The fuel pump in a gas station is one of many modern wonders you rarely take a moment to reflect on. Yet without it, your vehicle cannot be refueled, and your travel will be hindered. Consider this: how gas station crews make sure your tank is filled and ask you to pay later. What technologies and systems collaborate to maintain precision and safety? How many devices does the gas station pump contain to function? This article resolves all these questions and many others related to gas station pumps, covering both their technology and the mechanics of gas station technology. Whether you have concerns in the field of dispensing science, fuel engineering, or safety, this detailed guide enlightens you on how these important devices are taken care of.

Introduction to Gas Pumps

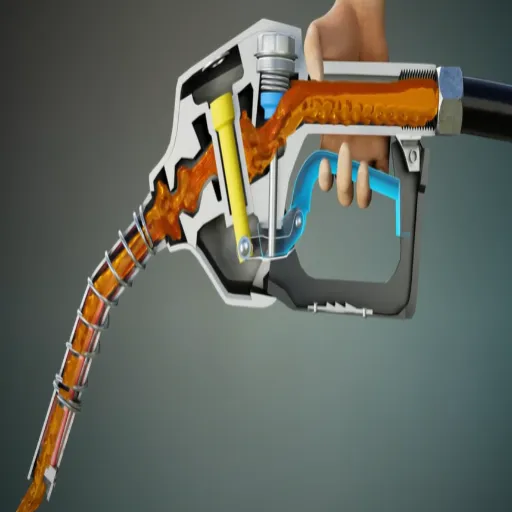

Gas pumps function as a vital interface for vehicles, providing fuel efficiently and safely. For fuel delivery, the pump system incorporates a flow meter that precisely measures the amount of fuel dispensed. Safety mechanisms, including spill and overflow prevention and automatic shut-off devices, are implemented. A steady supply is guaranteed by a suction system or pressurized piping that retrieves fuel from underground storage tanks and delivers it to the nozzle. Each transaction can be trusted to be correct thanks to the combination of advanced technology and safety standards that promote accuracy and dependability.

What is a Gas Pump?

The fueling station pump is a complex piece of equipment designed to provide a steady, reliable fuel supply to automobiles. A pump is intentionally designed to provide a steady, reliable supply, and modern fueling stations use a mix of electronic controls, sensors, and mechanical technology to dispense significantly precise amounts of fuel. A fuel pump not only provides fuel but also ensures ergonomics and safety. Modern fueling pumps have a display and touchscreen that allow fuel selection and real-time tracking of dispensed fuel.

The flow meter is the core of the fueling station, functioning as a pump and measuring the fuel volume that flows for dispensing with awe-inspiring accuracy, assuring the customer is given the exact amount of fuel requested. Fuel pumps are also eco-friendly as they include vapor recovery systems, which reduce harmful emissions while refueling.

Using suction systems or pressurized pipelines, fuel dispensed to vehicles in fueling stations is stored in large underground tanks. Sophisticated gas station pumps use advanced technology, such as an automatic shut-off system, to prevent fuel spills by halting the pumping when the vehicle’s fuel tank is full. Furthermore, fuel dispensers with card readers and payment processing systems facilitate fuel purchase transactions in a self-service mode.

Key Statistics: The milder recent data shows that there is a consumption of roughly 135 billion gallons of gasoline in the United States every year, which shows what they are used for and in what thirst they are poured. Looking forward, fuel pumps are becoming more advanced, allowing for contactless payments, alternative fuels, and even the Internet, ramping up the convenience and green usability.

Components of a Gas Pump

A gas pump isn’t just a gas pump. Each one is a machine designed to perform the task of delivering fuel to vehicles with maximum safety and efficiency. Along with achieving this primary goal, it is composed of various components that cooperate effectively to provide the intended service:

Nozzle

The nozzle is a part of a gas pump, and it is designed to serve the user with the purpose of transferring fuel into the vehicle’s compartment. Fuel dispensing nozzles in their modern form usually possess automatic shut-off features that halt fuel flow as soon as the tank reaches its full capacity. Such features greatly mitigate the risk of fuel spillages due to overflows.

