Gas pump nozzles may seem like simple, everyday devices, but they are an integral element of the safe and efficient transfer of fuel. These precision tools are crucial to every modern fuelling system, ensuring that gasoline, diesel, and other fuels are smoothly discharged without any leakage. But how does it really work, and why exactly does it look like that? Well, let’s take a deep dive and understand the mathematical intricacies of gasoline nozzles, the components that make them a reliable vending machine, and the reason why they are necessary in upholding environmental safety and operational efficiency. Here, you will learn about how the automatic shut-off mechanism works and its usefulness, and why nozzle compatibility is so crucial.

Introduction to Gas Pump Nozzles

The gas nozzles are one of the essential tools for delivering the fuel into the vehicle effectively and safely. They have been designed very accurately to control the flow of the fuel while preventing spillage and environmental pollution. Among some key features of the modern fueling nozzle is that it contains an automatic shut-off function to detect the pressure drop when fuel reaches the fill level of the tank. In this regard, once engaged, the flow will be stopped, and no further fuel will be dispensed or spilled into the environment. In addition, these nozzles are more durable and slanted towards suppliers on the different car fuel-tank model trees that are available; thus, all lining up with their free work-op for various models’ safe use materials. Advanced ones on the next side also assure reliability, ensuring user safety and official environmental protection regulations at all times, with the latter being such precious elements about pumping the Holy Fuel.

What is a Gas Pump Nozzle?

Gas pump nozzles are components with special structures to facilitate effective, secure, and safe transfer of fuel from the logical dispenser to the fuel tank of a vehicle. Indeed, they are constructed to precisely control the flow of fuel, prevent leaks, and hazards of using them. Your operations at the pump are made fully safe because of the automatic shut-off feature, allowing the fuel flow to stop when the gas tank becomes full, and their capability to function on a number of tank builds that match the needs of a broad range of vehicles. These nozzles are tough to withstand high usage. Nozzles are mostly made of robust materials such as aluminum or stainless steel, as they are ready to withstand heavy usage while decreasing the environmental hazards of fuel spillage or evaporation. In order to perfect the integration of anti-drip valves with vapor recovery and ergonomic designs in compliance with environmental standards, the gas pump nozzle has been optimized to optimize the dispensers for fuel dispensing.

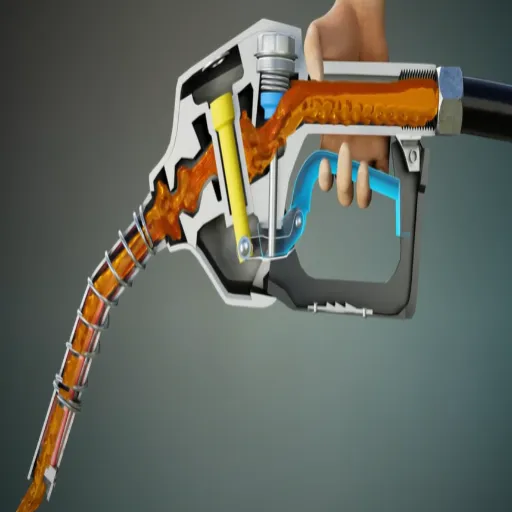

Components of a Gas Pump Nozzle

A gas pump nozzle consists of several critical components that ensure efficient, safe, and environmentally compliant fuel dispensing:

Spout

The spout works as the primary tube for delivering fuel into a vehicle’s tank. The end of the spout is usually tapered to fit snugly into the fuel port, and it may have anti-drip mechanisms to arrest any fuel despoilment after use.

Automatic Shutoff Mechanism

This system employs a venturi-based detection system to prevent spills. When the fuel in the tank obstructs the airflow inside the vent tube of the spout, the pressure change shuts off the fuel flow immediately.

Valve Assembly

The valve inside controls the fuel flow and permits the nozzle to maintain constant pressure. The user can adjust this valve using a lever or trigger to regulate the speed of fuel dispensation.

Vapor Recovery System

Regarding environmental laws, many nozzles are also equipped with a vapor recovery unit, a requirement that these units capture the fuel vapors displaced during the filling operation. This, in turn, restricts the release of the fuel vapor into the atmosphere and reduces the levels of harmful emissions.

