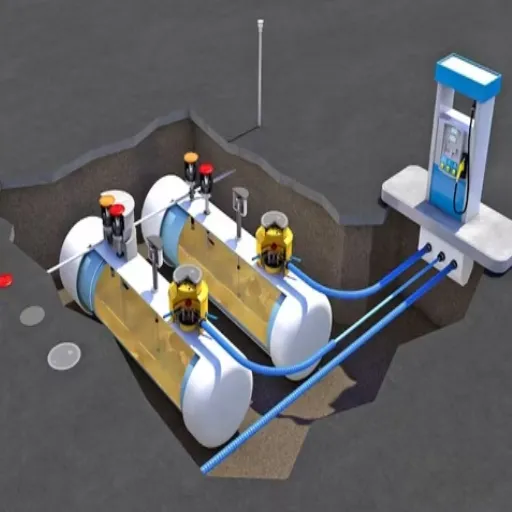

Fuel dispensers serve as the lifeblood of any gas station, where technical ingenuity and operational robustness come together to deliver fuel smoothly and safely. And well, hidden beneath the surface of any successful fuel dispenser is a harmonious concert of parts working together. Being an ambitious industry expert, true maintenance enthusiast, or a station operator, creating a list of essentials he must have to get started, this is the real breakdown. This article mainly discusses vital pieces of fuel dispensers, describing their functions and significance when it comes to having a well-performing device. This speech will provide some ideas for any technical animal wanting to fulfill every inline facet of their training and stents in between.

Main Parts of a Fuel Dispenser

Metering Device

A metering device is tasked to precisely measure the volume of fuel transmitted. In delivery, this is of utmost significance, leading towards operational efficiency and regulatory compliance within intercompany undertakings.

Nozzle

Flow controllers for nozzles are in view to guide fuel to be channeled into an automobile safely and efficiently. Most modern nozzles incorporate automatic shut-off for the highest levels of safety.

Pump

A pump will draw the fuel from the storage tank and will deliver it through a pipe that hangs to the nozzle, offering consistent flow and pressure through all stages of charging.

Hoses

Fuel hoses are designed for medical rubber, a high-pressure and petroleum product resistant to the weather, and provide a flexible link between the dispenser and the nozzle.

Flow Control System

This part is instrumental in regulating the flow velocity and pressure of the fuel so that dispensing is smooth and safe, avoiding spillage in the process.

Display

The display talks about the exact numbers, as the volume of fuel and the total cost to be paid, in real-time. It is an extremely clear unit that never compromises accuracy.

These key components, together, make sure that a fuel dispenser does its job effectively and in accordance with both customer expectations and industry standards.

Overview of Key Components

Fuel dispensing systems are complex systems consisting of several interconnected parts that work together to ensure purposeful operations. Proceeding from exhaustive research materials of some of the most highly respected authorities, come multifaceted elements of these functionalities listed below:

Pumping Systems

The duty of the fuel pumping systems is to remove fuel from the storage tank and to convey the fluid to the nozzle. These systems use rotary or piston-based technologies to keep consistent flow volumes, regardless of external influences.

Flow Meters

This key system measures the volume of fuel dispensed with high precision. While the selection among flow meters of today’s oil and bearing-based acts is usually between the choices of positive-displacement and turbine-based meters, either choice operates. Such selections ensure that there are no unsatisfactory readings, which could lead to breaches in industry standards and statutory compliance.

Nozzle Assembly

The nozzle comes with a special attribute that controls fuel discharge through a well-regulated and short interval. By this very feature, the built-in automatic shut-off makes sure that such action is brought to an end when the tank reaches full levels. Prevention of containment overflows is the grand touchstone in safety-risk prevention of this stringent approach to spillage and environmental risks, meanwhile.

ECU (Electronics Control Unit)

The ECU coordinates the functions of certain sensors with inputs from the machine’s operator so as to control the delivered output; this results in the synchronization of main machine components, efficient and economical use of power, and support for interaction with payment systems.

Safety Valves and Regulators

The design further incorporates several safety systems; emergency shut-off valves, pressure regulators, and the like are set up for preventing issues concerning pressure-violation while minimizing the probability of failure of such systems.

These are different aspects of advanced machinery in electronics.

