Working at a gas station covers more than just fueling cars and managing the store—it actually requires a lot of care and attention when it comes to safety for the employees, customers, and nature. Safety is quite a tough issue in gas stations since they are dealing with fire-prone liquids, high-pressure systems, and busy roads at the same time. This paper intends to outline the safety gear that every gas station must have over their heads and shoulders, as they not only shrink the hazard zone but also help meet the regulatory standards and keep the flow of operations steady. The discussion will cover fire suppression systems and spill containment kits, plus their importance to the fuel station’s safe and smooth running. Hence, this source will be a great aid for station owners, managers, and trade people in terms of a more secure service environment in regions.

Understanding Gas Station Safety

The safety of gas stations is all about establishing and putting measures in place that block accidents from happening, and at the same time, if they occur, they will not have a great impact. The most important safety practices are the following:

- Fire Prevention Systems: Installing fire suppression systems and the upkeep of fire extinguishers that are rated for fuel-related fires is a must for controlling the risks of combustion.

- Spill Management: For speedy handling of fuel leaks and also the avoidance of pollution of the surroundings, spill containment kits and absorbent materials should be sufficient and readily available.

- Clear Signage and Training: Placing warning signs at strategic points and conducting safety training for workers regularly helps to make sure that not only the employees but also the visitors are aware of the dangers and are taking the right actions as per the procedure.

- Proper Maintenance: Comments on all proceedings in the course of being forthright inspections may dramatically lessen the probability that a system disorder will lead to a safety concern.

Gas stations can significantly improve safety for workers, customers, and the nearby area if they focus on these essential measures.

Importance of Gas Station Safety

Gas station safety is a serious matter that has to be considered more than just an issue since it deals with the risks involved with the presence of flammable liquids, toxic gases, and heavy-duty machines. The processes of proper safety procedure adoption virtually eliminate fire, explosions, and environmental pollution as well as multiply compliance with legal and regulatory requirements by threefold. The implementation of extremely strict safety measures—such as the use of spill containment systems, fire suppression equipment, and constant supervision of hazardous material handling procedures—has the dual effect of saving lives and safeguarding the environment. Furthermore, regular training of staff in emergency response and equipment maintenance is crucial in minimizing the risk of accidents. When gas stations are safe, their operations become more effective, and at the same time, the customers’ and the community’s trust is raised.

Common Hazards at Fuel Stations

There are numerous risks at refuelling stations, and they constantly deal with these risks. Fire and explosion are among the various hazards that are present; they can, for example, happen through improper handling of flammable substances, fuel fumes, or sparks. Another major risk is pollution of the environment due to leaks of products, which, if not noticed, can further pollute soil and water. In addition, there are health risks; that is, one can be exposed to toxic vapors like benzene and suffer damage to the lungs, thus to the whole body. Furthermore, slips and falls are the most common accidents in the areas where the fuel pumps and the convenience store are, usually due toa wet floor or scattered items. Besides, accidents involving vehicles are another safety concern for fuel stations, both at the pumps and in the parking areas. The proper handling of these situations demands the strict implementation of safety measures in conjunction with the regular inspection of the equipment used.

Overview of Gas Station Safety Equipment

The installation of Gas station safety equipment is a very important part of the safety of people working or visiting the gas station; besides, it can be thought of as a routine that goes along with ensuring that all safety measures have been taken, that all people around are safe, and that regulations have been followed. Such equipment includes fire extinguishers and automatic valves that fasten the process of controlling the spread of fire by cutting off the gas flow at the pump. The spill containment system, which soaks up the materials and spill kits, is of utmost importance as it aids in cutting down the contamination of the environment and slip accidents through the control of the hazardous fuel leaky places. Furthermore, safety signage has also performed very well, by giving clear and prominent instructions for easy understanding of the right actions and the areas in danger. It has acted as a great tool in getting people to keep in mind the dangers that might be invisible but are still in the area.

Emergency stop buttons are strategically located so that in the event of any emergency, the fuel dispensing can be quickly turned off without delay. Meanwhile, the vapor recovery systems effectively utilize the harmful gaseous emissions,s and this is a direct benefit to the air quality. The gas station lighting systems, both inside and outside, help to make the area more visible during the night, hence criminals are less likely to operate there. To add to this, security cameras track the areas where danger might occur; they also serve as a source of evidence in case of incident investigations that are attributed to their alertness. It is the responsibility of entrepreneurs to ensure that safety measures are not only put in place but also adhered to, not only for their own integrity but also for creating a safe environment for all stakeholders.

