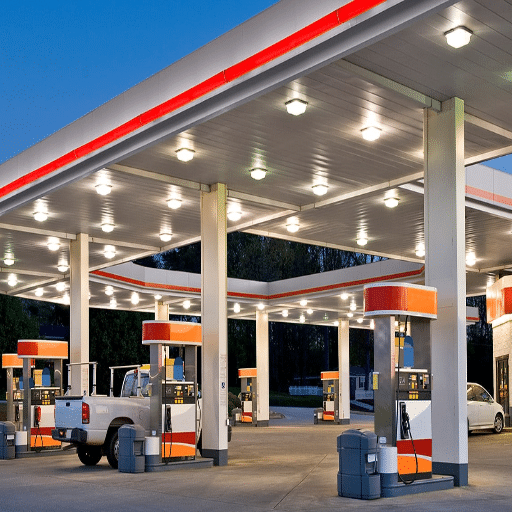

Understanding Emergency Shut-Offs at Gas Stations

Emergency off controls form safety measures to immediately stop the flow of fuel in case of fire, spill, or other emergencies. An emergency off switch is usually found near the gas station building or along a red panel that bears the label “Emergency Fuel Shut-Off.” Tapping that switch turns off all power to the fuel pumps to prevent dangers from proceeding and to minimize any potential hazards. Note the location of the above switch every time you fuel up, for swift access may be very crucial in an emergency.

What is an Emergency Shut Off?

The emergency shut-off is one of many safety features installed to immediately terminate the dispensing of fuel at a gas station in hazardous situations, like a fire, spill, or any other emergency. It accomplishes this by cutting power to the pumps so the flow of fuel can be stopped, which would otherwise worsen the accident. Usually, the shut-off should be installed in a place where it is highly visible, either on a panel close to the entrance of the building or in a well-marked area bearing signs like “Emergency Fuel Shut-Off.” Being acquainted with the emergency shut-off panel’s location will make one jump into action, saving lives, property, and the environment in the process.

Importance of Fuel Shut-Off Switches

The fuel shut-off switches are important for maintaining safety and preventing disasters in emergencies such as fuel leaks, spills, or fires. Their presence and functionality immediately stop fuel discharges to prevent the risk of explosions or further damage. These switches are most often positioned and marked in accordance with safety standards to be able to perform their function quickly when needed. However, maintenance, training about their use, and awareness programs must be conducted regularly for all staff and occupants to respond efficiently during an emergency. By cutting off the fuel supply, shut-off switches protect life, property, and the environment; thus, they are key considerations in the emergency plans of most industries.

Types of Emergency Stop Buttons

Emergency stop buttons may have many variations, each meant for a particular application and working environment. The three common types are:

Push-Pull

Common in industrial settings, a huge, red mushroom button activated by pressing down is reset by pulling it back up. It gives a bright view and can be pressed easily in emergencies.

Twist Release

Emergency stop buttons reset by twisting the knob after activation. They ensure that accidental resets do not occur in machinery systems, thereby requiring only deliberate actions to restore the system.

Key-Operate

Featuring a lock-and-key mechanism for the reset, these buttons are preferable for restricted areas where controlling access, such as power plants or hazardous workstations, is essential. They provide an extra layer of security to emergency procedures.

All these types of emergency stop buttons are constructed to meet stringent safety standards to perform reliably when the situation becomes critical. They should therefore be trained and tested properly to ensure their best use in real-life applications.