Functions of the Fuel Pump

The fuel pump plays an incredibly important role in the functioning of internal combustion engines by ensuring consistent delivery of fuel from the tank to the engine at the required pressure. Some of the main functions are as follows:

Delivery of Fuel

This pump functions to transport fuel from the tank to the engine, ensuring smooth, uninterrupted flow according to varying conditions of operation that require the engine to meet specific demands.

Controlling the Pressure

By ensuring that fuel pressure stays at optimal levels, it allows fuel to get atomized efficiently while also retaining the efficiency of the engine. This is especially important in fuel-injection systems that need fuel pressure set at some desired level while maintaining smooth and problem-free operation.

Avoiding Vapor Lock

The pump prevents the formation of fuel vapor in the gas lines by keeping the fuel under pressure and ensuring a continuous flow of fuel to the engine block, which could obstruct the flow of fuel to the engine.

Integration

Modern mechanical and electronic fuel pumps are usually integrated with the engine control unit (ECU) to adjust the flow of fuel depending on parameters like the engine’s speed, load, and temperature.

But mostly governed by the following statement: The fuel pump is the core component that holds the engine efficiency, performance, and reliability, and hence proper maintenance thereof will prevent an awry in its operation.

The Role of the Control Board

The controller serves as a focal node overseeing and adjusting the pump’s fuel and major engine components operations. The controller receives inputs from various sensors, monitoring fuel pressure, engine velocity, and temperature in keeping with the best possible delivery of fuel. By experiencing these signals, the control board could adjust the operation of the fuel pump while system demand keeps changing in real-time, thereby enhancing efficiency and reliability.

Furthermore, advanced diagnostics systems have integrated themselves with many of the modern control boards. These diagnostic systems recognize mostly probable faults or irregularities in the fuel-delivery and work in correlation with the ECU, in turn returning the problem to the operator for action that might prevent any fatal incident from it again. Therefore, the operation of this diagnostic-n-control entity offers operational safety and cuts back the maintenance downtime significantly by providing easy troubleshooting steps.

Control boards require themselves to be highly robust and equipped with substantial circuitry and fail-safes for bearing considerable stress whilst enduring extreme operational distress such as extreme temperatures and heavy vibrations. They also represent a crucial part of modern engine control systems, thereby spurring a greater fuel economy and better execution of the operation of vehicles. And their proper sets of calibration and maintenance are primed to prolong the correctness of their operation and structure.

Key Features of Dispenser Equipment

Correct Dosage

Ensures that the proper material can be dispensed, thus cutting back on wastage and increasing operational efficiency.

Robust Build

The entirety of the instrument is built with quality, high-grade materials that ensure it can stand up to hardworking environments. It is extremely durable in quality.

User-Interface Friendly

Panel controls are all easy to operate at a given instant, thus putting the best handle control capability in the hands of the operator.

Interchangeable

As it proves itself worthy for almost all liquids, gels, and powder materials, the pump is likely usable in many sectors.

Easy Maintenance

Much improved by a dual format, field-in-well serviceable components are placed in the system that helps in making the routine upkeep of the pumps easy, thus mitigating downtime in the process.

Safety Features

It is likely to have had a pressure safety arrangement to ensure safety in case the system fails.

Importance of the Display Board

In modern machinery, the control panel is a critical element; it displays information to the operator necessary for his operation, performance, safety, etc., and ensures that every aspect of the device is working at its best. Clear data on accurate pressure readings, water levels, and system diagnostics means that important decisions are made instantly. Built-in indicators or alarms make it easy to monitor for faults, thus promoting quick corrective action to avoid any downtime and to ensure maximum efficiency. Modern display boards also come with a view to being customized for the operators to accompany a choice in customizing interfaces for the selected group of applications to comprehensively improve workflows across industrial processes.

Understanding the Flow Meter

A flow metre is a device that is crucial for measuring the rate of flow of fluid from a system in terms of volume or mass, and this arises when attempting to control process variables in various industries such as sanitation, chemical production, and power generation. Some types of flowmeters include electromagnetic, ultrasonic, turbine, and differential pressure meters, each specifically crafted for certain applications based on fluid viscosity, pressure, and temperature.

Types of Flow Meters

Electromagnetic Flowmeters

Electromagnetic flowmeters generate a magnetic field and measure a voltage resulting from fluid flow, making them compatible with wastewater and slurry applications.