Essential Gas Station Equipment

Fuel Dispensers

Fuel dispensers are the main devices in gas stations that properly meter and transfer fuel to cars. Modern-day dispensers mostly have efficient payment systems integrated for user-friendliness and efficiency.

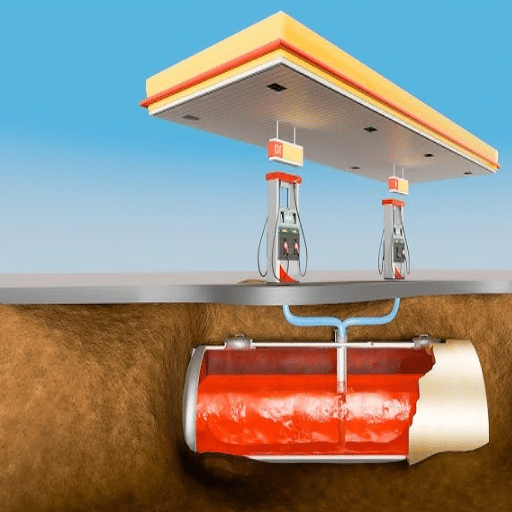

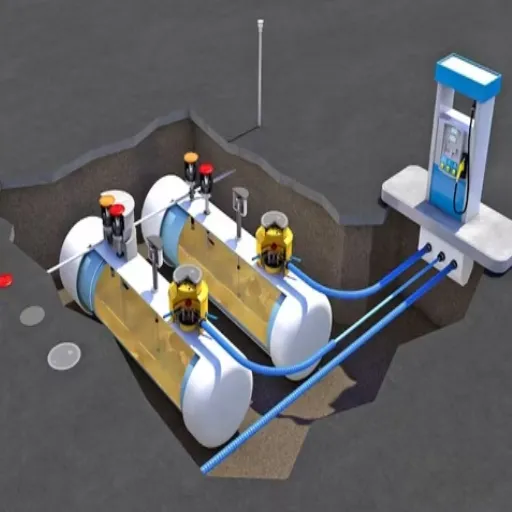

Underground Storage Tanks (USTs)

USTs are the main issue when it comes to fuel storage underground at the station in a proper way. EPA combines the tank’s construction and leak prevention to minimize the risk of contamination through environmental regulations.

Point-of-Sale (POS) Systems

The customers can have seamless transactions thanks to the POS systems. They have payment processing, inventory management, and reporting tools integrated, which make the operations smooth and efficient.

Air and Water Dispensers

Air and water services are the extra maintenance for vehicles that the pumps and stations provide. They not only increase the customer’s satisfaction but also contribute to the station’s overall value.

Spill Containment Systems

The implementation of spill containment measures, including absorbent materials and containment trays, will enable the proper control of fuel spills and thereby ensure compliance that ensures the safety and eco-friendliness of the area.

Types of Fuel Dispensers

The classification of fuel dispensers into various categories can be done considering their functionalities, technologies, and applications. The following are the major ones that occur in everyday life:

Mechanical Fuel Dispensers

Analog components and manual operations are the main features of mechanical dispensers. They are trusted and cost-effective and are usually found in places that can only offer basic infrastructure. Nonetheless, they do not come with sophisticated options that would provide such opportunities as automated surveillance or digital connections.

Electronic Fuel Dispensers

In these dispensers, electronic systems are incorporated to provide accuracy and more functions. They have often automated inventory tracking and remote management, and digital displays (including the transaction amount, fuel amount, and price) are also common in them. Electronic dispensers are preferred at modern fueling stations because they are quick and are compatible with the technology around.

Submersible Pump Fuel Dispensers

The fuel is pressurized and brought to the dispenser by a dedicated pump that is placed inside the tank through submersible systems. This arrangement leads to less vapor emissions, less damage done to above-ground components, and a steady fuel flow even at high-traffic stations.

Suction Pump Fuel Dispensers

In the situation described, the above-ground pump operates by generating a vacuum that sucks the fuel. While this technique is not suitable for large-scale businesses due to its inefficiency, it has advantages such as easy installation and maintenance, which consequently render this type of pump appropriate for smaller stations or places with low fuel consumption.

Multi-Product Dispensers (MPDs)

A single MPD unit equipped with different hoses dispenses multiple fuel types such as gasoline, diesel, or alternative fuels. The design not only saves space but also provides comfort for customers with different vehicle fuel requirements.