Hose

The dispenser is linked to the nozzle through fuel hoses. These hoses enable fuel transfer while ensuring that fuel is transferred safely. These fuel hoses are constructed to endure extreme pressure and harsh weather as a way to ensure safety and durability.

Dispenser Unit

The Dispenser Unit’s purpose is to be the main body of the gas pump while also housing other crucial parts. It also contains fuel measuring meters, which are very important as the dispenser unit also contains other essential components like pumps and valves that control the fuel flow.

Metering System

The metering system tracks the precise quantity of fuel dispensed to ensure proper billing to the consumer. Such systems, when advanced, implement electronic sensors to guarantee enhanced precision and reliability.

Display Screen

A display, whether digital or analog, shows the key data such as the amount of fuel dispensed, the total price, and the price per gallon. As well as fuel dispense information, many gas pumps have interactive touchscreens with enhanced features that may display promotional videos and assist with payments.

Payment System

Gas pumps contain payment systems for their safe operation, including card readers and keypads. The more advanced ones have keypads and card readers like the older ones, but they also have RFID payment cards and mobile wallet payments, which shows how advanced and secure convenience has become.

Fuel Storage Connection

Every gas pump has one or more underground fuel storage tanks connected to it by means of piping systems. The underground fuel tanks can store a huge volume of fuel, in the order of thousands of gallons, and are equipped with devices that detect if they start leaking, in a bid to avoid pollution.

Vapor Recovery Systems

During refueling, fuel vapors are released and, for the greater part, concern is about the air pollution caused by these vapors. The fuel vapors released are captured by using fuel vapor recovery systems, and for the greater part of the fuel vapors, fuel vapor recovery systems safely return the vapors to the underground storage. The fuel vapor recovery systems are required for use by most gas stations because of environmental laws.

Safety Mechanisms

Fuel vapors recovery systems, emergency shut-off switch, and breakaway valve are some of the safety devices to be installed in fuel pumps. Breakdown of devices, fuel leaks, and fuel pump damage are some of the accidents to be prevented by the security devices.

Some advanced fuel pumps now allow the remotest monitoring and diagnostics using smart technology through connectivity to cloud services. Cloud services connectivity to fuel pumps ensures smart and proactive fuel pump maintenance, and ensures the least downtime for fuel stations. There seems to be consistent improvement of the fuel pump parts to ensure smart user convenience, secure safety, and environmental care, which is the industry’s goal.

How Gas Pumps Work

Fuel dispensers function using a mixture of mechanical and electronic parts that ensure fuel is delivered efficiently and securely. Upon fuel selection and pump activation by the customer, the fuel is pulled from the underground storage tank by the motor inside the pump. The fuel is thus dispensed via the nozzle after it is filtered and delivered through pipes.

The flow control mechanism ensures that the fuel goes through the proper channel and dispenses correctly. The flow of fuel is fixed and controlled by variable speed motors and a valve system so that the correct fuel amount is delivered and no spills occur. Modern fuel dispensers are equipped with high-precision fuel metering systems, which ensure that the volume of fuel is measured with an accuracy of ±0.3% of the fuel volume dispensed.

Gas pumps have embedded safety systems. For example, the vacuum assist system facilitates vapor recovery to reduce the harmful fumes emitted during fuel transfer. Furthermore, spill prevention nozzles shut off the flow of fuel when the fuel tank is full.

Electronic fuel dispensers now come with real-time electronic and payment displays. Stations can instantly change their pricing, and customers can use tap-to-pay and mobile wallet payment methods. On a larger scale, some fuel stations collate fuel dispenser data for analysis for better fuel dispensing and energy-saving measures, which also aid with eco-friendly initiatives.

The fuel dispenser today is a perfect example of the combination of technology and innovative fuel dispenser engineering, where efficiency, safety, and usability are given utmost priority.

The Fuel System

The fuel system in a gas pump functions to deliver fuel to vehicles effectively and safely. The system includes the underground storage tanks, the pump that draws the fuel, and the nozzle for dispensing the fuel into the vehicle. Sensors and regulators in the system ensure the fuel is measured accurately and that there is no overfilling or leakage. Advanced systems have safeguards to identify vapor emissions and safeguard the environment. The refilling process is dependable and secure due to the cooperation of all these materials.