Ultrasonic Meters

Ultrasonic meters use sound waves to find velocities and are non-intrusive, which is particularly useful for clean to mildly contaminated liquids.

Turbine Flowmeters

In contrast, turbine flowmeters allow fluid motion to flow with a rotating rotor, while the flowmeters provide accuracy for oils and low viscosity fluids.

Differential Pressure Meters

Differential pressure meters are one of the more versatile tools, where flow rate is calculated using pressure differences across a constriction.

The selection of a flow meter is reliant upon the system when we see the required accuracy, range, and the fluid which is involved. The correct choice assists in the overall effectiveness of the system, thereby improving its reliability, maintaining consistency of data so useful for decision-making. Regular calibration and maintenance are singularly crucial toward the objective of maintaining overall accurate and durable operation in any flow measurement system.

How the Nozzle and Hose Work Together

The flush islets, according to the integrated system in any sense in controlling fluid flow, pressure, and direction. The hose, which is a flexible pipe, allows the transport of fluids even under different pressures and different environmental conditions. It should be able to tolerate certain limits of pressure and temperature, thereby allowing durability and uniform flow. In this case, as opposed to the hose, the nozzle constitutes the terminal device that affects the rate of flow of fluid, rather than its pressure and treatment by its design and internal mechanisms.

When fluid exits the nozzle, the reduction of cross-sectional area increases its velocity, producing a spray or a jet, depending on the type of nozzle. This relationship is governed by factors which have been outlined by Bernoulli in the Equation, which states an inverse proportion for the application of pressure to that of velocity. Either flexibility in the hose or accuracy with the nozzle will be responsible for the effective delivery of fluids from industrial processes to firefighting and irrigation systems. Compatibility between the hose material and the nozzle material, as well as between their dimensions and flow specifications, is necessary in order to avoid pressure drops, leaks, or failure to operate efficiently.

Specialized Fuel Dispenser Technologies

In the ever-modernizing fuel dispensing industry, engineers are striving to make advancements made to the accuracy of measurement, safety, consumption, and energy conversion of various fuels. Indeed, the spirit of the modern dispenser is being led by the latest changes in the technology of electronic metering technique to ensure accurate fuel measurement-while using the recovery system to lower the emitted waste into the environment. Another very outstanding quality of the modern dispenser is the utilization of RFID technology in conjunction with the automated payment interface, which has made transactions extremely secure. With different materials incorporated into their design to resist corrosion and so cater to fuel compatibility, corrosion resistance is a composite action.

Contactless Payment Systems

Contactless payment systems were developed to simplify the transaction process and reduce user contact; they employ Near Field Communication (NFC) and RFID technologies. With these systems, a device or card allows a transaction to be completed by tapping at the payment terminal, taking some pressure off the transaction and allowing processing speeds to be accelerated. Most importantly, during a deal, tokenization and encryption shield the sensitive payment data against unauthorized exploitative activities, thereby minimizing the risk of fraud. Another feature these systems support is the flexibility offered by numerous devices, such as smartphones, smart watches, and contactless-enabled credit or debit cards. The extension into several industries has now become a symbol of importance, as they accept contactless payments. When magnified by the layer of security for fraud prevention and anonymity for the user, contactless payments are a watershed for modern payment technologies.

Digital Wallet Benefits

The digital wallet helps customers store considerable data, such as loyalty cards, identification documents, and subway tickets, causing them to avoid the hassle of carrying physical cards and IDs. The digital wallet helps to make the remote identity verification process easier and quicker, whilst brick-and-mortar shops provide digital payment options to allow in-store payments.

Some of the key advantages include heightened security—through tokenization—of credit card data, thereby reducing the risk of fraud. Moreover, under the widely-expanding consumer profile leaning toward a time-slice society stocked with convenience and mobile wallets, the platform allows meeting Apple Pay, Google Pay, and Samsung Pay public requirements. For gas stations, installing this system not only increases consumer satisfaction, but also reduces lines, in turn hacking out operational and handling costs otherwise necessary for cash. Contactless payments are not just symbols of modern convenience, but also are strategic weapons to keep oneself ahead in a digital-first economy.