The evolution of fuel dispensing mechanisms parallels the advancements in technology that bring along the aforementioned features of contactless payment, enhanced security, and IoT connectivity, which together increase the operational efficiency of the overall system.

Storage Tanks and Their Safety Features

Storage tanks are indispensable components in the process of fuel handling and storage, which is why the application of very strict safety measures to completely remove the risks is a must. These tanks, for instance, are constructed from very robust materials, such as steel or fiberglass, to provide them with good stability and good rust resistance. One of the security precautions is the construction of double-walled tanks, which not only have one wall inside and another outside separating them for leak detection systems but also are leak-proof due to this very arrangement.

Moreover, present-day tanks are equipped with extra precautionary measures that facilitate the detection of potential leaks and the monitoring of adherence to environmental regulations via the installation of automatic tank gauging (ATG) devices. These instruments assess the heights of the liquids in the tanks, indicate any leaks, and guarantee that the tanks meet the requirements of environmental regulations. Furthermore, overfill prevention equipment, such as valves and alarms, is included to prevent spillage during the transfer of liquids into the tank. Moreover, underground tanks are safeguarded against corrosion by installing cathodic protection systems that direct electric currents away from the tanks.

Typically, safety standards and protocols are established by organizations such as the Environmental Protection Agency (EPA) and UL (Underwriters Laboratories), and they play a major role in the design, installation, and maintenance of storage tanks. The installation of vents to manage the pressure changes caused by temperature variations and to ensure that the fuel can be stored safely in varying environmental conditions is one of the main components of these safety measures. Although these steps might seem complicated, they serve not only to protect the operations and workers but also to prevent any harm to nature.

Automatic Tank Gauging Systems

Automatic Tank Gauging (ATG) systems are necessary for the effective and safe management of fuel storage. This kind of monitoring uses advanced sensors and technology to keep track of fuel levels, detect leaks, and also monitor temperature inside the tanks all the time. An ATG system generally consists of a tank probe and a control console. The probe is inserted into the tank and serves to monitor the liquid levels and other factors, whereas the console receives that data and can emit alerts in case there are changes or issues.

By utilizing advanced Automatic Tank Gauging (ATG) systems, companies can comply with the regulations set by the authorities, as these systems not only simplify the management of the stock but also assist in performing the leak detection tests that are required by the EPA, which is regarded as one of the most stringent regulatory bodies globally. Moreover, they improve operational accuracy by cutting down manual measurements, thus reducing the probability of errors, and also through the timely identification of potential hazards like leaks or overfills. The combination of all these features leads to higher safety, elimination of pollution, and access to important data that is necessary for operational planning and management.

Safety Tips for Gasoline Stations

- Ensure Proper Ventilation: Gasoline stations can take in their stride these risk-reduction measures, staff and customer protection, and an environmentally friendly operation through the application of the advocated practices.

- Avoid Open Flames: Smoking and flames should be completely banned, and these places should be properly marked as no-smoking and no-flame areas.

- Use Approved Containers: Only containers that are properly labeled can be used for the storage and transport of gasoline.

- Supervise Fueling: Do not leave the fueling process unattended, as this may lead to spills or accidental overflows.

- Respond to Spills Immediately: Fuel spills should be absorbed with suitable absorbent materials, and the residues disposed of following regulatory guidelines.

- Regular Maintenance: Regularly check pumps, hoses, and connections to detect and fix leaks before they become a problem.

Gasoline stations can take in their stride these risk-reduction measures, staff and customer protection, and an environmentally friendly operation through the application of the advocated practices.

Best Practices for Refueling Operations

Refueling is a commonplace but very important task that requires top-notch safety measures to be strictly followed, hence reducing risks and guaranteeing efficiency. Best practices, which are indispensable and number one, are presented below according to professional advice:

Engines and Devices Off

The engine of the vehicle must always be turned off before you start to refuel the vehicle, and also do not use any electronic devices, such as mobile phones, near the fuel, which can cause static electricity or sparks.

Fuel Containers to be Grounded

It is advisable to place the portable fuel container on the ground and not in a car during the fuel pouring process. This practice will lower the risk of static electricity discharge and will also eliminate any possible ignition sources.

No Overfilling

Never try to “top off” the tank or container. One of the many repercussions of overfilling is spillage, which not only significantly increases the risk of fire but also contaminates the nearby areas with easily flammable materials.