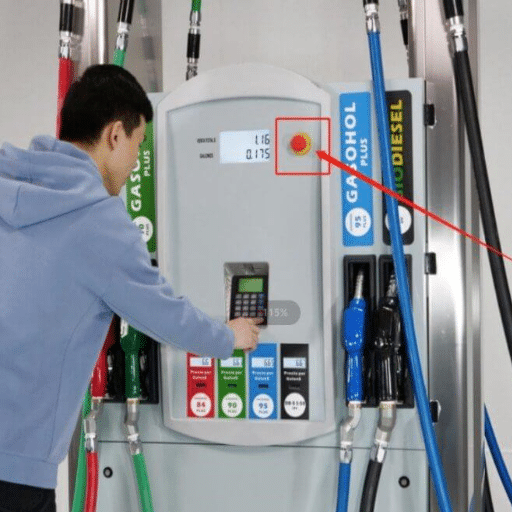

Identifying the Emergency Stop Button and Switch Locations

Emergency stops and switches are installed in locations highly visible and easily accessible, ensuring that they can be operated immediately during emergencies. Locations usually include control panels, console-type machines, entryways, or exit paths to workstations. Depending on the size of the area or the complexity of the system, several emergency stop systems are strategically distributed to cover the entire area. These emergency stops must be clearly labeled, using bright colors like red and yellow, together with standardized symbols for ease of recognition. Periodic inspections must be carried out to affirm that all emergency stops remain accessible and operational.

Typical Locations of Emergency Stop Buttons at Gas Stations

Prior Experience-Making relevant-quality works, generally gas stations have emergency stop buttons placed in highly visible and easy-to-access areas to allow speedy action in emergencies. Locations usually include the following:

Near Fuel Dispensers

Sometimes, the emergency stop buttons are installed beside fuel dispensers so that the flow of fuel can be stopped immediately if something goes wrong, a spill, for instance, or a fire.

Inside the Cashier Station

In some gas stations, the emergency stop button is located behind the counter or inside the cashier station so the attendants can quickly stop any further fueling operation.

On Exterior Walls or Pillars

Emergency stop controls may also be installed on exterior walls or pillars near the forecourt for quick access by customers or employees.

Whatever way you put it, these placements ensure quick activation of the emergency shut-off from multiple locations on the property, thereby emphasizing maximum safety and approachability in times of great risk.

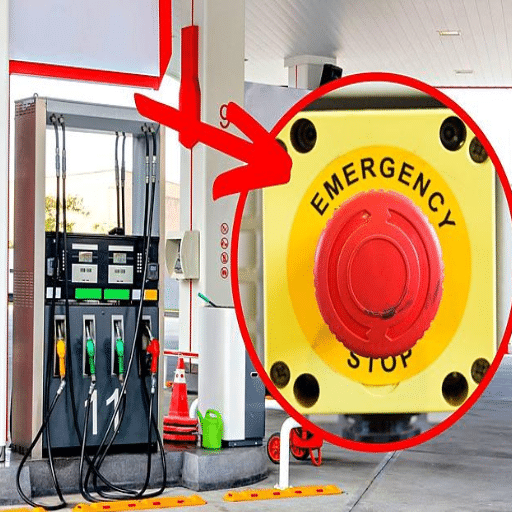

How to Recognize Emergency Shut-Off Switches

An emergency shut-off switch is a device that is deliberately made easy to identify so that it can be acted upon swiftly in the event of a crisis. Generally, these switches will be affixed with clear labels such as “Emergency Stop” or “Fuel Shut-Off,” commonly in bright red or yellow color tones to attract attention. They tend to be encased in a rusty metal casing with big push buttons or toggles that make it hard for people to miss them. Signage or pictograms emphasizing their purpose are often displayed nearby, helping with rapid identification of their utility by the range of staff and customers during emergencies.

Visual Indicators and Signage for Emergency Stops

Any visual indicator and signage for emergency stops should provide the highest level of safety and be able to enhance a quick response to emergencies. Generally, because it must be noticeable, an emergency stop button is colored in bright colors, such as red or yellow. These colors are the standard for all safety precautions and allow the emergency stop buttons to stand apart from all other equipment. Labels that either say very clearly “EMERGENCY STOP,” or signs that convey the meaning universally in big, bold letters, are then displayed around or upon the buttons themselves.

Emergency stop signage often includes pictograms or symbols that graphically explain an emergency stop function. For example, a straightforward pictogram with a hand pressing a button can impart instant recognition. The placements of stop devices and signage are considered amenity points wherein they are typically located at eye-level heights, so-called high-visibility locations, and within easy reach; hence, an operator might have no qualms about hitting them in their time of need, and even untrained persons may never hesitate to hit those stops if emergencies so call for it.