Nozzle Lever and Latch

The lever, which is engaged by the user, regulates fuel flow. Certain nozzles incorporate a “latch” feature as well as a system that locks the lever in place during refueling. This makes it easier to use than the lever. The safety feature protects against the accidental opening of the lever.

Seals and O-Rings

Integral to the activity of the nozzle, these aids are critical in establishing and maintaining sealed airways through the nozzle and into the system.

In striking a balance within these components, refueling nozzle technologies remain at the forefront. They are indispensable for fueling in compliance with industry standards so that fueling operations can be enacted efficiently and effectively to prevent injury or hazard to workers or guests.

Types of Gas Pump Nozzles

Gas pump nozzles. The working mechanism and the intended applications distinguish the different categories. And they include the consequent kinds:

Automatic Shut-off Nozzles

No technology is needed to stop the flow of fuel once the tank is full to prevent spills and overflows supplied with sensors are supplied to sense the tank filling level. The automatic shut-off nozzles are the best nozzle type for retail fueling.

Vapor Recovery Nozzles

Vapor recovery nozzles exist as a technological compromise with environmental agencies. The factor is vapor-returning devices because external pressure allows the recovery of counterpressure vapor collected during refueling from the atmosphere.

High-Flow Nozzles

They are used mainly for commercial and industrial purposes. High-flow nozzles deliver fuel continuously at higher flow rates. They are designed for refueling the largest vehicles and equipment requiring no breaks till refilling, such as trucks or construction machinery.

Manual Nozzles

Manual nozzles provide the user with full visual control of and full responsibility for the lifeblood, fuel. Unlike automated dispensing nozzles, manual nozzles are typically utilized with antiquated Piston pumps of the yesteryears (or earlier) or by choice for certain applications needing very close manual control.

Prepay or Cardlock Nozzles

In other uses, these nozzles are part of an automated fueling system integrated with advanced electronic control. They need to prepay or cardlock before being activated for fueling, so only authorized secure usage shall take place.

Each type of nozzle is designed to provide critical coverage for some specific need in relation to the requirements and can comply with environmental and safety standards widely accepted in the respective fueling context.

How Gas Pump Nozzles Work

The fuel dispenser operates with different flow rate laws and an automatic shut-off system to facilitate the fuel transfer efficiently and safely. During the activation, the fuel is forced through the nozzle in order to flow into the vehicle. The key component of the nozzle is the automatic shut-off sensor; this, in itself, stops the overfill. A system exploits direct flow towards this small tube in order to be measured at the sensor hole in the tip of the nozzle to tell when the fuel rises to a level between the sensor hole and the mouth of the tank. When the fuel reaches a level and covers the opening, the rising fuel turns off the mechanism automatically, engineered, thus terminating the fuel flow immediately. In this way, there will be increased accuracy alongside any spillage prevention and increased safety.

The Mechanism of Fuel Transfer

The fuel transfer process is strictly governed by a system that contains highly precise engineering. Such engineering is necessary to maintain the safety and efficiency of the system. The fuel pump is at the core of this device. It performs by generating pressure sufficient to transfer fuel from storage tanks through a pipe system to the nozzle. New fuel pumps have often been enhanced with safety features like flow rate and pressure monitoring, which safeguard against over-delivery. These systems are also equipped with vapor recovery systems that charge to collect the lighter hydrocarbon gases and put them back into the storage tanks. To monitor the precise volume of fuel dispensed, metering devices are present in the dispenser, ensuring that the amount dispensed is accurate in line with their industrial specifications. All of these approaches must blend into each other to create a seamless fuel transfer activity that emphasizes the preservation of the environment, operational safety, and stringent fuel measuring.

Understanding Automatic Shut-off Features

Apart from the delivery of fuel to fuel dispensers, making refueling a hazardous operation, the automatic shutoff features on them are crucial for safety, efficiency, and environmental protection in the refueling exercise. These systems are engaged using a mechanical or pressure-based mechanism for sensing when the tank is about to reach its capacity. The minute airflow tube that is housed inside the nozzle of the fuel-dispenser nozzle will sense changes in the pressure as fuel is added to the tank, and trigger the shut-off valve, bringing the delivery to a halt. This greatly helps in avoiding spillage or overflow that would probably lead to fire or contamination in any form or degree.