Check Ventilation Regularly

Take care that all refueling works are done in areas with good ventilation to avoid creating a toxic environment due to the accumulation of fumes. Vapors in confined areas are the cause of severe health and fire risks.

Use Only Approved Equipment

Always use certified fuel nozzles, hoses, and containers that are meant for gasoline or diesel only, in order to align with safety and operational standards and avoid using unconventional setups or worn-out equipment.

Static Buildup Prevention

Initially, touch the metal components of the vehicle or pump before lifting the nozzle to eliminate static electricity. This measure helps to prevent ignition caused by static discharge by reducing the potential.

Safety risks can be tremendously lessened, if not eliminated totally, by applying these rules in the refueling practices. Besides, the developments in environmental and operational standards will not be a cause for worry to the operators and the customers.

Regular Maintenance of Safety Equipment

The regular upkeep of safety apparatus is paramount to the maintenance of the reliability of operations and to meeting the requirements of safety regulations. The main practices are to set up an inspection routine, which is already scheduled, to notice wear and tear, and to make sure that all parts are working properly. Fire extinguishers should have inspections done monthly and should also experience professional servicing yearly, and records of maintenance history should be kept to monitor the maintenance of that particular fire extinguisher. Personal protective equipment (PPE), which consists of helmets, gloves, and respirators, should be checked continuously for damage, good fitting, and cleanliness, and worn-out items should be replaced immediately to ensure that the safety of the user is not compromised.

Moreover, safety measures such as alarms, extinguishers, and emergency lights need to be tested for effectiveness according to the manufacturer’s recommendations or local ordinances, typically on a quarterly or yearly basis. Besides, calibration of gas detectors, pressure gauges, and other monitoring devices is equally important to guarantee the accuracy and reliability of the equipment. Proper storage conditions, which include controlling the surrounding temperature and humidity, provide good protection against harsh environments and thereby extend the lifespan of safety equipment.

A digital tracking system can contribute a lot to maintenance practices by offering automated reminders and in-depth reports. Conforming to the relevant standards, like those of OSHA or NFPA, will not only ensure safety at work but also keep the organization in the good books of the law. Regular training sessions for employees in the area of safety equipment, proper maintenance, and use not only help in establishing a safe working environment but also significantly lower the probability of failure during emergencies.

Enhancing Security at Fuel Stations

In order to improve security at fuel stations, it is necessary to use a mixture of physical measures, technological systems, and staff training. The installation of high-resolution surveillance cameras with constant monitoring not only deters criminal activity but also provides evidence in case of incidents. Illumination that is sufficient in and around the premises eliminates blind spots and guarantees visibility at all times. Secure payment systems, such as chip-enabled or contactless payments, reduce the likelihood of fraud taking place. Moreover, training employees to recognize suspicious behavior and to respond in a suitable manner encourages an active safety awareness. Conducting regular audits and inspections is another way of making sure that the security measures are being properly maintained and that updates are made when necessary.

Importance of Gas Station Security Systems

Security systems at gas stations are the most important for the protection of the property, the safety of customers and employees, and the smooth running of the gas station. These systems act as a deterrent to theft and vandalism, which are the most common risks in a gas station that operates around the clock and handles large amounts of cash. The combination of surveillance cameras, alarms, and access controls allows operators to watch over activities in real-time and quickly deal with possible problems.

Among modern security measures are such high-end video analytics that they are capable of spotting suspicious actions, which is a big improvement in the overall security. Furthermore, secure payment methods like EMV-compliant terminals not only protect customers’ credit card information but also prevent potential data breaches and skimming attacks. In addition, security systems help with regulatory compliance by providing comprehensive records of daily operations.

The adoption of complete security systems permits gas station owners to avoid financial losses, augment customer confidence, and create a safer area as a result. Besides minimizing liability, the implementation of these measures also leads to the streamlining of operations, which ensures long-term profitability and operational integrity.

Monitoring with Surveillance Systems

For monitoring gas station activities effectively, surveillance systems are a must, as they offer critical areas such as fueling stations, payment points, and convenience stores real-time oversight. High-definition cameras with night vision and wide-angle lenses provide clear footage at all times, and the advanced features like motion detection and automatic alerts keep the operators aware of the situation. The criminal activities, such as fuel theft, vandalism, and unauthorized access, are deterred by these systems, and in case of incidents, the perpetrators are identified through the key evidence provided by the investigations.