Understanding Fuel Types

Fuel types significantly impact a vehicle’s functioning, its cost-effectiveness, and the environmental impact it has. Some of the primary fuels in use today include gasoline, diesel, ethanol blends, and electric power, each of which is designed for particular vehicles and technologies.

1. Gasoline

Gasoline is the fuel most widely used in passenger vehicles because of its widespread availability and energy density. Regular gasoline has an octane rating of 87, whereas premium gasoline has between 91 and 93, with higher octane fuels improving combustion. Engines designed to use premium fuel are higher performance, and higher octane levels reduce knocking.

2. Diesel

Diesel is predominantly used in heavy vehicles such as trucks, buses, and other large vehicles. Its higher energy content, as well as its better efficiency when compared to gasoline, allows for longer mileage and a higher level of torque. With modern innovations such as ultra-low sulfur diesel (ULSD), which has 97% less sulfur, it has become a cleaner option with fewer emissions.

3. Ethanol Blends

Ethanol is a renewable fuel manufactured from vegetation such as corn and sugarcane and is blended with gasoline. E10 (10% ethanol and 90% gasoline) and E85 (used in flex-fuel vehicles) containing up to 85% ethanol are common blends. Though ethanol fosters energy independence and lowers greenhouse gases, it hurts fuel economy in comparison to gasoline.

4. Electric Power

Electric vehicles (EVs) are distinct in that they do not need any liquid fuel. They utilize rechargeable batteries and do not have tailpipe emissions, which makes them environmentally superior. Owing to battery technology, contemporary EVs can have a range of over 300 miles with a single charge.

Furthermore, the development of hydrogen and biodiesel fuels as alternative fuels offers new possibilities for cleaner energies. Purchasers should be advised to select a fuel type that satisfies their vehicle’s needs and their preferences regarding the cost, efficiency, and environmental impact.

Storage Tanks and Their Function

Storage tanks are integral in the appropriate handling and storage of fuels, chemicals, water, and other liquids and gases. Through the use of storage tanks, the materials stored can be secured against early degradation, waste through evaporation, and physical damage. Today, there are various types of storage tanks, such as fixed-roof tanks, floating-roof tanks, and pressurized tanks, each aimed at specific materials and purposes.

Storage tank technologies have advanced with the introduction of corrosion-resistant materials such as stainless steel and fiberglass-reinforced polymers, which improve the lifespan and lower the maintenance cost. Such tanks are used to store cryogenic gases such as liquefied natural gas (LNG), enhancing storage safety and efficiency. Storage tanks for LNG, as reported by industrial data, can maintain temperatures as low as -260°F (-162°C) to keep the gas in a liquefied state.

For the storage of large amounts of liquids, floating-roof tanks are used as they help in lowering loss through evaporation, thus lowering the impact on the environment. The storage of volatile organic liquids benefits the most from such tanks, as the adjustable roof of the tank enables the minimization of the vapor space. More so, advanced monitoring systems that work with these tanks enable temperature, pressure, and fluid levels to be monitored accurately in real-time, thus ensuring efficiency and adherence to safety standards.

In summary, storage tanks continue to be vital in various industries, utilizing cutting-edge materials and smart technologies in the construction of tanks to be innovative stores that address growing needs safely and effectively.

Flow Meter and Gas Flow Mechanics

The essence of a flow meter is to gauge the speed and quantity of a gas moving through a pipeline or system. Flow meters are crucial in numerous sectors, including natural gas processing, chemical manufacturing, and HVAC systems, as they enable the correct and efficient regulation of gas flow. This is paramount for operational efficiency and safety.

The dynamics of gas flow are dictated by a mix of pressure, temperature, and volume, often reflecting fluid dynamics. Cutting-edge flow meters, such as thermal mass flow meters and ultrasonic flow meters, enable the attainment of precise measurements. For example, thermal mass flow meters are capable of measuring gas flow rates at low flow rates or for varied gas mixtures by measuring temperature changes due to the gas flowing over heated sensors. Conversely, ultrasonic flow meters are gas velocity calculators that employ sound waves, which makes them appropriate for numerous applications as well as advanced in precision.