The illumination of signs with LED lights could be recommended by safety instructions to highlight the position of an emergency stop, especially in darker areas. Hence, the amalgamation of suitable design and correct placements helps ramp down the critical time response while increasing safety in critical scenarios.

When and How to Use the Emergency Stop Button

The emergency stop button should be pressed immediately when a hazardous situation threatens safety, equipment, or the environment. For example, a malfunctioning machine may be detected, an accident prevented, or a dangerous operation stopped. Initiate it by firmly pressing the stop button, which instantly shuts down the machine or process. However, always ensure it is safe before resetting and restarting the equipment and following the manufacturer’s instructions or site-specific procedures.

Situations That Require the Emergency Shut Off

The emergency shut-off should be used in critical instances, including but not limited to the following examples:

Should any equipment behave strangely-almost to say overheating, unusual vibration, or strange, the emergency shut off sort of standstill-would prevent further damage or failure from occurring.

In case sparks, smoke, or exposed electric wires indicate an electrical fault, immediate shut off would ensure safety from electrical fires or shocks.

If a worker is about to suffer an injury resulting from equipment malfunction or unsafe operation, the emergency shut-off will stop the hazardous activities at once.

When hazardous materials are involved, shut-off systems are needed to stop the machinery to avoid further spill of chemicals or exposure to toxic materials.

Should flames, intense heat, or other signs of ignition appear near the machinery, activating the emergency system will help contain the danger and allow for safe evacuation.

Always assess the situation at once and ensure the safety of all persons in the area.

Step-by-Step Guide to Using the Emergency Stop Switch

Identify the Emergency Stop Switch

Locate the emergency stop switch on the machinery. It is a big and red button that is usually highly visible, with yellow or another contrasting color around the button to speed recognition during emergencies. One should familiarize oneself with the position and look of it before operating any machinery.

Assess the Emergency

Evaluate the situation, and observe whether initiating an emergency stop is required. An emergency involves the malfunction of the equipment, safety hazards such as entrapment or fire, or imminent damage to property or personnel. Rapid and correct assessment of the situation is very critical.

Activate the Emergency Stop Switch

Push the button firmly or engage the pull mechanism, as the case may be, therefore placing the entire machinery immediately at a halt from emergency, either by cutting off its power supply or initiating some restraints on operational safety of the machine. Depending on the design of the equipment, the mechanism may also be locked into position to prevent an accidental restart.

Inform Supervisors and Team Members

Inform all individuals responsible for the emergency stop. By informing others, one ensures that the emergency is contained and safety protocols are followed. This step is very important in an operation of large scale or in an operation where more people are working and coordination is very important.

Wait for Safety Confirmation

Do not restart the machine unless it has been approved as safe to work by the appropriate set of trained personnel. The restarting would involve, in an actual situation, some resetting of the emergency stop, which can be a turn or a pull, or a disengage operation, depending on the design of the equipment.

Document the Incident

After resolving the emergency, record the cause of activating the emergency stop and the corrective actions that were carried out. The records can contribute to safety operational improvements and thus avoid future incidents. For example, statisticians report that in industrial environments, detailed incident reporting is able to reduce system failures by nearly 20%.

Use of the emergency switch following these steps can greatly reduce the hazard to life and damage to equipment in unexpected events.

Post-Emergency Procedures and Safety Checks

The activation of an emergency stop demands following a structured procedure that guarantees the safety of people and equipment. Firstly, make sure that the emergency has ceased entirely and that no further risk exists. A full inspection of the equipment involved must proceed in order to ascertain possible damage. Studies indicate that checks carried out immediately after incidents decrease by 25% the possibility of a subsequent failure and thus emphasize their great importance.

Make certain all components of the emergency stop system, including switches, wiring, and relays, are in good working order. If faults are found, rectify them immediately, as investigations indicate that overlooked malfunctions cause a 30% recurrence of safety problems. Also, competent personnel should perform a root-cause analysis to identify the causes leading to the emergency stop activation, facilitating the implementation of countermeasures.