Moreover, the interoperability of surveillance with cloud-based data storage solutions not only guarantees security and long-term retention of data but also remote and easy access. Hence, owners and managers can monitor the operations from anywhere. The modern systems are also compatible with AI, such as the capabilities of facial recognition and behavior analysis, which further reduce the incidence of detection and increase security efficiency in general. A gas station can thus not only be compliant with the law but also secure its assets and provide excellent service by establishing a solid surveillance infrastructure.

Protecting Your Business from Theft

Stealing and robbery prevention is paramount to the success and long-term survival of businesses. There are certain risks regarding gas stations, which include: shoplifting, fuel, and employee theft. To overcome these problems, businesses must use advanced technologies along with strict procedures and staff training. The use of high-definition surveillance cameras equipped with AI technology for things like license plate recognition and motion detection are installation option that can deter thieves and provide necessary proof in case of incidents happening. Point-of-sale (POS) systems that are integrated with real-time inventory tracking make it possible to quickly detect discrepancies, which in turn lowers the chances of internal theft. On top of that, creating a workforce that is well-trained and skilled in theft prevention techniques, such as observing for suspicious behavior and adhering to cash-handling protocols, can tremendously lower the possibility of security breaches. On the other hand, working hand in hand with local police and getting involved in crime prevention programs can add to the overall security measures. By applying these tactics, businesses can not only reduce their theft-risks but also secure their financial and operational health.

Streamlining Operations for Efficiency

To efficiently streamline the operations, businesses should mainly concentrate on three strategies:

Evaluate and Optimize Workflows

Perform a comprehensive review of current processes to single out inefficiencies or blockages. Do away with outdated practices and replace them with smoother ones, making sure that each step is value-adding to the whole operation.

Leverage Automation Technology

Bring in automated tools and software solutions for the purpose of dealing with tasks that are either time-consuming or repetitive. Besides, by getting rid of manual work through automation, you will not only cut down on mistakes but also increase efficiency and allow your workers to engage in activities that are of greater strategic importance.

Implement Continuous Training

Make it a point that the worker’s skills are continually updated, not only in efficient practices but also in the latest technologies. Regular training can be the cause of skill enhancement, performance improvement, and the alignment of operational goals with the company’s objectives.

By placing their emphasis on these strategic areas, firms are capable of turning efficiency to their advantage, diminishing their operational expenses along with improving their productivity altogether.

Improving Operational Efficiency with Modern Fuel Management

Modern fuel management leading to operational efficiency has to bring in advanced systems along with data-driven approaches to use fuel in an optimized way. The main methods are:

Implementing Fuel Management Systems

With the help of modern fuel management systems, enterprises can not only get real-time information on fuel consumption, but also set up automatic reporting and discover inefficiencies. Besides, the systems give in-depth analytics that help the companies make decisions, even to the extent of controlling costs and reducing waste.

Applying Telematics

Telematics integration gives the closest possible data about the performance of the vehicles, the amount of fuel used, and the habits of the drivers. Businesses can, at that point, through the examination of such data, find the points of their operations that need improvement, support the practice of fuel-efficient driving, and make sure that their vehicles are maintained for optimum use of fuel.

Automated Fuel Inventory Implementation

Automated fuel inventory systems apply sensors along with software to monitor the fuel levels, consumption rates, and the need for refilling. This leads to a great reduction of manual errors, no more waiting due to a lack of fuel, and a guarantee of constantly supplied fuel.

Embracing Alternative Fuels and Eco-Friendly Practices

The shifting to alternative fuels, like biodiesel or electric energy, doing eco-friendly routing and idling, and so on, can considerably boost long-term fuel efficiency and lessen environmental impact.

It is through the use of these strategies that companies will be able to cut down on their operational costs, lower their carbon emissions, and thereby improve their productivity, which, in turn, will strengthen their competitive position in the market.

Integrating Point of Sale Systems

The incorporation of point of sale (POS) systems into my operations allows me to process transactions quickly and also manage stock in real-time. In addition to that, I am able to monitor sales trends, improve the quality of financial reports, and provide better customer service by means of quicker and more efficient service thanks to POS technology. This all-encompassing strategy makes it easier for me to manage the operational processes and provides the management with the data necessary for making decisions that would lead to business growth in the long run.

Ensuring Compliance with Safety Regulations

To meet safety regulations requirements, a systematic methodology of recognizing, comprehending, and following the standard and legal requirements of the respective industry is the way to go. This entails performing continual audits and inspections for evaluation of risks in the workplace and taking corrective actions to rectify any matters. Documentation and training are vital in the sense that only through them can managers make workers aware of the safety measures and their roles. The utilization of technology, such as compliance management software, can assist in making the whole process easier by keeping track of the regulations, automating the reporting, and ensuring the records are kept. Being aware of updates to the law and getting in touch with professional consultants or legal advisors are two other ways to make sure that the law is followed, risks are minimized, and fines are avoided.