Flow measurement has improved with features such as digital processing, remote monitoring, and IoT compatibility. Such characteristics allow for immediate analytics and diagnostics, hence reducing the time machines are out of use and enhancing the management of processes. According to reports, the flow meter market is expanding globally, fostered by the need in various industries, especially those that center on energy-saving and emission control.

The right flow meter type also needs to be selected to improve the efficiency of the gas flow system. Of course, consideration has to be given to the kind of gas, the precision, the temperature, and the pressure ranges. Adapting such machinery to be used with predictive maintenance systems does improve the useful life of the machinery and its functionality, which is proof that the cooperation of flow machinery and accuracy is crucial for the industries of today.

Automatic Shut-Off Mechanism

An automatic shut-off system refers to any safety mechanism that stops fluid or gas flow upon detecting certain triggering conditions, such as a leak, a pressure threshold, or a failure in the system. Such a system safeguards equipment, prevents waste, and prevents further accidents while ensuring flawless operation within the set limits. It is designed to shut valves automatically, with the use of triggers or sensors, so as to guarantee speedy and dependable responses to irregularities.

How the Pump Knows When to Shut Off

Different types of sensors, custom algorithms, and rules for preset shut-off are all examples of elements that can be used to tailor operations to a certain environment. Watch pressure with pressure sensors and keep an eye on fluid flow with flow meters. Once the system detects abnormal parameters—like a pressure drop or an increase in flow rate, the system should attempt to shut off the pump and prevent damage or inefficiency. In fact, modern pumps use microprocessors that can process information and, like a human, make decisions in a matter of milliseconds. For example, the system may stop a centrifugal pump if it detects cavitation, a low inlet pressure problem that can cause damage to the pump in the long run.

On top of that, many systems have incorporated IoT technology, which provides analytics and monitoring from a distance. Due to this, operators can establish thresholds and get alerts about how the system is functioning. The information from the IoT-enabled pumps can also be used for predictive maintenance, which can impact the downtime and the useful life of the devices. It has been proven that the use of automated shut-off systems can lower the risk of system failure by 30%, which implies that these innovations are necessary additions in the industrial and commercial space. With the technologies, the operation is safe, efficient, and cost-effective.

Importance of Automatic Shut-Off

Automatic shut-off systems help reduce safety issues, save resources, and improve efficiency. In particular, such systems in industrial environments are linked to reductions in unnecessary energy and water use. Recent statistics reveal that energy use in facilities with such systems is approximately 25% lower than in those that depend on manual systems. In addition, such systems contribute to safety by lowering the risk of injuries from equipment overheating or fluid spills.

The smart shut-off valves connected through IoT devices enable operators to monitor and control remotely in real-time, as mentioned in the 2023 report on industrial technology trends. The ability to respond and locate issues as quickly as possible helps lower the overall operational downtime by up to 40%, and the automation, combined with predictive analytics, not only protects the equipment but also leads to cost savings. The extensive use of automatic shut-off technologies is not simply to gain increased efficiency, but rather to be a critical part of today’s responsible operations.

Safety Features in Modern Fuel Pumps

Today’s fuel stations are equipped with a variety of modern fuel pumps, each of which complies with and even exceeds the modern environmental standards fuel stations are under. These fuel pumps have multiple safety and efficiency features that greatly improve their operation, fuel consumption, and safety. For one, the fuel pumps contain automatic shut-off designs that cease fuel dispensing immediately once an abnormality is detected. Through the use of these mechanisms, environmental pollution, fire hazards, and fuel overflows can be greatly reduced. This is especially true since evidence reveals that the implementation of this kind of design helps reduce fuel spills by an incredible 90%. Given the importance of fuel stations, proper fuel management is critical.