Finally, recording all observations generated during the post-inspection includes any faults found and their repairs. Regular maintenance combined with detailed reports has been demonstrated to enhance the life span of equipment and avoid costly instances of operational downtime. Prioritizing safety procedures in the workplace will ensure a resilient and reliable workplace environment.

Practical Tips for Using Emergency Shut-Off Systems

Know Your System

Have employees become acquainted with the emergency shut-off system-its location, and operation. Periodic training sessions could be beneficial.

Test the System Regularly

Conduct periodic testing of the shut-off system to ensure proper functioning. Test as often and as per the methods described by the manufacturer.

Keep It Clear

Always maintain an unobstructed path to the shut-off system. Do not place equipment or materials that can hinder quick access during an emergency.

Labels and Signage

Ensure labels and signage are clear and visible to demarcate the system’s location. This will help employees to easily find it during an emergency.

Inspect Regularly

Perform regular inspections to determine signs of wear or damage. Resolve them immediately before further consequences on the system are realized.

Keeping with such simple practices could ensure workplace safety and lessen the chance of equipment failure in the heat of a crisis.

Steps to Take in an Emergency Situation

Stay Calm and Assess the Situation

An occasion to view the surroundings and notice immediate dangers. Keeping calm will help you make clear and effective decisions.

Ensure Safety from Hazards

Ensure safety from hazards, such as fire, toxic chemicals, or unstable structures. Prioritize your safety.

Alert Emergency Services

Telephone 911 or the local emergency number. Supply details concerning the emergency, including location and any injuries.

Warn and Help Others

If other persons are in the area, give them a warning of what is happening. Get them out if it is safe to do so, particularly those who may require assistance, like children and persons with restricted mobility.

Emergency Procedures

If at a workplace or public place, follow the procedures implemented in that location. This might include using the designated escape routes or assembly points.

Administer Basic First Aid if Necessary

If a person is injured and it is deemed safe to do so, the population aid must administer basic first aid until advanced help arrives. Get skilled in basic life-saving treatments, such as CPR, radiate help when needed.

When Waiting for Advanced Help

Staying at a safe site and complying with the instructions of emergency responders will be beneficial. Provide them with accurate information and stay calm, which will go a long way in managing the situation for them.

Regular Maintenance and Checks of Shut-Off Switches

Inspecting and maintaining shut-off switches is essential to ensure emergency operations. Testing should be performed periodically to ascertain proper working. Keep switches clean from dust, dirt, or other buildup that could affect performance to be affected. Visual inspection for corrosion, loose connections, or wiring damage should be performed, and any issues must be rectified immediately. Compatibility with the current systems should also be verified, and components redesigned or replaced if necessary. Maintenance logs should be kept up to date to record performance over time and ensure compliance with safety regulations. Always consider the manufacturer’s instructions and hire a professional service for any complex repair or upgrade.

Tips for Gas Station Safety Awareness

Turning Off Your Engine

Turn the engine off at all times while refueling to prevent an accidental ignition of fuel vapors.

Avoid Smoking or Open Flames

No smoking near fuel pumps or open flames so that no risk of fire or explosion occurs.

Handling the Fuel Properly

Make sure that the fuel nozzle is fully inserted into the tank, or avoid spilling, causing an accident by overfilling.

Discharge Your Static Charge

Before touching the nozzle of the gas pump, set down the static charge by touching a metallic surface away from the pump itself.

Keep Children and Pets Inside the Vehicle

Be sure that children and pets remain safely inside the car when the gas tank is being filled.

Be Alert in Your Surroundings

Be aware of the presence of other vehicles, pedestrians, and anything unusual in the area to prevent accidents or unsafe situations.

With these simple techniques, safe and efficient traveling at a gas station can be ensured.

Educating Employees on Emergency Procedures

Proper education in emergency procedures will undoubtedly provide safety to employees and a quick response to unforeseen incidents. First, schedule training sessions on a regular basis, never leaving out the steps to be followed in handling simple emergencies, such as fires, spills, or even power outages. Employees must be aware of the location of evacuation routes, fire extinguishers, and the operation of other safety equipment. It should also be made clear to whom they are to report during an emergency and how an alert is sent to others.

