interfaces and the acceptance of contactless and digital payment methods, so as to offer maximum convenience to the patron. Conversely, for business establishments, these dispensers will offer value in the future by way of sustainability, precise functioning, and flexibility against changing fuel management needs. Thus, a progressive partner in fueling operations of the future.

Exploring the Encore Ultra-Hi Flow Dispenser

Encore Ultra-Hi Flow dispenser meets the highest demands of commercial fuel operations. Featuring a design meant for maximizing speed and throughput, it can quickly refuel a truck with flow rates reaching 60 gallons per minute and significantly reducing downtime for fleets. The dispenser is equipped with an advanced metering system to ensure accuracy of measurements, so as to aid operational accuracy and the acceptance of industry standards.

Among the features is extraordinarily tough construction for heavy use, compatibility with high-capacity tanks, and hydraulic systems optimized for ultimate performance. User-interface enhancements allow smoother interaction with the machine, and payment solutions provide flexible options for either conventional or digital methods. Contributing to an eco-friendly environment, the dispenser reduces emissions by fuel flow efficiency optimization.

Placing heavy emphasis on reliability, accuracy, and adaptability, the Encore Ultra-Hi Flow Dispenser stands as an absolute necessity for contemporary fueling infrastructure that seeks operational excellence in the myriad of applications.

Setting Up Your Fuel Station

Site Selection and Permits: Find an acutely located piece of land that experiences high footfall and stands to be globally recognized; make sure all zoning permits, environmental clearances, or other licences relevant to the local government are obtained.

Infrastructure Installation: Fuel tanks, dispensers, safety equipment, and utility connections should be installed according to industry standards and safety protocols while making sure that placements make the systems easy to operate and efficient.

Supplier Agreements: Work with reliable fuel suppliers for steady delivery of high-quality fuels, negotiating good terms to maintain supply stability and reduce costs.

Compliance and Safety: Follow all health, safety, and environmental regulations; inspections in regular orders, and robust systems should be put in place for spill containment, fire safety, and emergency responses.

Technology Integration: Equip systems with modern payment methods, digital display monitoring, and inventory management programs to ensure smooth running and customer satisfaction.

By ensuring each point is addressed systematically, a fuel station operating at maximum efficiency will be established. The fully compliant station shall be a reliable source of service to its customers.

Essential Equipment for a Fuel Station

The operational set-up of a fuel station requires critical equipment and system choices, enabling efficient operation and adherence to industrial standards. Below is an overview of vital components gathered from major industry resources:

Fuel Dispensers and Pumps: A modern dispenser is considered essential with respect to the accurate delivery of fuels. Systems with computerized flow meters, EMV-compliant payment systems, and/or remote monitoring should be used to maintain high operational reliability and security.

Fuel Storage Tanks: Underground/above-ground storage tanks (USTs/ASTs) are employed to store various types of fuels. Such tanks must be made up of corrosion-resistant materials and equipped with leak detection systems to conform to environmental protection regulations.

Fuel Management Systems: Trickle-management systems aid inventory control, prevent losses, and allow the masses to monitor fuel levels in real time. Such systems are employed to maintain an accurate record of stock levels, thereby preventing overfilling or shortage.

Point-of-Sale (POS) Systems: Integrated POS systems featuring credit card readers, RFID compatibility, and digital interfaces ensure borderline smooth customer transaction processes while guaranteeing speed.

Safety Equipment: Spill containment systems, emergency shut-off switches, fire extinguishers, and vapor recovery systems stand among the essential safety equipment. Lesser than the highest standards of safety set by local and federal regulations would be intolerable.

Canopy and Lighting: An impervious canopy and effective lighting are necessary for keeping the dispensing areas free from weather effects and for proper visibility, thus forming a combination that enhances safety and comforts the customer during nighttime hours.

Air and Water Stations: Tire inflation via compressors and the provision of potable water heighten customer satisfaction and improve goodwill in favor of repeat visits.

The establishment of these essential items allows fuel station operators to create a fully functioning, safe, and customer-friendly environment that accords with the requirements placed on it by regulations.

Understanding Mobile Fuel Solutions

Makes mobile gasoline a new innovative approach of storing and delivering fuel right to the ultimate consumers or businesses, thus removing the need for a gas station. Currently, these systems are trucks or mobile units specially equipped to carry and service fuel safely and efficiently. Primary components of mobile fueling systems include specialized tanks, pumps, and meters, along with a tracking system, to track the deliveries and ensure conformity with safety and environmental regulations.

Mobile fuel solutions allow firms to refuel fleets and machinery on-site-with less downtime and higher efficiency. The opportunity is especially beneficial to construction, logistics, and agriculture, in which operations are mostly remote or time-sensitive. Through the usage of enhanced fuel tracking software in mobile fuel solutions, one can concentrate on the monitoring and reporting of fuel consumption.

Mobile fuel solutions need to conform to regulations and have rigorous safety measures such as spill prevention systems, fire suppression systems, and handling methods. In addition to local and federal requirements regarding operator safety, they also aim to protect the environment. With the digital revolution in full swing, many service providers now organize delivery schedules, track usage, and handle invoicing through apps, thus bringing in much-needed agility and user-friendly interaction.

In overcoming issues pertaining to traditional methods of fueling, mobile fuel solutions have become a key player in modern energy logistics, hence ensuring extreme convenience, efficiency, and scalability, operating in compliance with regulatory frameworks.

Installation and Maintenance Tips

Proper site preparation must be ensured when installing mobile fuel storage systems. The ground should be level and sturdy enough to hold the storage unit when it is full. The unit has to be secured according to all manufacturer specifications in order to prevent any instability. Make sure tanks are kept away from buildings, sources of ignition, or open flames, conforming to standards set by local fire codes or environmental regulations. Secondary containment systems are required for installations to contain spills or leaks; examples are spill berms and drip pans.