Moreover, the fuel pumps have integrated vapor recovery systems that work by collecting the fuel vapors that tend to form during the refueling process and are harmful to the environment. These systems actively reduce the emission of fuel vapors, improving the air quality. The reduction of fuel vapors has been mandated to ensure that the systems focus on enhancing and complying with the environmental standards. In cases of fuel vapors, there is a possibility of a fire breakout, and these sensors are meant to detect any fire and switch off the fuel pumps instantly, thus mitigating the risks associated with fuel use.

Fuel stations also employ digital fuel pump monitoring systems, which enhance fuel pump safety. The use of real-time diagnostics alongside remote fuel pump monitoring enables the fuel pump operators to fix any pressure or fuel pump issues at an early stage. Fuel pump industry-specific studies show that the use of real-time fuel pump monitoring technologies reduces fuel pump maintenance by 25% and also increases the fuel pump lifespan.

Fuel pump safety technology is continuously advancing, allowing the pumps to become safer and eco-friendly, along with being more cost-effective, which benefits both consumers and businesses.

The Role of the Nozzle

The nozzle assumes a vital function within fuel pump systems as it regulates fuel dispensation. Not only does it measure delivery for excellence and save fuel in the process, but it also integrates safety features, including an automatic shut-off. Such features prevent fuel overflow, improve safety, and allow for an uninterrupted refueling experience.

Functionality of the Gas Pump Nozzle

Nozzle fueling devices are intended to minimize abandonment of liquid fuel due to spillage for safety and convenience. They serve as interfaces between the vehicle’s fuel storage and the gasoline and diesel fuel dispensers. A key component of a fueling nozzle is the automatic shut-off system that initiates when the storage tank is full. This mechanism works through a tiny Venturi in the nozzle that senses fuel level pressure changes and quickly stops the flow to avoid spilling.

Modern fuel dispensing nozzles also have vapor recovery systems that capture petrol vapors during fueling. This helps to reduce the environmental impact of fueling by cutting the emissions of volatile organic compounds, which are produced by petrol vapors and are a source of smog and other pollution. Moreover, nozzle construction materials such as strong stainless steel and special rubber sealing not only sustain the nozzle’s life but also maintain its compatibility with changing fuel formulations, like ethanol fuel mixtures and biodiesel.

Environmental Impact: Research shows vapor recovery technology-fitted nozzles can capture and recover 98% of fuel vapors, a major step towards fuel dispensing sustainability.

Addressing safety, operational effectiveness, and eco-friendly concerns, the pump nozzle is a vital piece of equipment in fueling systems as it continues to incorporate changes in fueling regulations and fuel dispensing technologies.

How the Nozzle Affects Fuel Dispensing

Ensuring fuel is dispensed accurately and efficiently depends largely on the functionality and design of a gas pump nozzle. The modern gas pump nozzle is equipped with advanced flow meters that not only measure but also verify the exact amount of fuel dispensed, thus satisfying the fuel regulations and the consumer. Fuel spillage is reduced, and both the user and the environment are safeguarded with innovations like automatic shut-off mechanisms that also prevent fuel overflows. The fuel overflows prevention is an additional fuel spillage control.

Some nozzles that are equipped with vapor recovery mechanisms help to reduce the re-fueling hydrocarbon emissions, which are an air quality concern. These technologies, fuel vapors recovery, are proven to capture as much as 98% of fuel vapors, thus enabling a significant control of emissions at fuel stations. In addition, nozzles are now manufactured to accommodate different fuel types, such as compressed natural gas (CNG) and hydrogen, thus enabling the use of fuel from alternative energy sources. These developments highlighted the use of nozzle technology to solve fuel dispensing systems and environmental challenges.

Maintenance of the Pump Nozzle

To ensure that a pump nozzle operates efficiently, safely, and for as long as possible, it must be maintained properly. Every few weeks, an inspection should be done for fuel leakage, especially for fuel worn out in the seals, gaskets, and other components. Damaged fuel components not only increase the chances of fuel leakage but also reduce the nozzle’s performance. In fact, an estimation from nozzle performance studies suggests that a leaking nozzle can lose up to 10% of the valve fuel, which is a direct fuel cost.