Insights on Gilbarco and Other Brands

Gilbarco is one of the most trusted brands for fueling and payment technology solutions on the market, specializing in point-of-sale systems, dispensers, and cloud-based payment solutions for fuel stations. They create products that are famous for their strength, reliability, and sophistication, and this is what clients prefer for the complete integration of the payment system with operational equipment. The addition of contactless payment solutions by Gilbarco can be perceived as their striving for innovation, always ensuring improvement in compatibility with the exigencies of safety standards and newer levels of customer demand.

Leading Industry Brands

Ingenico

Another one of the industry’s most significant contributors involves the popular and specialized brands of Ingenico and Verifone, also landing in the ecosystem of payment systems. Ingenico’s business is in the provision of end-to-end ultimate secure devices for paying, supporting both contactless and EMV transactions while underpinning fraud prevention and compliance with global security standards.

Verifone

Verifone, on the other hand, has introduced its cloud-based payment platforms, thereby enhancing transaction customization and bolstering data analytics to the advantage of small and medium-sized enterprises. Both companies, therefore, together are stretching technology’s frontiers to ensure a united approach to efficiency, convenience, and security aspects in today’s payment technology.

The Function of PCI and Pulsers

Peripheral Component Interconnect (PCI) is a high-bandwidth, high-throughput hardware interface standard developed to provide a reliable communication medium for carrying traffic between the motherboard and any number of additional components, including graphics cards and network adapters. Put simply, PCI was designed to support relatively high-speed data transfer with a minimum of latency, therefore making it very suitable for tasks or applications requiring the use of robust, very reliable interfaces. You could have access to different revisions and forms of this standard, which include PCI-X, PCIe, and mini-PCI, capable of supporting a plethora of applications meant to see the light of day or be kept in the dark, right from consumer electronics to the highest caliber of mission-critical enterprises.

Pulsers refer to devices that generate individual electrical impulses for medical or engineering purposes. Their operation, along with further definition, is stated as being compulsory for the medical diagnosis and treatment of a disease or physical condition… For this range of applications, pulsers are generally mounted onto flywheels to determine speed. In order to accomplish that feat, the timing resolution of the pulser needs to be of several nanoseconds. Because of the high speed and data transmission capacity of radar, Bangladesh, and imaging devices, RF and digital signals will be unfavorably modified by timing errors. Thus, a timing solution with intervening periods of a few nanoseconds and repetition rates with an accuracy of several seconds for the completion of very basic tests is an urgent need. Assuming the large number of variations and the cycle of engineering design work through which such devices would return over the years, a list of ways to use pulsers within electronic systems in collaboration with radio-wave-timed applications is devised. The following list shows applications of pulsers in conjunction with PCI in the above context.

Maintenance of Gas Station Dispensers

For better precision, security, and reliability of a Site’s dispensers, the condition of the dispensers ought to be kept energized. The following are the essential steps:

Calibration at Regular Intervals

The test should be done and the dispenser calibrated in the machines for correct delivery of every amount of fuel each time the dispenser is used, and for a minimum tolerance thereof: Thus, one must utilize certified devices so that it can confirm to the possession of local standards.

Checking for Wear and Damage

The hoses, nozzles, and seals must be carefully examined for wear, cracks, and leaks. It is never too soon to replace a component upon detection of a problem to avoid fuel loss or any other hazard.

Cleaning and Debris Disposal

Carrying out the cleaning process without leaving out dirt, dust, and fuel that hinder or can cause damage to the system will also reduce any instances of fire hazards.

Filter Insertions

The manufacturer gives guidelines for the replacement or renewal of fuel filters whenever fuel distribution is managed to prevent contamination and ensure fuel flows are created steadily.

Software Upgrade

The up-to-date software on dispensers must be maintained for working and interfacing conveniences with the payment system.

Services for Servicing

Be assured that certified technicians conduct periodic checks and furnish the necessary repairs so as to handle complex problems and confirm safety with respect to regulations. All this helps in enhancing the reliability of vending machines. Guaranteeing Customer Satisfaction.

Regular Checks for Key Parts

Checking the most sensitive and critical parts of the dispenser, located in prime areas, is a significant recommendation to prevent damage and run the functions smoothly. They include:

Nozzles and Hoses

Examine all nozzles and hoses to ensure that they are not worn out, cracked, or leaky, leading to discrepancies in fuel dispensing and safety hazards.