The practical automatic shut-offs are considered safe for use as fuel-dropping devices, and they fulfill the strict regulations concerning safety. As simple as maintenance may be, unit servicing is critical because debris or wear can plague the machines otherwise. An autoload with the finest of engineering and industry standards is to provide huge savings in safe and nature-friendly refueling.

Flow Rate and Pressure Considerations

Critical parameters for liquid handling systems to be designed and operated around include flow rate and pressure. Flow rate and pressure directly influence the efficiency, operational safety, and equipment service life. The flow rate considers the volume of fluid passing per unit of time within a system, said volume from such carrying units as gallons per minute beyond liters per second. In contrast, pressure, appreciated incidentally as pounds per square inch (PSI) or Pascals (Pa), defines itself as the force exerted by fluid inside a system.

It is a prerequisite to get the proper balance, which helps to maintain a high flow rate and high pressure. Indeed, the highest flow rates can decrease output effectiveness due to turbulence or cavitation, whereas system operations also may collapse due to insufficient pressure. Fluid viscosity differs concerning the pipe or hose diameter and especially with consideration in accordance with the specific application uses, which together define the full performance capability. Consistency of inspection and calibration ensures full combined system integrity under such operating circumstances, which might vary. A combination of computational tools with regular system maintenance efforts can greatly remedy these concerns and eliminate divisions in identifying and hence ensuring a heightened level of reliability.

Different Types of Fuel Nozzles

Fuel nozzles are classified based on their design and application. They include:

- Pressure swirl nozzles that depend on a pressurized fuel supply to induce the swirling action to generate a fine and uniform spray. They are mainly used in aviation and power generation.

- Air blast nozzles that use their own air stream to atomize fuel for greater fuel efficiency and fine pattern spraying. Ideal for high-performance engines such as jet turbines.

- Simplex nozzles are straightforward but able to perform one job-defined, fixed flow rate, and are usually found in smaller engines where performance needs are minimal.

- Duplex nozzles with dual fuel circuits mean they can handle varied fuel flow rates given changing conditions, making them well-suited for systems with a broad range of operation.

Choosing the right nozzle allows the operator to maximize fuel efficiency with regard to the specific application’s needs.

Standard vs. High Flow Nozzles

Regular nozzles, contrasting high flow nozzles, differ primarily in the fuel delivery capacity, which affects their performance and efficiency. Nozzles of regular size are ideal for typical applications with moderate fuel demand. They incorporate a characteristic build design for adequate atomization and reliable performance under standard load conditions in the engine. They are meant for engines with a comparatively regular output.

High-flow nozzles, on the contrary, are engineered to cater to higher fuel delivery requirements for high-performance engines or demand higher power output from the system while under full load. Increased outlet flow rates under correct atomization must be maintained-highly essential for optimum combustion for the high-demand scenarios.

Standard or high-flow nozzles will be based entirely on the particular requirements of their application; for example, standard nozzles are suitable for everyday utility engines, while high-flow nozzles provide high performance and are meant for special engines that require enhanced fuel delivery to match operational requirements. To make an informed decision, the operator will have to take into consideration engine design, operating loads, and performance objectives.

Manual Fuel Nozzles vs. Automatic Fuel Nozzles

Manual fuel nozzles require operators’ hands-on engagement during refueling, hence their simple structure and application. They are used most often for spot fueling or with small-volume needs where flow may need to be tightly controlled. However, the added manual control could be a pitfall in case of any minor oversight, leading to overflow or spillage.

In contrast, an automatic nozzle comes with some kind of flow velocity itself, which, when the tank is full to the desired quantity, shuts off the fuel flow through a shutoff mechanism. This design minimizes the chances of overfill and enhances convenience in large-page or frequently fueling operations. Made for big commercial and industrial filling stations, with priority set on efficiency and client safety. When costs are a factor, the choice of the device will, in fact, be appropriate relative to its usage.

Specialized Diesel Fuel Nozzles

Specialized gear is designed for higher detent. It includes automatic shut-off valves, canopies to check out spillage, and assurance against overfill. Compatibility is of primary concern. All machinery must blend properly with standard diesel tanks and pumps; different-sized nozzles very effectively check possibilities for cross-pollination with petrol systems.