Perform regular inspections of tanks, hoses, dispense systems, and other elements to inspect and fix wear, corrosion, damage, etc. Also, clean filters and nozzles from time to time to ensure fuel purity and spirits’ efficiency. Check if legal standards, such as vapor recovery system application, are met, and if not, have components replaced. In all cases, maintenance logs need to be kept and updated to serve as evidence for regulatory compliance and ensure continuity of operations. Such proactive servicing and frequent system checks will increase the longevity and safety of your fuel storage equipment.

Where to Buy Fuel Dispenser Pumps

Purchasing pumps for fuel dispensers can be done from reputed manufacturers, through authorized distributors, and specialized fuel equipment suppliers. Top brands such as Wayne, Gilbarco, and Tokheim stand for quality options that are made for durability and within safety laws. These pumps can often be bought from their official websites or certified dealerships. For added convenience, established marketplaces dealing in industrial equipment can also be checked out for fuel storage and dispensing systems. One should always look into the credibility of the seller, along with ensuring that the product comes with a warranty and/or support services.

Finding Competitive Prices for Dispenser Pumps

When trying to find competitive rates on dispenser pumps, first compare what is offered by the leading manufacturers, including Gilbarco Veeder-Root, Wayne Fueling Systems, and Tokheim. These firms often make available the pricing and specifications for their models through their respective official websites, thereby allowing transparency and direct access for interested parties. Other trusted online marketplaces, such as GlobalSpec, Alibaba, and Grainger, should be explored, as common listings of a broad variety of commercial fueling equipment can be found in these portals at various pricing scales. Make sure to utilize the advanced search options provided where applicable so that you can narrow down by price, features, or shipping terms. For the best value, try to negotiate bulk rates or check if refurbished units are available at a significant discount. Always verify the authenticity and warranty of any product before buying.

Contacting Suppliers and Requesting Quotes

When shopping for suppliers, I make it a rule to always provide clear information about my requirements, including the type and quantity of fueling equipment required, specific features needed, and my delivery time frame. I usually ask about price and whether it is possible to get bulk discounts; I also ask about warranties and the availability of refurbished units if that applies. I compare several quotes and check on the supplier’s dependability and the authenticity of their products before deciding.

Trustworthy Sources for Retail Fuel Equipment

Sourcing retail fuel equipment entails trusting reputable suppliers in order to ensure the equipment is high-quality, long-lasting, and meets industry specifications. Derived from an intimate study of the top-listed sources:

Petro Service Limited – Petro Service offers arguably the widest array of fueling equipment: dispensers, tanks, and point of-sale systems. Product specifications, competitive prices, and warranty terms favorable to the customer are downloaded from their site. Discounts for bulk orders and refurbished items are some highlighted services and products.

Gilbarco Veeder-Root – A globally acknowledged name in the line of advanced sales and installation of fueling solutions: new generation payment systems and efficient dispensers alike. They also provide extensive product support, including installation and maintenance. Please inquire within the site with transparent pricing and warranty choices.

Franklin Fueling Systems – With a focus on quality and engineering expertise, Franklin Fueling Systems offers end-to-end fuel management solutions. It includes underground storage systems, vapor recovery products, and everything in between. Price, specification, eco-friendly product variants, etc., are all listed on FAQs and support pages.

If done rigorously, cross-checking suppliers will enable comparing price models, checking for availability of features required, shortlisted, should they are refurbished units, and confirming quality assurance involved. A line of action will very much cut down the hours of scribbling and provide peace of mind when deciding.

Reference Sources

Building a Hydrogen Infrastructure in Norway

Consumer Protection Related to Dispensing Pump Manipulation in Gas Stations

Electric Vehicle Waves of History: Lessons Learned About Market Deployment of Electric Vehicles

Frequently Asked Questions (FAQs)

Advantages of a portable fuel dispenser pump?

A portable fuel dispenser pump offers flexibility and convenience to fuel businesses. The pump can dispense fuel on-site so that one can really deliver fuel to customers as opposed to operating from a fixed fuel station. Such an arrangement works well for remote locations and the temporary supply of fuel.

Would you tell us something about how a fuel dispenser pump can help improve the fueling service?

Fueling with a modern fuel dispenser pump will improve customer service by fast dispensing and speeding up dispensing-related operations. New technology guarantees that the fuel is accurately dispensed, reducing the waiting time for the consumer and increasing customer satisfaction, which is a factor for retail stations and c-stores in retention.

Can you name the fuel options that one could provide through a fuel dispenser pump?

Selection is based on the type of fuel to be sold at a given station. Existing setups must be taken into consideration when deciding on a new equipment purchase that might require future expansion. Consider also the manufacturing price and the overall reliability of the vendor, just to name a few.

How do I get a quote for a fuel dispenser pump?

You could reach us through our website or by calling our customer support to get a quote for the fuel dispenser pumps. Our expert team will evaluate your needs and provide a competitive quote specifically for your fuel dispensing requirements, allowing you to receive the greatest value for your investment.

What would be a turnkey solution for the installation of fuel dispensers?

A turnkey solution for fuel dispenser installation means the customer receives a full package consisting of the equipment and installation. This way, setting up the fuel station or c-store can be simply done, and the business owner can remain focused on running the business while being sure all components will mesh well.

So, how does new technology in fuel dispensers shape petroleum businesses?

The new technology of fuel dispensers greatly affects those petroleum businesses by making them efficient and low in cost to operate. With all the new things like remote monitoring, payment integration, etc., a fuel station can reduce its operation cost, provide better customer services, and thus enhance profitability for itself, hence staying relevant to the demands of today’s customers.