Fuel Filters

Inspect fuel filters and replace these be replaced every once in a while to facilitate proper flow, which otherwise can be blocked and damage the entire internal system.

Pumps and Motors

Zero in on pumps and motors; inspect these, taking notice of the pressure and absence of irregular noises, an indication of a probable mechanical failure.

Electronics

Keep verifying cabling, sensors, and payment hardware components equally a ensure perfect transactions and functioning.

Safety Devices

It is imperative to test shutdown valves and fire suppression systems to ensure their positioning and operations are law-compliant on the site’s performance index.

Incorporating these checks in a preventive maintenance routine contributes to the smooth running of the operation, minimizes downtimes, and extends the usable life of the dispensers.

Common Issues with Fuel Dispenser Parts

Like any other complex mechanical device, fuel dispensers may face different operational problems over time. Below are some of the common difficulties and assumed causes that can surface while issuing fuel:

Faulty Hose or Nozzle Connection

Leaking hoses and nozzles are often the result of wear and tear or damage to seals and gaskets. Deteriorated components should cease to be in use and must be replaced periodically to prevent fuel loss and environmental hazards.

Metering and Calibration Errors

Malfunctions in the measurement and calibration of fuel quantities can result from worn metering components or improper calibration. Calibration should be conducted periodically for an accurate measured result in compliance with legal jurisdiction.

Electronic Failure

Here we are talking about the shortening of the life of keypads, indicator displays, card readers, etc., by rust, moisture, electrical spray, or archaic software. Verifying the PCB is free from any damage and constantly updating the Control firmware is quite necessary.

Clogged Filters

As fuel filters become progressively clogged with sediments and contaminants, fuel delivery and discharging efficiency decline due to the lesser evaporation of fuel. Therefore, fuel filters must be replaced regularly for maximum performance.

Pump Motor Failure

Pump breakages are typically due to wear and tear, leakage, or overvoltage electrical faults. The lifespan of these motors can be extended through occasional regeneration of lubricants and permanent thermal monitoring.

Professional maintenance programs addressing these issues and employing quality parts contribute to reducing the occurrence of failures of the fuel dispensers, thereby lessening overall downtime and improving compliance adherence among fuel dispenser users.

Best Practices for Fuel Pump Maintenance

Scheduled Post and Cleaning

Periodically inspect pumps and nozzles for blockage, wear, and leaks. Taking care of filters and strainers is necessary to protect against clogging that would cut down on efficiency. Sometimes these visual checks may uncover invisible signs of cracks, rust, and other surface deterioration.

Scheduled Component Maintenance

Plan for regular maintenance of essential components, including pressure regulators, hoses, and seals. Component replacement with high-quality, industry-tested materials would assure enduring strength and maximal utility.

Monitoring and Lubricating Moving Components

All moving parts, especially pump motors and mechanical seals, should be properly lubricated to decrease friction. Over-lubrication needs to be avoided as it might lead to the build-up of residue, thus impairing efficiency.

Correct Dispensing Apps

Inspect the calibration of dispensing meters and flow controllers on a regular basis to ensure the meter measures the fuel correctly. Meters that are out of tolerance could be the cause of compliance and customer problems.

Maintain Electrical Systems

Inspect electrical connections, wires, and control boards routinely for signs of damage or overheating. Find and replace all damaged connections and guarantee proper grounding of all installations.

Guarding against Environmental Elements

Using weather-proof coatings and covers is recommended against rusting due to ambient humidity and exposure to chemicals. It is also strongly advised against extreme temperatures and damage to the outboard dispensers from sunlight.

Training for Staff and Documentation

Train the staff on how to run, clean, and maintain the equipment, and then make sure they document everything they do. Good paper trails always help maintain a level of accountability proportional to bad behavior from an individual.

Following these guidelines ensures that their operation is optimized, they meet regulatory standards, and they will have a long lifespan, significantly reducing the costs of repairs and downtime.

Modern Trends in Gas Dispenser Technology

Current gas pump technology enhancements are like at all for streamlining throughput, usability, and ecological sustainability.

For some trends:

Integration of Digital Payment Systems

Many new dispensers will accept contactless payments, support apps, or offer faster, more secure ways to pay.

Enhanced Fuel Monitoring Systems

Highly improved sensing and control technologies are being built to ensure the accuracy of the dispensing of each drop of fuel with almost nil leakage or theft.