The high-flow automatic diesel fuel nozzle is so suitably designed for commercial and industrial refueling, where speed and efficiency are the utmost. Manual nozzles, on the other hand, are less automated; however, the human element lends high recognition and accuracy, making them appropriate for small-scale applications. When choosing a nozzle, some factors, e.g., flow rate, material durability (aluminum or stainless steel), and compatibility with the size of nozzles, must convey merit relative to its envisaged application. Lastly, the standards must be observed for safety reasons as long as the longevity of long-term services is to be ensured, and no hindrances are caused through any malpractices.

Maintenance and Safety of Gas Pump Nozzles

Ample Maintenance Practices

The constant upkeep of gas pump nozzles ensures not only their consistent functioning but also the safety of the user. Their examination is well-advised in this regard on account of: nozzles can be seen for signs of wear and tear, such as cracks, leaks, and corrosion; any damaged components are to be replaced at once. Preventative cleaning of the nozzle’s spout and any filter attached is intended to prevent obstructing the flow of fuel, while regular lubrication of all else prevents the performance failure of the moving parts.

Safety Guidelines

A nozzle under no circumstances should be without an automatic shutoff safety device to stop tank overflow. To avoid potential hazardous incidents, choose nozzles compatible with the fuel dispensed for users’ convenience. Employers must teach staff how to operate the nozzle safely, how to act in a spill or leak situation, how to restrict nozzles associated with dispenser types under consideration, and what is expected of all, and then consistently comply with said instructions. Regular safety inspections ensure adherence to safety guidelines that will minimize potential hazards and operational risk.

Regular Maintenance Practices

The right maintenance of the fuel equipment is crucial for ensuring efficiency, safety, and compliance in this context. A senses check involves a maximum of three minutes of inspection for the nozzles, hoses, and seals for signs of wear, cracks, or damage that could lead to leakage or malfunction. Corrosion and blockage in the dispensing system should never be underestimated because they affect performance and safety alike.

Regular calibration of dispensing meters aims at accurate dispensing of fuel and identification of inaccuracies more quickly. Also, cleaning, whether by debris or anything else, is done to ensure the removal of unnecessary particles from the filters and strainers to maintain the system and flow and to prevent blockages. Automatic shutoff equipment must be maintained completely for its reliability. Automatic shutoff features have to be checked on a periodic basis, mainly to guard against the hazards of an overflow.

Finally, keep extensive, detailed documentation regarding maintenance activities, inspections, and repairs in order to aid compliance with both industry-defined standards as well as regulatory requirements. Proactive maintenance eliminates the vast dangers of equipment failure, thereby ensuring an added reliability in sustaining the fueling operation.

Common Issues and Troubleshooting

Various problems can occur during fueling operations. An epitome approach to these becomes a follow-up.

| Issue | Cause | Solution |

|---|---|---|

| Fuel System Leaks | Seals become faulty or cracked, pipelines are corroded, or loose connections are giving way. | Conduct regular checkups on joining areas and seals. Damaged parts should be replaced on time, and proper tightening of fittings must be performed to prevent fuel leakages. |

| Blocked Filter or Lines | Dirty filters get clogged due to the accumulation of different waste or microbial developments in the fuel. | Apprehend proper changing intervals for filters. Always carry out tests to know the contamination levels of the fuel. If the fuel is overly contaminated, clean the system. |

| Failure of NAY Pump | Electric issues, component wear, or mechanical obstruction on the way of the oil flow. | Make some being present even though checking: electrical wiring for article defects in relation to its connections; The pump for either internal flaw or blockage, giving lubrication to moving parts. |

| Varying Flow Rate | Air entry in the system or blockages in the delivery lines or pipes. | Ensure all connections are airtight. Remove all air pockets by bleeding the system and also any blockages within the lines. |

| Tank Overfills or Spills | Either a malfunctioning of safety mechanisms or an error from operators. | Safety shutoff valves should be tested for the appropriate performance and calibrated as needed. Ensure that employees receive training related to safe fuel handling and overfill prevention practices. |

A proactive approach to maintenance, regular inspections, and timely repair will mitigate such issues and ensure consistent fueling operations. Proceed cautiously with complex community guidelines and endorsed policies as rendered by different equipment sources.