Reference Sources

Dos & Don’ts at the Gas Pump – Auburn University

A detailed guide on safety measures and emergency controls at gas stations.

Gasoline Safety – Texas Department of Insurance

A comprehensive guide on safety precautions during refueling and handling gasoline.

Dos & Don’ts at the Gas Pump – Maryland Department of the Environment

Safety guidelines for refueling vehicles and handling gasoline.

Frequently Asked Questions (FAQs)

Pump safety: What are the necessary safety gadgets at gas stations for the fuel pump?

At gas pumps, the main safety equipment is made up of emergency shutoff switches, automatic leak detectors, flame arrestors, electrical grounding and bonding systems, superior quality hose breakaway couplings, and properly marked spill kits. These devices are important for leak detection, fire containment, and environmental protection to the extent that they not only protect the public and workers but also ensure safe operating conditions around gas pumps.

Complete guide: What process should I follow to select the right equipment that can meet the regulatory requirements, together with safety and environmental requirements?

Choosing the proper equipment is an exhaustive process that entails selecting the devices that meet the local and federal standards, such as leak detectors, vapor recovery systems, and secondary containment for underground storage tanks. Maintenance and monitoring plans, alarm systems, and documentation are alsovery crucial. The comprehensive guide method includes examining important features, vendor certifications, and lifecycle costs to make sure you get the best quality products, and you enjoy peace of mind while minimizing the risk of getting fines and facing environmental hazards.

Alert systems: In what way can the alarm systems and monitoring play a significant role in reducing theft and enhancing safety and security?

Alarm systems and live monitoring can dissuade thieves by making the staff aware of suspicious movement, illegal use of the pump, or access after hours. Good lighting, along with occasional security guards, can support the integrated CCTV, door sensors, and alarm systems in deterring theft and protecting the public. The customer experience also improves to the extent that trust in site safety and security increases.

Comprehensive guide: What are the maintenance and monitoring practices that need to be carried out to have safe operations?

The comprehensive guide to maintenance consists of daily visual inspections of gas pumps, regular testing of leak detectors, scheduled calibration of dispensers, prompt repairing of broken components, and routine tests on tank tightness. The maintenance and monitoring practices reduce the chances of environmental hazards, increase equipment life, and keep customers happy by making sure the systems for tire inflation, windshield stations, and gas pumps are working well.

Fuel pumps: What are the training and procedures to be implemented so that customers are protected during the filling process and at night?

The staff’s training must cover emergency shutdown procedures, the use of fire extinguishers, and spill responses, plus assisting customers in safe operations. Well-lit forecourts, clear signage, and effective alarm systems are vital at night. Staff should be proficiently trained and knowledgeable in recognizing leaks and dealing with environmental dangers in a manner that not only protects the customers but also contributes positively to the whole customer experience.

Air and water: What ancillary equipment, such as air and water stations, will be safety area plans?

Ancillary equipment, consisting of places where the customer can inflate tires and clean windshields, should be installed using heavy-duty, anti-tamper designs and giving clear instructions for use. Checking and maintaining these stations regularly will not only prevent hazards but also improve the customers’ experience. They are not the primary safety devices; however, they are part of a comprehensive guide to customer service and safe and functional operations.

Safeguard measures: What is the impact of leak detectors and spill kits on reducing environmental hazards?

Leak detectors and spill kits are the mainstays of both safety and pollution control. Leak detectors alert to the occurrence of fuel leaks at an early stage, hence the staff can pinpoint the source and deploy the spill response plans, whereas spill kits comprise the absorbing materials, barriers, and PPE to isolate and expeditiously dispose of the spills. The duo collaborates to significantly reduce contamination risks and assists in complying with regulations, thus providing operators and customers with tranquillity.

Pump security: What features should a gas station security plan contain to safeguard customers and discourage theft?

A good security plan for premises should include good lighting, monitoring by CCTV with clear visibility, alarm systems, security personnel or guards on site at all times, and cash handling and access during nighttime security procedures. These security measures will not only keep the money safely away from thieves but also create a secure environment for the customers and even improve their experience. Regular reviews and updates will ensure that the plan continues to be in line with the evolving threats and technological advancements.