Conduct drills with real emergencies to further instill the training and to cultivate readiness. Give the employees an emergency contact list within easy reach and instruct them on the use of the first aid kits. Procedures should be reviewed regularly while considering safety regulations and with the possibility of lessons learned from previous situations. A well-educated workforce becomes a force to reckon with in a crisis where risks and lives, as well as property, stand to be protected.

Customer Awareness: Knowing What to Do in Emergencies

Being customer-focused, the very first things are: to take a deep breath and follow any instructions given by the staff or emergency responders. Locate yourself with emergency procedures set forth at the site, including exits, emergency equipment, and assembly points. Pay heed to warning signs or public announcements. Request guidance whenever in doubt or in need of further guidance. The wisdom of being aware and prepared indeed can make all the difference in the endeavor for personal safety when faced with critical situations, and quite importantly so!

Regular Maintenance and Testing of Emergency Systems

Emergency systems throughout their lifecycle need maintenance and testing for them to be reliable under operational situations. Condition-based scheduling protocols must be imposed for inspecting alarms, fire sprinkler systems, and emergency lighting. This will weed out and fix any faults detected. Fire drills and evacuation exercises allow for hands-on familiarization for staff with the procedures and also pinpoint weaknesses. This can be supplemented by keeping communication systems up to date and tested for fast information dissemination in an emergency. Independent professionals are employed for testing, like Inverness Systems, to ensure faultlessness that meets safety regulations to save life and property.

Reference Sources

Flood Impacts on Emergency Responders Operating at a City-Scale

Design and Operation of the Hydrogen Supply Chain for Fuel-Cell Vehicles in Expo Shanghai 2010

Frequently Asked Questions (FAQs)

Where Is the Lock-Up Emergency Shut Off at the Gas Station?

The emergency stop at gas stations is located close to the pump, usually on the side of the pump or on a post nearby. The switch is generally always situated, marked, and recognizable due to its bright red color that indicates the importance of its functioning in case of emergency.

What Are Fuel shut-off switches at The Gas Stations?

Fuel shut-off switches at gas stations are devices that stop fuel flow when an emergency occurs. These switches prevent fuel spills and protect customers from environmental hazards and threats.

How Do You Activate the Emergency Button at a Gas Station?

The emergency button at the gas station can be activated when found close to the fuel pump. Press it down and hold to efface the emergency shut-off and to de-energize the fuel supply instantly. Somewhere else, spills or basically testing on emergencies will necessitate such steps.

Why is it important to Know Where the shut-off switch is?

The importance of knowing the shut-off switch at a gas station cannot be emphasized enough when it comes to safety. When an emergency a turbulent fuel spill, a fire, is the best time to take quick action to turn off a fuel supply to avoid further danger and save lives, so it is a very crucial step in a gas station’s safety procedure.

Are There Videos Showing How to Locate Shut-Off Switches at Gas Stations?

Certainly, there are videos that give demonstrations on locating and operating shut-off switches at gas stations. Such tutorials provide tremendous visual help with which a user must equip him or herself to undertake the necessary steps in an emergency.

What Should You Do upon Witnessing a Fuel Spill at a Gas Station?

If you accidentally witness a fuel spill in a gas station, it is very important to keep calm and alert the staff immediately, who will then know the response manner, including shutting off the fuel supply using the emergency shut-off switch. Do not try to clean the spill yourself since it is dangerous.

How are shut-off valves used in Emergency Conditions?

The shut-off valves are intended to stop the flow of fuel quickly during emergency operations. In the case of fire or a large spurting of fuel, these valves may be activated manually through the emergency shut-off switch to prevent gasoline from flowing and worsening the situation.

Where Is The Main shut-off in A Gas Station?

The main shut-off is usually located in a secured area near the fuel pumps, which often could be under a utility room or outside the station. The shut-off is usually accessible to trained staff, such as firefighters, who might need to turn off the fuel supply in the event of an emergency response.