Safety Measures at Gas Stations

Inherent risks remain when gas stations are maintained in a fuel-laden context while high-traffic customer flows frequently prevail; therefore, the necessary safety measures must be all-encompassing. The key safety practices listed below are agreed upon as standard and set recommendations:

FIRE PREVENTION:

- All equipment, such as pumps and tanks, should be grounded to ensure it is rid of any electrical charges or static electricity.

- Open flames, smoking, and devices that spark may never be used in fueling areas.

- Fire extinguishers and emergency shutoff switches should be installed and regularly maintained, and they must be within easy reach.

Petrol Handling Procedures:

- The staff should be trained in the appropriate fuel handling techniques for avoiding spillages and overflow.

- Implement the ‘auto-stop’ system with nozzles to prevent unintentional overflow once fueling.

- All kinds of spillages must be addressed; spillages involving large quantities should be escorted by skilled professionals.

Electrical Safety:

- Regular inspection of the electrical system will ensure preventive maintenance, with an eye on critical components that can contribute to either short circuits or malfunctions.

- Provide explosion-proof lighting and electrical components as per safety codes in hazardous locations.

Customer Safety:

- Clear them with notices indicating signs that engines are off, no usage of mobile devices, and refraining from re-entering vehicles while refueling.

- Put up information related to emergency numbers and accident protocols of accidents.

Storage and Equipment Maintenance:

- Timely leak tests across storage tanks, pipelines, and dispensers to maintain proper fuel levels, prevent leaks, and document evidence of corrosion.

- Carry out leak-detection exercises and pressure monitoring on fuel tanks to comply with environmental regulations.

- Ensure the fueling tanks are never over-pressurized proximally during filling.

Emergency Preparedness:

- Design an emergency response program for fires, spills, or any other critical event.

- Equip the station with alarms and communication systems capable of promptly alerting the coverage group.

- Organize training programs for employees on evacuation, first aid, and the handling of safety equipment.

Abiding by these will surely lessen operational risks and guarantee safety conformity, thus securing the employees and customers while keeping current with safe circumstances is complicated for the maintenance of sound safety processes.

Future Innovations in Gas Pump Nozzle Technology

Gasoline nozzle technology progresses towards efficient, environmentally friendly, and user-friendly measures. In other words, the latest nozzle integrates the flexible version with sophisticated vapor recovery systems aimed at reducing fuel evaporation, air pollutants, and dumping within the introduction. Secondly, a user-friendly detection cut-off system, in the sense that precise output and prevention products from spilling. Now, let’s start to introduce smart nozzle technologies that integrate IoT to allow the tracking of fuel consumption, equipment maintenance schedules, and system diagnostics in real-time. The rise of these technological advancements results in setting an enviable operational safety environment, less wasteful practices, and compliance with environmental criteria.

Advancements in Fuel Dispenser Systems

Digital Payment Solution Integration

One of the greatest improvements hailed by the modern fuel dispenser systems is the integration of payment technologies. The contemporary multi-product dispensers can now be built with contactless payment, which would be in RFID, NFC, mobile wallets, or app-based systems within the system. While one digitizes transactions, the other one ensures security against card skimming and other fraud. EMV (Europay, MasterCard, and Visa) standard implementation minimizes malicious attempts at processing payment and protects payment systems.

Advanced Data Analytics and Monitoring

Today’s fuel dispensing systems are more and more embedded with advanced data analytics and real-time monitoring tools. It is through IoT operational capability, and the use of connected devices, that fuel consumption patterns can be followed, pump performance can be monitored, and maintenance requirements can be predicted. These features help optimize fuel inventory management, reduce downtime, and enhance overall operational efficiencies. Besides, cloud platforms afford a way of remotely diagnosing systems and instantaneously providing software updates, keeping systems up to date with scant manual intervention.

Alternative Fuels Adoption

In order to meet current global aspirations in sustainability, new fuel dispensation systems are being designed to cope with alt fuels- electrical power, hydrogen, and biofuel. Motorists on some occasions now are able to fill up charges on their electric cars using the same kinds of nozzles and plumbing from which gasoline is pumped, convenient for those operators of EV ecosystems or hybrids. Hydrogen dispensation facilities will become more important both in terms of spatial considerations and their role as a new tool for municipalities and jurisdictions adopting clean energy alongside other clean fuel options. These technological developments are being made possible because the sectors are trying to embed concerns relating to the environment while setting themselves to supply renewable energy fields.