Energy-Efficient Designs

The system manufacturers are becoming environmentally aware by introducing components that curtail energy inefficiency, such as, for example, LED boards and improved pump motor design with minimal energy use.

Environmental Compliance

New designs give priority to the environment according to the law for implementing advanced vapor-recovery systems and low-emission filling.

User-Centric Interfaces

The mutual advantages of touchscreens and multilingual support to operate more intuitively to cater to more varied requirements of the customers.

These are indisputable trends in the industry, each of which culminates in something important—either innovation, sustainability, or customer satisfaction.

Advancements in Display Boards

Digital variation in display boards has taken leaps forward; recent boards not only offer better resolution, dynamic content characteristics, and energy-efficient design, but likewise have good contrast ratios with well-tweaked brightness to suit both outdoor and indoor functionality for delivering information in real time, which makes display boards flawlessly combine the software, maintaining much of its maintenance.

Innovations in Fuel Dispenser Design

Version 2 of print is constantly improving, from the perspective of the design of the fuel dispenser, with the implementation of IoT-based technology to increase fuel dispenser output in a highly precise way. IoT optimizes real-time checking over fuel levels, dispenser efficiency data, and the requirement for servicing. The total of these advantages should ensure that the dispenser provides timely service with minimum downtime since application of advanced technology in terms of electronically programmed fuel sensors and flow meters will give the highest attainable accuracy and all but eliminate leaks and inaccuracies associated with fuel delivery.

Fuel dispensers have also been affected by contactless payment. They offer the advantage of secure, seamless transactions by convenience-enhancing systems. Environmentally conscious concerns have driven the adoption of vapor recovery systems in every installation, with energy-efficient designs contributing to reduced emissions and operational costs. The advent of intelligent screens with an interactive interface helps communicate clear, individualized messaging offers to the customer. All this means that progress in the world of fuel dispensers has made a side game-according to the current complex attitudes of sustainability, efficiency, and experience of adjustment with new technologies.

| Component | Primary Function | Maintenance Frequency | Common Issues |

|---|---|---|---|

| Metering Device | Precise fuel volume measurement | Quarterly calibration | Calibration drift, wear |

| Nozzle | Safe fuel delivery with auto shut-off | Monthly inspection | Leaks, worn seals |

| Pump | Fuel transfer from tank | Bi-annual service | Motor failure, pressure loss |

| Hoses | Flexible fuel connection | Monthly inspection | Cracks, weather damage |

| Flow Control System | Regulate flow and pressure | Quarterly check | Pressure irregularities |

| Display Board | Show volume and cost data | Software updates as needed | Electronic failure, moisture |

| ECU | System coordination and control | Annual firmware updates | Software glitches, sensor errors |

| Fuel Filters | Contamination prevention | Replace every 3-6 months | Clogging, reduced flow |

Conclusion

Understanding the intricate components and systems that comprise modern fuel dispensers is essential for anyone involved in the operation, maintenance, or management of gas stations. From the fundamental metering devices and pumps to the sophisticated electronic control units and contactless payment systems, each component plays a vital role in ensuring safe, accurate, and efficient fuel delivery. The harmonious interaction of these parts creates a reliable dispensing system that meets both regulatory requirements and customer expectations.

As technology continues to evolve, fuel dispensers are becoming increasingly sophisticated, incorporating IoT capabilities, advanced monitoring systems, and environmentally friendly designs. The integration of digital payment solutions, enhanced vapor recovery systems, and energy-efficient components represents the industry’s commitment to sustainability and customer satisfaction. Regular maintenance, proper calibration, and adherence to best practices are crucial for maximizing the lifespan and performance of these complex systems.

Whether you’re a station operator seeking to optimize performance, a maintenance professional working to prevent downtime, or an industry expert staying abreast of technological advancements, comprehensive knowledge of fuel dispenser components is invaluable. By understanding how each part functions individually and as part of the larger system, stakeholders can make informed decisions about equipment selection, maintenance schedules, and upgrade priorities. This knowledge ultimately translates to improved operational efficiency, reduced costs, enhanced safety, and better service for customers at the pump.