Cleaning obstructions from the nozzle and accumulated fuel residue within the restraining fuel flow is equally critical. Fuel flow cleaners should be removed using cleaning agents that do not damage the nozzle material or cause corrosion. Breakaways and swivel joints should, in addition, be checked intermittently to guarantee their efficient functioning and adhere to safety rules.

For enhanced safety functions, spill risks during refueling increase significantly with worn-out spill refueling shutoff systems; thus, their automated shutoff systems must be replaced. During refueling, equipment should be serviced for fuel dispensing calibration, since proper fuel measurement reduces fuel loss and fosters customer goodwill. The performance and reliability can be improved with a routine maintenance schedule and proper documentation to support maintenance of procedures for pump nozzles.

Modern Innovations in Gas Pumps

There have been refinements in the efficiency, safety, and convenience of gas pumps and gas pump technology in general. With the growth of touchscreen interfaces, functions can now be completed faster and more intuitively. Android Pay, Apple Pay, and tap-to-pay cards not only make transactions more secure but also speed them up. Analyzing data in real time to check fuel quantity and usage is being integrated in some pumps to fuel analytics and fuel management systems. Fuel analytics and fuel management systems help operators in inventory management. These refinements help in complying with eco-friendly refueling regulations. One of the eco-friendly innovations is the vapour recovery system, which helps in reducing emissions during refuelling. All of these innovations help in refueling, as well as answering the needs of the industry and the consumers.

Advancements in Fuel Dispenser Technology

The continued evolution of fuel dispenser technology has a transformative impact on the energy and mobility sectors. One of the most notable developments is the integration of Internet of Things (IoT) technology, which allows for real-time monitoring and predictive maintenance, cutting downtime by as much as 20%. Smart dispensers with IoT sensors are able to monitor key performance indicators and flag issues that can lead to greater problems if left unaddressed.

Moreover, the fuel dispensers’ contactless payment systems have experienced rapid growth in usage, with data showing a 30% rise compared to traditional payment systems. This change is motivated by the customers’ wish for ease and shorter waiting times.

The provision of hydrogen and electric fueling stations is advancing as well, with the fueling for alternative fuels undergoing refinement. To illustrate, hydrogen fueling stations are now faster, offering refills of a full tank in less than five minutes, which is now on par with gasoline refueling speeds. Likewise, ultra-fast EV charging dispensers may recharge vehicles to 80% in 20 to 30 minutes, boosting the adoption of clean energy vehicles.

Lastly, more efficient vapor recovery systems that capture up to 95% of harmful emissions during refueling are innovations driven by the focus on sustainability. Not only does the industry comply with strict environmental regulations with these advancements, but it also shows a strong willingness to fight climate change. Altogether, the developments in fuel dispenser technology show that technology is evolving with a strong consideration for efficiency, customer convenience, and the environment.

Integration of Vapor Recovery Systems

In refueling areas, harmful pollutants are released into the atmosphere, which has to be controlled, and alongside that, the organizations have to comply with other environmental laws. At our company, by adopting the vapor recovery systems in all refueling areas, we will ensure that fewer pollutants are released to the atmosphere, which will show the commitment of our company towards environmental and sustainability laws, and in addition, it will not affect the other operations of the company.

Future Trends in Gas Station Pumps

The landscape of fueling stations is gradually morphing — and for good reason. It’s now common to see fueling stations equipped not only with biofuel dispensers and hydrogen fueling pumps but also with meters for electric vehicle (EV) charging. In response to the rise in the number of EVs, fueling stations are now beginning to install fast charging stations to satisfy the demand of their customers and to support renewable energy.

Fueling stations are also now adopting new digital technology. From touchless payment to mobile apps and even to fueling station IoT monitoring, everything is becoming more convenient to use and more efficient to operate. Not only is new technology beneficial to the customer, but new tools such as real-time diagnostics and predictive analytics are beneficial to the maintenance crew.

The eco-friendly devices that improve fuel vapor recuperation and the energy-efficient pump designs are attempts to reduce the environmental impact of fueling stations and improve the fuel vapor recuperation devices. The smart and autonomous refueling, which makes use of AI to improve and automate the refueling, is also expected to be released soon.