Smart Nozzles and Automation Trends

Smart nozzles and automation trails are upgrading the field of expelling fuel to find higher efficiency and accuracy. I think this integration of smart technologies enables prompt monitoring of pumping inaccuracy, thus mitigating wastage. Automation really allows real-time data tracking, flow and leak detection, and flow rate optimization that enhances overall reliability and safety in operation. By proceeding with these intelligent systems, the industry has convinced itself about the ability of technology to fast-track processes in offering sustainable solutions.

Environmental Considerations and Efficient Fuel Transfer

One fundamental aspect in designing and operating fuel distribution equipment is ensuring that ways adhere to ecological obligations. The key contributors might include spill prevention systems, systems for recovering vapor, and the choice of ways and means to use sustainable materials. Components of optimized fuel distribution equipment, like double-walled storage tanks, would entail systems such as pressure monitoring to prevent leakage, and systems for automatic emergency closing of the solenoid valve, therefore reducing the likelihood of any possible contaminants from affecting the equipment. The efficiency of the equipment designed to fit the fuel-carrying process shall, correspondingly, cut energy expenditure, reduce nearly all emissions together with other substances contaminating the global economy, and enhance the employment of in-house resources. The adoption of ecologically extendable technologies such as electrical or hybrid pumping systems, or biodegradable fuels, coincides with the advancement requirements of operational status over environmental goals.

Reference Sources

Using Multiple-Phase Nozzles to Produce Water Droplets for Removing Smaller Dust Particles

Frequently Asked Questions (FAQs)

What is a gas pump nozzle spout, and how does the swiveling hose affect fuel loading?

The gas pump nozzle spout is a metal or plastic tube that is attached to the fuel inlet of your vehicle’s fuel tank, mostly with a hose swivel that allows accompanying spout rotation for shoving into the opening in the tank. Less swirling by the hose swivel, less kinking, and wear on the fuel hose, which in turn helps in maintaining good flow from the fuel pump, as well as aligning the drop nozzles fitting correctly and reducing overflow and spillage.

What is the 3-notch hold open clip, and how do a hold open clip and a full grip guard affect the safety?

A 3-notch hold-open clip is a small mechanical latch that secures the gas pump handle in a partly open position to allow continuous fuel flow without having to hold the trigger; different grip guard designs, like the open clip and full-grip or clip full-grip guard, provide different engagement strengths. A bit of an aside here – Using any hold-open clip and full grip guard may allow the bypass of the auto-shutoff and result in situations in which some fuel is overfilled or poured out, so be very careful when using them and never leave fuelling unattended.

Can a fuel transfer pump or diesel nozzle be utilized with an unleaded gasoline tank?

It is wrong to utilize diesel nozzles and diesel-configured fuel transfer pumps in gasoline tanks because diesel nozzles and source equipment can be contaminated, and the properties of diesel are not similar to those of gasoline. Cross-contamination can be detrimental to engine performance and can impair fuel systems. Always use the appropriate nozzle for fuel and well-visible signage for either gasoline or diesel fuel pump nozzles. Where possible, clean or set aside equipment, such as a fuel transfer pump, for one type of fuel.

What do inch NPT fittings have to do with the mounting of a fuel line on a fuel pump or with the fitment of a hose swivel?

Inch NPT (National Pipe Thread) fittings are a standard thread connection often used for attaching fuel hoses, hose swivels, and nozzles to fuel pump outlets or adapters. When installing a fuel line or attaching a hose swivel, one should match the correct inch NPT size and subsequently use suitable sealing tape or compound so that a failure-free, heavy-duty connection will be able to serve well in automobile-grade and commercial fueling.

Discuss how fuel nozzle features, such as venturi design and heavy-duty construction, influence fueling performance.

Making it the ultra-reliable auto-shutting Atomac design materialized from one crucial design idea. A rubber or polymer diaphragm is one low-reliability technology that is not suitable for use on a nozzle that handles a flow of 1500 GPM.