Key Takeaways

- Fuel dispensers consist of multiple interconnected components working together for safe and accurate fuel delivery

- Critical parts include metering devices, nozzles, pumps, hoses, flow control systems, and display boards

- Regular maintenance and calibration are essential for accuracy, safety, and compliance

- Modern dispensers incorporate advanced technologies like IoT, contactless payments, and vapor recovery systems

- Common issues can be prevented through proper inspection, timely component replacement, and staff training

- Industry trends focus on sustainability, energy efficiency, and enhanced user experiences

- Understanding component functions enables better decision-making for operations and maintenance

Final Recommendations

For Station Operators: Implement a comprehensive preventive maintenance program that includes regular inspections, calibration checks, and component replacements. Invest in staff training to ensure proper operation and early detection of potential issues.

For Maintenance Professionals: Stay updated on the latest technologies and best practices in fuel dispenser maintenance. Use certified equipment for calibration and testing, and maintain detailed documentation of all maintenance activities.

For Equipment Managers: When selecting new dispensers or upgrading existing systems, prioritize equipment with advanced monitoring capabilities, energy-efficient designs, and compatibility with modern payment systems. Consider long-term operational costs alongside initial investment.

For Compliance Officers: Ensure all dispensers meet local and national regulations. Schedule regular inspections by certified technicians and maintain comprehensive records of calibration, maintenance, and any modifications to the systems.

Gas Pump Parts

Dispenser Maintenance

Flow Meters

Control Systems

Payment Technology

Safety Systems

Industry Standards

IoT Integration

Contactless Payments

Reference Sources

“Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)”

“Replacing Metal Parts with Resin in Pipe Installations and Gas Equipment”

“Investigation of the structure and wear resistance of the nanocomposite coating of chemical nickel”

Frequently Asked Questions (FAQs)

What are the primary components of the fuel dispenser?

The primary components of the fuel dispenser would include the fuel pump, flow meter, control board, and nozzle. These parts allow for efficient dispensing of any type of fuel-whether gasoline or gas, while, with the accompanying controls, ensuring the safety and efficacy of the gas station.

How does a fuel dispenser work in dispensing fuel?

The fuel nozzle is basically designed to regulate, monitor, or control the flow of fuel passing through it and end up in the vehicle’s fuel tank. With the nozzle appropriately placed in the tank and the system promptly activated, fuel can be pushed through the hose and fill up the vehicle justifiably.

What are the different types of fuel dispenser pumps?

As far as the types of fuel dispenser pumps are concerned, there are several types. Different models of fuel dispenser pumps are available for gasoline, diesel, and alternative fuels. They are specially designed for the operation with various fuel types in a safe manner and for accurate dispensing.

How to Check Pump Integrity?

Regular maintenance and internal-component checks in the fuel supply system include the check valve, hose, and nozzle to ensure the correct operation of the system. This would prevent leakages and also ensure that the system operates in a safe and efficient mode.

What will the flowmeter do in the case of a fuel dispenser?

The flowmeter is assigned to calculate the volume of fuel dispensed. Batch-wise, it calculates the right amount to be billed per gallon or per liter of fuel dispensed, thus promoting transparency and accuracy in transactions.

How do added electronic parts in a fuel-dispenser system work to expand functionality?

The electronic controls and display screens play their part in enhancing different functional activities of the fuel-dispensing system. Making the dispenser look good certainly catches the attention of prospective customers. Last but not least, they help provide an increasingly relevant, better customer-centered role at the gas service point.

What do I need to know to select the right gas dispenser parts?

When selecting fuel dispenser parts, bear in mind their compatibility with the current equipment, their compliance with safety standards, as well as the type of fuel involved. It is essential to choose items that have been designed and certified to meet the industry’s standards for precision in fuel measurement.

What can I do to fix fuel dispenser components in an emergency?

When it comes to emergency repair issues with fuel dispenser components, this should be left to technicians. In the interest of safety and following safety guidelines, it is stressed that any fault must not result in a compromise of safe operation of the dispenser or the integrity of the fuel supply system.

What are the maintenance requirements for fuel hoses and nozzles?

Fuel hoses and nozzles should be maintained by inspecting they are free of wear and tear, ensuring connections are tight, and cleaning them so they do not catch long exposure to chemicals; this, in turn, supports mixed results that ensure the process is both safe and efficient. The maintenance also extends their lifespan as critical components.