These changes in pumps at gas stations are fueled by changes in regulation as well as fuel consumers. These changes are meant to address the impact on the environment and the refueling convenience that a person experiences while supporting clean energy at gas stations.

Key Takeaways: Gas station pump technology continues to evolve with enhanced safety features, environmental considerations, and customer convenience at the forefront. From automatic shut-off mechanisms to vapor recovery systems and contactless payments, these innovations ensure efficient, safe, and eco-friendly fuel dispensing for millions of vehicles worldwide.

Reference Sources

“Consumer Protection Related to Dispensing Pump Manipulation in SPBU (Gas Station)”

“A Survey of Renewable Energy Sources and Their Contribution to Sustainable Development”

Frequently Asked Questions (FAQs)

What Are Gas pumps ‘ systems?

Gas pump systems are made up of electronic and mechanical components that work together to transfer fuel from storage tanks to a vehicle’s fuel tank. A submersible pump is the main component that extracts fuel from underground storage tanks and pushes it through a small pipe to the dispenser nozzle. A fuel flow meter controls the flow of fuel and makes sure the right amount of fuel is dispensed to the customer.

What Functions Does the Gas Pump Nozzle Serve?

The nozzle is essential as it enables the safe and effective distribution of fuel to a vehicle’s fuel tank. On the other hand, the fuel nozzle prevents spillage; it has a spill protection feature that ensures that when the fuel nozzle is placed in the tank, it seals off any possible spillage. Additionally, a spill prevention method is the automatic shut-off feature that is designed into the nozzle. It disables fuel flow once the fuel tank is full, preventing further fuel flow into the nozzle.

What Is the Functioning of the Automatic Shut-off Feature in Fuel Pumps?

In fuel pumps, especially the modern ones, they have an automatic shut-off feature, and it functions fluently with the change in air pressure. The fuel pumps’ shut-off feature, which is the fuel level rising, creates a blockage that chokes the air pressure above the fuel, signaling the pumps to shut off fuel flow. This feature is helpful in the prevention of spills and other fuel-related hazards.

What Technology Is Gas Pumps Based On?

The technology behind gas pumps includes various components, such as the impeller, which moves the fuel upward, and the flow meter that measures the amount of gasoline dispensed. All the components work together to ensure that fuel delivery is consistent and safe. Additionally, fuel pumps now have advanced technology in the form of sensors that detect when your fuel tank is full. This enables efficient fuel management.

How Do Gas Station Pumps Handle Air Pressure?

Gas station pumps handle air pressure with vents and valves that regulate the air flow into the tank. For fuel to be dispensed, air must enter the storage tanks to fill the space left by the fuel. This system maintains pressure equilibrium and prevents fuel flow obstruction and vacuum formation.

Why Do Gas Pumps Stop Flowing Once the Handle Is Removed?

Once the handle is removed, fuel flow is interrupted, which means fuel cannot flow continuously. The removal of the handle is an indicator that fuel spillage has to be prevented. The feature also ensures that while removing the nozzle, the customer does not have to worry about fuel flow.

Are Gas Stations Allowed to Top off Your Tank?

Topping off your fuel tank may seem harmless; however, it usually leads to fuel spills, which are dangerous. Fuel pumps are usually equipped with mechanisms to prevent fuel overflow by shutting off the fuel supply. Attempting to force fuel into the tank after this can cause gasoline to flow backward into the nozzle or vapor recovery system, both of which are hazardous.

Why Is the Flow Meter Important in Fuel Dispensing Systems?

The fuel flow meter in fuel dispensing systems is crucial in ensuring the correct fuel quantity measurement and helps ensure customers pay the correct amount for their fuel. The fuel flow meter also helps in the proper management of the fuel nozzle in ensuring fuel flow is consistent and reliable.

How Is Dispensing Fuel Affected by Static Electricity?

Dispensing fuel can be dangerous because of static electricity, as it can cause an explosion from sparks. Fueling facilities have the necessary precautions, such as grounding systems that remove static electricity, to ensure safety. Customers are also reminded to abstain from fueling practices that can cause static electricity, such as sliding on car seats and using a mobile phone.